Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2340 results about "Conductor pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Conductor Pipe is a large diameter pipe that is set into the ground to provide the initial stable structural foundation for a borehole or oil well. It can also be referred to as a drive pipe because it is often driven into the ground with a pile driver.

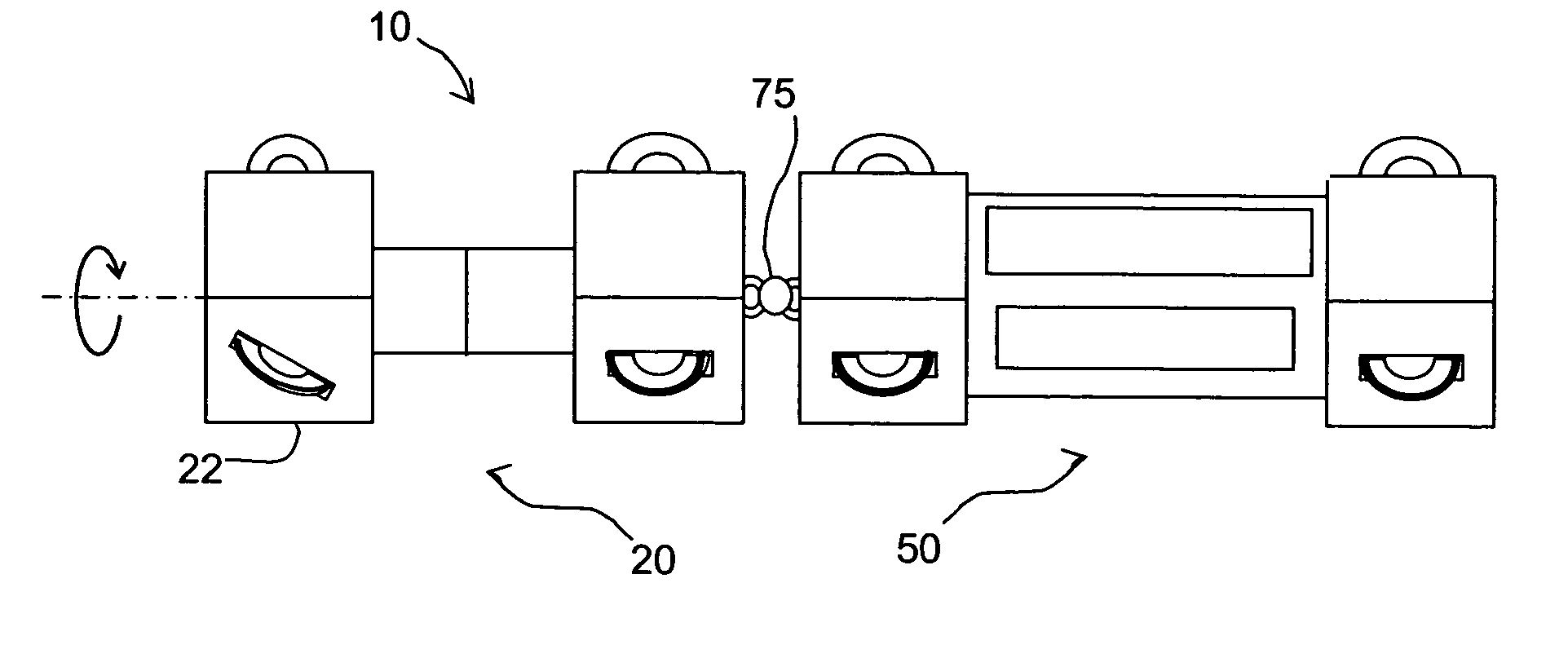

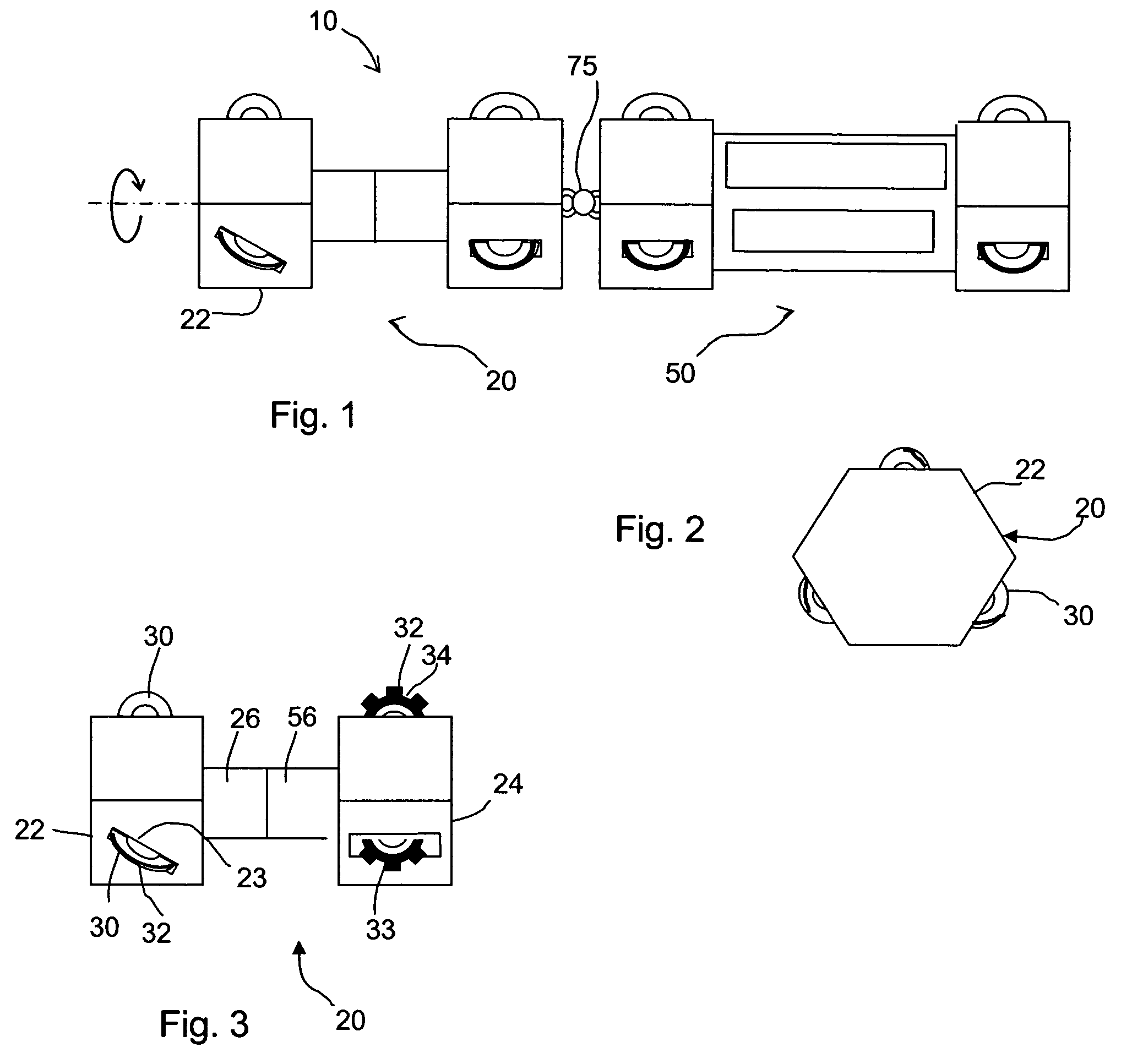

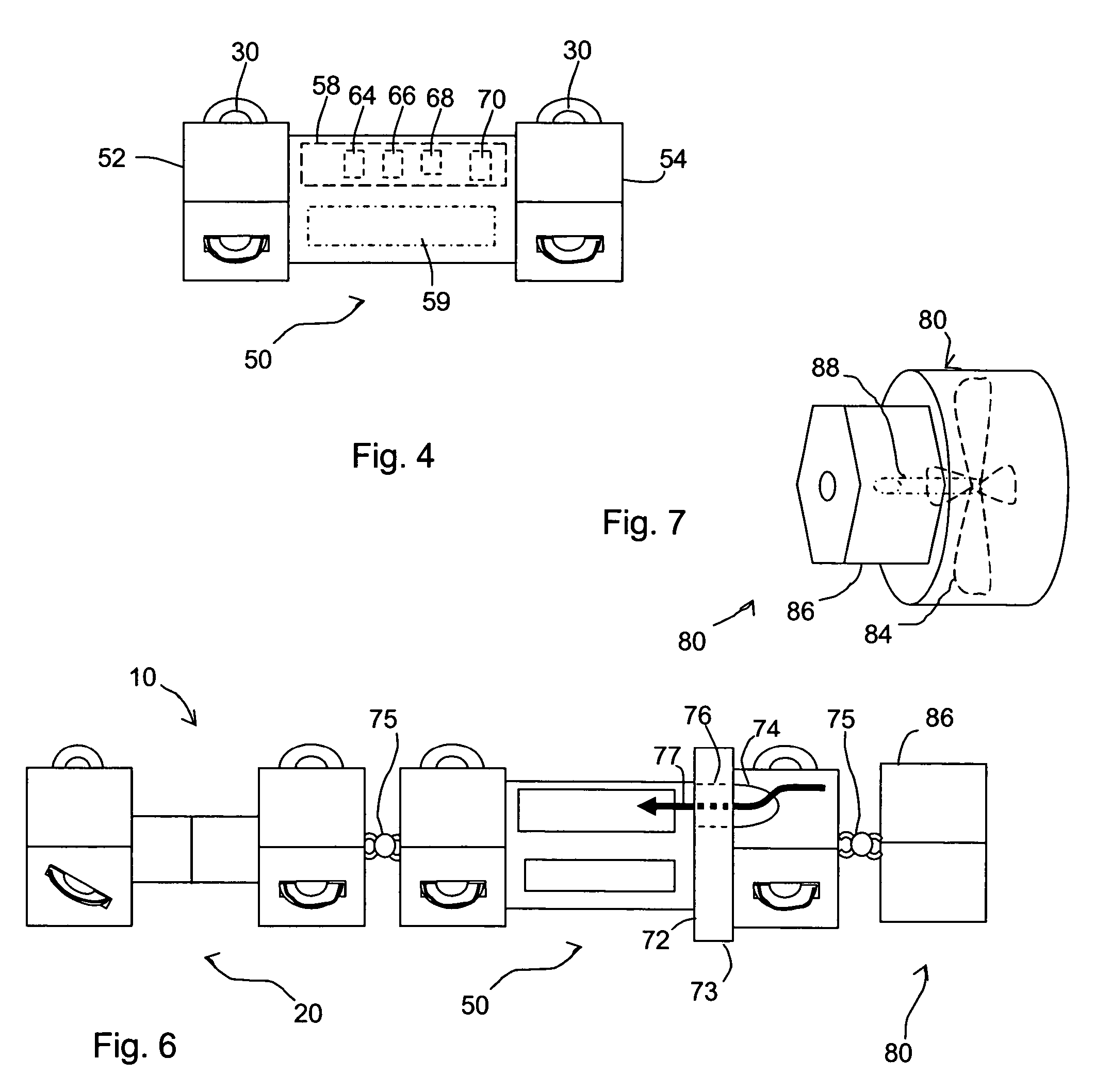

Autonomous robotic crawler for in-pipe inspection

The specification discloses a robot for inspection adapted to travel virtually unlimited distances through small-diameter enclosed spaces such as conduits or ducts, preferably using a fluid-driven screw-drive propulsion system. The robot preferably includes a plurality of wheels inclined at an angle greater than zero degrees and less than ninety degrees to the longitudinal axis of the pipe, a plurality of wheels aligned parallel to the longitudinal axis of the pipe, and a power system for causing relative rotation of the sections bearing the pitched and non-pitched wheels. The robot may include internal fluid flow passages, notched wheels, multiple retractable wheels, and is configured so as to have an operating diameter less than six and preferably less than two inches.

Owner:RICE UNIV +1

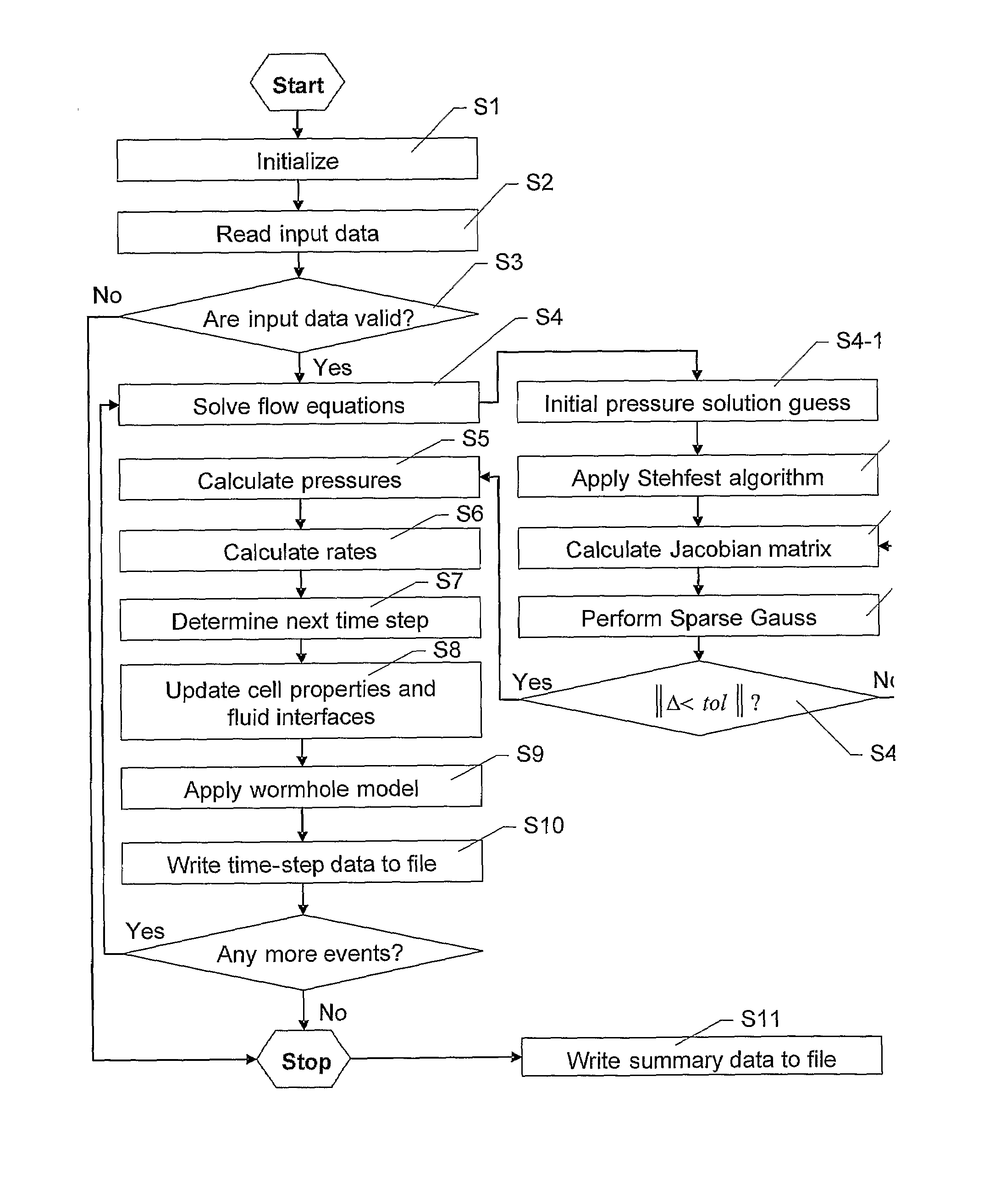

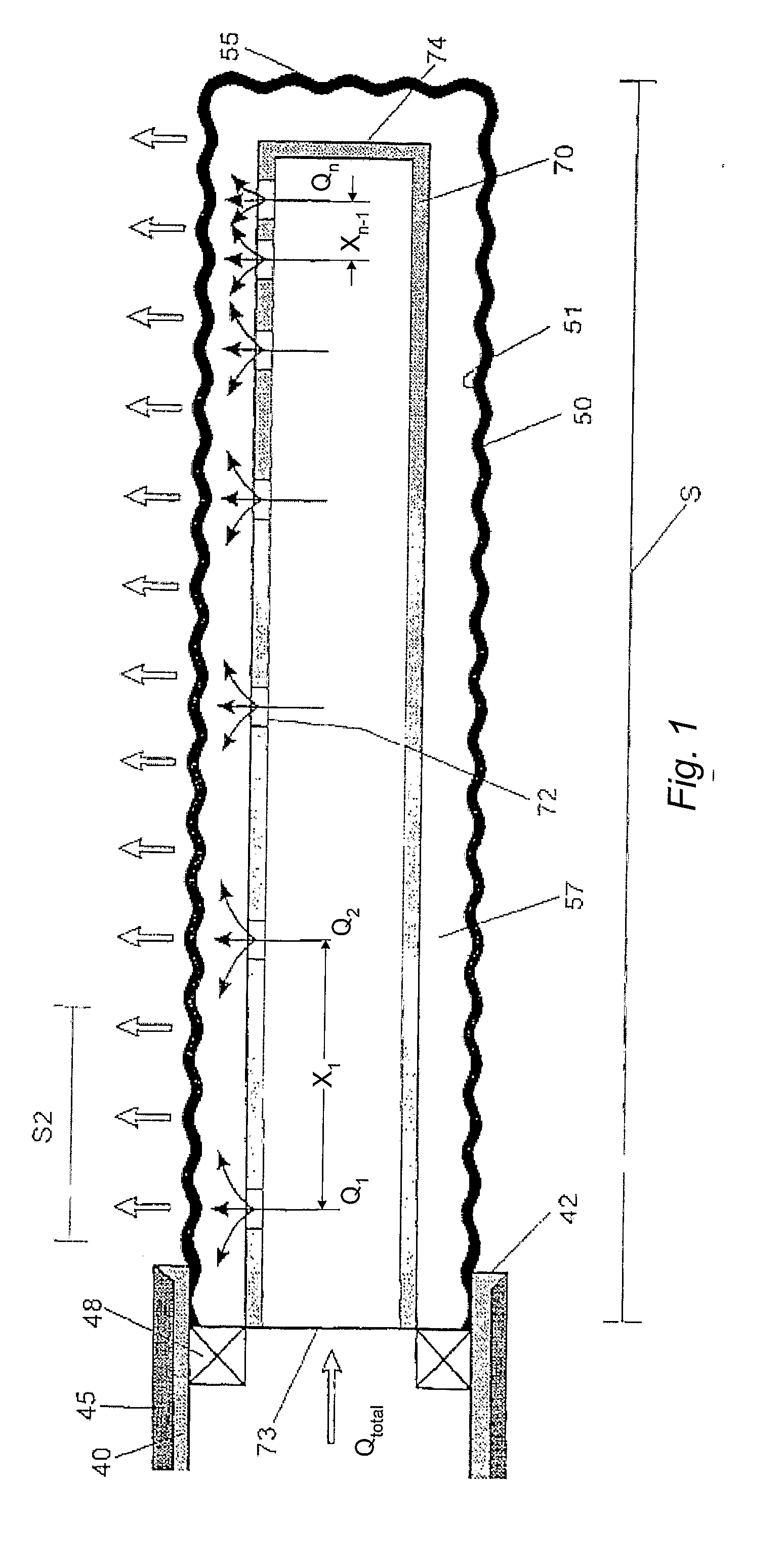

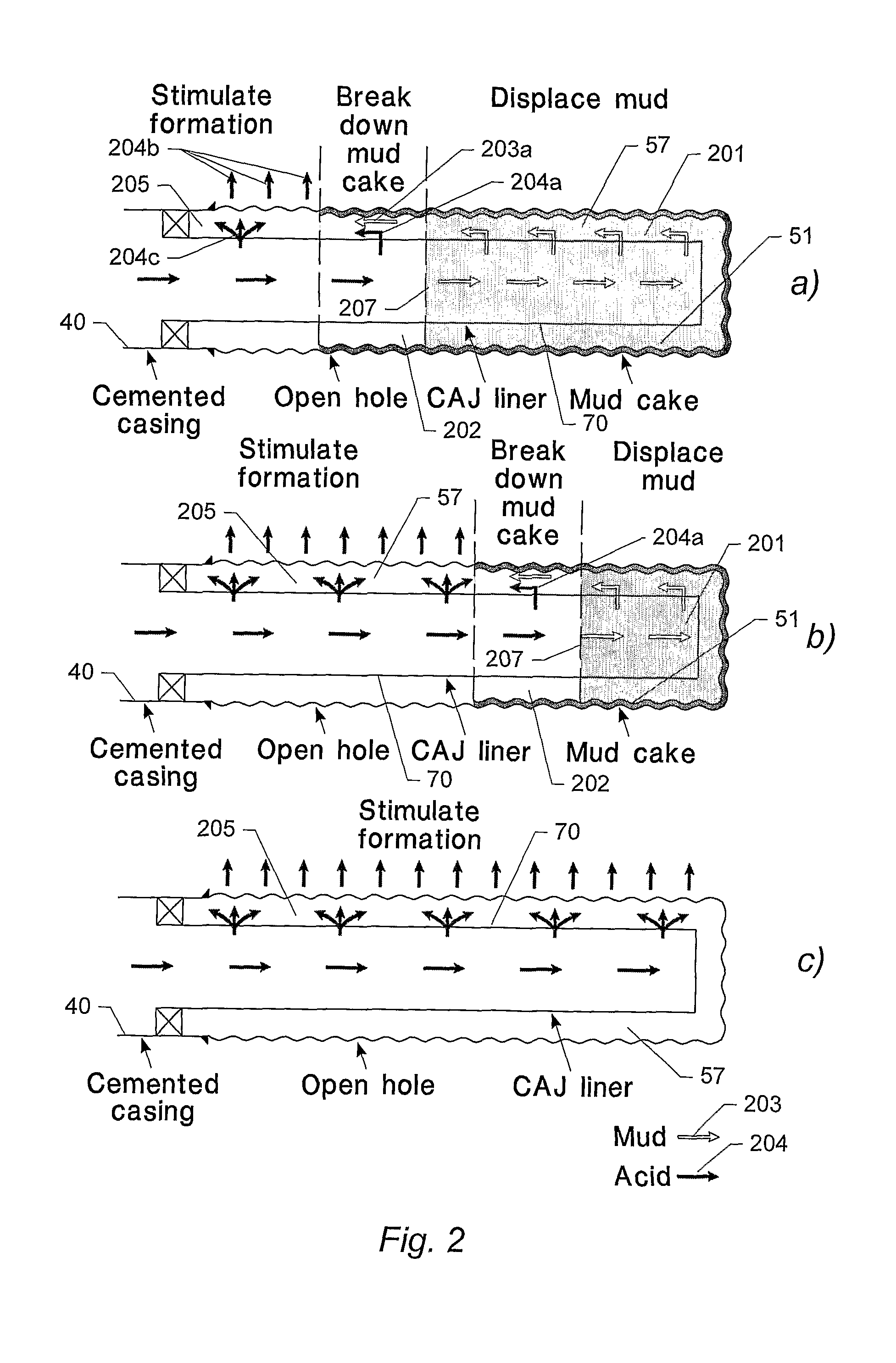

Flow simulation in a well or pipe

ActiveUS20090294122A1Accurate and efficient numerical solutionImprove modeling accuracySurveyFluid removalFluid transportEngineering

A method of simulating fluid transport in a system for stimulating a well in a material formation of a resource reservoir, the system comprising a conduit element arranged in said well, the conduit element comprising a conduit wall including one or more openings for discharging a fluid into the material formation surrounding the conduit element; the method comprising establishing and numerically processing a transport model of fluid transport inside the conduit element. The transport model further includes a model of fluid transport in a predetermined space around said conduit element.

