Diaphragm wall and construction method thereof

An underground diaphragm wall and construction method technology, which is applied in excavation, artificial islands, water conservancy projects, etc., can solve the problems of limited applicability, need for further verification, and lack of waterproof and anti-seepage functions, so as to improve the waterproof performance and ensure the groove wall Stability, effects of coordinating differential settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

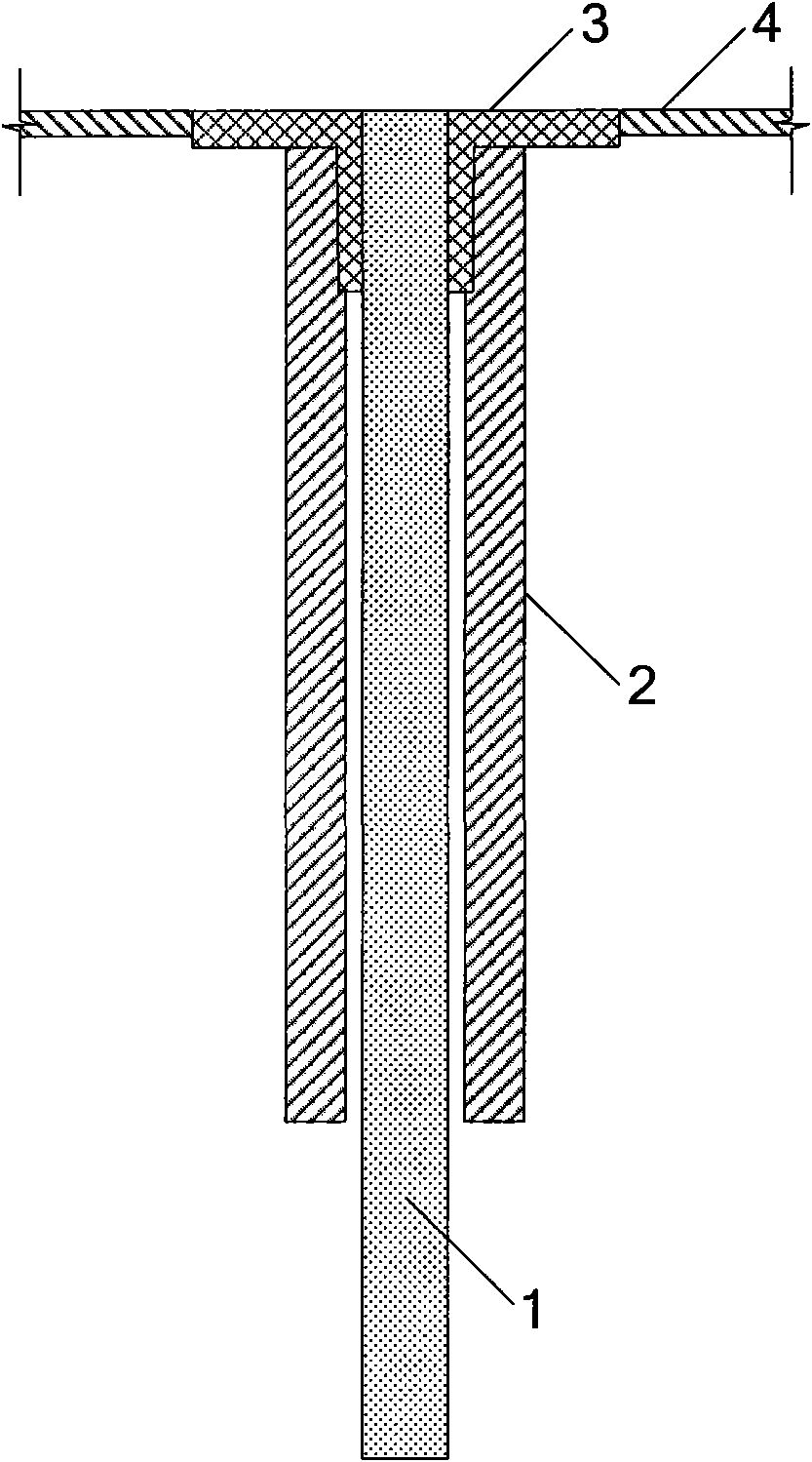

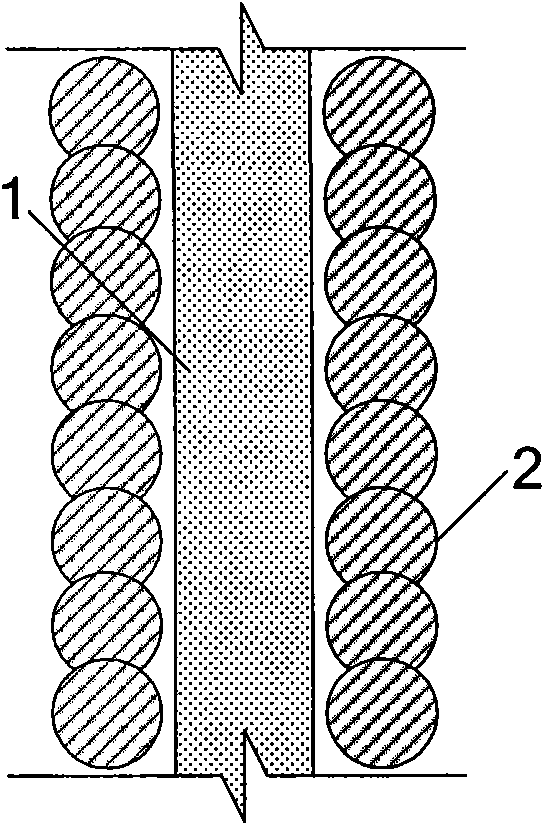

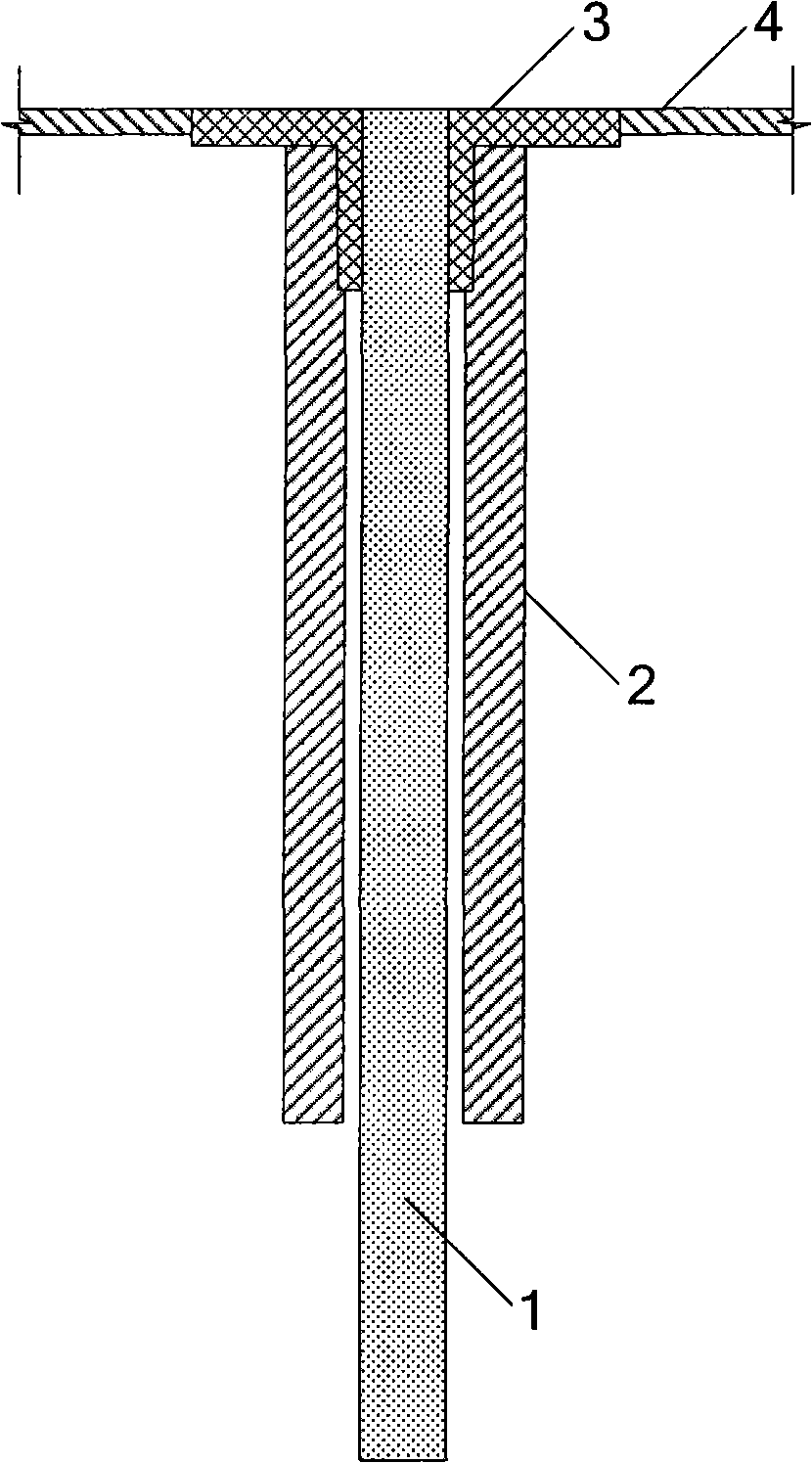

[0036] See figure 1 , is the underground diaphragm wall involved in the present invention, comprising an underground diaphragm wall body 1 , cement-soil mixing pile 2 , guide wall 3 and rigid floor 4 . There are multiple cement-soil mixing piles 2, symmetrically arranged on both sides of the underground diaphragm wall body 1, and the cement-soil mixing piles 2 are engaged. The guide wall 3 is a monolithic reinforced concrete structure in a double L shape, symmetrically arranged on the top of the cement-soil mixing pile 2, and the distance inside the guide wall 3 should be greater than the width of the underground diaphragm wall 1 to ensure that the trenching machinery Operation. One end of the guide wall 3 is arranged between the cement-soil mixing pile 2 and the underground diaphragm wall 1 , and the other end is connected to the rigid floor 4 . The rigid floor 4 is also a monolithic concrete floor 4, which is connected with the guide wall 3 as a whole.

[0037] The presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com