Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Guaranteed shear performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

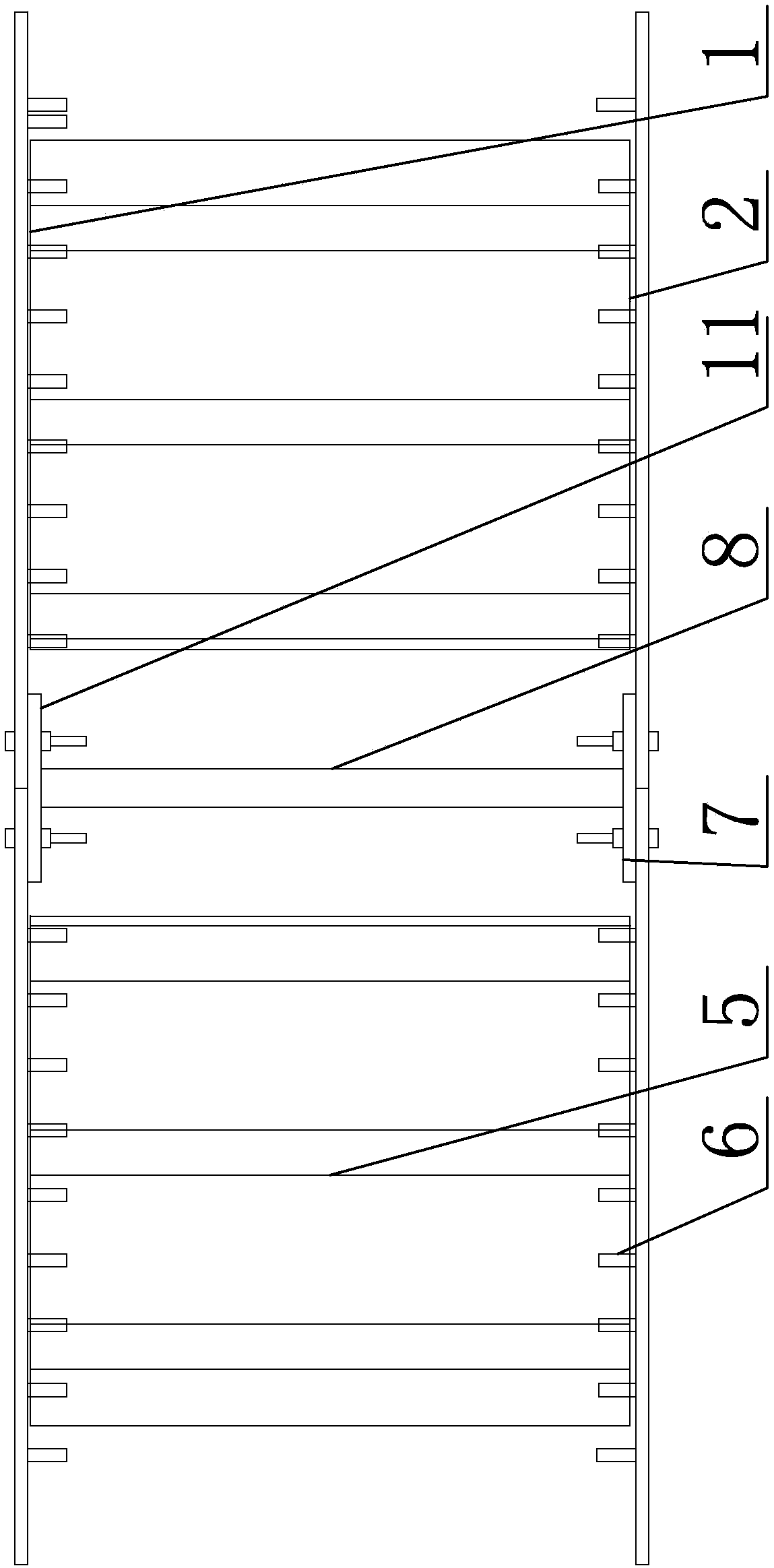

Method for prefabricating assembly type reconstructed and expanded building structure joint and structure node of building