Owner:TOTAL E&P DANMARK AS

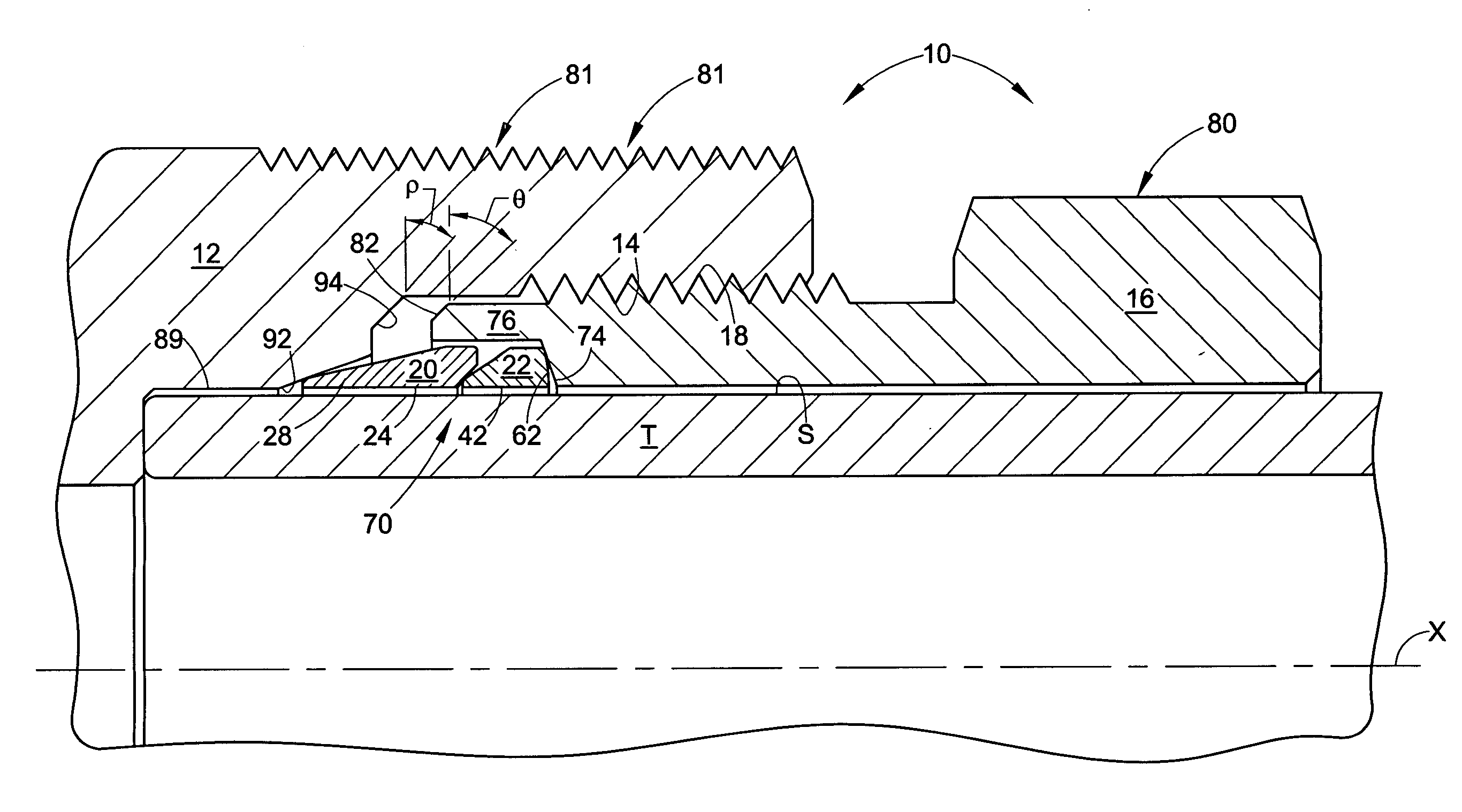

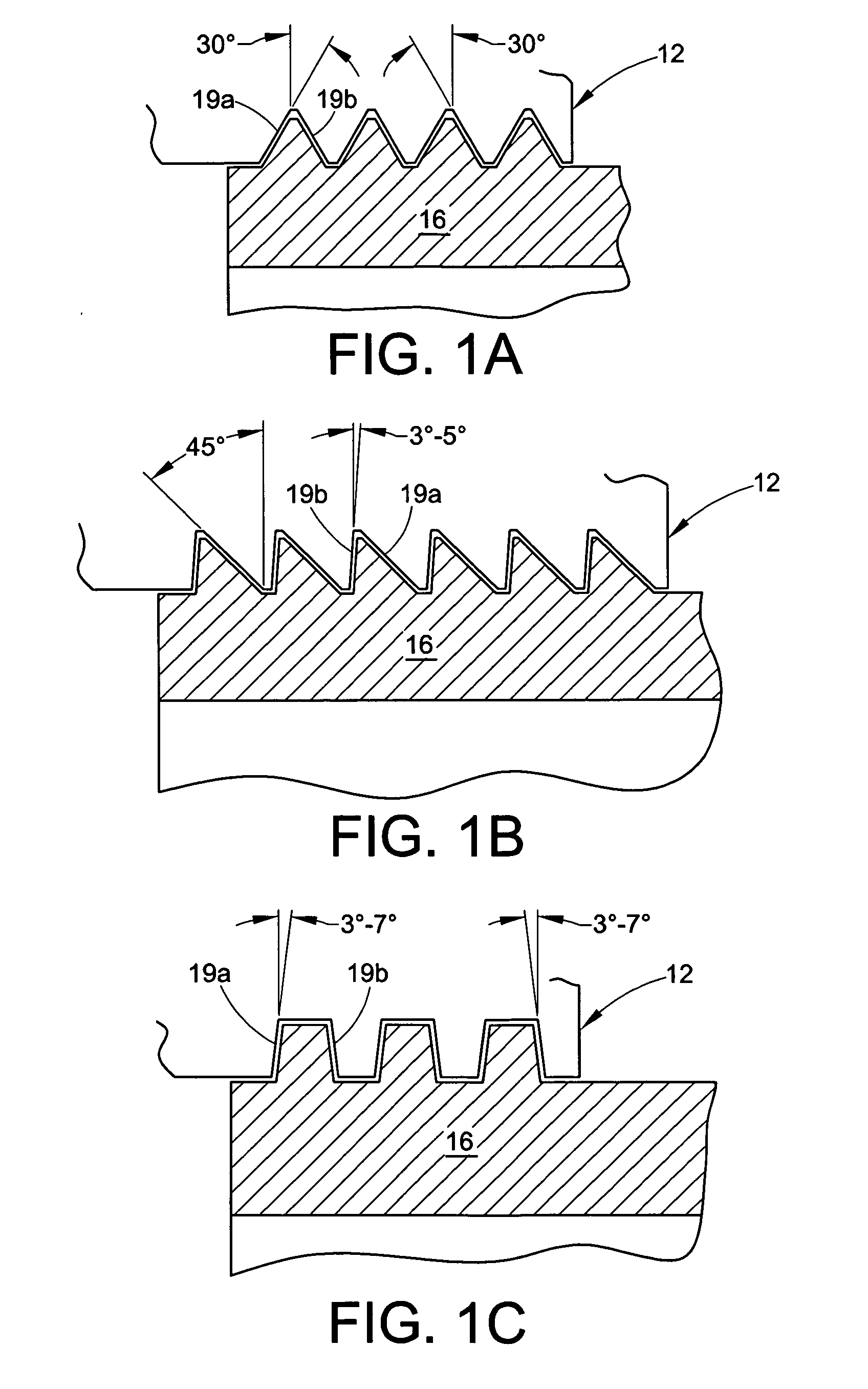

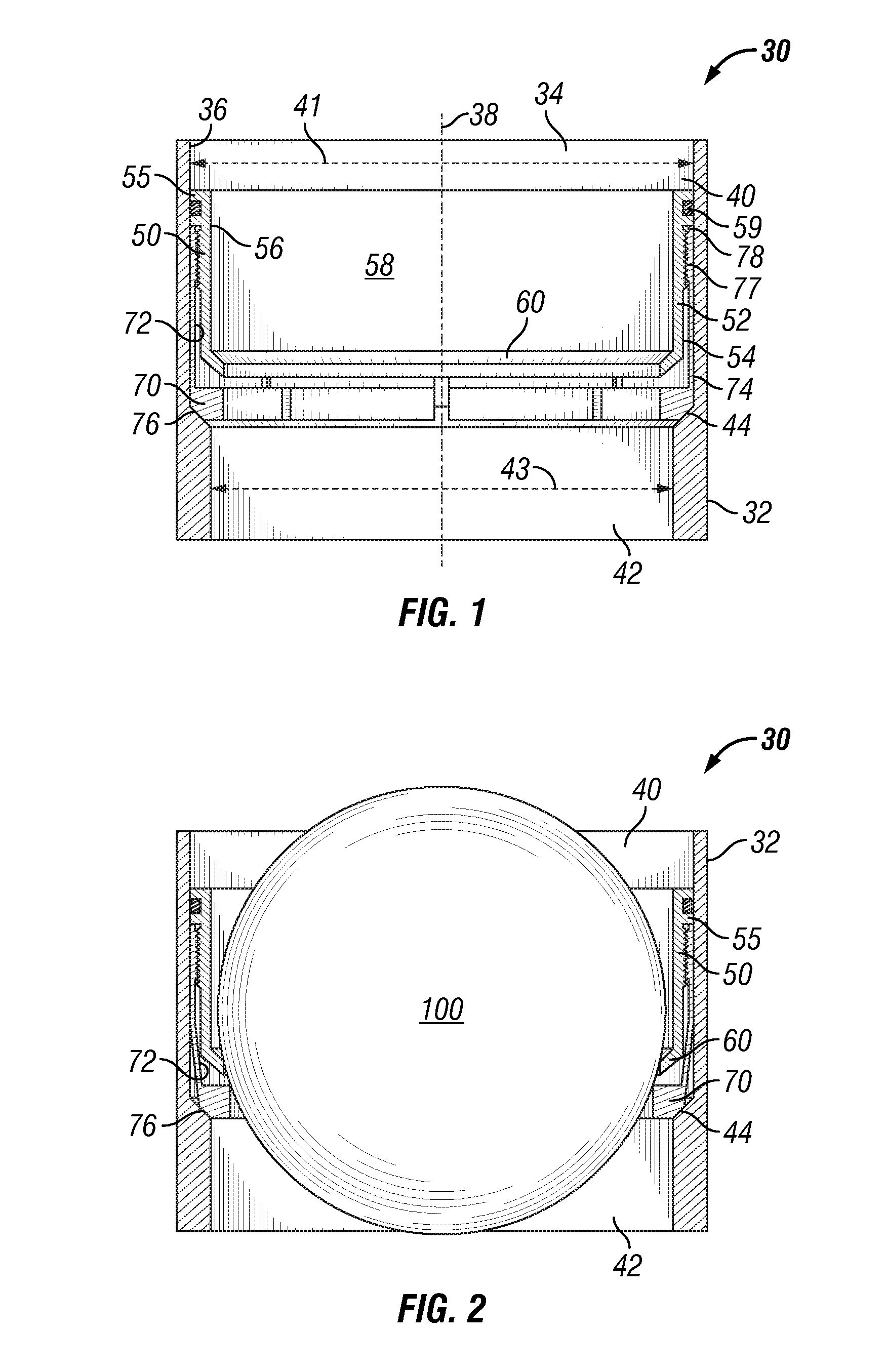

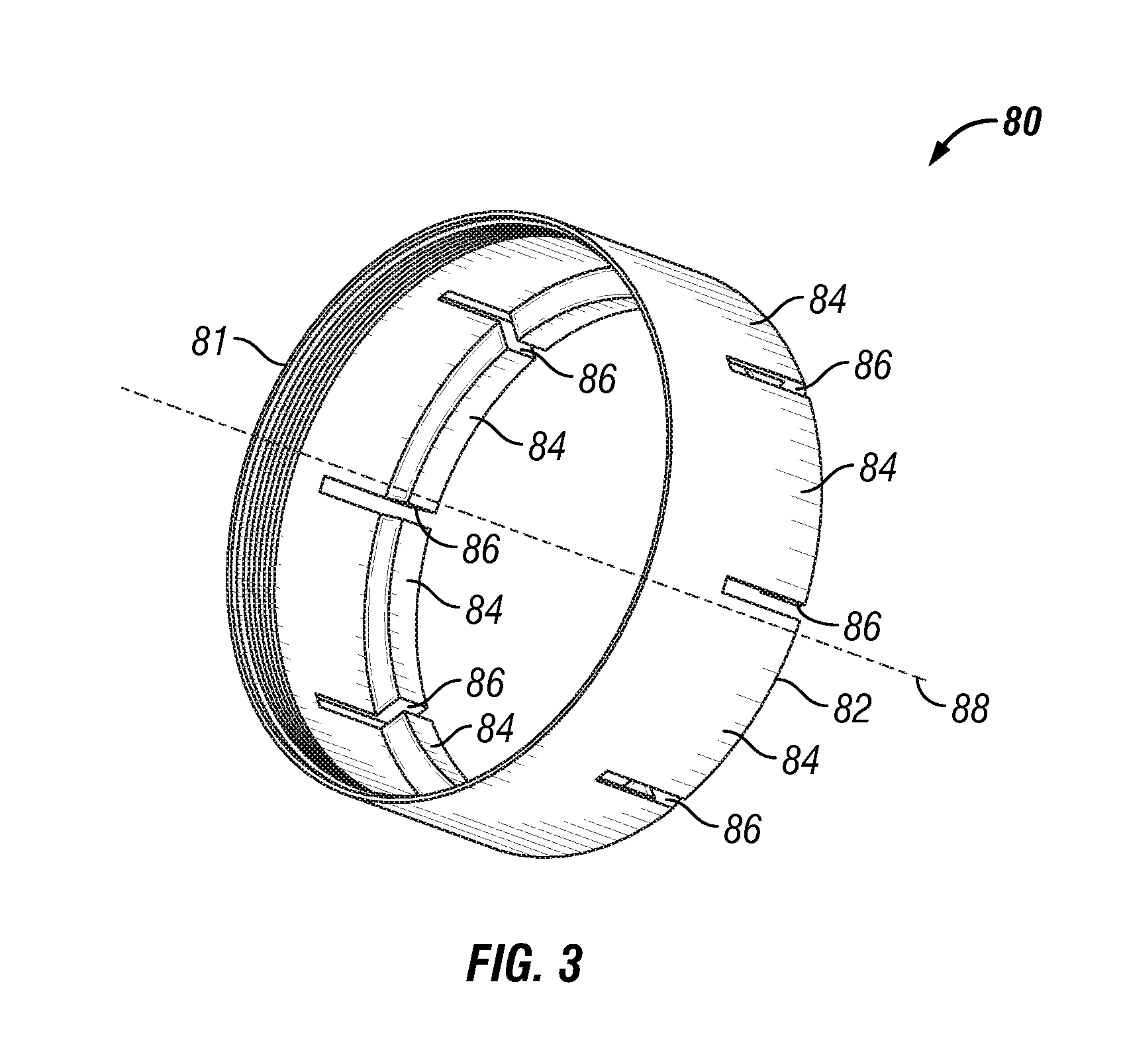

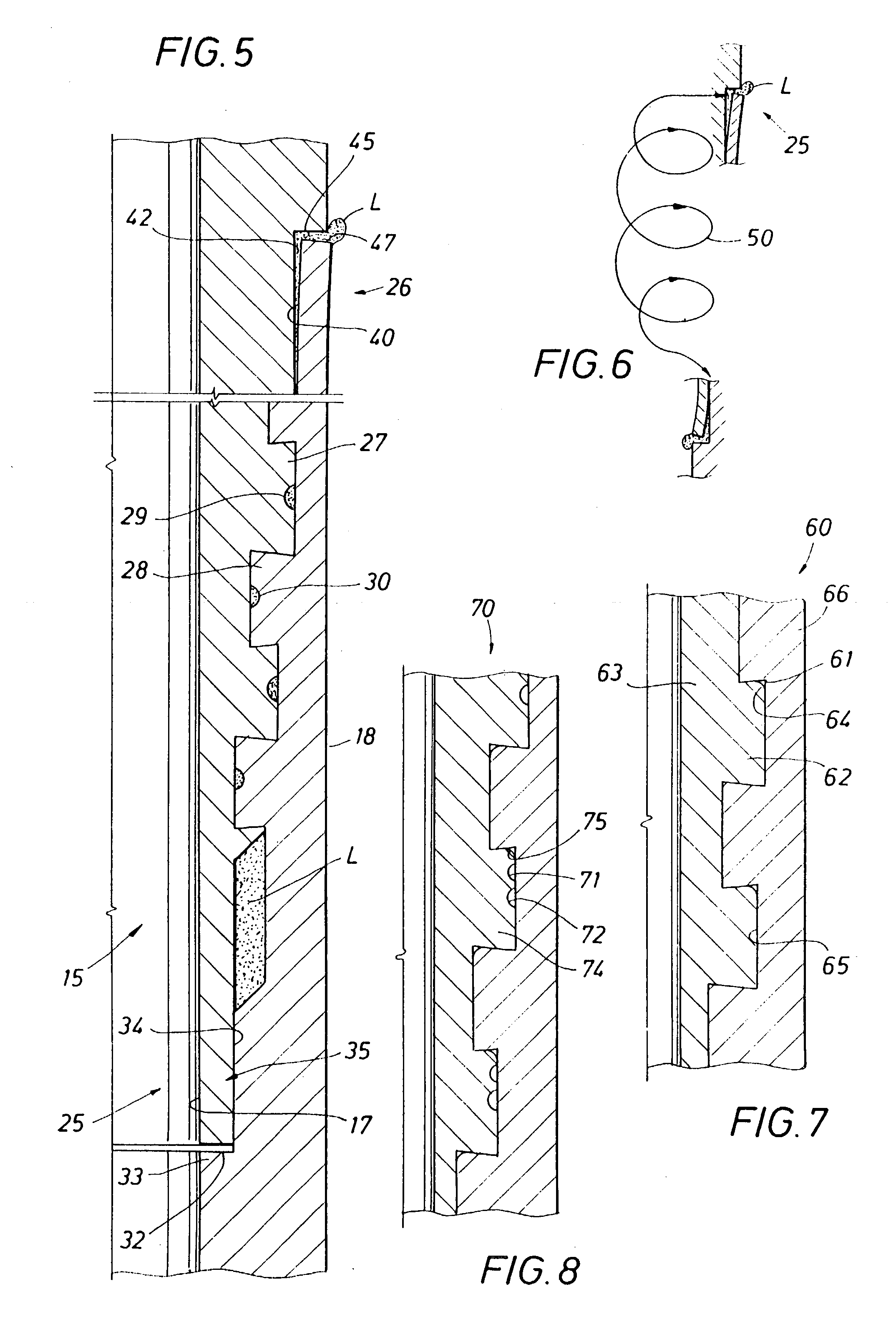

Fitting for tube and pipe

ActiveUS20050242582A1Shorten the lengthSecure retentionSleeve/socket jointsFluid pressure sealed jointsEngineeringHigh pressure

A fitting for a tube or pipe capable of functioning a high pressures having a first fitting component adapted to receive the conduit end; a conduit gripping device such as a ferrule or ferrules and a second fitting component that can be joined to the first fitting component to cause the conduit gripping device to grip the conduit and seal when assembled. In one aspect of the invention, the first fitting component is constructed from a material that is softer than the material used to construct the second fitting component. An additional aspect of the invention include a retaining portion on the second fitting component that constrains the tube gripping device against pressure. The retaining portion can also be configured to retain the tube gripping device to the second fitting component prior to installation and in a finger-tight condition. A further aspect of the invention includes a first fitting component in which an exterior portion of the component is work hardened radially outward from the tube gripping device. The fitting may optionally be provided with a structure to effect the pull-up by torque functionality.

