Lateral earth pressure sensor embedment method and device in earth

An earth pressure sensor and lateral earth pressure technology, which is applied in the field of construction engineering, can solve problems such as inconsistency between deformation and soil, large error in earth pressure test results, and large rigidity, so as to facilitate standardized production and installation, and test results Reliable, well-protected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

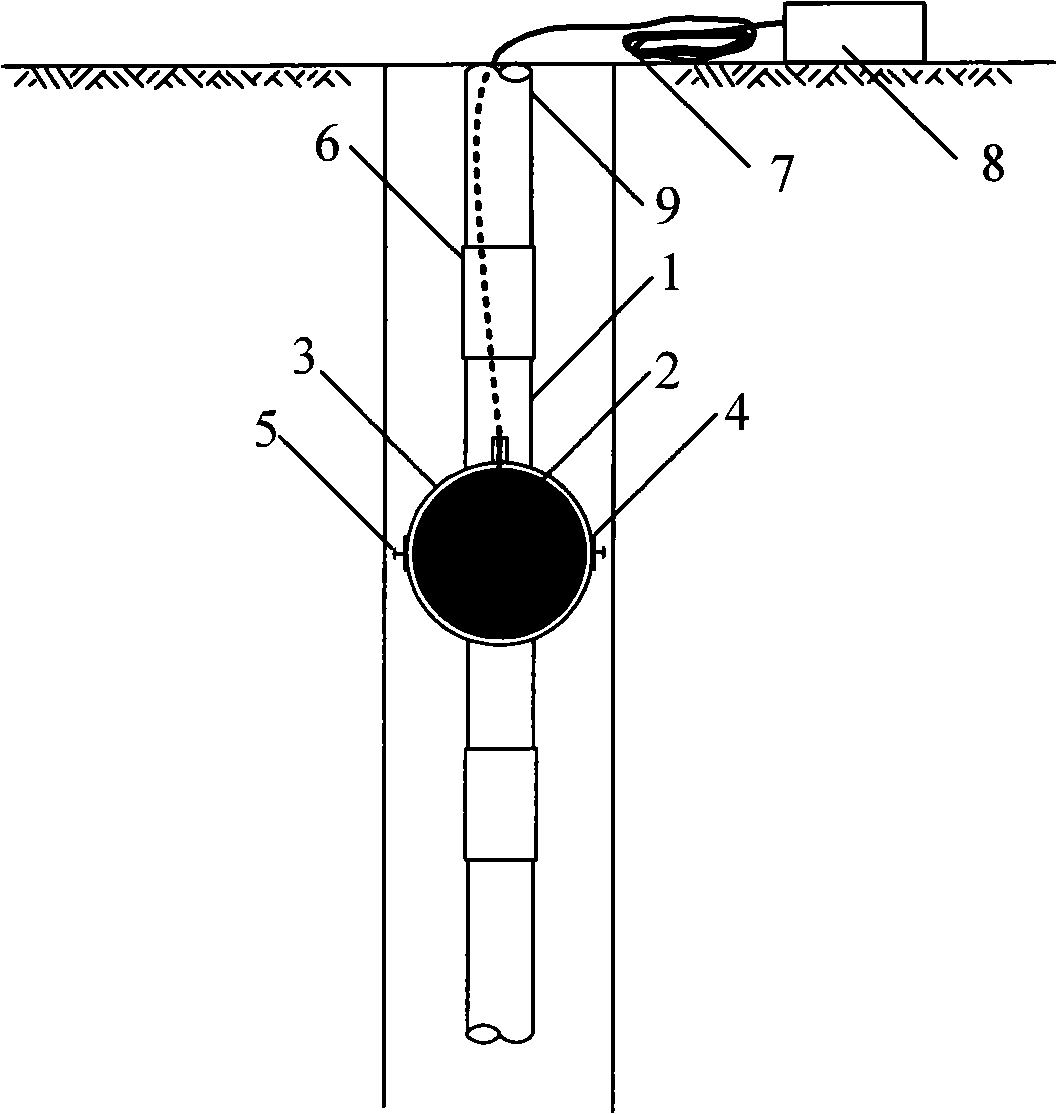

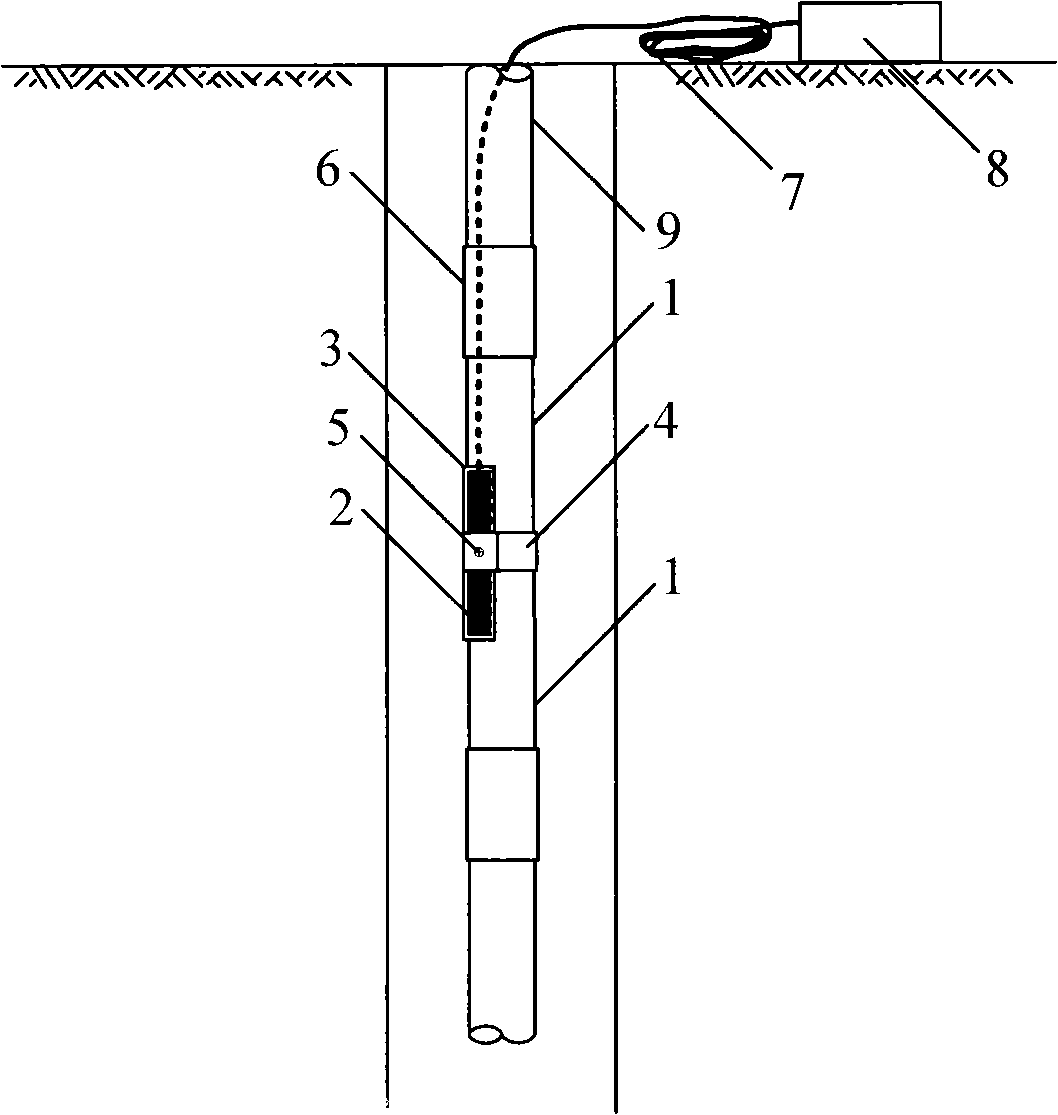

[0030] The project example is the comprehensive reconstruction (phase I) project of a certain area in Shanghai. The east side of the construction site of the project is the Huangpu River flood control wall, which was built in the 1970s and was heightened and reinforced in the early 1990s. The traffic around the construction site is heavy, and there are underground pipelines distributed. The new temporary flood control wall has effectively isolated the construction area from pipelines and roads.

[0031] The foundation pit engineering of buildings in the land area of this project is divided into 4 construction areas A, B, C and D. The enclosure structure adopts an 800mm thick underground diaphragm wall with a depth of 27m to 28m, and three horizontal reinforced concrete supports are used in the pit. The excavation method of the foundation pit is conventional construction. The excavation depth of the foundation pit is 13.5m, and the total extension of the foundation pit is 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com