InactiveCN106285035AImprove construction progressEasy to control project qualityBuilding repairsSocial benefitsPre stress

The invention belongs to the technical field of industrial and civil building structures and particularly relates to a method for prefabricating an assembly type reconstructed and expanded building structure node and the structure node of a building. The practical problem that linkage between a newly-built structure and an original structure is not easy to process is solved, the newly-increased loads of the original structure are reduced, and damage to the original structure is reduced. According to the particularity of reconstructed and expanded construction, the expanded structure connection mode is innovated, by the adoption of the prestress post-anchoring technique, the defects of rigid joints of a traditional expanded concrete structure are overcome through hinge joints, and steel bar interference and steel bar bond stress losses are effectively avoided. By applying the prestress post-anchoring threaded rod prestress, the shearing property of the joints is improved. By applying the technique, when reconstruction and expanding are conducted, the reinforcing and modification workload of the original structure can be reduced to the greatest extent, the construction period of the reconstructed and expanded engineering is shortened easily, quality control is facilitated, the engineering investment is reduced, and good economic benefits, social benefits and application prospects are achieved.

Owner:XIAN CHANGQING TECH ENG

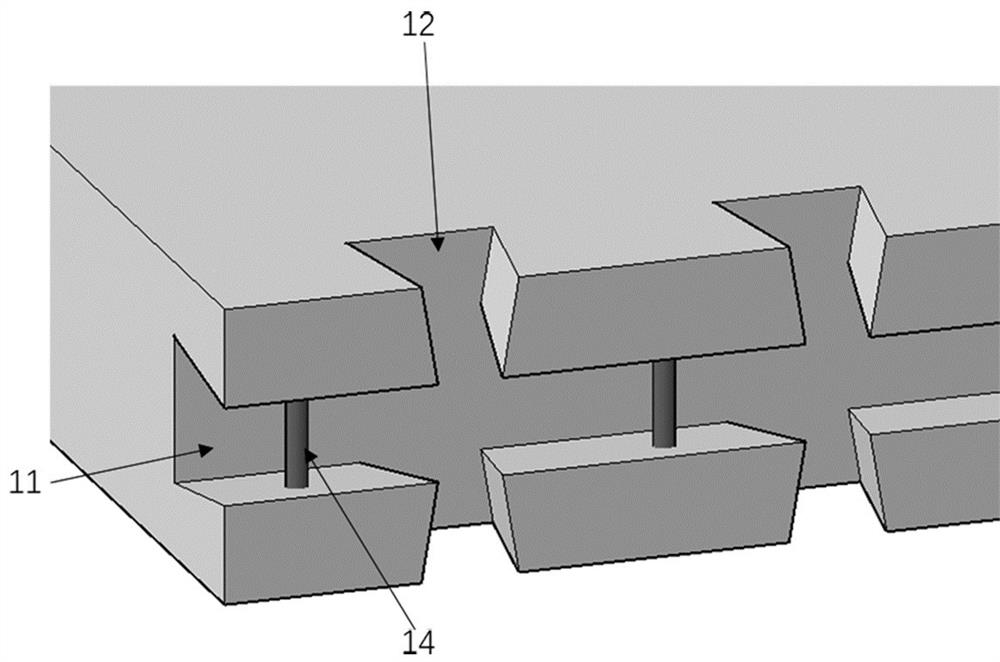

Technique for strengthening boundary face of functional gradient material of shield duct piece by using FRP rib

InactiveCN1916365AGuaranteed stabilityGuaranteed continuityUnderground chambersCeramic shaping apparatusReinforced concreteGradient material