Owner:SWAGELOK CO

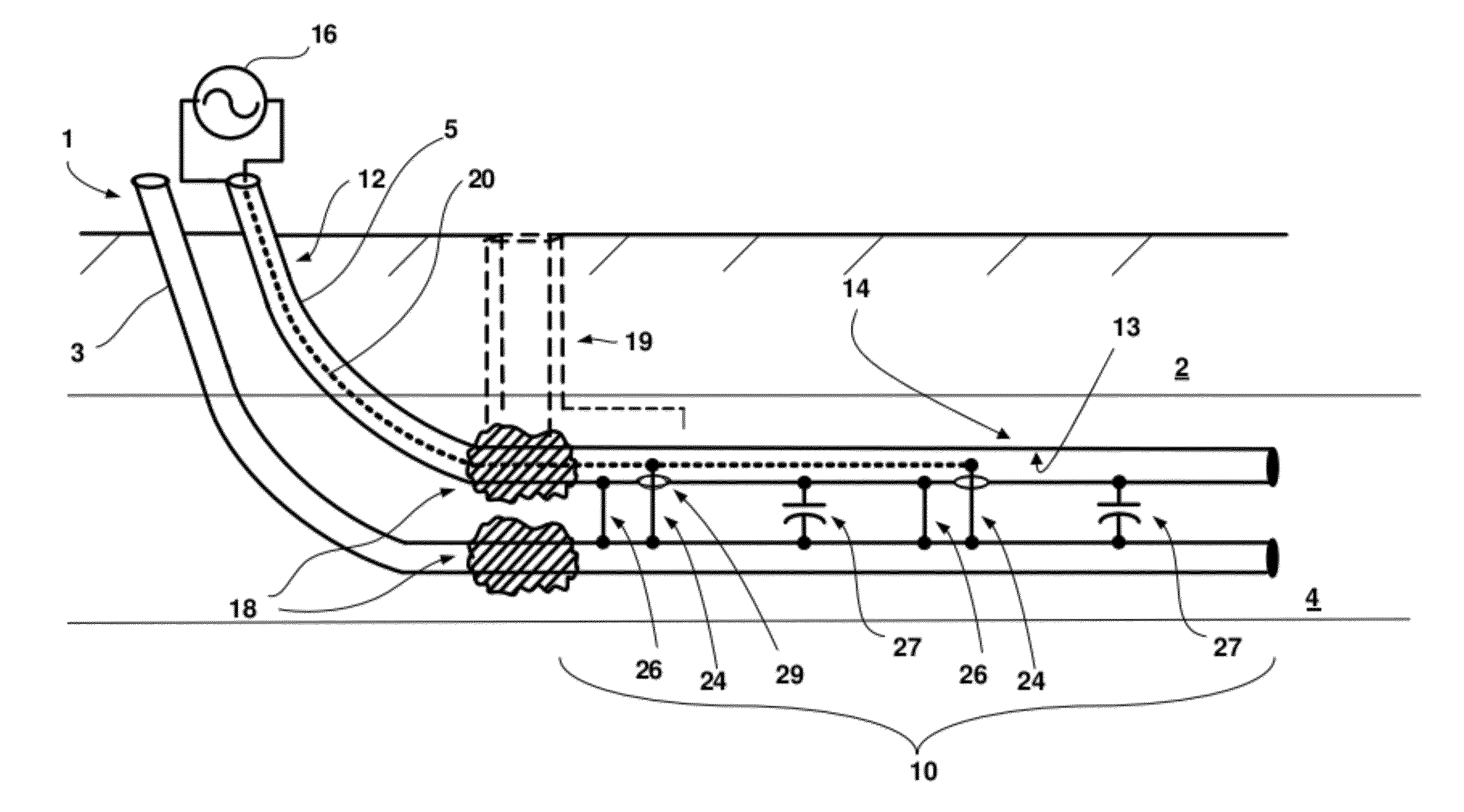

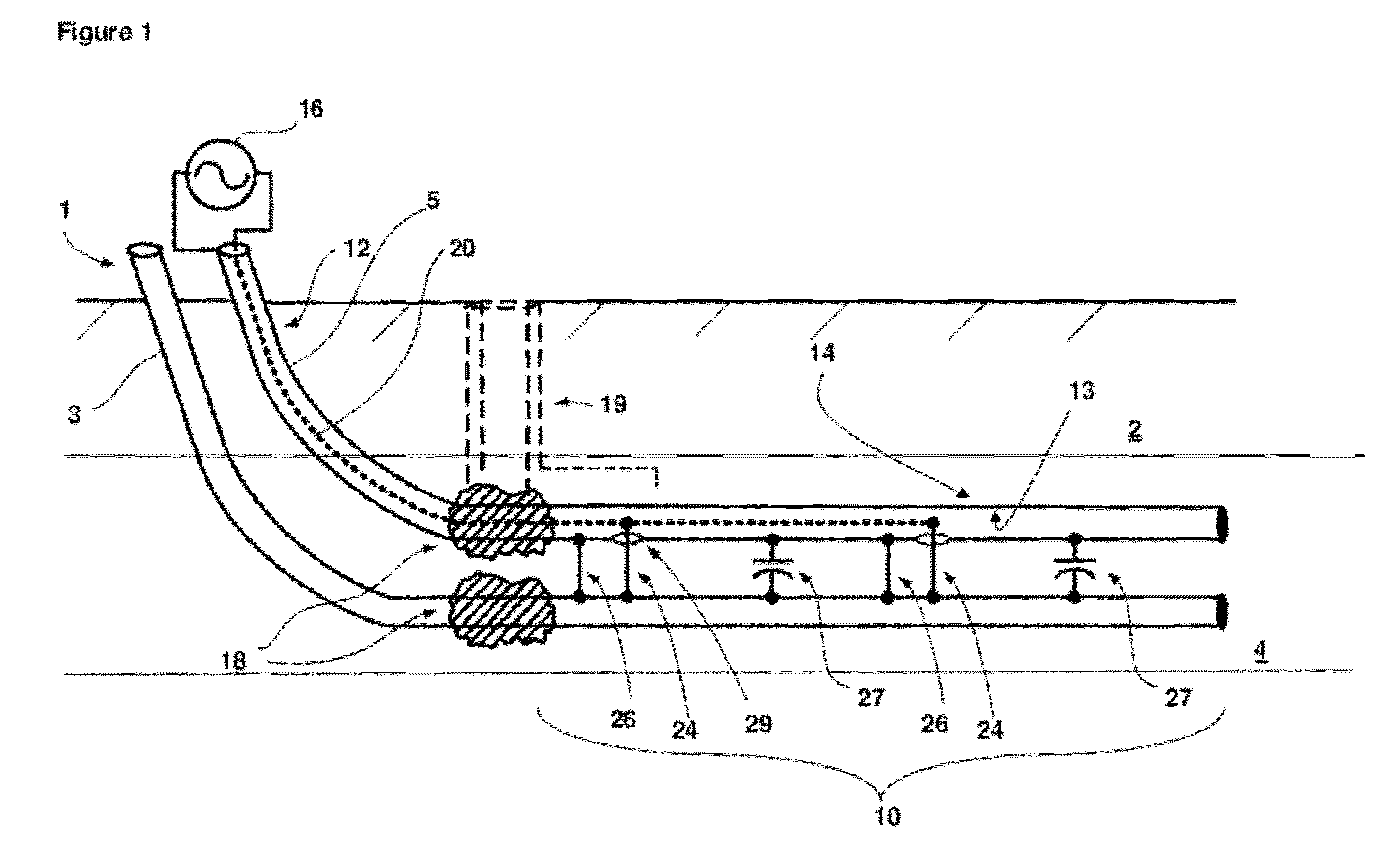

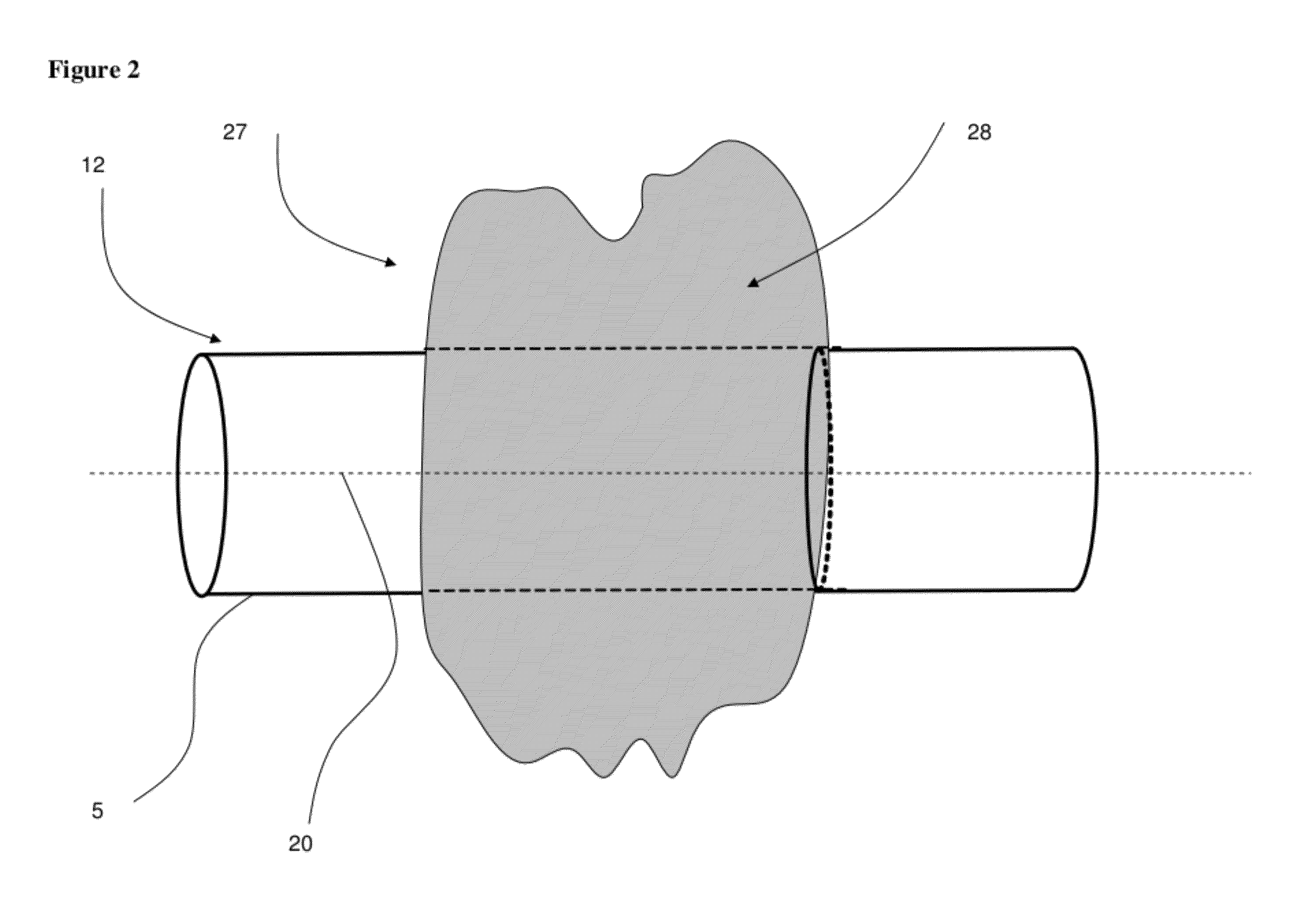

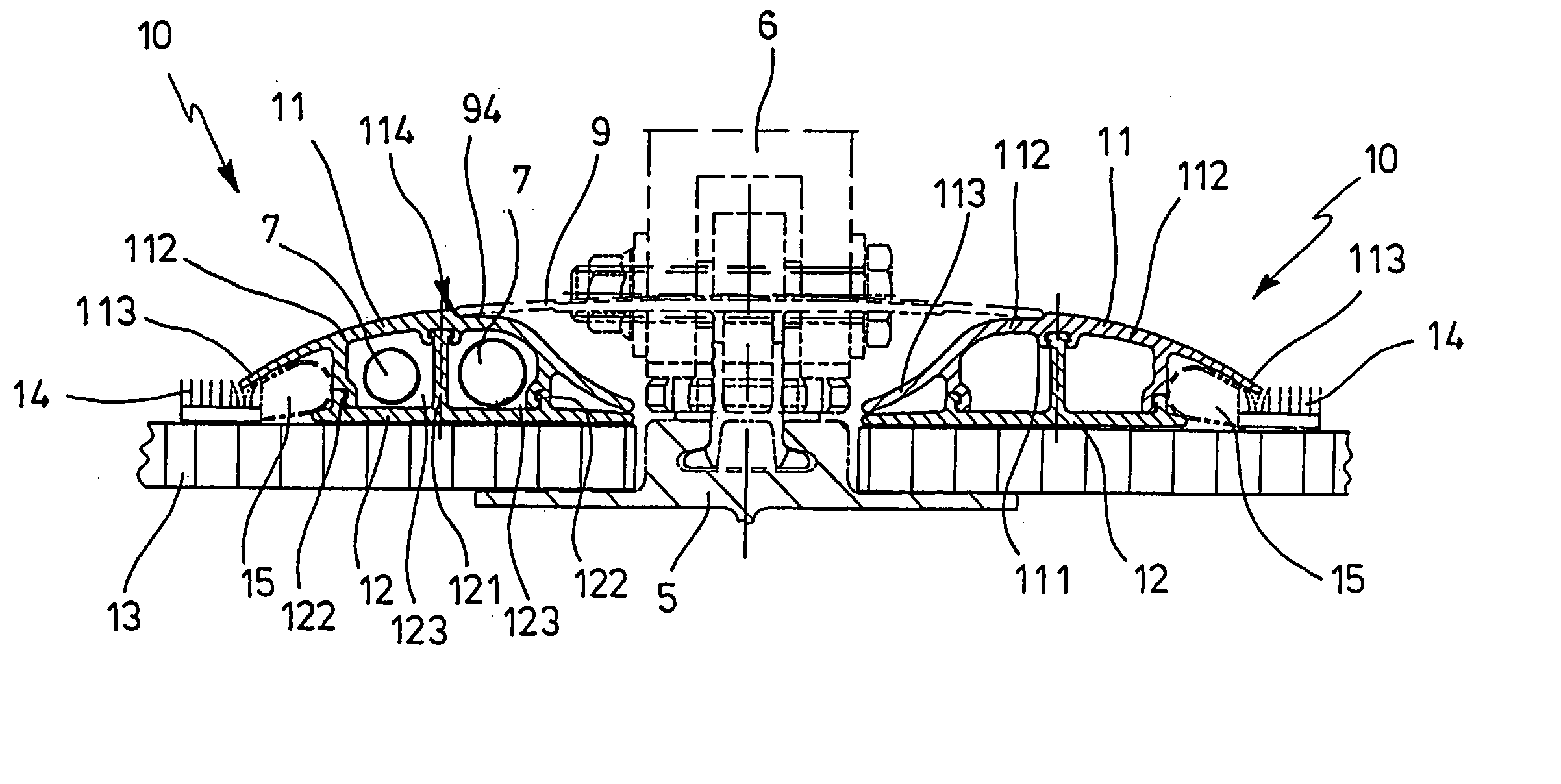

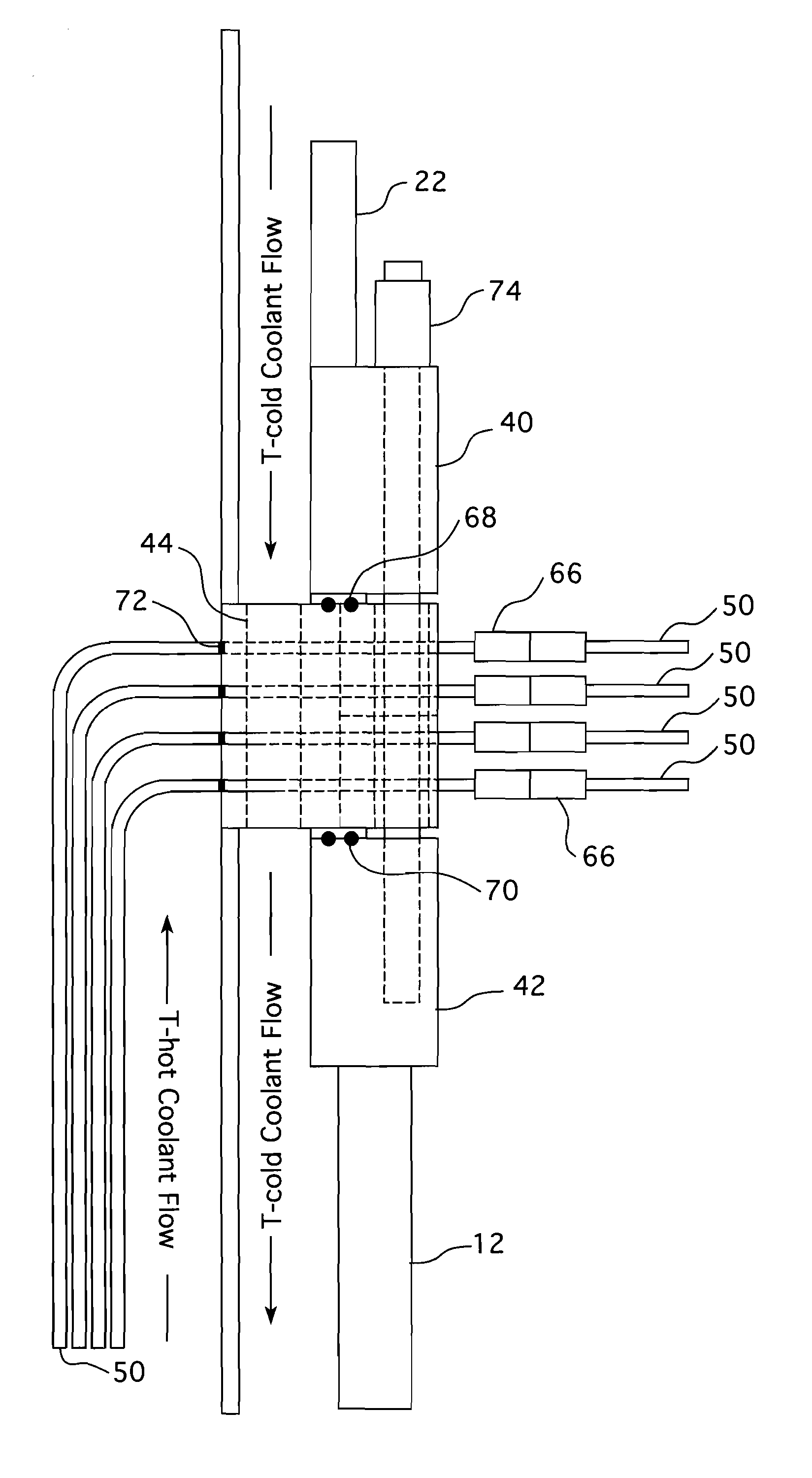

Radio frequency heat applicator for increased heavy oil recovery

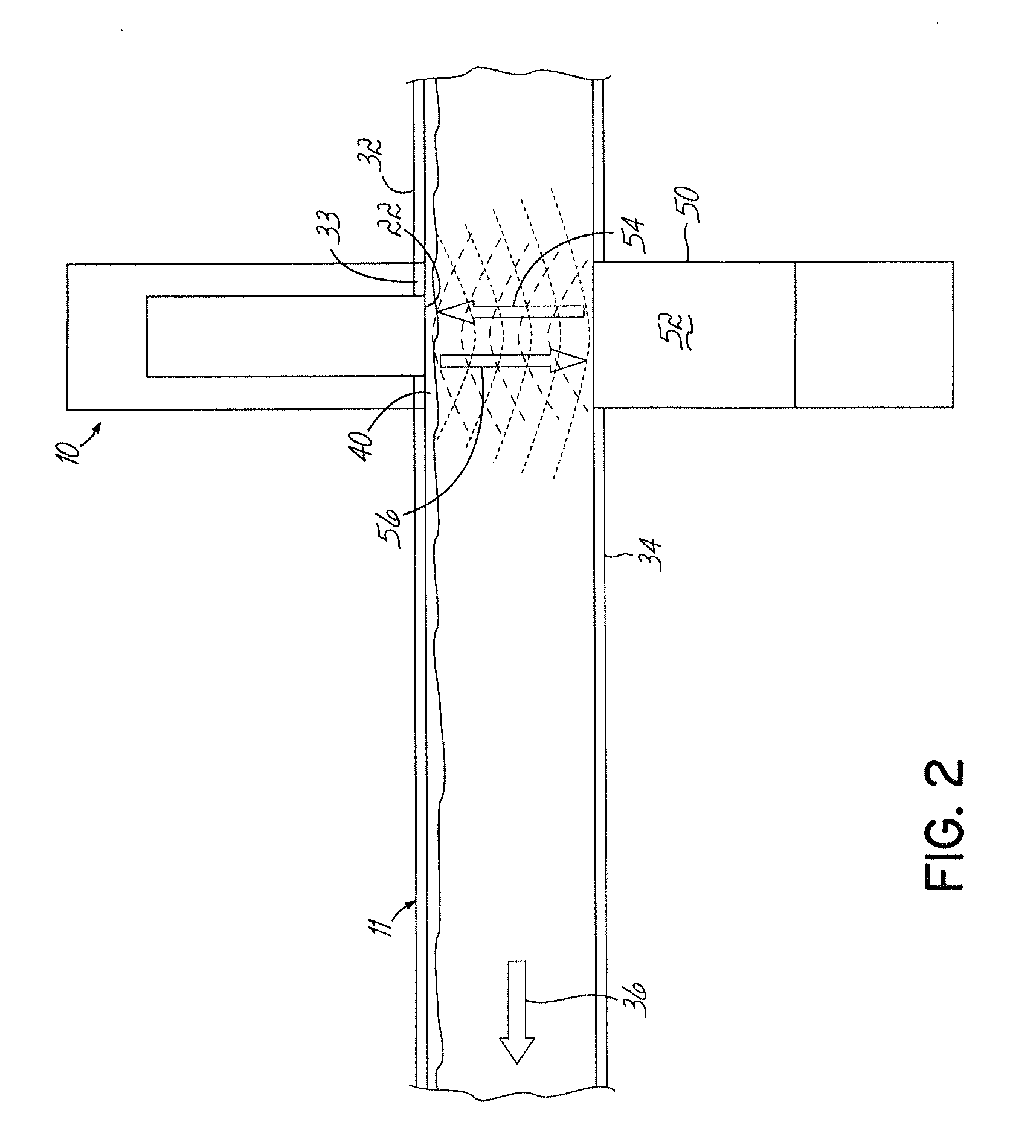

A radio frequency applicator and method for heating a geological formation is disclosed. A radio frequency source configured to apply a differential mode signal is connected to a coaxial conductor including an outer conductor pipe and an inner conductor. The inner conductor is coupled to a second conductor pipe through one or more metal jumpers. One or more current chokes, such as a common mode choke or antenna balun, are installed around the outer conductor pipe and the second conductor pipe to concentrate electromagnetic radiation within a hydrocarbon formation. The outer conductor pipe and the second conductor pipe can be traditional well pipes for extracting hydrocarbons, such as a steam pipe and an extraction pipe of a steam assisted gravity drainage (SAGD) system. An apparatus and method for installing a current choke are also disclosed.

Owner:HARRIS CORP

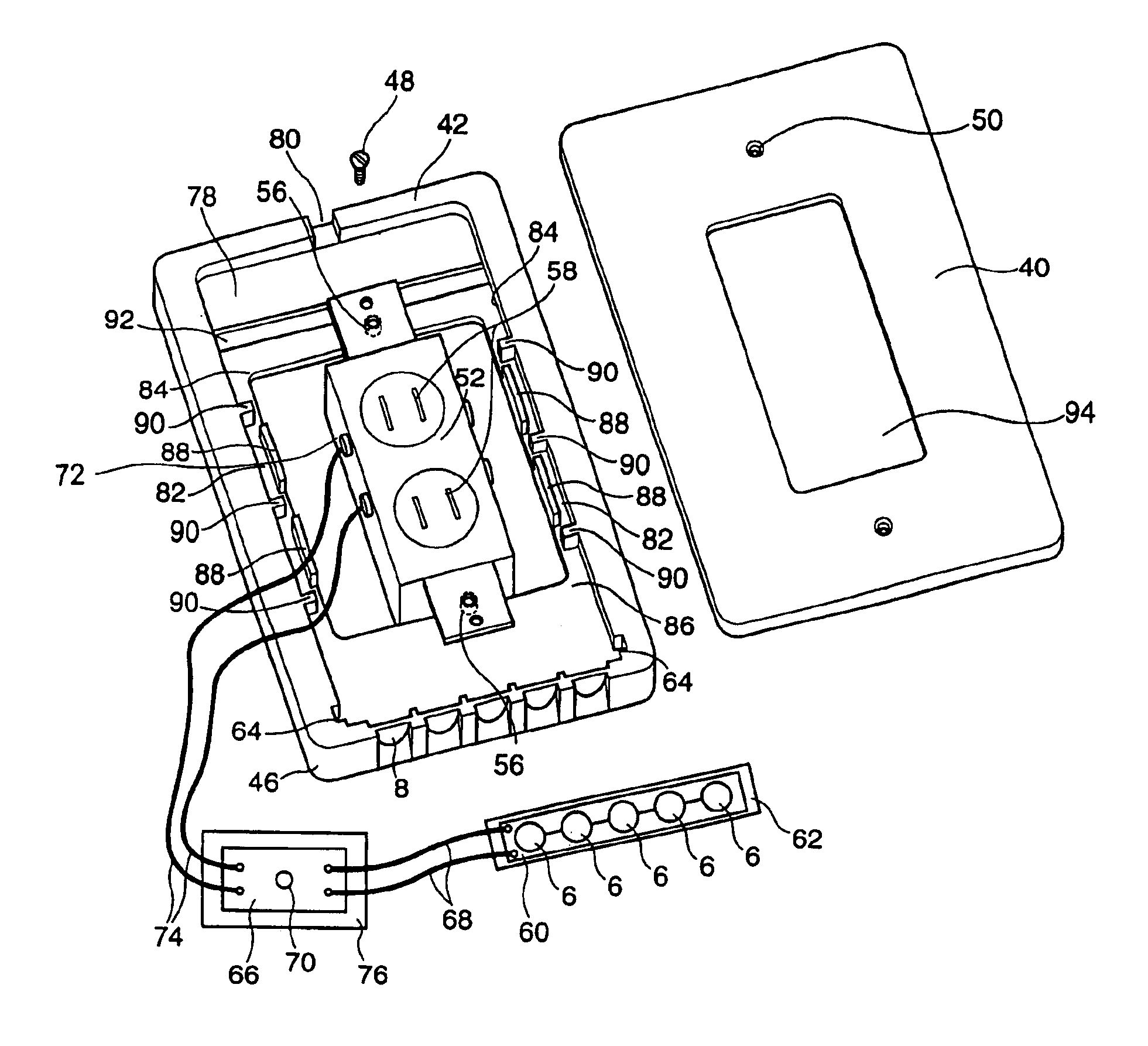

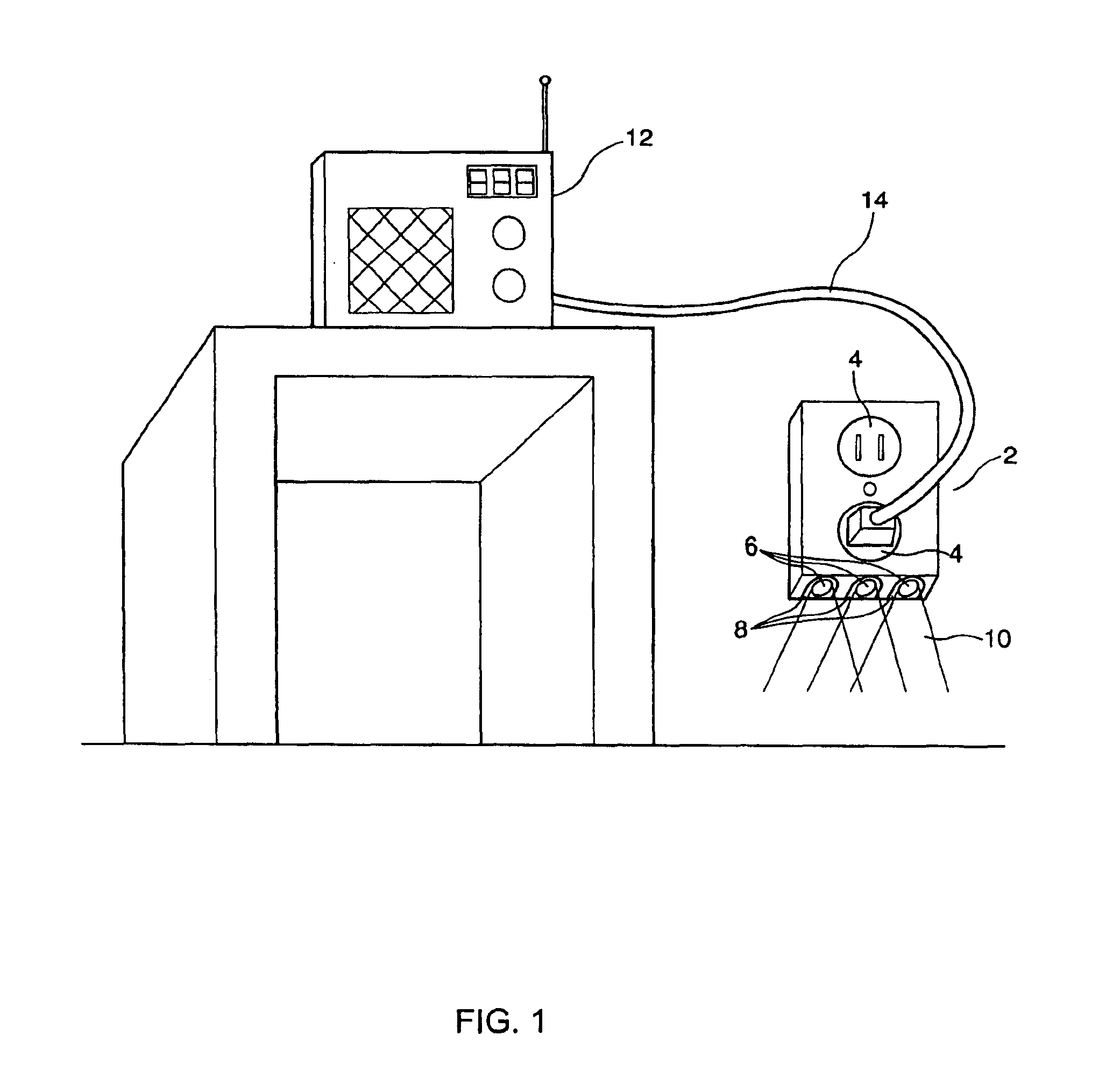

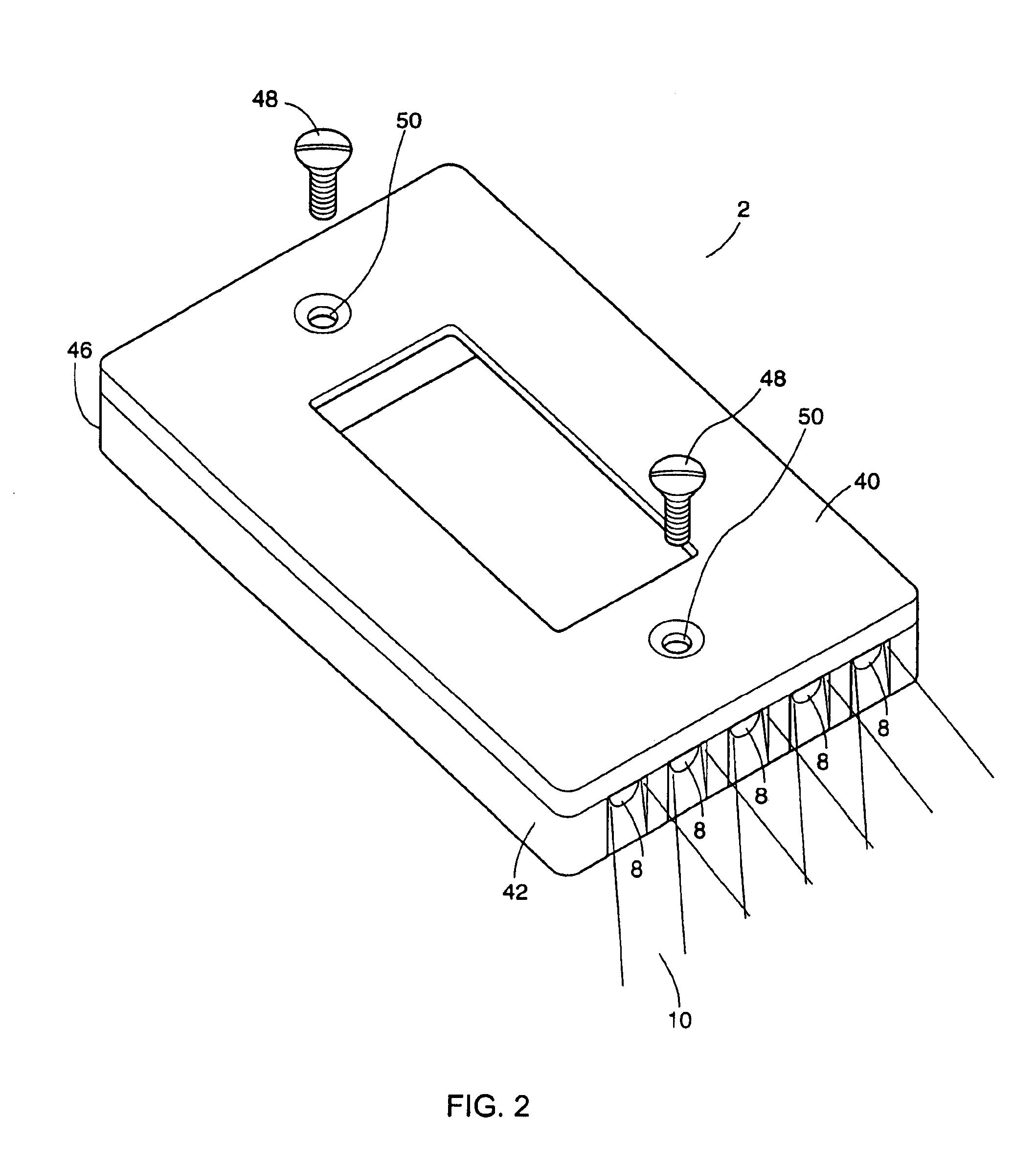

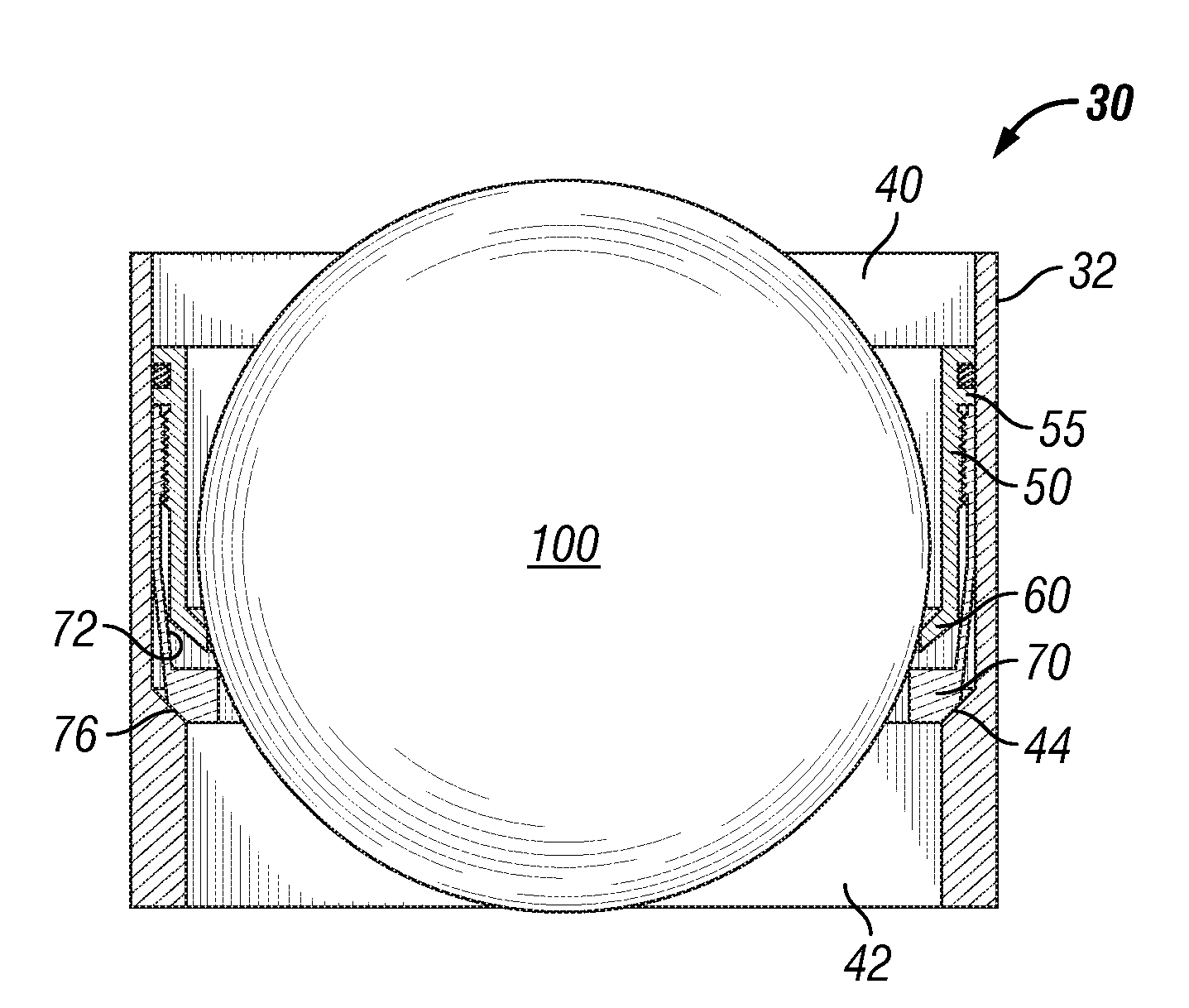

Frame assembly and light for an electrical wall conduit

A frame assembly for covering a wall conduit having a connection to electrical power and a component associated with the wall conduit requiring access through the frame assembly is provided. The frame assembly comprises a light powered by an electrical circuit connected to the connection and a frame for housing the light. The frame has an opening allowing access to the component through the frame, a side and an aperture in the side allowing the light to illuminate a space outside the frame assembly through the aperture.

