Comprehensive shaft sinking method of positive and raising boring for vertical shaft

A vertical shaft and forward technology, applied in the field of drilling, can solve the problems of low construction cost, slow well completion speed, and long equipment occupation time, and achieve the effects of reducing the storage area, increasing the well completion speed, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

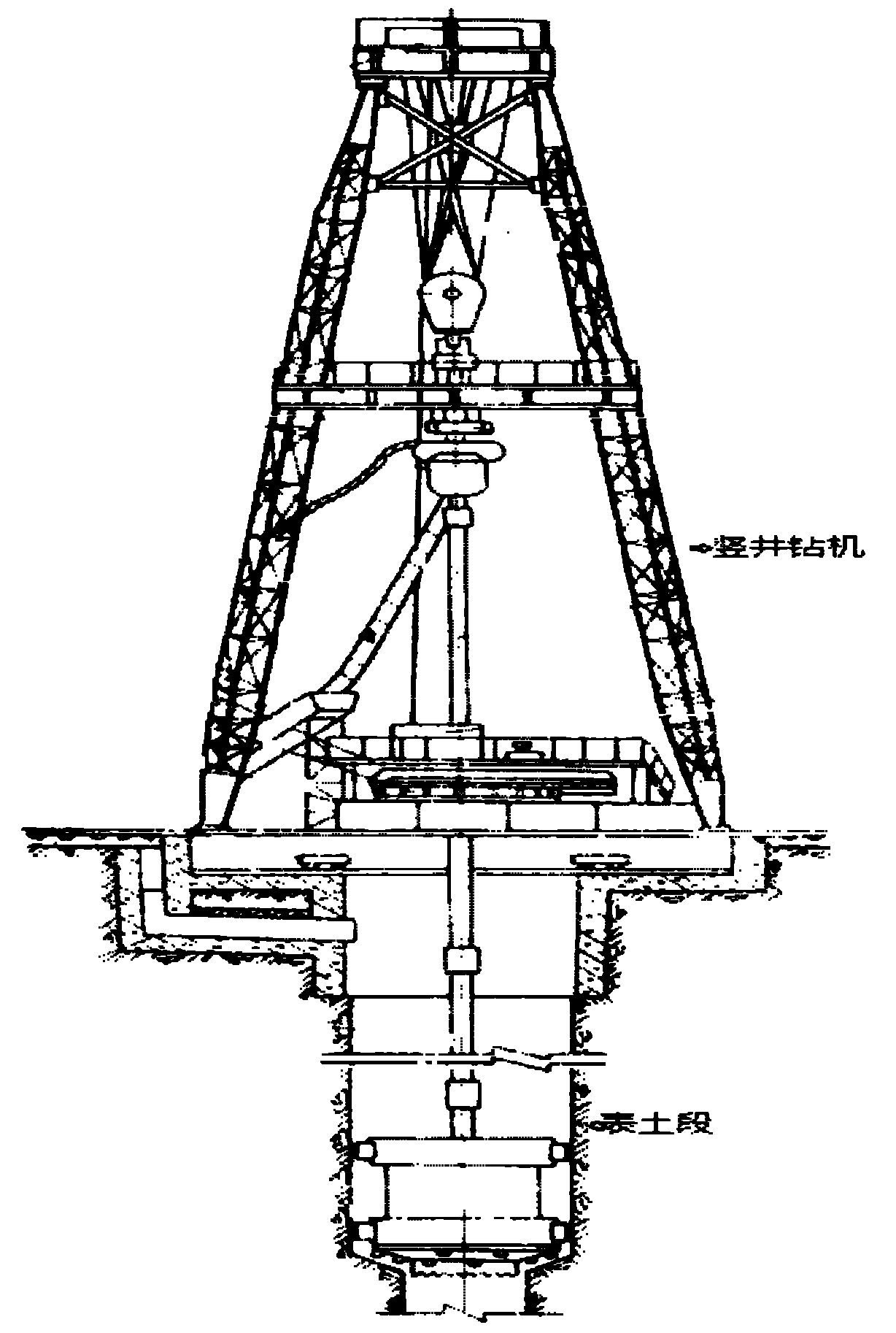

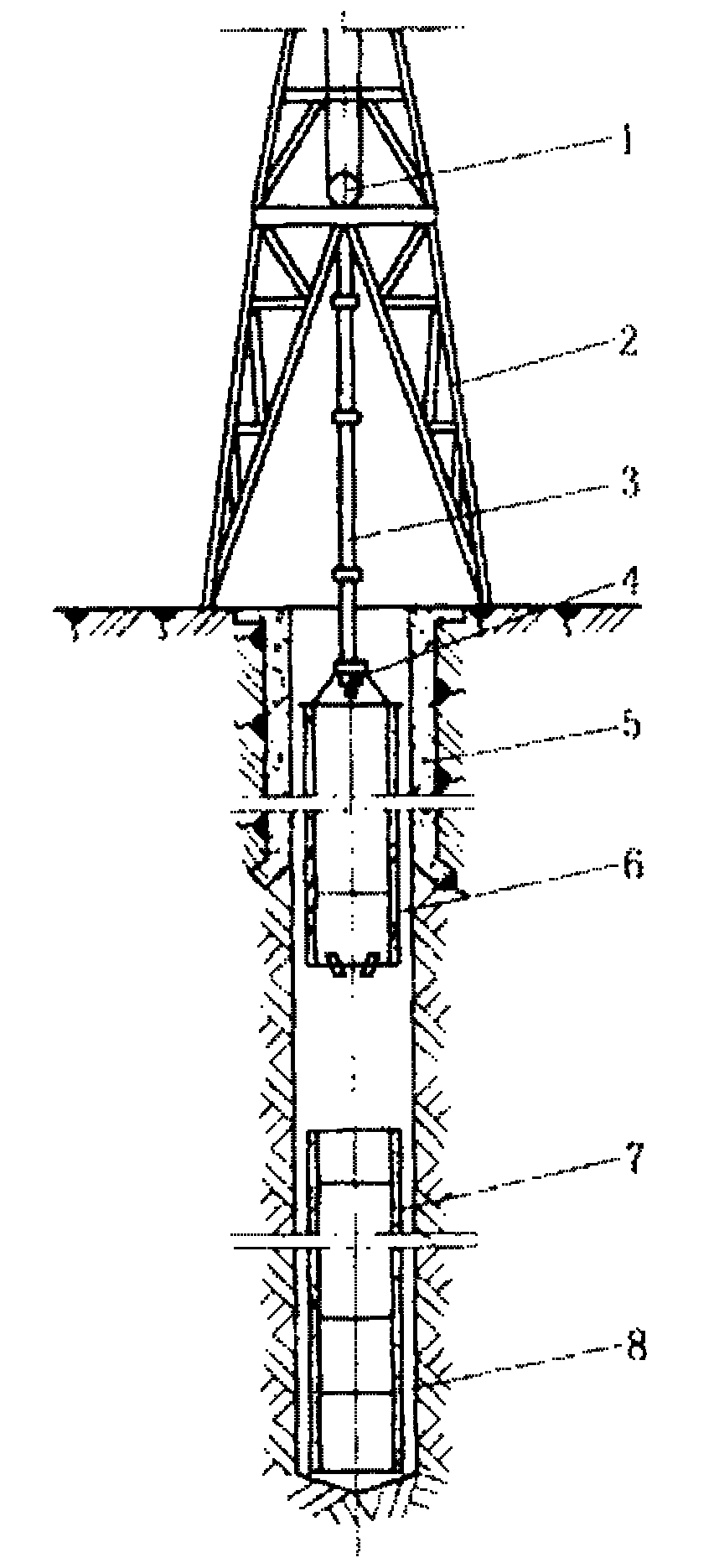

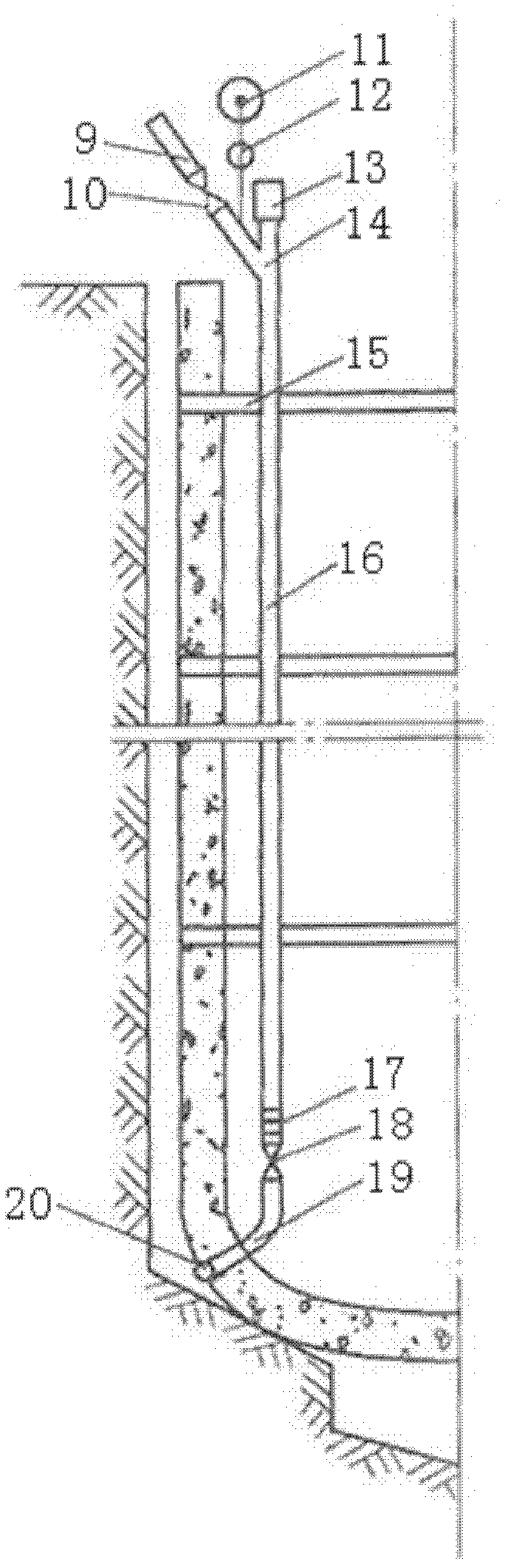

[0030] Such as figure 1 , figure 2 Shown, a kind of shaft forward, counter-shaft comprehensive sinking method, comprises the following steps:

[0031] Step 1. Use the shaft drilling rig to drill into the bedrock section to form a well hole in the topsoil section. The drill bit of the shaft drilling rig rotates to break the rock and breaks the rock into cuttings. The drill bit of the shaft drilling rig is equipped with a spherical tooth hob or a wedge hob , the speed of the vertical well drilling rig is 0-8r / min, the pressure of the drill bit of the vertical well drilling rig is less than 60% of the weight of the drill bit in the mud, when drilling in the transition zones and weathered zones of various strata, the drilling pressure should be appropriately reduced on the basis of the original Small 5-10T;

[0032] Step 2. Input compressed air through the air pipe in the drill pipe of the shaft drilling rig, and discharge the mud containing cuttings generated during the drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com