The present invention relates to a technical process for reinforcing functional gradient material interface of shield-driven tunnel concrete segment by utilizing FRP rib. Said technical process includes the following steps: (1), creating FRP rib anchorage reinforcement transition zone; laying and sticking flexible FRP mesh fabric on the surface of reinforcing cage in reinforced concrete segment steel mould, on the mesh fabric distributing FRP ribs according to the point lattice form to form FRP rib anchorage reinforcement transition zone, in which the FRP ribs and FRP mesh fabric are adhered together and formed into an integral structure; (2), in the reinforced concrete segment steel mould pouring the high-performance concrete whose strength grade is greater than C50 to upper surface of reinforcing cage to form reinforced concrete structure layer; and (3), utilizing pumping process to pour high-antipermeable protective concrete to surface of steel mould on the reinforced concrete structure layer to form high-antipermeable protective layer.

Owner:WUHAN UNIV OF TECH

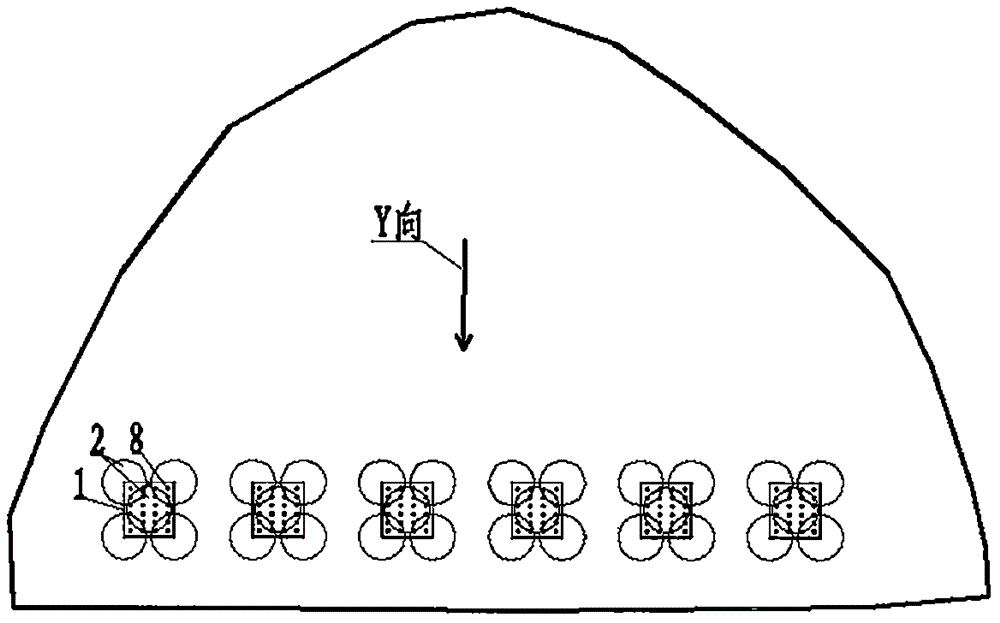

Miniature jet grouting pile group and implementation method

InactiveCN106088110AGuaranteed shear performanceGuaranteed shear resistance of micropile groupsExcavationsBulkheads/pilesLandslideStructural engineering

A miniature jet grouting pile group is composed of a plurality of miniature pile bars, jet grouting piles and a cap. The miniature jet grouting pile group is characterized in that a rectangular miniature pile group is formed by the miniature pile bars,five jet grouting piles are arranged at four vertex angles and the center of the miniature pile group, and the top of the rectangular miniature pile group is rigidly connected into a whole through the cap. The miniature jet grouting pile group has the following advantages that (1) the jet grouting technology is introduced to medium-small sized landslide control projects or large-plasticity soil slope reinforcing projects; (2) the construction speed is high; (3) the durability of an anti-sliding support structure is improved; and (4) the arrangement mode is flexible and variable.