Owner:BLACKBIRD TECH

Ball seat having ball support member

ActiveUS20120261115A1Reduce the possibilityIncrease pressureFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

Apparatuses for restricting fluid flow through a well conduit comprise a tubular member having an inner wall surface defining a bore and a seat in sliding engagement with the inner wall surface. Operatively associated with the seat is a plug element support member having an expanded position when the apparatus is in a run-in position and a contracted position when the apparatus is in a set position. A plug element adapted to be disposed into the bore and landed on the seat to restrict fluid flow through the bore and the well conduit is used to move the seat which in turn moves the plug element support member from the expanded position to the contracted position, thereby providing support to the plug member landed on the seat.

Owner:BAKER HUGHES INC

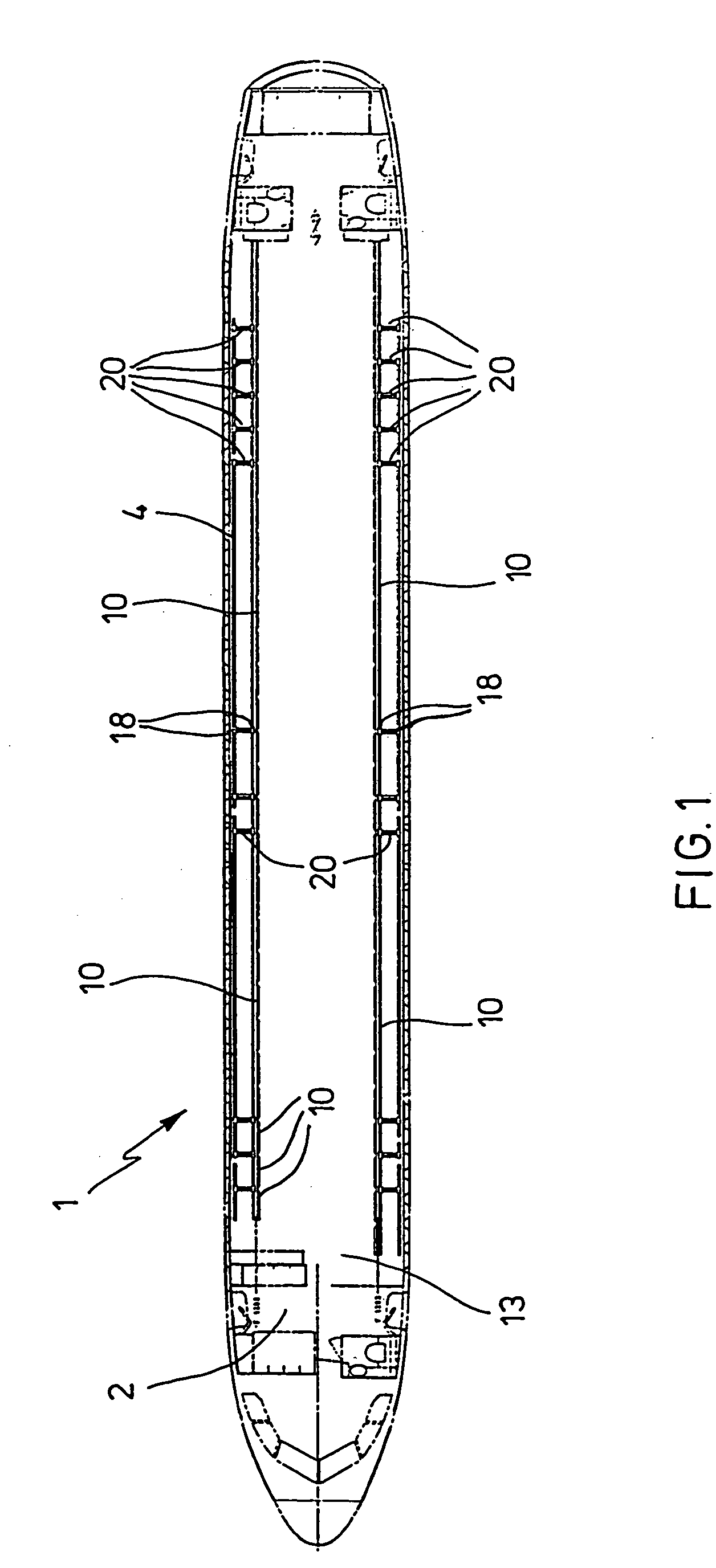

Arrangement for laying cables in the floor area of a passenger transport aircraft

ActiveUS20040129445A1Minimal complexityMinimal effortPipe supportsClosed circuit television systemsNacelleEngineering

A conduit system for laying cables along the floor of a passenger cabin of an aircraft includes longitudinal and transverse cable guide elements respectively forming cable channels, and cable branch junctions at intersections of the longitudinal and transverse guide elements. Each guide element includes a lower part secured to the cabin floor, and an upper part secured (e.g. snap fitted) onto the lower part to cover the cable channel. The cable branch junction includes a lower section secured to the floor and covered by an upper section, and allows the cables to continue straight through the junction or to be deflected by 90° or by 180°. With this arrangement, a greater number and greater diameter of cables can be laid out with a minimal installation effort. The components of the system are easily adaptable to any required installation layout, while providing a continuous covered protected enclosure for the cables.

Owner:AIRBUS OPERATIONS GMBH

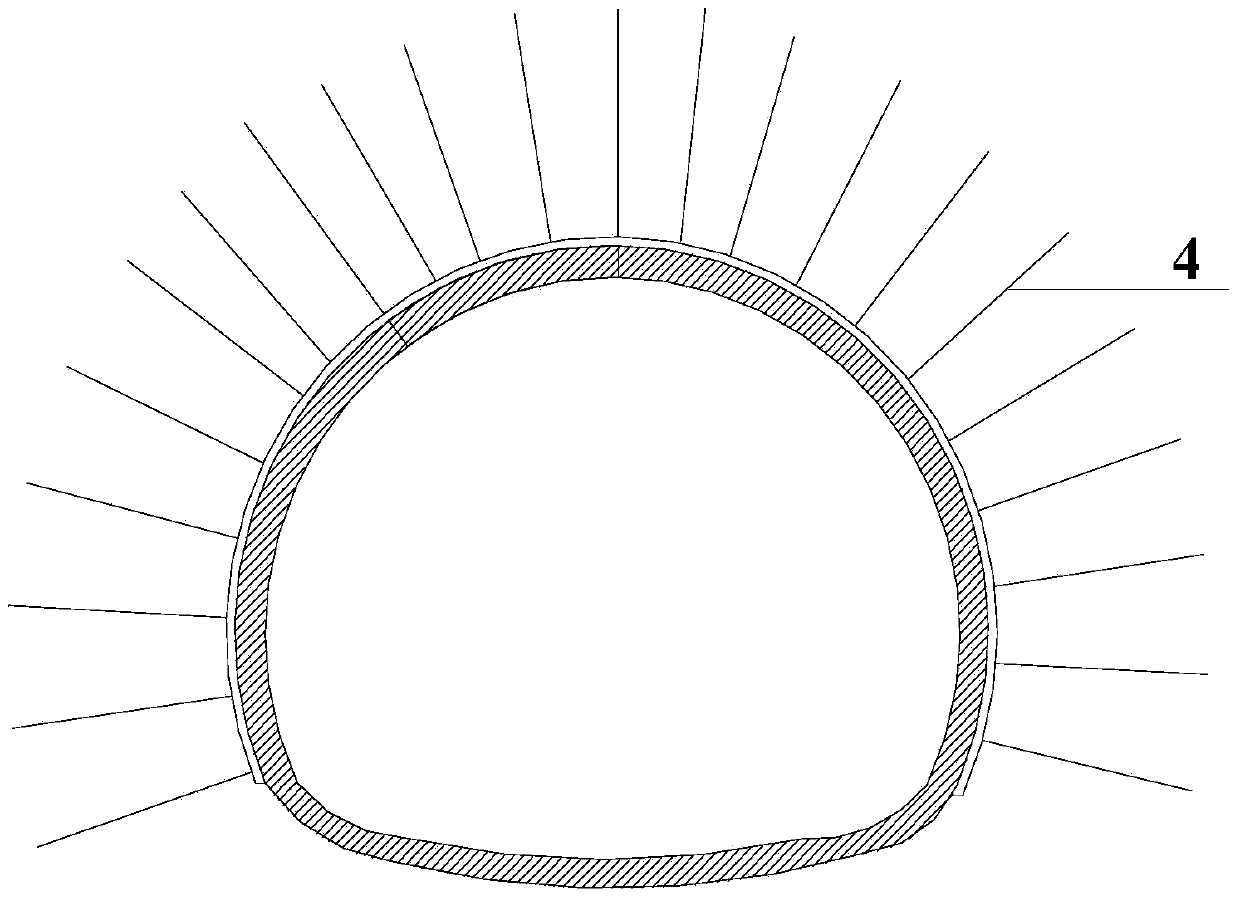

Vertical shaft construction method under unfavorable geological condition

The invention discloses a vertical shaft construction method under a unfavorable geological condition, comprising the following construction steps of: 1, pouring cover-weight concrete at a position wherein a well head of a vertical shaft is; 2, arranging two circles of advance consolidation grouting holes in the cover-weight concrete and arranging anchor bar bundles in the grouting holes, wherein the depths of the grouting holes are the same as the depth of the vertical shaft and the depths of the anchor bar bundles are the same as the depths of the grouting holes; 3, drilling pilot holes from top to bottom of the vertical shaft by utilizing a raise-boring machine; 4, drilling pilot shafts from bottom to top of the vertical shaft by utilizing the raise-boring machine; 5, carrying out advance support before expanding excavation; 6, carrying out hole drilling , blasting and the expanding excavation from top to bottom on the vertical shaft; and 7, carrying out reinforced support after the expanding excavation. By means of the vertical shaft construction method disclosed by the invention, the problems of the excavation of the light-section deep vertical shaft under the unfavorable geological condition are solved; and through the advance consolidation before the pilot hole construction, the advance support of small pipes before the expanding excavation and the steel support and bolt-spray support after the excavation, the influences of hole collapsing during the pilot shaft excavating and collapse after the expanding excavation on the construction are effectively eliminated.

Owner:SINOHYDRO BUREAU 5

Method of repairing tubular members on oil and gas wells

The disclosure concerns a method and apparatus for repairing or structurally reinforcing an oil and gas well tubular member, or an assembly of tubular members. The assembly to be repaired can include a smaller diameter inner flow conveying conduit (or production tubing) and a larger diameter concentrically placed surface casing, providing an annulus in between the production tubing and the surface casing. A third casing pipe of largest diameter, the drive pipe is placed around the surface casing string. Other “conductor” casing pipes can be positioned around the surface casing inside the drive pipe. Part of the surface casing string (or other conductor pipe) can suffer damage due to corrosion. A sleeve or repair member is placed around the casing string or other tubular member at a damaged portion.

Owner:MADCON CORP

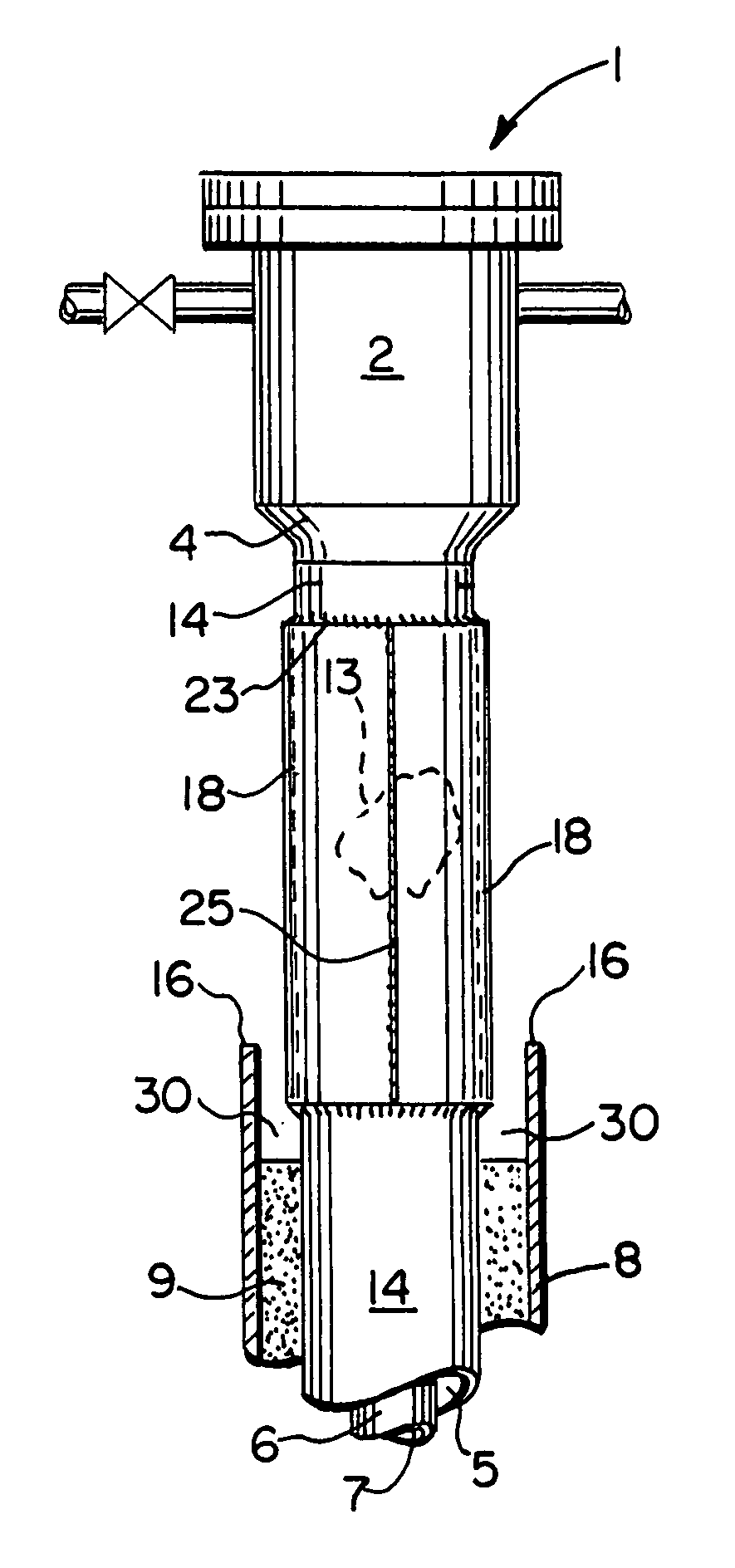

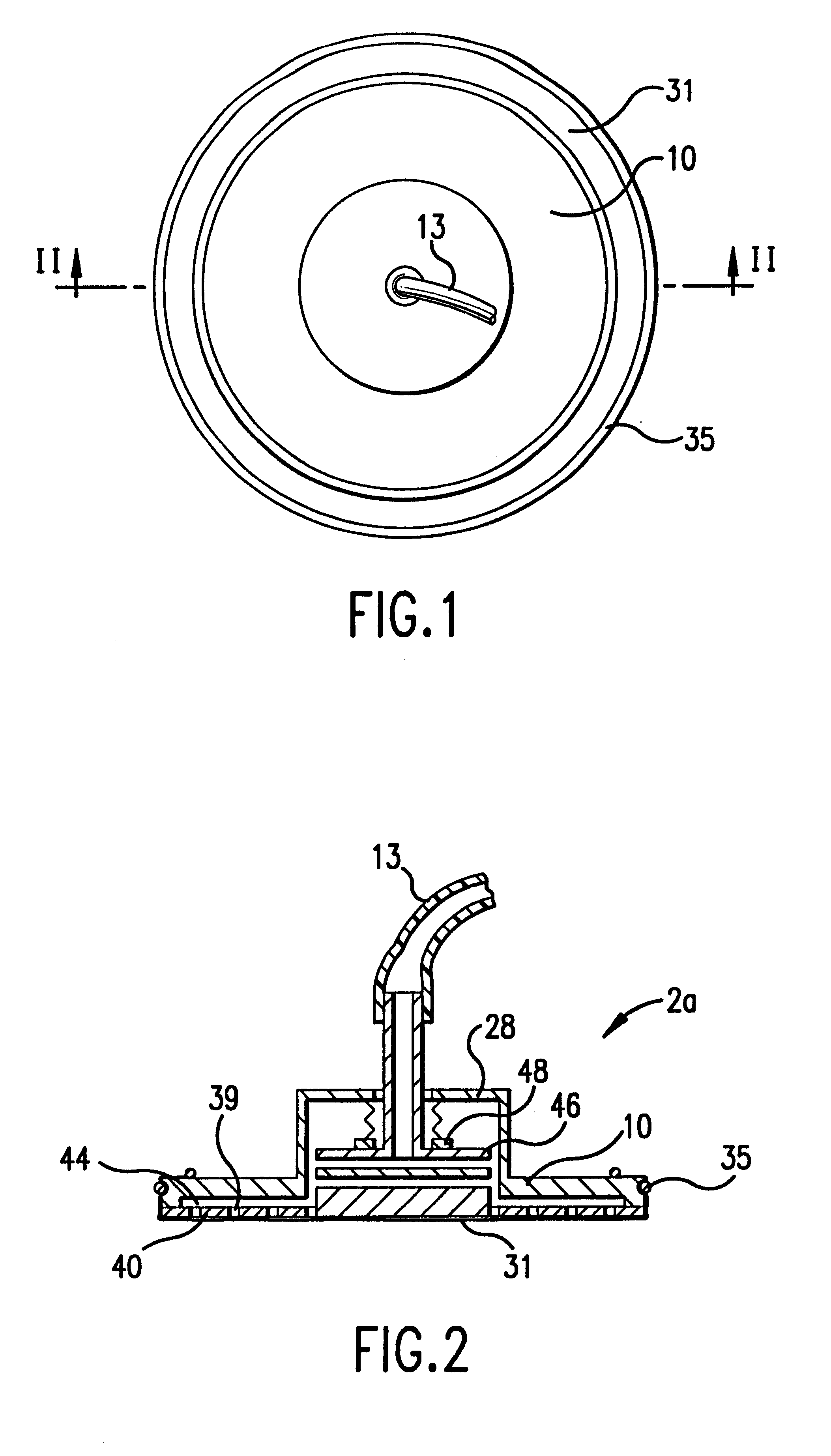

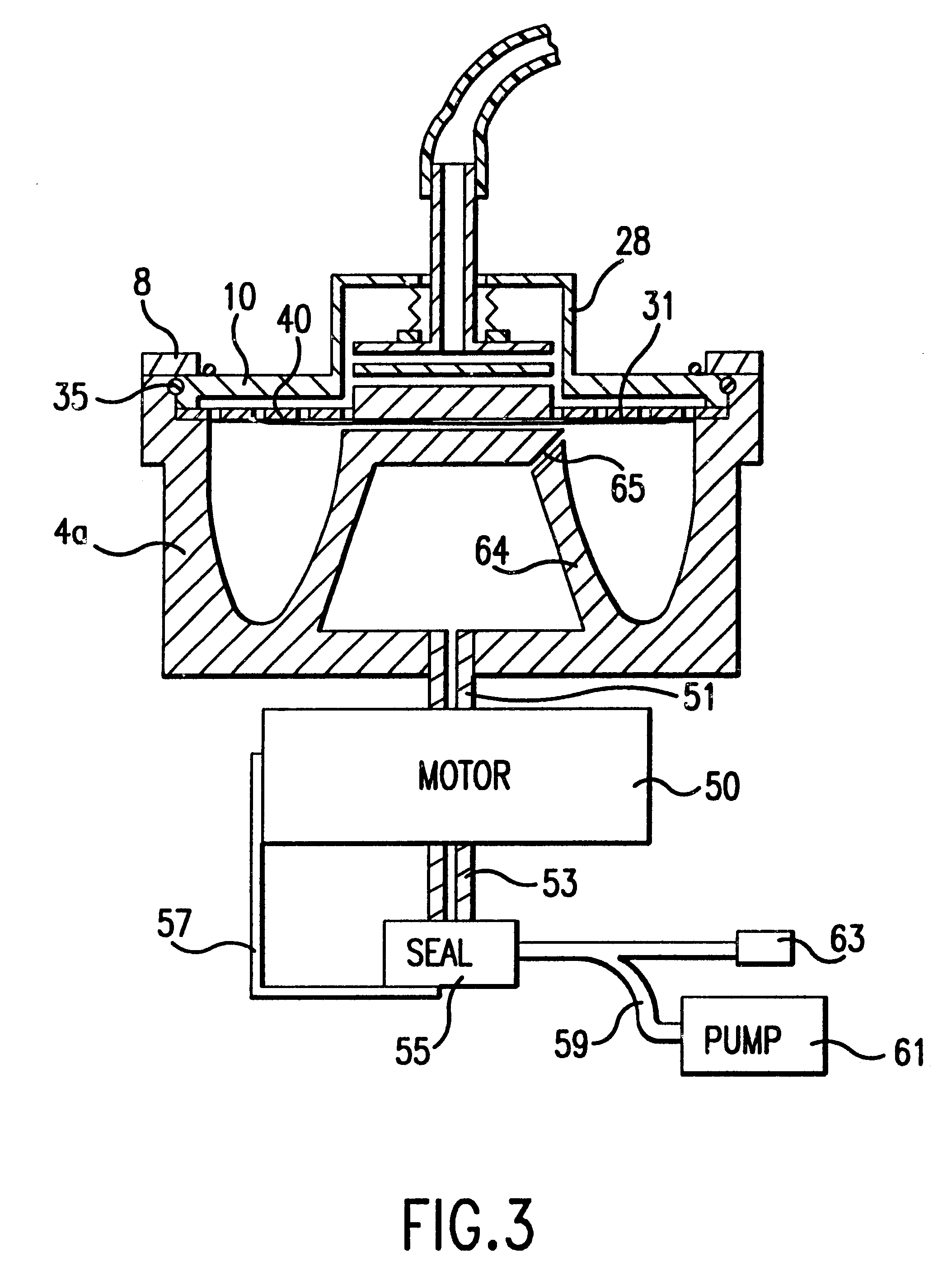

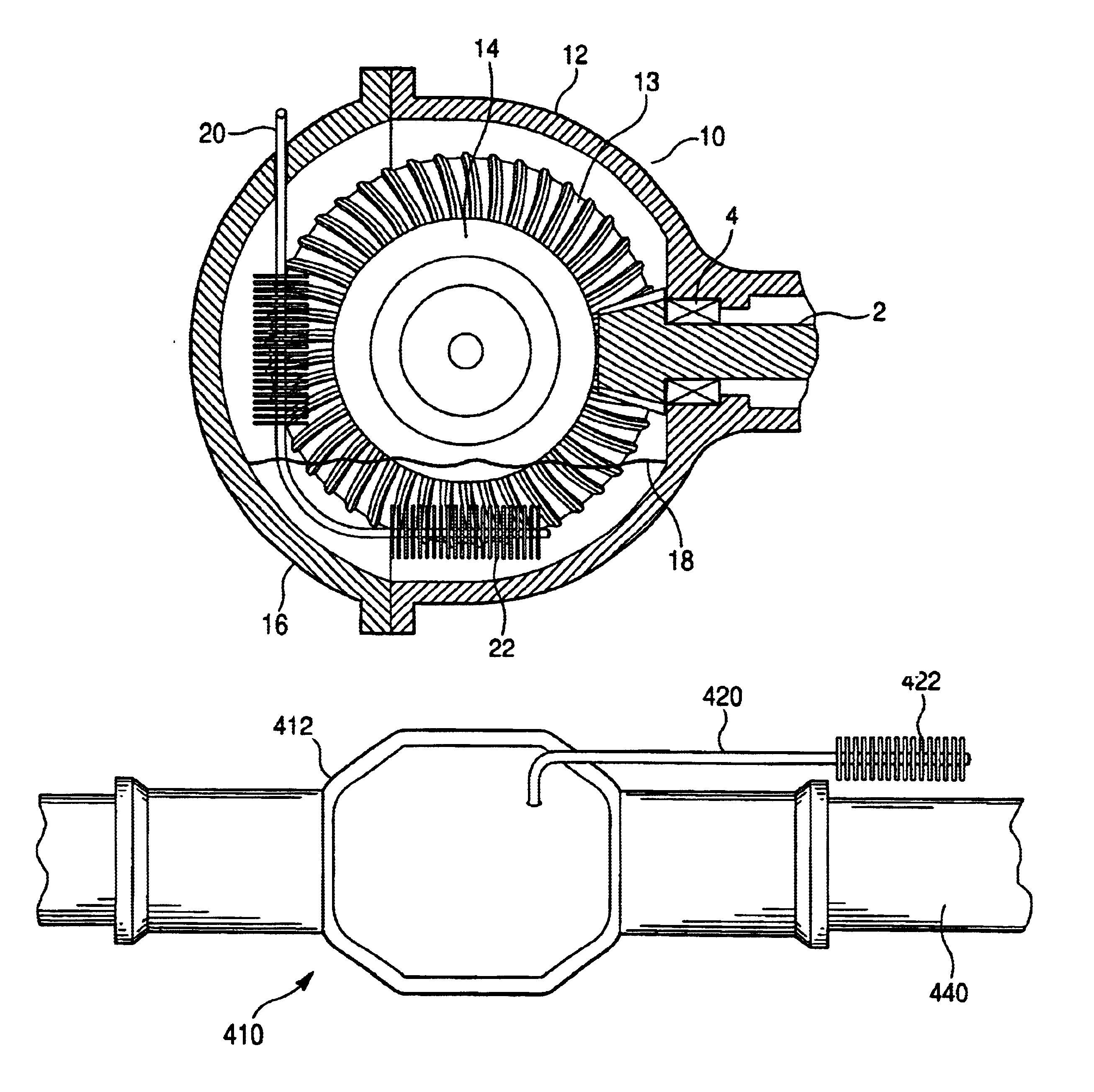

Rotor with elastic diaphragm defining a liquid separating chamber of varying volume

A rotor for collecting and centrifuging biological fluids in a range of volumes. The rotor includes an elastic impermeable diaphragm which defines at least a portion of a variable-volume processing chamber, where the fluid is centrifuged. The rotor includes a rigid mounting member, to which the diaphragm is mounted and which is held and spun by a chuck. Preferably, this rigid mounting member includes a boundary wall which together with the elastic diaphragm defines the chamber. The boundary wall may be a substantially imperforate circular wall which extends to the periphery of the processing chamber but defining one opening, preferably near the axis of rotation, permitting a conduit or conduits to pass therethrough so as to be in fluid communication with the processing chamber. The rotor may include a separate structure for controlling the flow of liquid out of the chamber into the conduit. In a preferred embodiment, this outlet-control structure is a perforate, substantially rigid wall or plate, located within the processing chamber and mounted adjacent the rigid boundary wall. In an alternative embodiment, the outlet-control structure for controlling flow from the processing chamber to the conduit may include at least one tube or preferably a set of tubes, wherein each tube provides fluid communication between the chamber and the conduit. In one preferred embodiment, grooves in the boundary wall may be used as the outlet-control structure.

Owner:HAEMONETICS

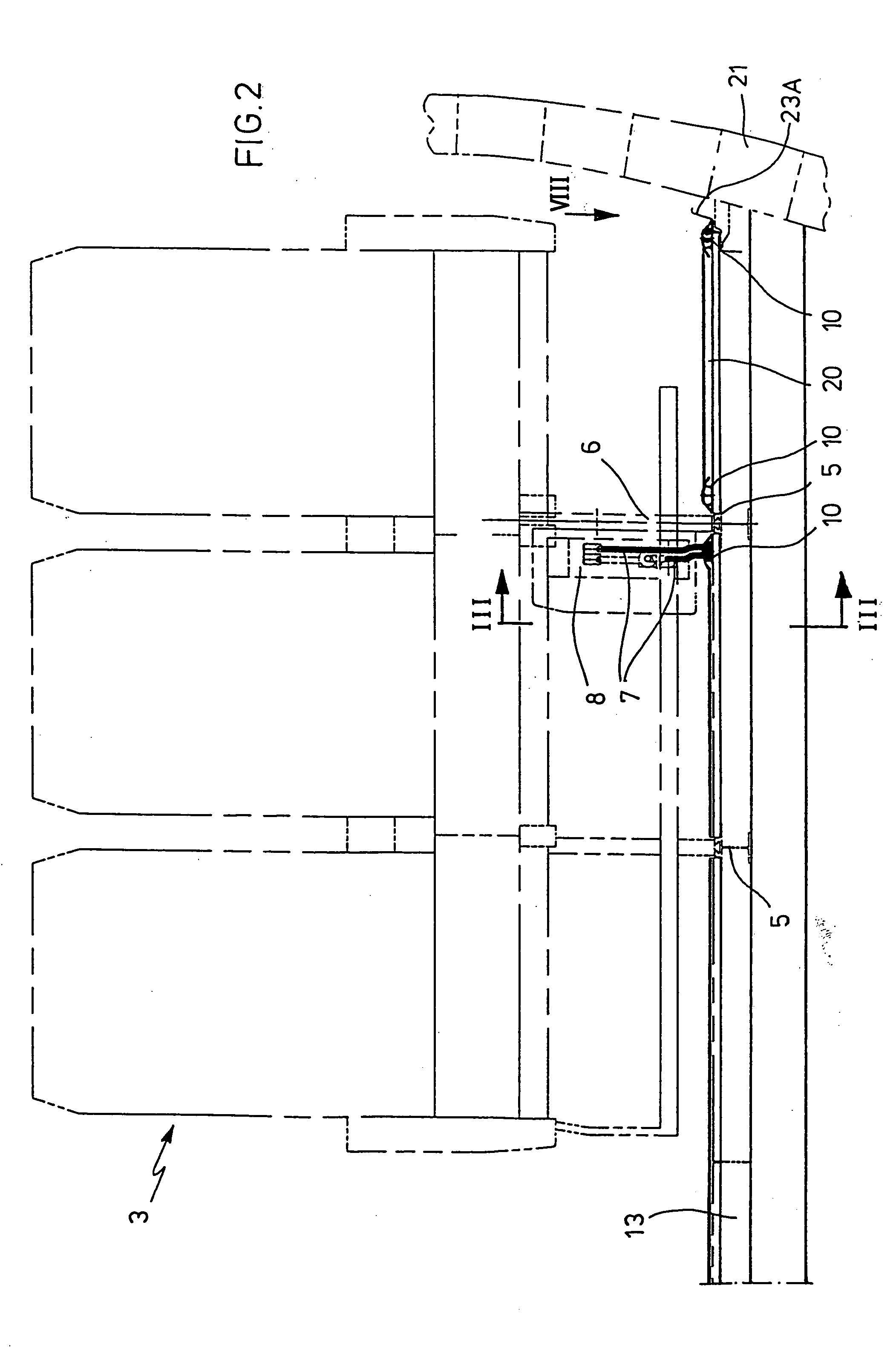

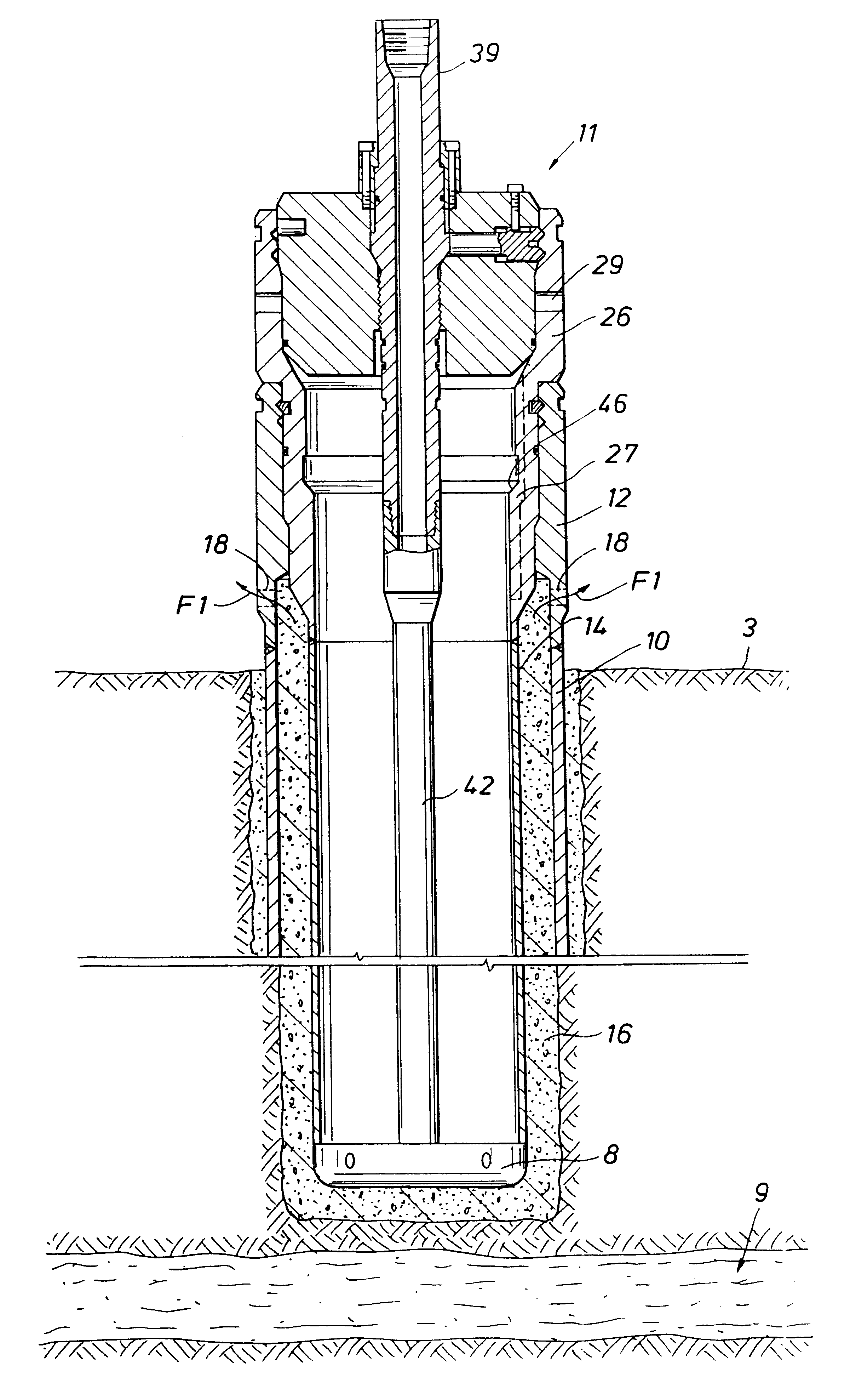

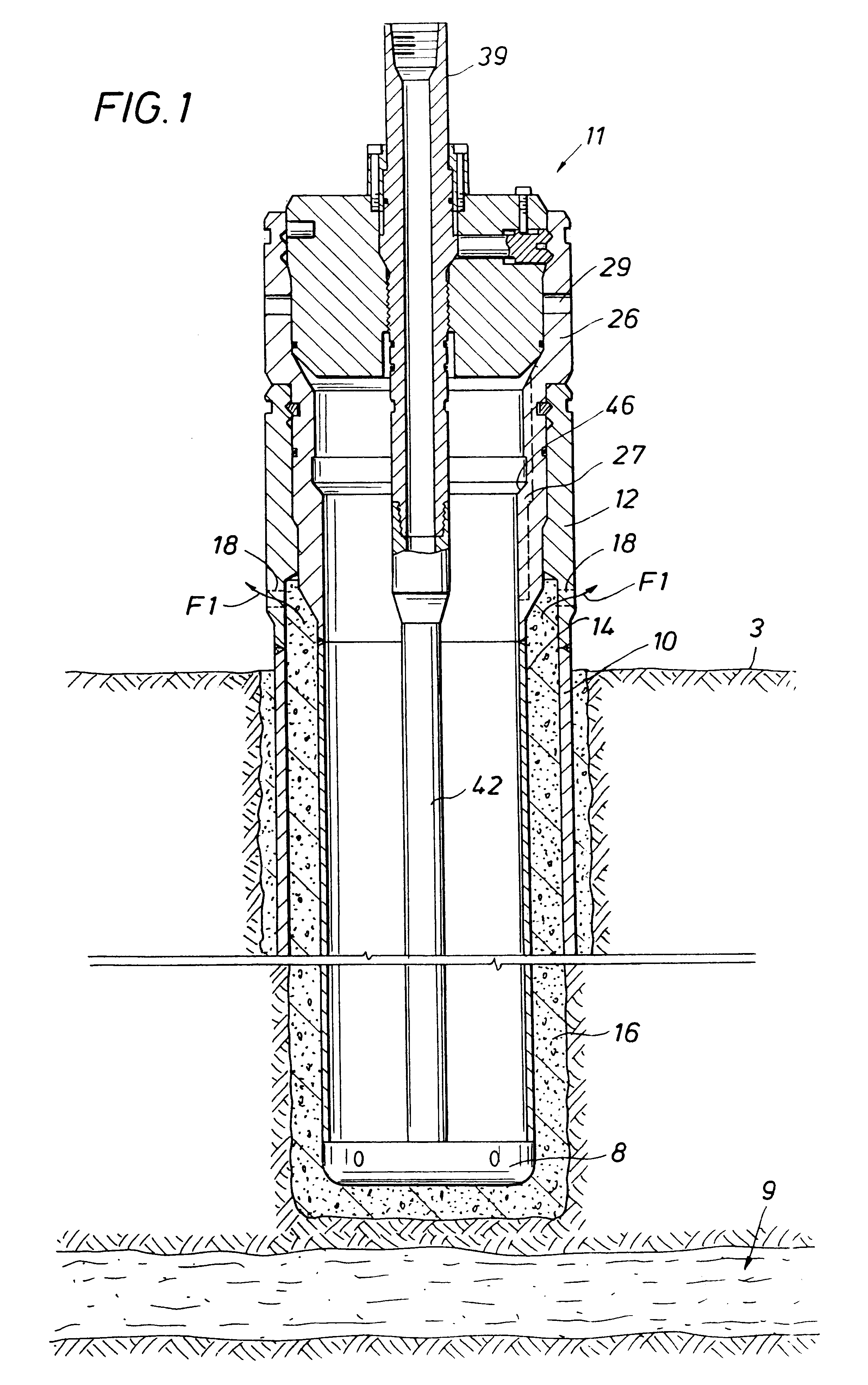

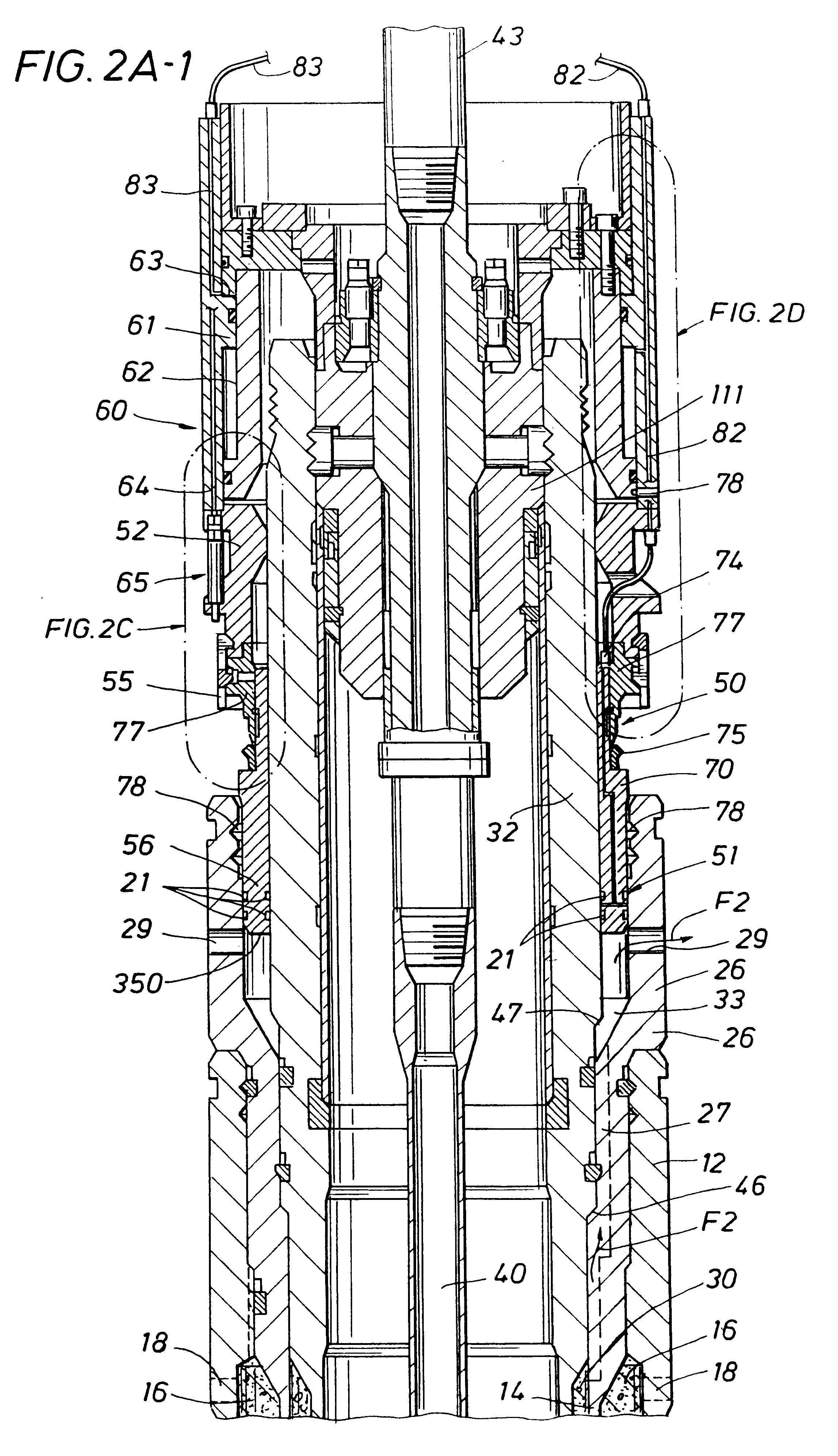

Subsea wellhead system and method for drilling shallow water flow formations

A shallow water flow subsea drilling system is disclosed. A wellhead system is provided with a 36'' conductor pipe in which a 26'' casing and 26'' wellhead housing are landed. The 26'' casing extends to a depth above a shallow water flow zone. A borehole through the shallow water flow zone is sized to accept a 20'' casing to the top of which is secured an 18¾'' wellhead housing. An annulus between the 26'' and 18¾'' housings communicates with cement returns from the 20'' casing. Flow-by holes in the 26'' wellhead housing are sealed with a retrievable seal assembly and actuating mechanism run on the same running tool with the 20'' casing and 18¾'' wellhead housing. A hydraulic feedback mechanism is provided to sense at the service vessel whether or not the seal assembly has been correctly positioned in the annulus. The seal assembly is pressure tested in the same trip while in its pack-off condition and can be retrieved with a second running tool trip.

Owner:FMC CORP

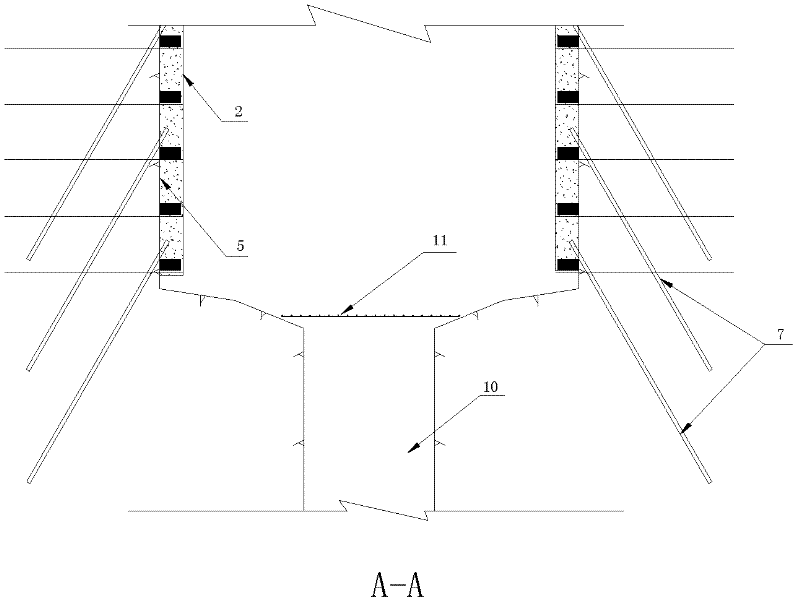

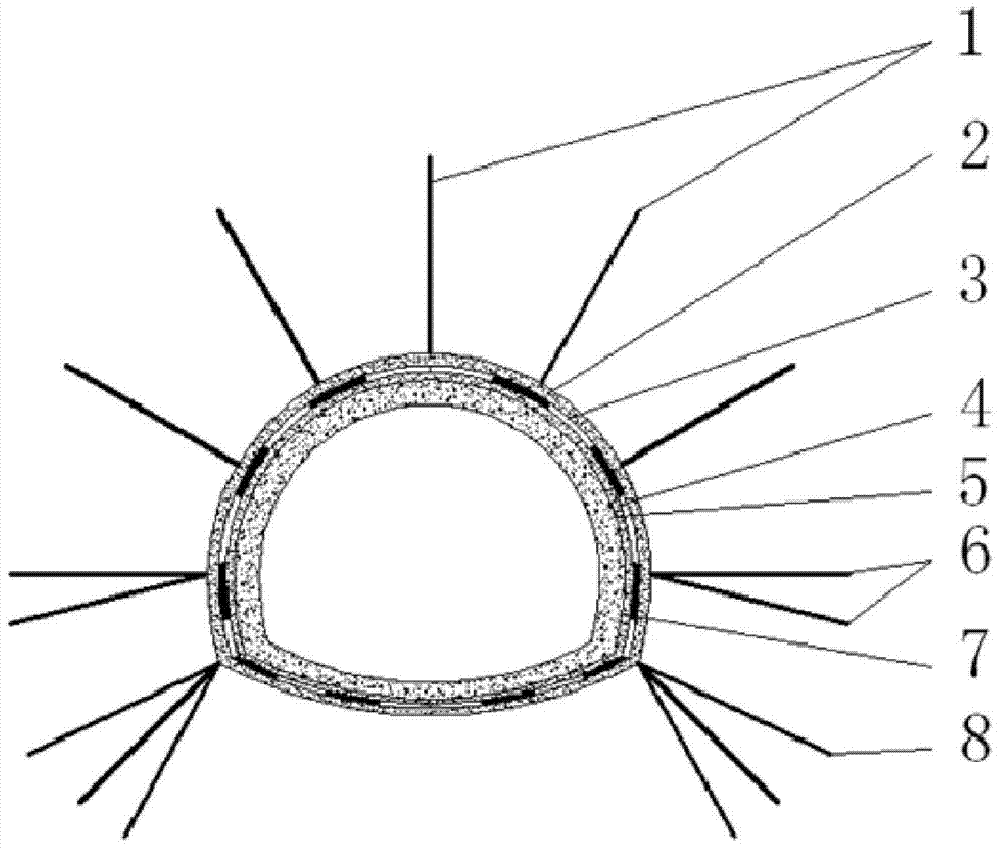

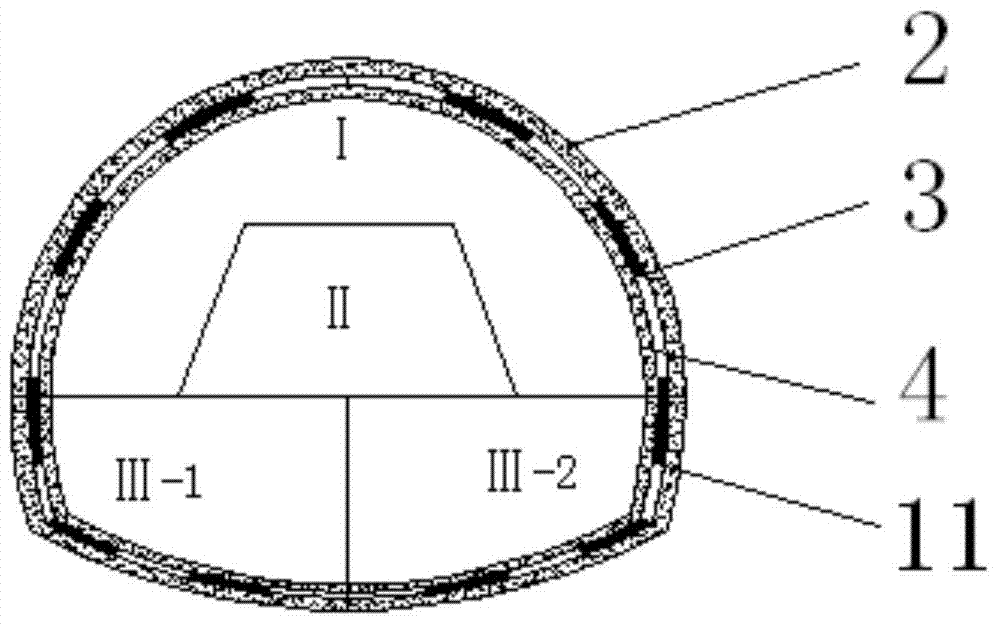

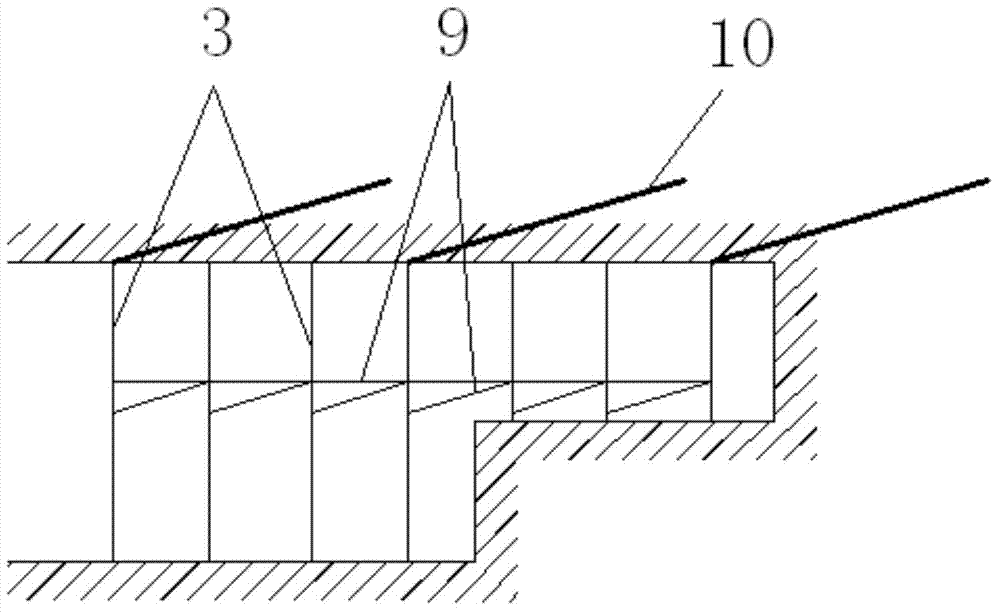

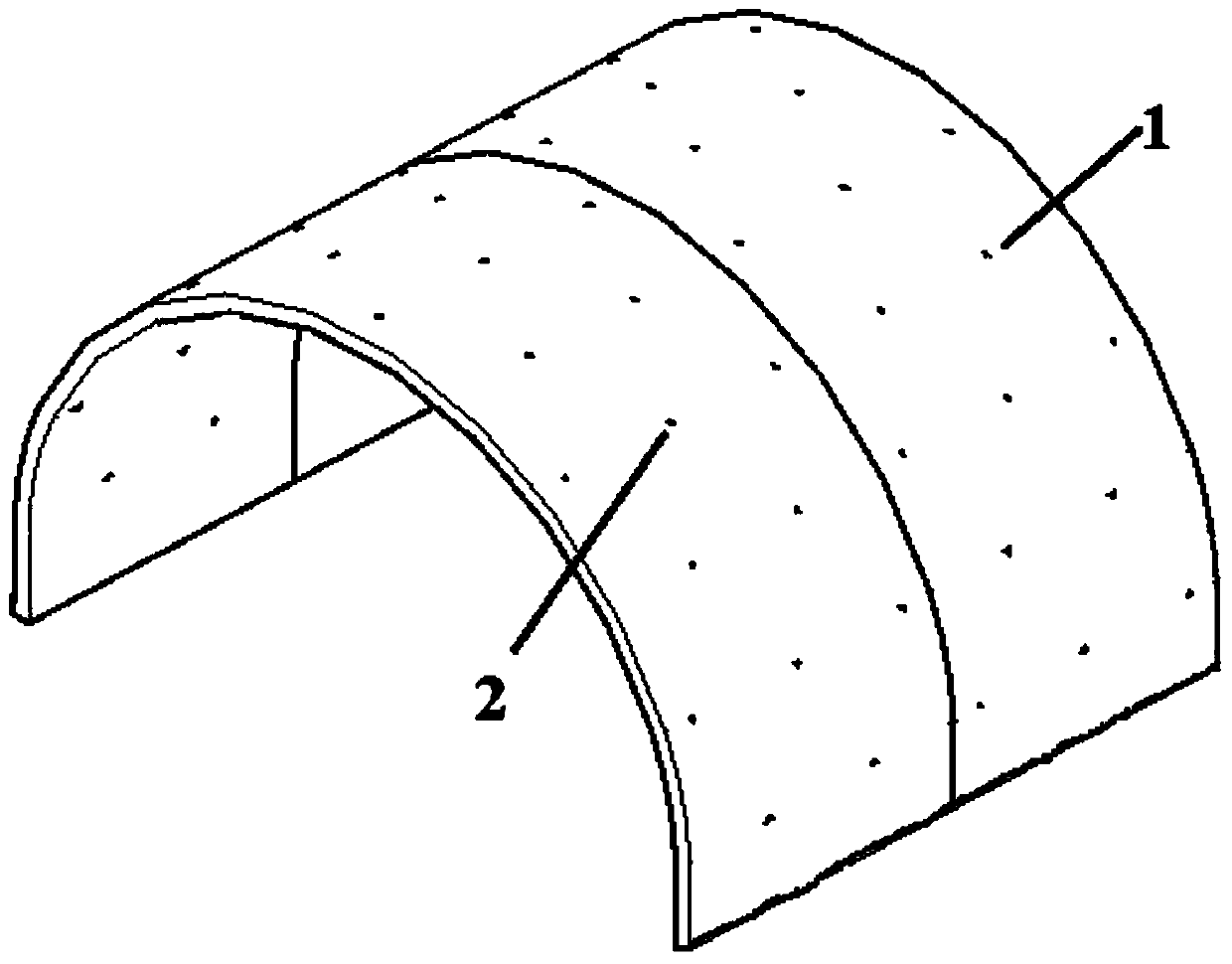

Soft rock large-deformation tunnel supporting system and construction method thereof

InactiveCN104847374AEnsure safetySmall overall deformationUnderground chambersTunnel liningSupporting systemLarge deformation

The invention discloses a soft rock large-deformation tunnel supporting system and a construction method thereof. The system comprises a forepoling, a preliminary bracing, a waterproof layer, a secondary lining and other main structures, wherein the structures are constructed in sequence according to construction procedures. Surrounding rock is reinforced through advanced small pipe grouting by means of the forepoling, the preliminary bracing comprises lengthened anchor rods, a primary spraying layer, steel arches and a re-jetting layer, feet-lock bolts are further arranged at the positions of an upper bench and arch feet to be welded to the steel arches, the adjacent steel arches are connected through longitudinal connecting ribs, and the secondary lining is constructed at last to form the supporting system. The steps are simple and linked with one another, supporting lag caused by idling of labor force is avoided, and large-deformation of tunnels is well controlled.