Owner:NORTHWEST RES INST CO LTD OF C R E C

Core tube inverse superimposed underground diaphragm wall and construction method thereof

ActiveCN105275013ASolve the lack of carrying capacityImprove integrityArtificial islandsUnderwater structuresSlurry wallCarrying capacity

The invention discloses a core tube inverse superimposed underground diaphragm wall. The core tube inverse superimposed underground diaphragm wall comprises a core tube underground diaphragm wall body below a raft top elevation and a core tube underground diaphragm wall body above the raft top elevation. The underground diaphragm wall body below the raft top elevation comprises first advance width sections and first follow-up width sections. The underground diaphragm wall body above the raft top elevation comprises second advance width sections, second follow-up width sections, connecting beams, post-pouring gap sections arranged at the connecting positions of the second advance width sections and the second follow-up width sections and the connecting positions of the width sections and the connecting beams, and outer lining walls arranged at the outer sides of the width sections and the post-pouring gap sections. Wall body lacing wires and stirrups are pre-embedded in the two side edges of steel reinforcement cages of the second advance width sections and the second follow-up width sections respectively. Box irons are pre-embedded in the end portions of the two sides of the second advance width sections and the second follow-up width sections, and the box irons stretch into the underground diaphragm wall body below the raft top elevation. The invention further discloses a construction method for the core tube inverse superimposed underground diaphragm wall. According to the core tube inverse superimposed underground diaphragm wall, the outer lining walls are arranged additionally on the two sides of the underground diaphragm wall body above the raft top elevation, and the problem that an existing underground diaphragm wall is insufficient in carrying capacity is solved; in addition, two different underground diaphragm wall connecting modes are adopted, so that not only are requirements for stressing and constructing met, but also the shear performance of the underground diaphragm wall is guaranteed.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