Owner:CHANGAN UNIV

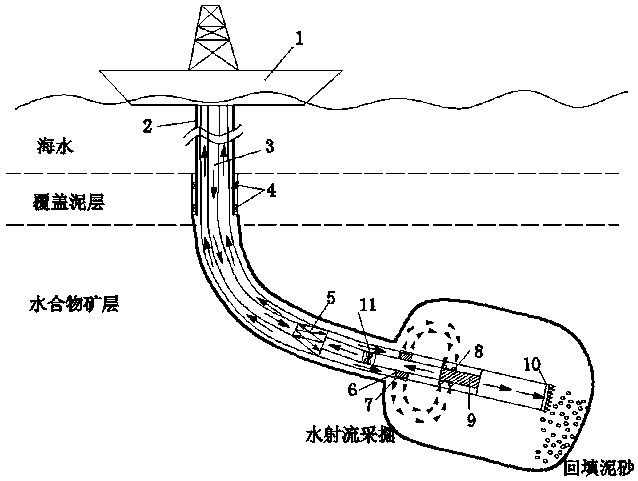

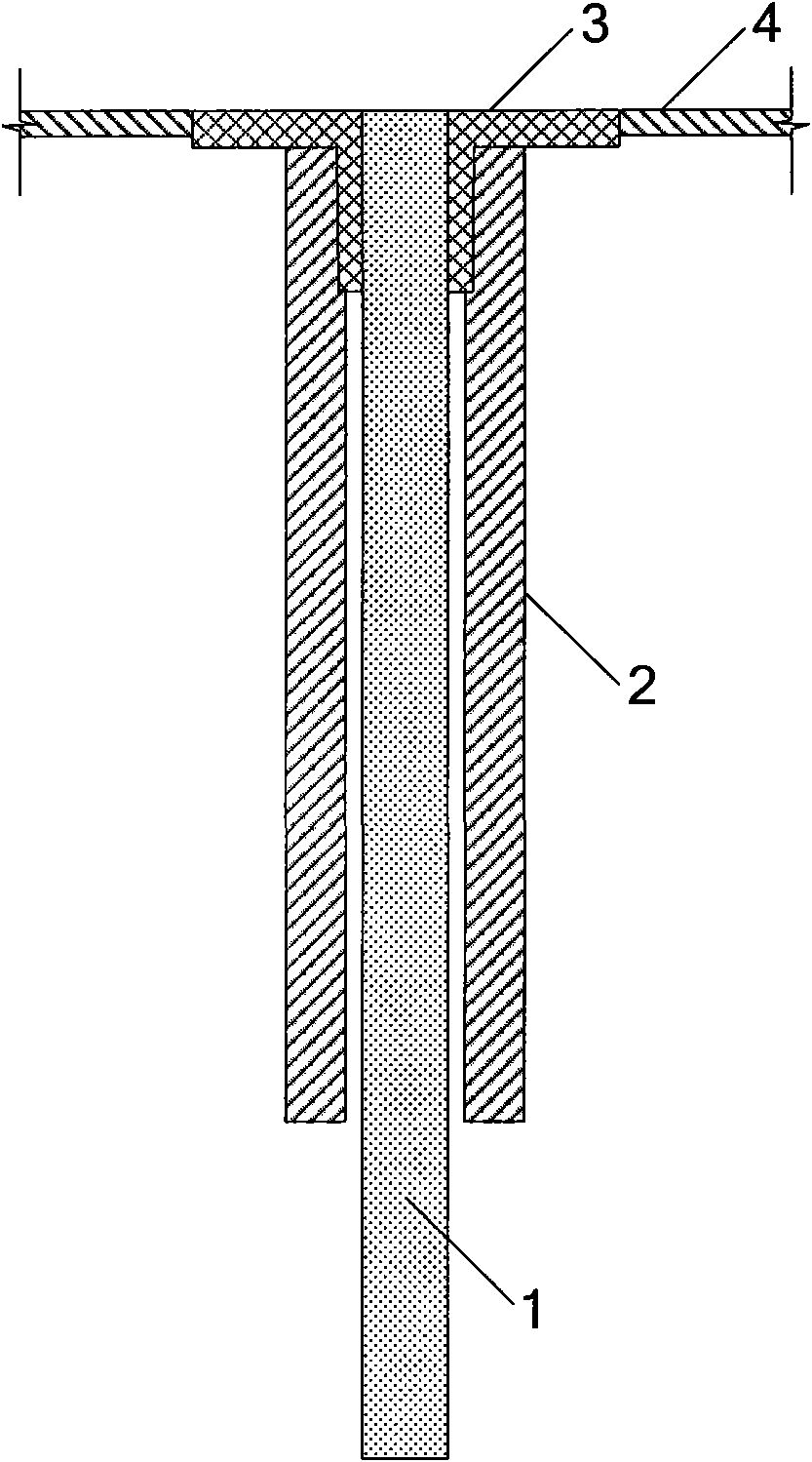

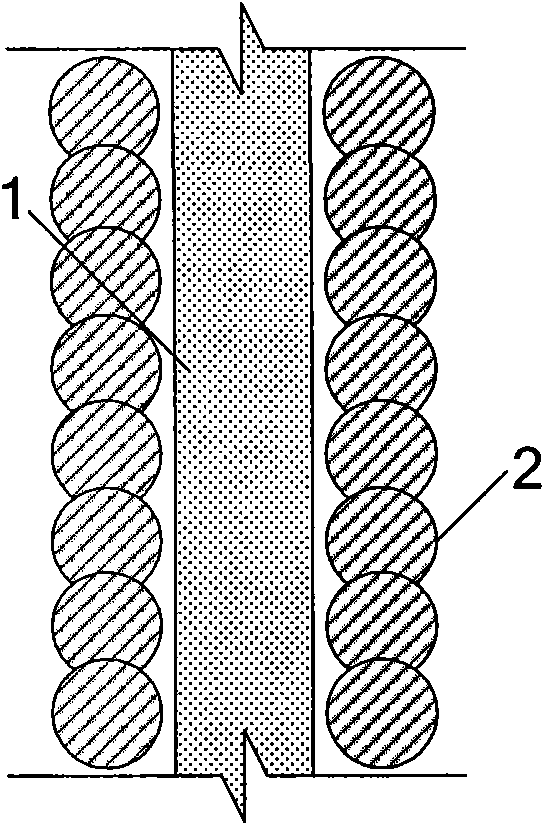

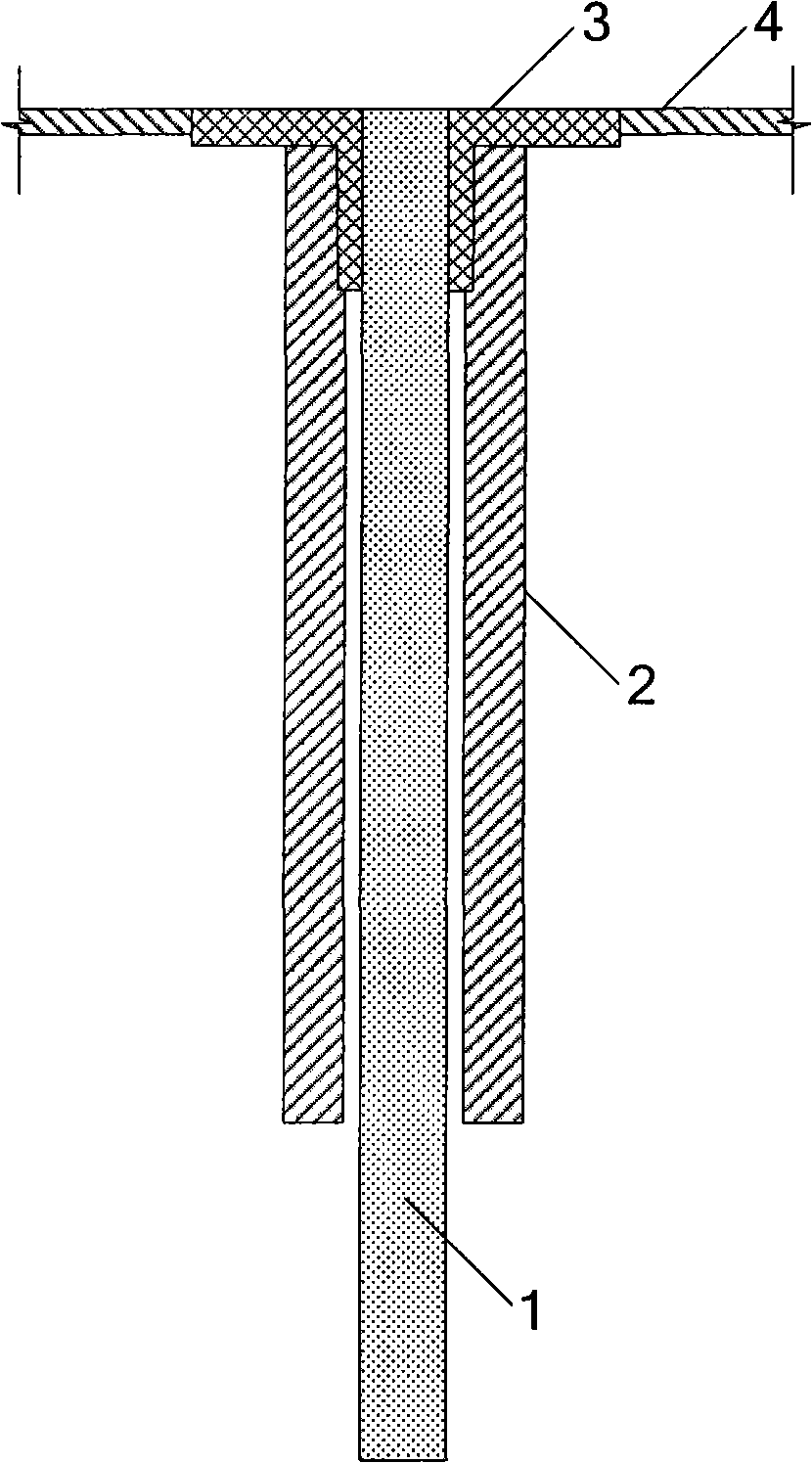

Submarine shallow layer non-stratified natural gas hydrate pilot hole pull-back jet break-up exploitation method and exploitation device

The invention discloses a submarine shallow layer natural gas hydrate pilot hole pull-back jet break-up exploitation method and exploitation device, and belongs to the technical field of submarine hydrate exploitation. The exploitation method mainly comprises the following steps that a water insulation pipe is lowered to the position adjacent to a hydrate deposit, turn drilling is conducted in thehydrate deposit by means of mechanical or jet-flow drilling, and a pilot hole with a certain inclined angle is formed; after drilling reaches a preset position, a continuous pipe and an exploitationcrushing system are pulled back, meanwhile the surrounding hydrate ore body is crushed by means of a spray head jet flow, hydrate particles formed are collected into a closed pipeline with seawater, silt in the crushed particles is separated out by means of an in-pipe downhole separator, curing agent is added, then the particles are backfilled to a gob in situ, and the hydrate particles after separation are pumped to the sea surface for treatment together with the seawater. By means of the exploitation method and the exploitation device, efficient, safe and sustainable exploitation of the submarine shallow layer natural gas hydrate is achieved, the exploitation efficiency is ensured, and meanwhile a potential safety problem is effectively avoided.

Owner:SOUTHWEST PETROLEUM UNIV +2

Diaphragm wall and construction method thereof

InactiveCN102312445AGuarantee the stability of the tank wallBreak hydraulic connectionArtificial islandsExcavationsSlurry wallSlag

The invention discloses a diaphragm wall and a construction method thereof, wherein the construction method is carried out according to the following steps: step 1, the underground obstacles at the trench section position and the two sides of the trench section of the diaphragm wall are cleared; step 2, two ranges of cement stirring piles are respectively and symmetrically distributed at the two inner sides of the trench section of the diaphragm wall to reinforce; step 3, an integral pouring type concrete guide wall is formed at the top parts of the cement stirring piles, the cross section of the guide wall is L-shaped, one end of the guide wall is arranged at the inner sides of the cement stirring piles, and the other end of the guide wall crosses the top parts of the cement stirring piles; after the guide wall is built, an integral pouring type concrete rigid terrace is formed at the other end of the guide wall; step 4, the trench construction is carried out between the two ranges of cement stirring piles through a trench machine, and the bentonite mud is adopted in the trench section to protect the wall during the trenching; step 5, after the trenching is completed and reaches the scale height, slags of the trench bottom are removed, a diaphragm wall reinforcement cage is hoisted to be placed in the trench section, and a guide pipe method is adopted to carry out underwater concrete pouring; and step 6, after the concrete reaches the design strength, high pressure grouting is carried out on the bottom of the diaphragm wall. The diaphragm wall can integrate soil blocking, water resisting and bearing into a whole through the method, so good social and economic benefits are obtained.

Owner:CCCC THIRD HARBOR CONSULTANTS

Pipe and cable support apparatus and method

The present invention relates to a support block and a system for roof cooling. The support block supports a pipe above a structure, wherein the pipe has a cross sectional area and a diameter of predetermined dimensions, and the support block includes a number of outer surfaces each having an opening and a cavity. Each cavity has a cross sectional area larger than the cross sectional area of a pipe and the opening can be less than the diameter of the cavity cross sectional area or slightly less than the diameter of a pipe. Dovetail notches on the surfaces of the support block are present to attach the support block onto the roof. Adhesives can be used in the dovetail notches or an adaptor plate attached to the roof can be used to attach the support block to the adaptor plate. Alternatively, the support block can be used to assist in supporting and routing any type of conduit or cabling.

Owner:PATTERSON VENTILATION

Connector for flexible tubing

ActiveUS8297661B2Easy to trackPipe couplingsRopes and cables for vehicles/pulleyEngineeringMechanical engineering

A connector is provided for connecting a flexible conduit with a second conduit having a barbed outer surface. The connector accommodates the end of the flexible conduit and the end of the second conduit in a manner which prevents removal of the flexible conduit and the second conduit from the connector. Optionally, the connector has a ring that may be used to apply additional pressure and security to the outer surface of the flexible conduit. additionally, the connector may have a wireless enabled communication and optionally, memory device such as a RFID tag attached or affixed to it.

Owner:MILLIPORE CORP

Cast-in-Place Fiber Technology

Novel tools and techniques for installing lines or cables, including, without limitation, power lines, low voltage lines, telecommunications lines or cables (e.g., telephone cables, network cables, television cables, etc.), and / or the like, and, in particular, installing optical fiber and / or other lines, slightly below ground level in a roadway or other ground surface. In some cases, a method might include creating a channel in the ground surface, placing one or more lines (e.g., power lines, low voltage lines, telecommunications lines, and / or the like) in the channel, and placing a capping material in the channel, thereby encapsulating the lines. In some cases, placing the one or more lines in the channel might include placing a conduit (containing the one or more lines) in the channel, and encapsulating the one or more lines might include encapsulating the conduit. The capping material might include polyurea, thermosetting material, and / or any other suitable material.

Owner:CENTURYLINK INTPROP +1

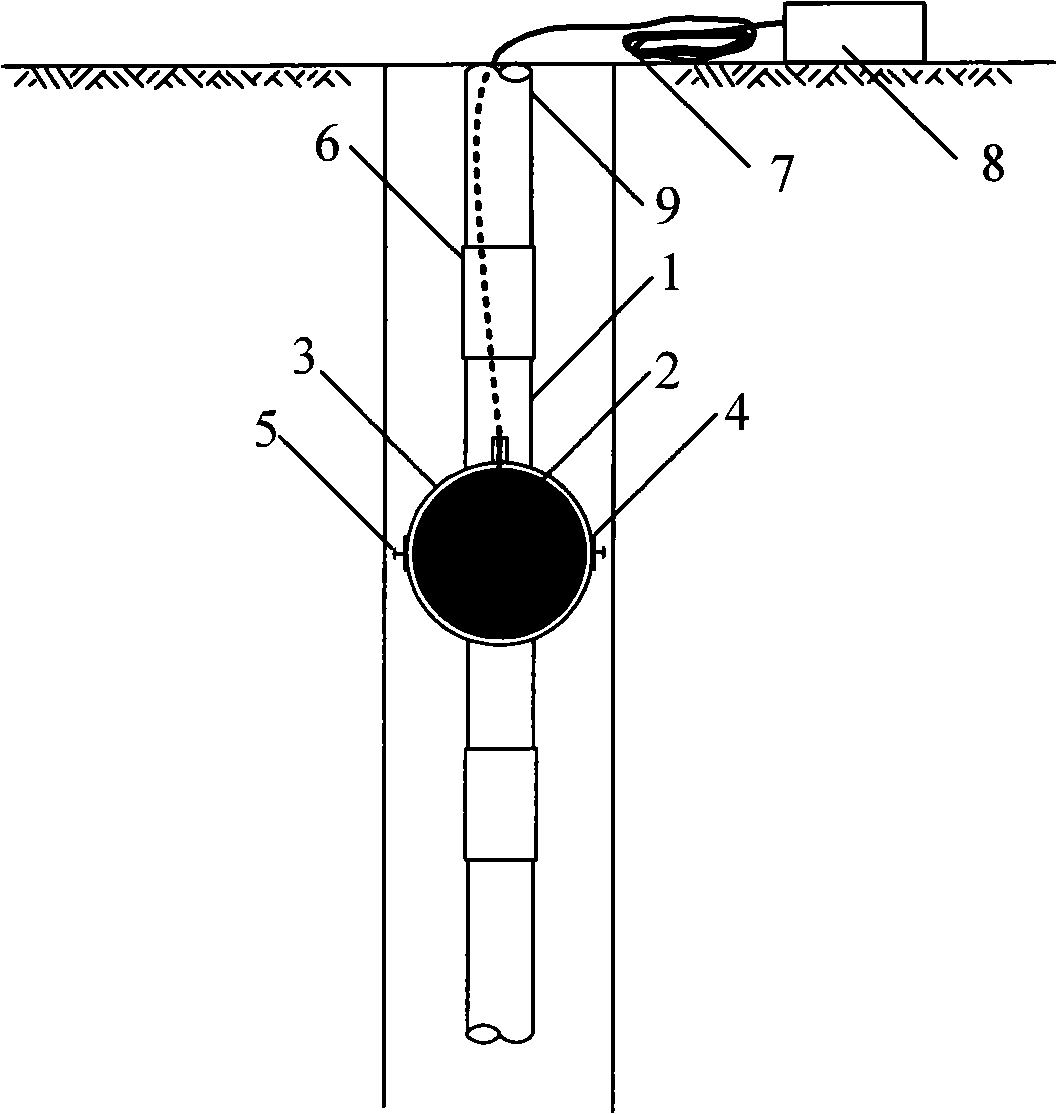

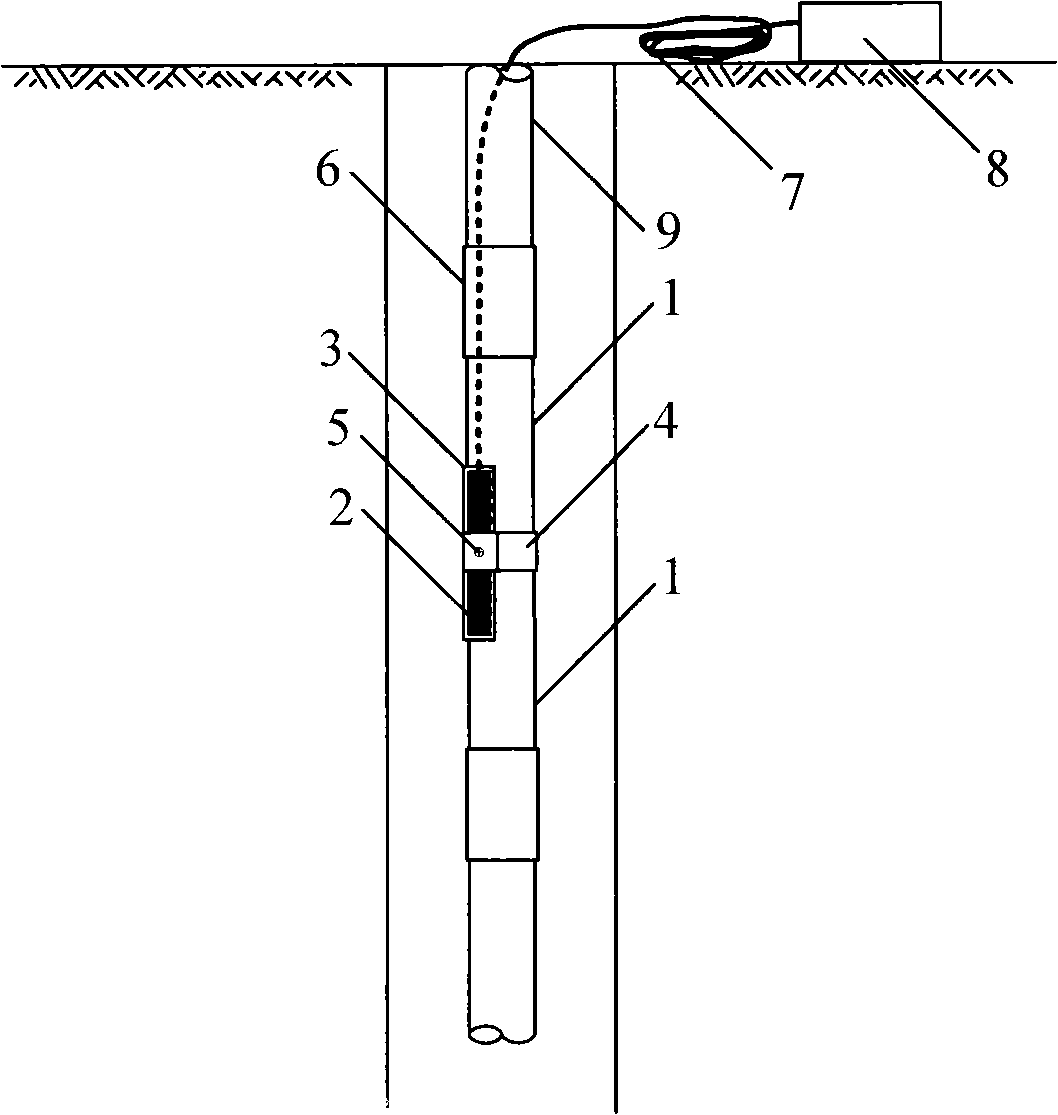

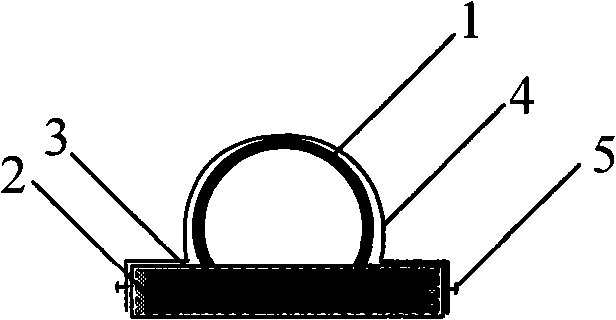

Lateral earth pressure sensor embedment method and device in earth

InactiveCN101358455ALow priceLow bending stiffnessArtificial islandsForce measurementSteel jacketData acquisition

The invention relates to a method for embedding a side-direction soil pressure sensor in the soil and a device thereof, which belongs to the technical field of construction engineering. The device comprises a sensor installation pipe, an extension pipe, a soil pressure sensor, a protective steel jacket, a U-shaped protective steel clip, a rigging screw, a connector pipe, a data transmission guide wire and a data collection instrument. The data transmission guide wire of the soil pressure sensor is connected with the data collection instrument. A notch is arranged in the center of the sensor installation pipe; the soil pressure sensor is put into the protective steel jack and then the soil pressure sensor and the protective steel jack are embedded in the notch; the U-shaped protective steel clip and the rigging screw are used to fix; the connector pipe is used to extend the sensor installation pipe and the extension pie to the design length; the pipes are put into a soil drilling hole; the guide pipes are fixed temporarily, and then fine sand is backfilled into the drilling hole; after the fine sand is consolidated, and the side direction soil pressure test is carried out. The invention has the advantages of convenient installation and operation, economy and practicality, high survival rate of the sensor embedded, capability of quite accurately measuring the side direction soil pressure in the soil, and accurate and reliable test result.

Owner:SHANGHAI JIAO TONG UNIV

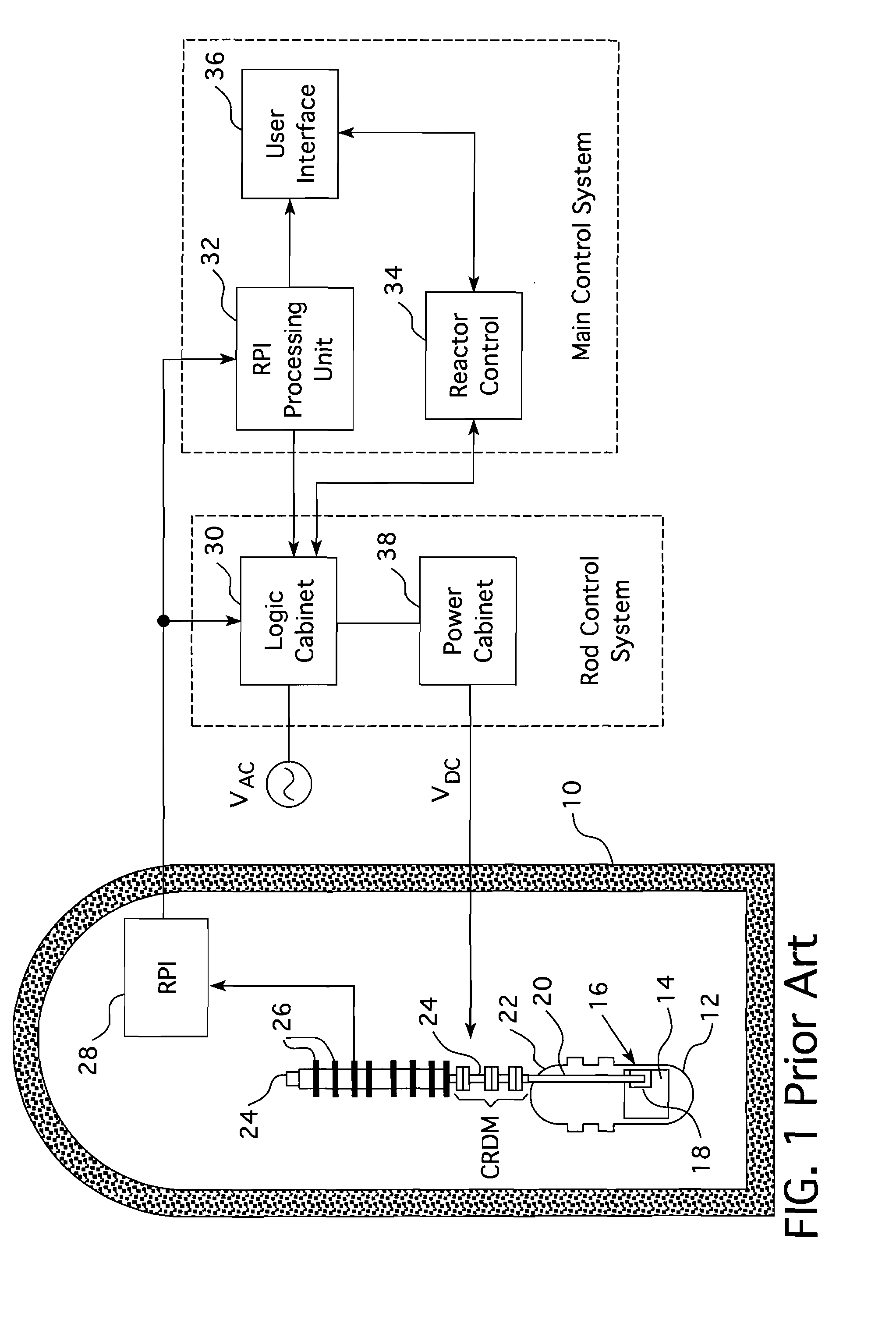

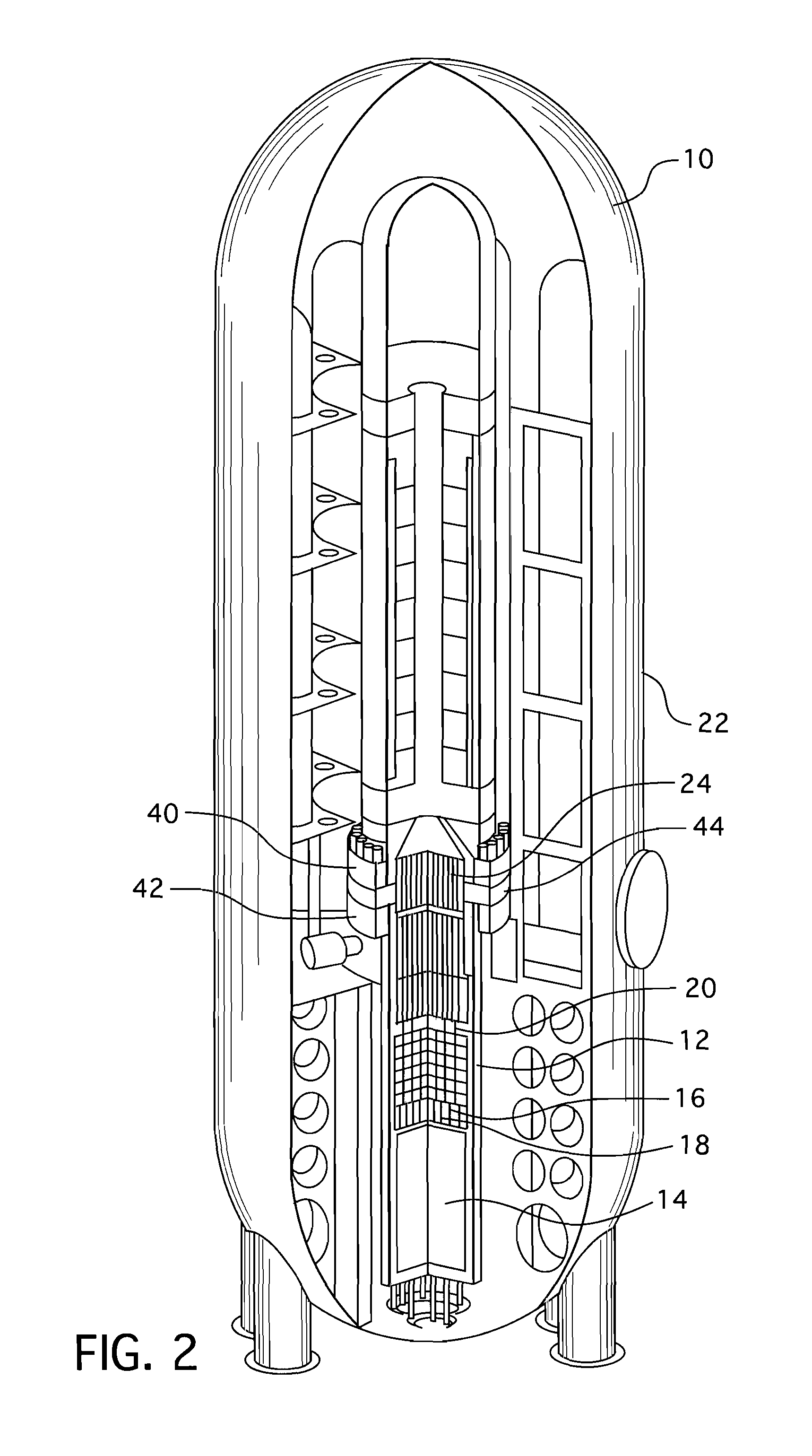

Instrumentation and control penetration flange for pressurized water reactor

A nuclear reactor having a penetration seal ring interposed between the reactor vessel flange and a mating flange on the reactor vessel head. Radial ports through the flange provide passage into the interior of the reactor vessel for utility conduits that can be used to convey signal cables, power cables or hydraulic lines to the components within the interior of the pressure vessel. A double o-ring seal is provided on both sides of the penetration flange and partial J-welds on the inside diameter of the flange between the flange and the utility conduits secure the pressure boundary.

Owner:WESTINGHOUSE ELECTRIC CORP

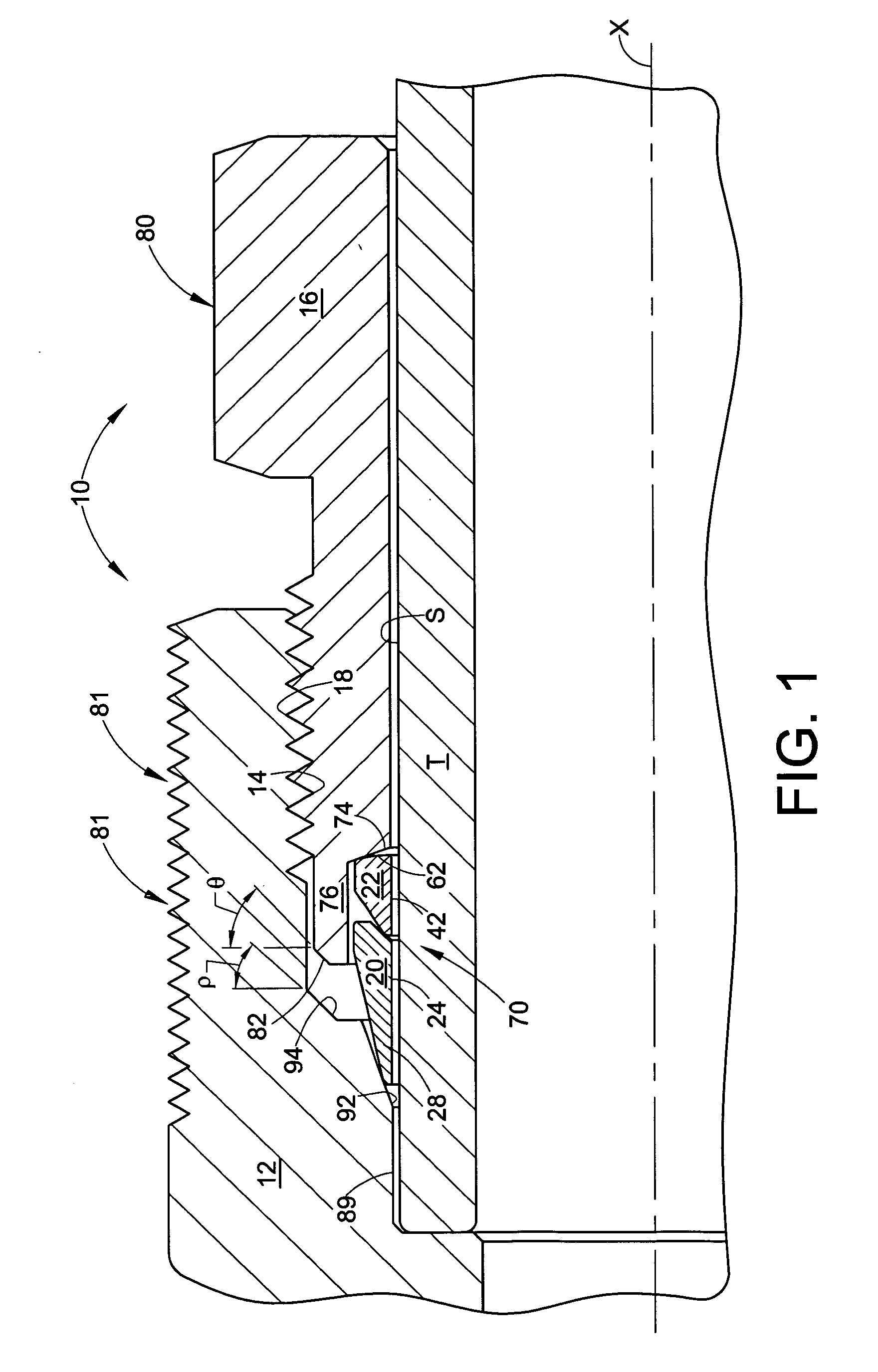

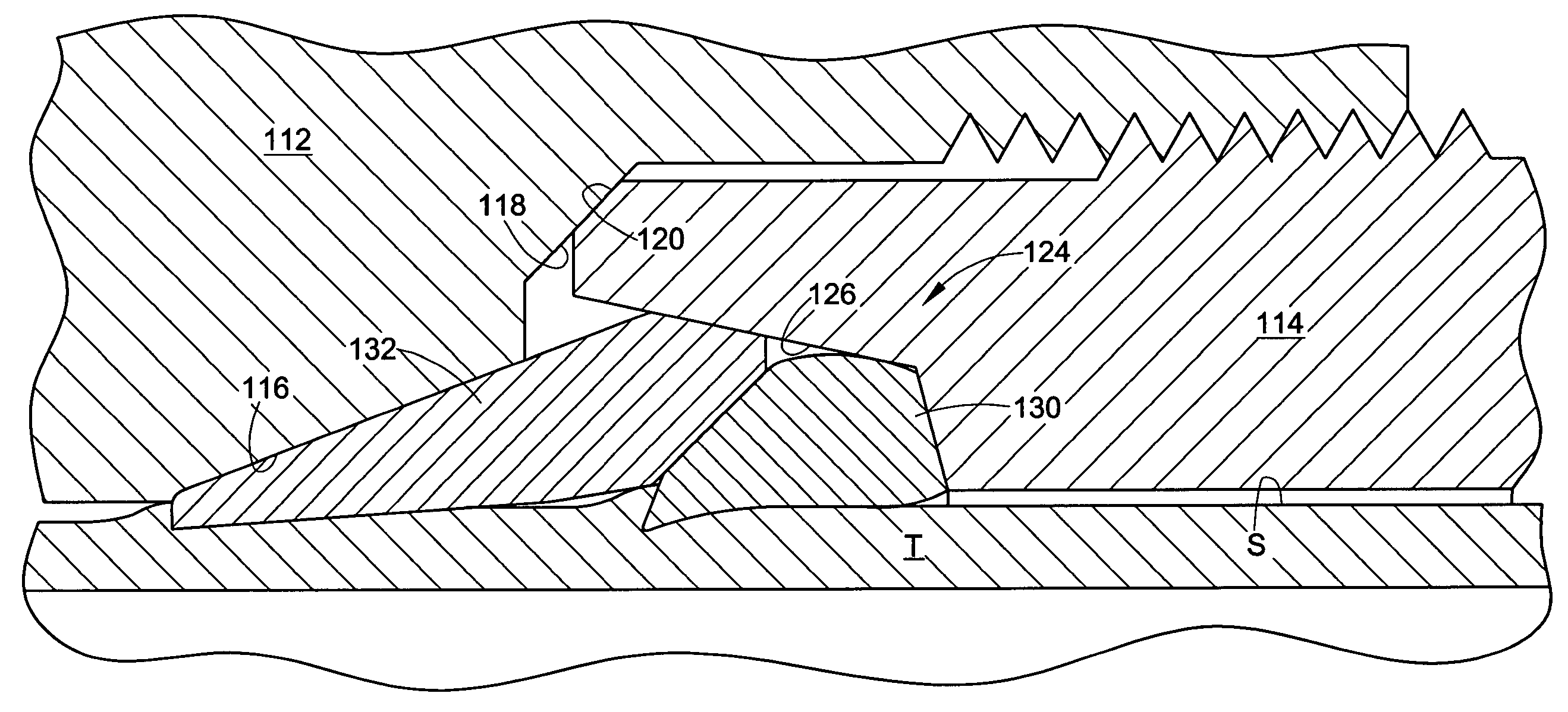

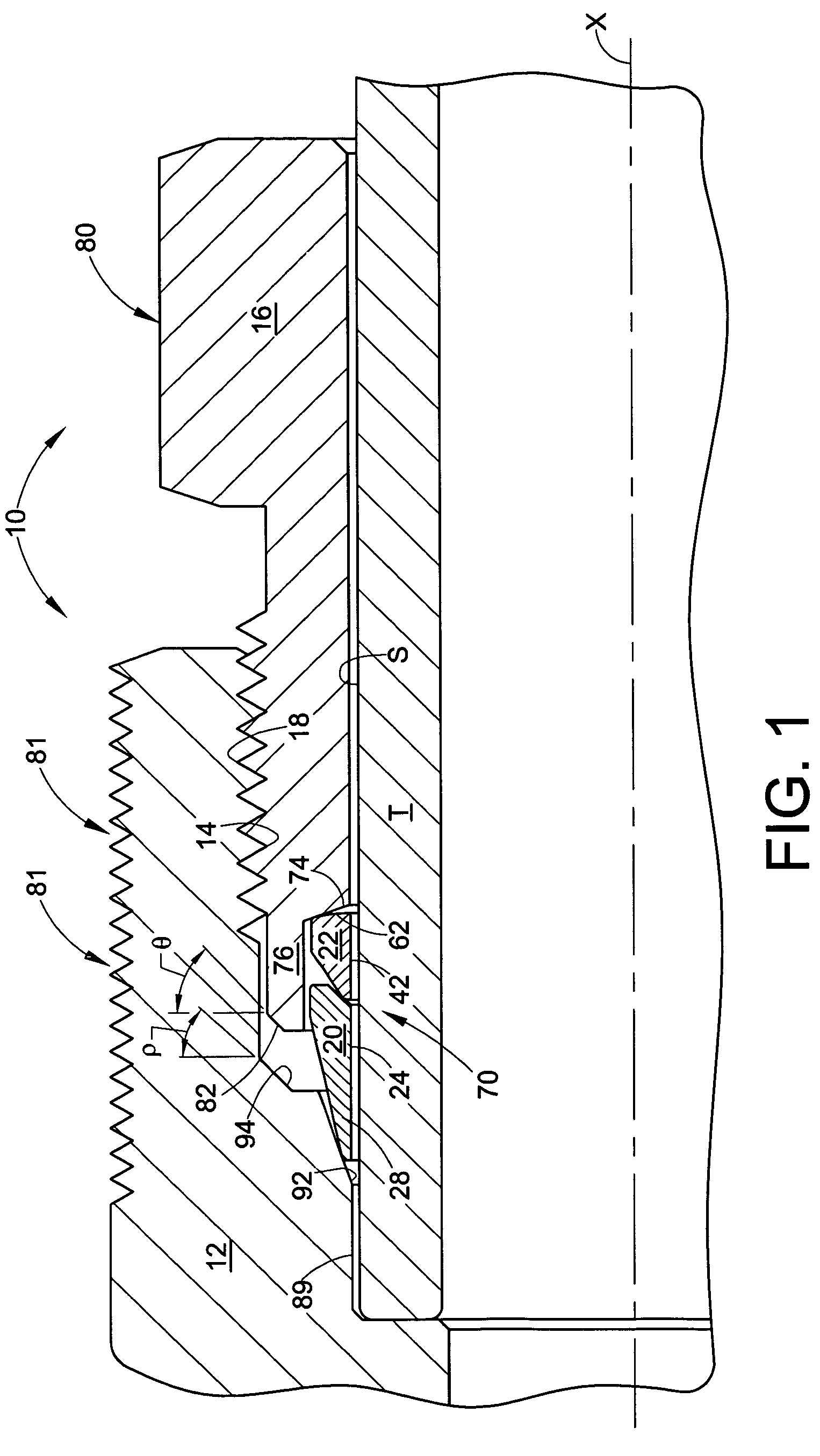

Fitting for tube and pipe

ActiveUS7695027B2Secure retentionShorten the lengthSleeve/socket jointsFluid pressure sealed jointsEngineeringHigh pressure

A fitting for a tube or pipe capable of functioning a high pressures having a first fitting component adapted to receive the conduit end; a conduit gripping device such as a ferrule or ferrules and a second fitting component that can be joined to the first fitting component to cause the conduit gripping device to grip the conduit and seal when assembled. In one aspect of the invention, the first fitting component is constructed from a material that is softer than the material used to construct the second fitting component. An additional aspect of the invention include a retaining portion on the second fitting component that constrains the tube gripping device against pressure. The retaining portion can also be configured to retain the tube gripping device to the second fitting component prior to installation and in a finger-tight condition. A further aspect of the invention includes a first fitting component in which an exterior portion of the component is work hardened radially outward from the tube gripping device. The fitting may optionally be provided with a structure to effect the pull-up by torque functionality.

Owner:SWAGELOK CO

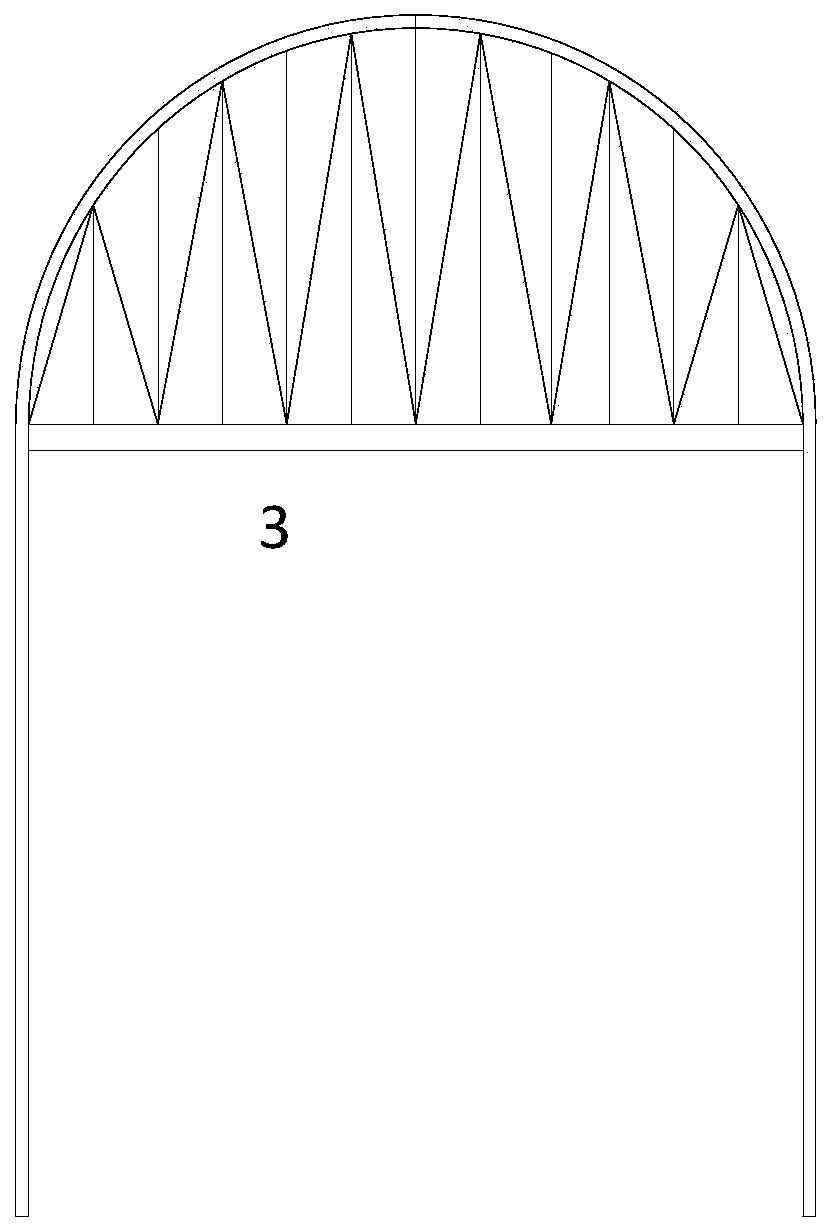

Treatment method for fault fracture zone collapse in tunnel construction process

InactiveCN104196546AReduce the risk of secondary landslidesLess investmentUnderground chambersTunnel liningShotcreteFracture zone

The invention discloses a treatment method for fault fracture zone collapse in the tunnel construction process. The method includes the steps that firstly, arch reinforcement is conducted on every two adjacent surrounding rocks in a collapse segment; secondly, a collapse body is removed, and concrete is jetted to the collapse tunnel face after the collapse body is removed to close the collapse segment; thirdly, a lifting jack acts on the four corners of each bottom of racks of formworks, the interval identical to the width of a steel arch is reserved between the formworks, formwork erection is conducted in time, and the formworks and the steel arch jointly form a supporting layer; fourthly, through holes reserved in the formworks in advance, an arch apex concrete layer is formed in a high-pressure grouting mode, and small grouting guide pipes are punched into arch springs and the side walls of the steel arch; fifthly, the front end of a bottom die composed of the formworks and the steel arch is grouted and reinforced through the small guide pipes, operation of the next construction circulation stage of the collapse segment is conducted, and the first step, the second step, the third step and the fourth step are specifically repeated; sixthly, after second circulation is finished, supports of arch protecting layer concrete are formed through conveying ports embedded through the second step.

Owner:SHANDONG UNIV

Optical fiber composite electrical power cable

The present invention discloses an underground power cable with an optical fiber for measuring temperature distribution. In this power cable, an optical fiber for measuring temperature distribution is housed in a stainless steel tube with high strength, and an optical fiber guide is placed between the core and the sheath of the cable. When the fiber optic guide is placed in the power cable, a supporting material with a relatively lower strength than the fiber guide is also provided in the cable to prevent the optical fiber from being damaged by external force and prevent the inner insulating layer from being damaged by the fiber guide. In addition, fixing straps can be added to fix the contact between the fiber guide and the core, so as to prevent the fiber guide from being severely bent or tilted to one side when the cable is bent.

Owner:LG CABLE INC

Heat pipe for differential assembly

An apparatus to regulate and control the temperature of an axle assembly for a vehicle. A heat pipe is inserted though the axle housing cover, the heat pipe travels the length of the cover. Near the lower region of the carrier and beneath the lubricating fluid level, the heat pipe bends to continue in the horizontal direction. Disposed about the terminal end of the heat pipe below the lubricating fluid line are a series of cooling fins. Heat generated within the lubricating fluid that is heated during operation conduit is dissipated via the cooling fins.

Owner:TORQUE TRACTION TECH INC

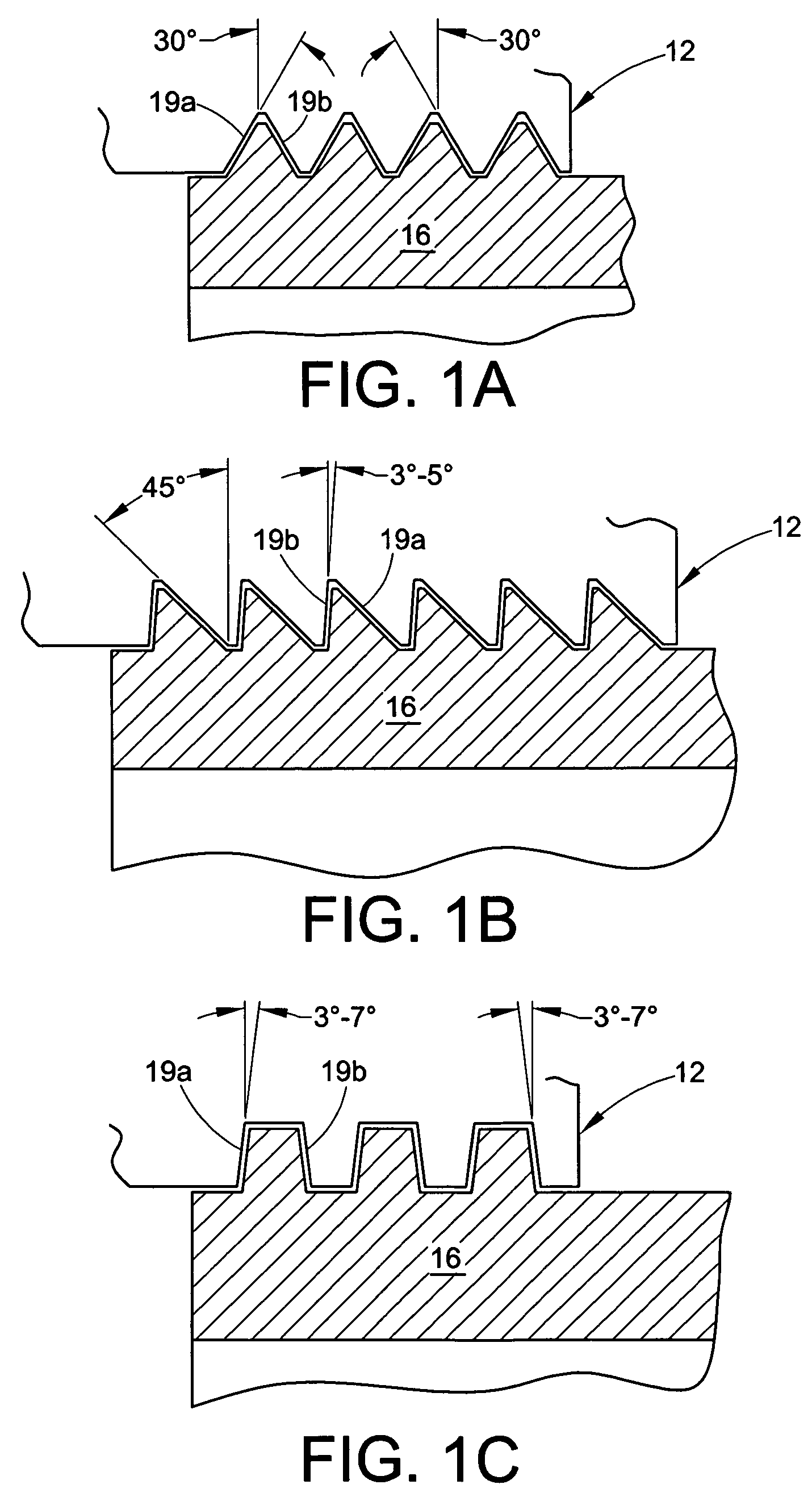

Pressure relieved thread connection

Lubricant escape passages are formed in the threads used to connect one tubular body to another. The passages conduct trapped thread lubricant out of the threaded area to prevent the creation of high lubricant pressure that may damage or cause improper make up of the threaded connection. The passages may be grooves in the crests of the thread teeth and / or may be corner bevels on the thread teeth. In a conductor pipe or other pipe assembly using axially spaced internal and external seals at each axial end of the threaded area, the escape passages form a helical flow path through the engaged thread area. The external seal prevents the entry of corrosive fluids into the threaded area and the internal seal prevents leakage through the threaded area from within the conductor pipe. When the lubricant pressure increases excessively during assembly or impact loading of the connection, the lubricant escapes past the seals to prevent connection damage. When used with a wedge or other metal-to-metal thread engaging designs, the escape passages may be interrupted at some point intermediate their helical path to provide a pressure seal at the point of interruption. Relieving trapped lubricant from a wedge thread connection permits consistent final makeup positions that ensure optimal pressure sealing.

Owner:GRANT PRIDECO LP

Deep water drilling with casing

InactiveUS20060196695A1Easy to participateDrilling rodsReciprocating drilling machinesCross connectionWell drilling

Methods and apparatus are provided to place a conductor pipe and a casing in a subsea environment. In one embodiment, a conductor pipe is jetted or drilled into the subsea floor. Thereafter, a casing drilling assembly comprising a drill casing and a drilling assembly is connected to the drill pipe using a crossover. The drilling assembly urged into the seafloor until a casing latch on the drilling assembly is engaged with a casing profile of the conductor pipe. During drilling, instrumentation in the drilling assembly may be used to measure geophysical data. The measured data may be used to optimize the drilling process. After the drill casing is engaged with the conductor pipe, cementing may be performed to set the drill casing.

Owner:WEATHERFORD TECH HLDG LLC

Concrete pouring control system and method for cast-in-place pile

InactiveCN103437358AImprove pouring qualitySave material costFoundation engineeringControl systemQuality control

The invention relates to the field of cement buildings, and aims to provide a concrete pouring control system and method for a cast-in-place pile. The system comprises a guide pipe for cement filling and a lifting device connected with the guide pipe, wherein the lifting device operates through a motor and drives a cable to lift the guide pipe to rise; a pressure sensor is arranged at the bottom, in a certain height position, of the guide pipe, and the pressure difference is sensed in the height position and is converted into a signal which is transmitted to an external control host machine to be processed so as to control the time and the speed for lifting the guide pipe by the motor. According to the system and method, the quality control is carried out in the pile foundation concrete pouring process to remarkably improve the pouring quality, so that the conscientious work is changed to the transparent work which can be constantly monitored and controlled, and the construction is brought into a standardized and normalized track, thereby saving a great amount of material cost.

Owner:杭州银博交通工程材料有限公司

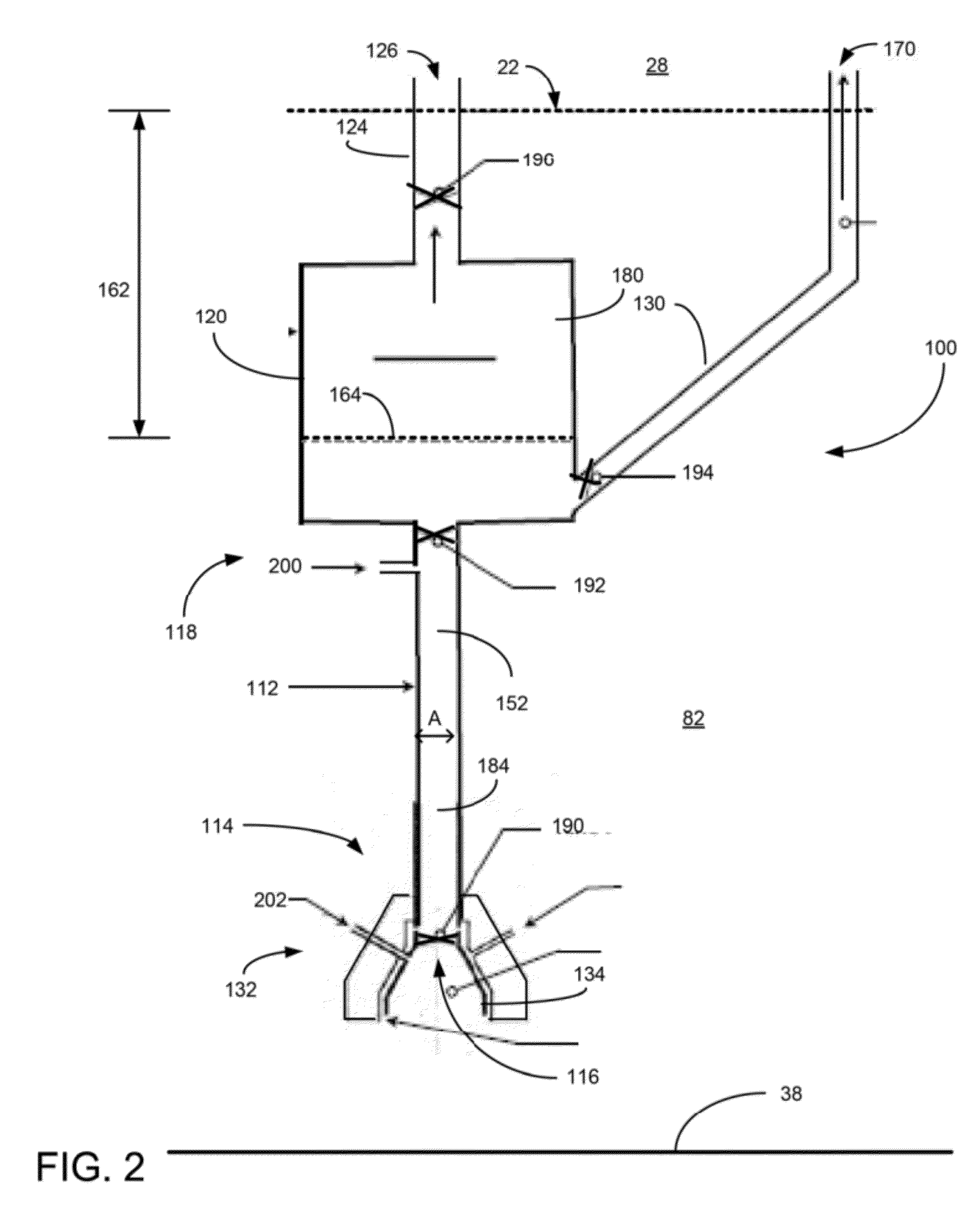

Universal Subsea Oil Containment System and Method

A system, method, and apparatus for containing oil and gas leaking from an underwater wellhead or other man-made structure. The apparatus includes a conduit having an upper end and a lower end with an opening. The conduit is sized for the lower end to be positioned over a plume leaking from the man-made structure and the upper end to be substantially near or at the seawater surface. The apparatus also includes a port for introducing a suitable gas such as nitrogen into the interior of the conduit for displacing seawater from the interior of the conduit. In addition, the apparatus includes a plurality of valves for metering liquid and gas flow within the interior of the conduit. The conduit is positioned over the leaking man-made structure and oil and gas flow upward from the leaking man-made structure through the interior of the conduit.

Owner:CARTER GEORGE +1

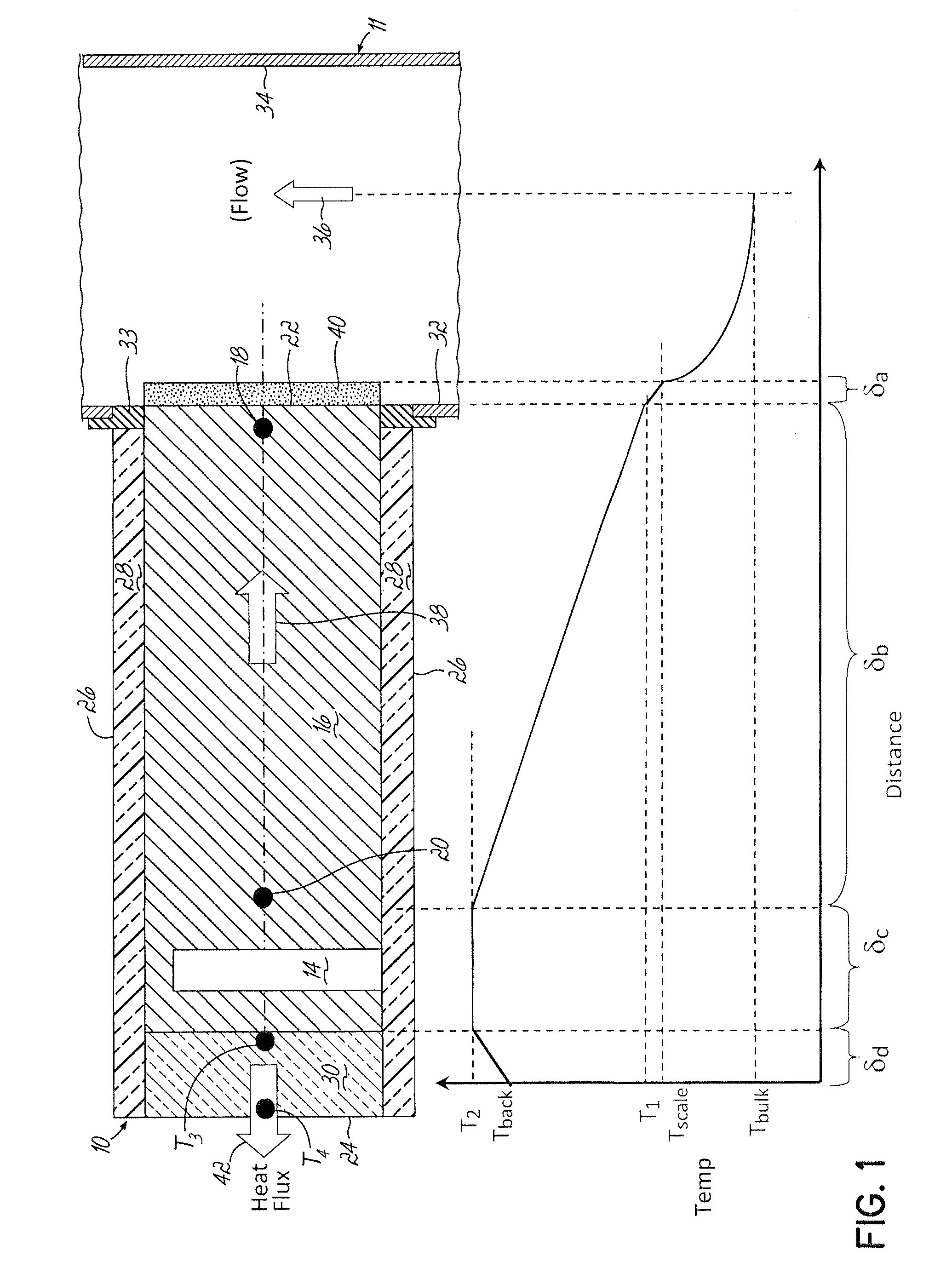

Method and apparatus for estimating fouling factor and/or inverse soluble scale thickness in heat transfer equipment

ActiveUS20140177673A1Accurately indicatedUseful insight natureThermometer detailsAir-treating devicesHeat fluxHeat flow

Scale deposition on a heat transfer surface in a liquid system such as a heat exchanger is estimated by directing of small portion of the liquid flow through a test cell, consisting of a sensor positioned on and projecting through a conduit wall. The sensor consists of a conductive block containing a heater and having a heated wetted test surface that is flush with the inside of the conduit wall and in contact with the flow through the conduit. Within the conductive block are two temperature sensors which are at different distances from the heated wetted test surface and the heater. The periphery of the apparatus is designed to reduce heat flow through the periphery and allow greater heat flow through the heated wetted test surface. By comparing the temperature differential between the two temperature sensors to the differential when no scale is present, the presence of and amount of scale can be determined, based on reduced heat transfer through the heated wetted surface caused by the accumulated scale. The change in the temperature differential is directly proportional to the scale thickness for a given type of scale. When the thickness of the scale is determined by another means, the nature of the scale can be implied. The sensitivity of the measurement can be adjusted to accommodate a very wide range of bulk liquid or ambient temperature via adjustment of the heat flux through the provided secondary heat flux path.

Owner:SOLENIS TECH CAYMAN

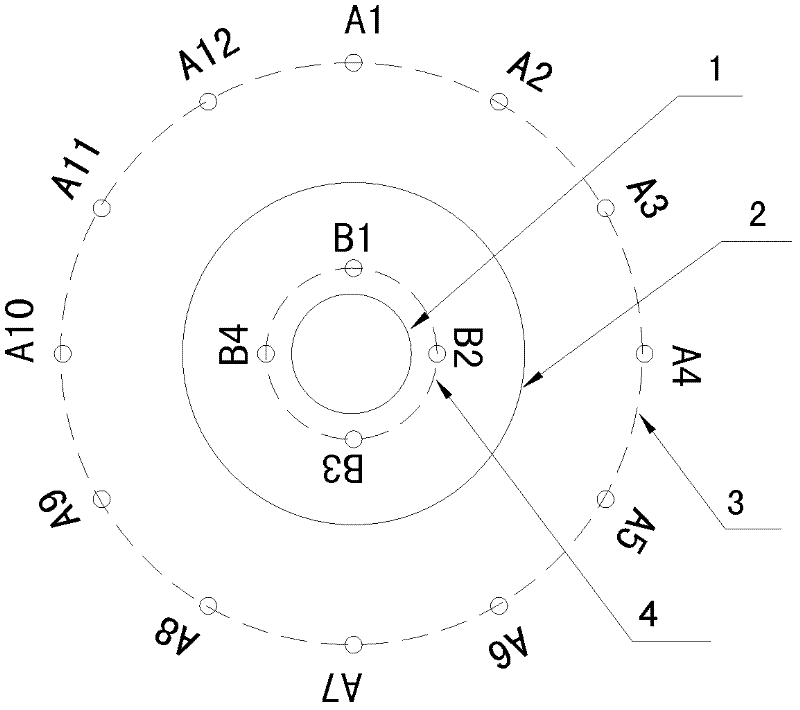

Dry-method hole forming filling pile structure for post-grouting matched rotary drilling rig and construction method

ActiveCN105239563AIncrease side frictionImprove bearing capacityBulkheads/pilesSurface layerEngineering

The invention discloses a dry-method hole forming filling pile structure for a post-grouting matched rotary drilling rig and a construction method. The filling pile structure comprises a hole pile body arranged in a terrace. The hole pile body is composed of concrete and a steel reinforcement cage arranged in the concrete. The steel reinforcement cage comprises cylindrical main ribs which are evenly distributed. Hoop ribs and reinforcing hoops are arranged on the outer sides and the inner sides of the main ribs respectively. Multiple grouting pipes are evenly arranged in the circumferential direction of the steel reinforcement cage. The construction method includes the steps that firstly, a site is cleaned and leveled; secondly, measurement and take-off operation are performed and a pile position is buried; thirdly, the drilling rig is in place and drills the surface layer and a steel protective barrel is buried; fourthly, the center line of the pile is rechecked; fifthly, a pile hole is drilled; sixthly, a bearing stratum and the formed hole are checked; seventhly, the hole is cleaned; eighthly, a grouting pipe is manufactured and installed; ninthly, the steel reinforcement cage is lifted to be in position; tenthly, a concrete pouring guide pipe is installed; eleventhly, the concrete is poured; twelfthly, the grouting pipe is cleared out through clean water; and thirteenthly, grouting is performed. By the adoption of the structure and the method, the side friction resistance force of a rock-socketed section of the end of the pile is improved.

Owner:GUIZHOU KAILIN CONSTR GRP CO LTD

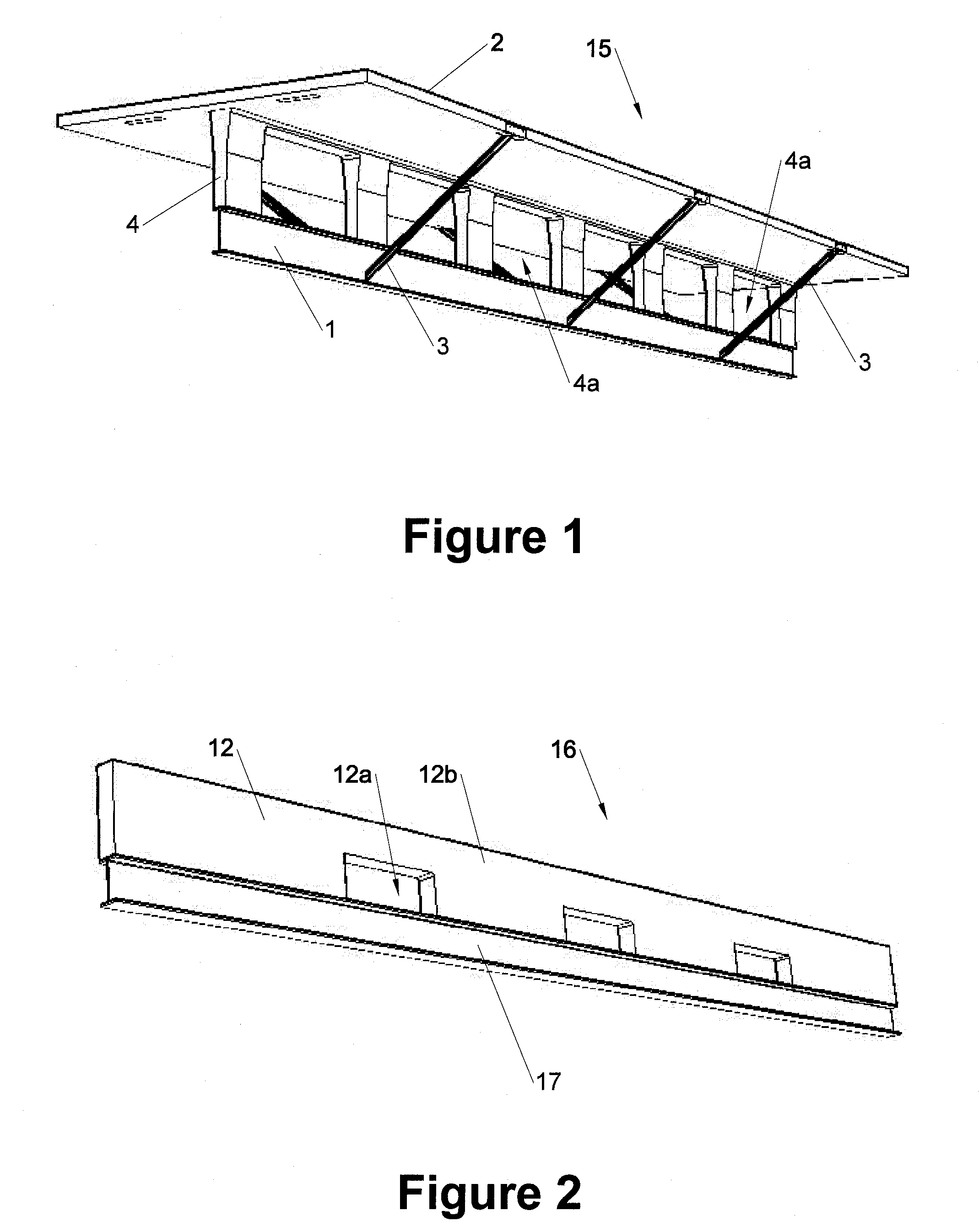

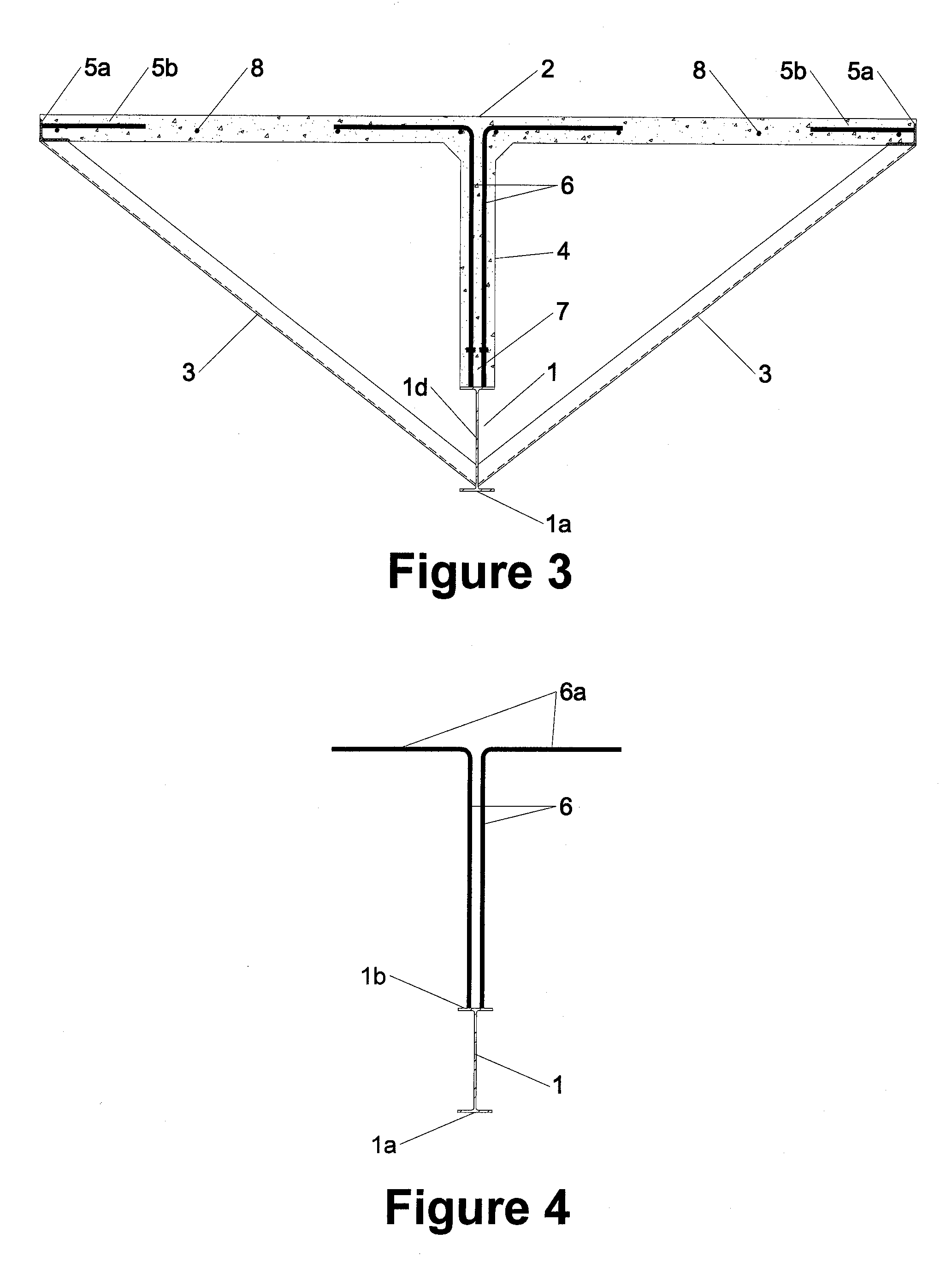

Precast composite structural floor system

ActiveUS20090288355A1Reduce weightQuick and efficientBuilding roofsWallsComposite constructionFloor slab

A precast composite flooring system utilizes girders and floor panels having steel lower structures placed in tension and concrete upper structures places in compression. Openings through a stem wall allow ducts, pipes, and conduits to be run therethrough. The system provides reduced weight over conventional precast or pour in place systems, allowing further reduction in the weight and size of other building components. The floor deck does not use tensioning strands, allowing openings to be formed at nearly any stage of construction and with reduced concern over cutting steel reinforcement. The floor panels and girders bolt together and bolt to a steel column frame, allowing for more efficient assembly.

Owner:VELOCITY I P

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com