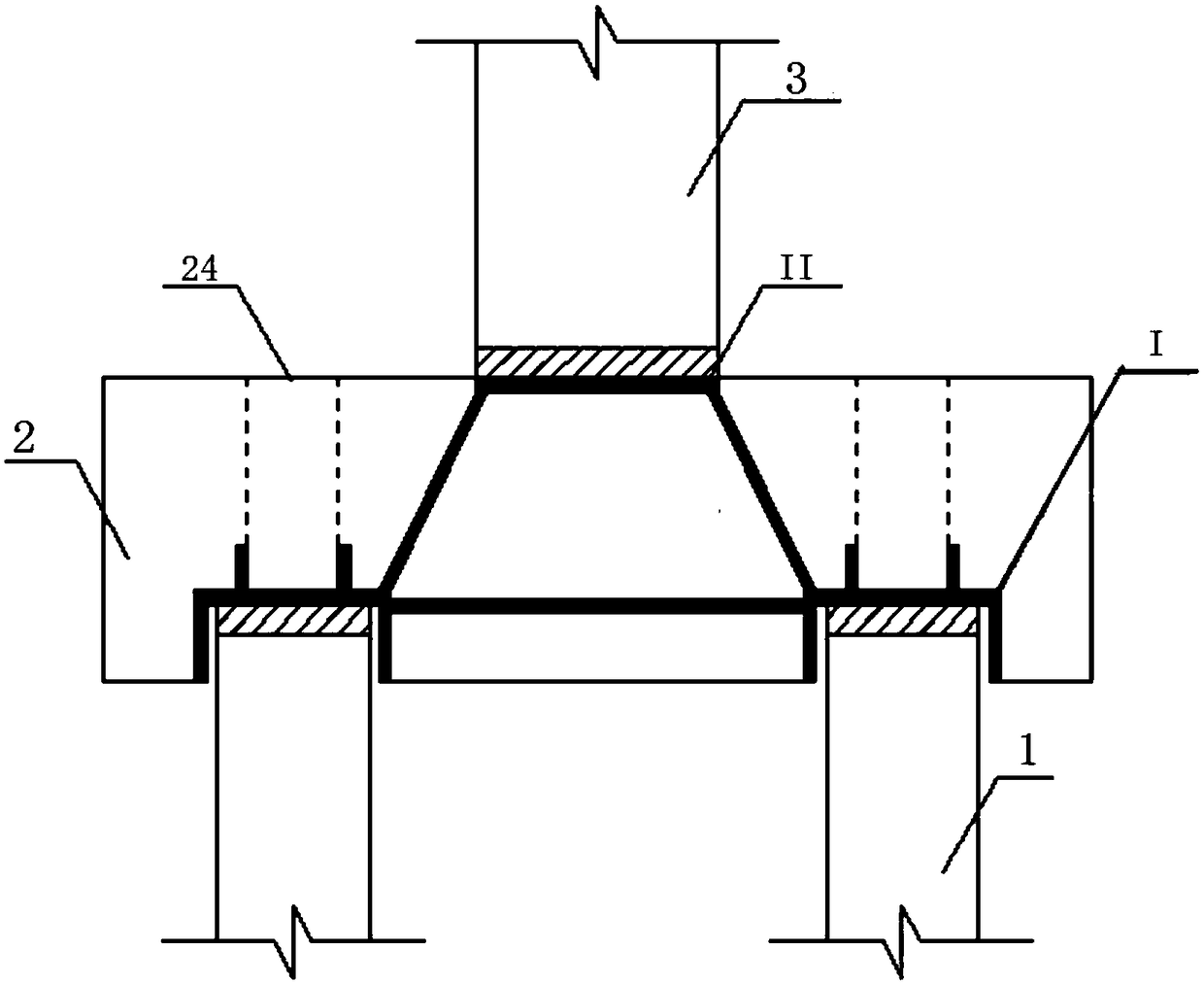

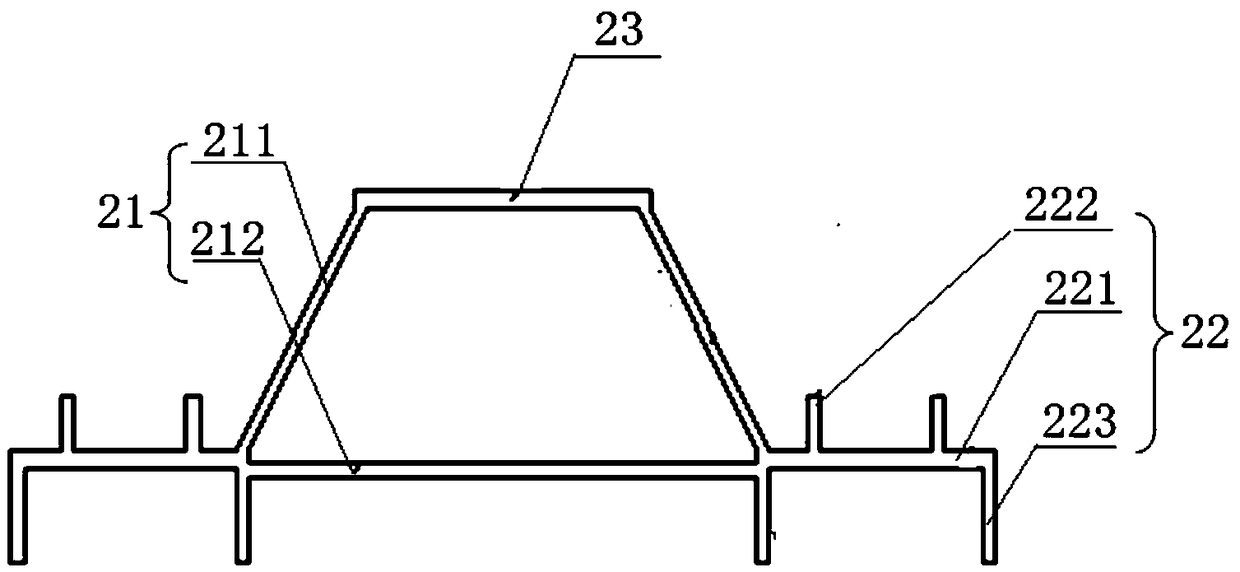

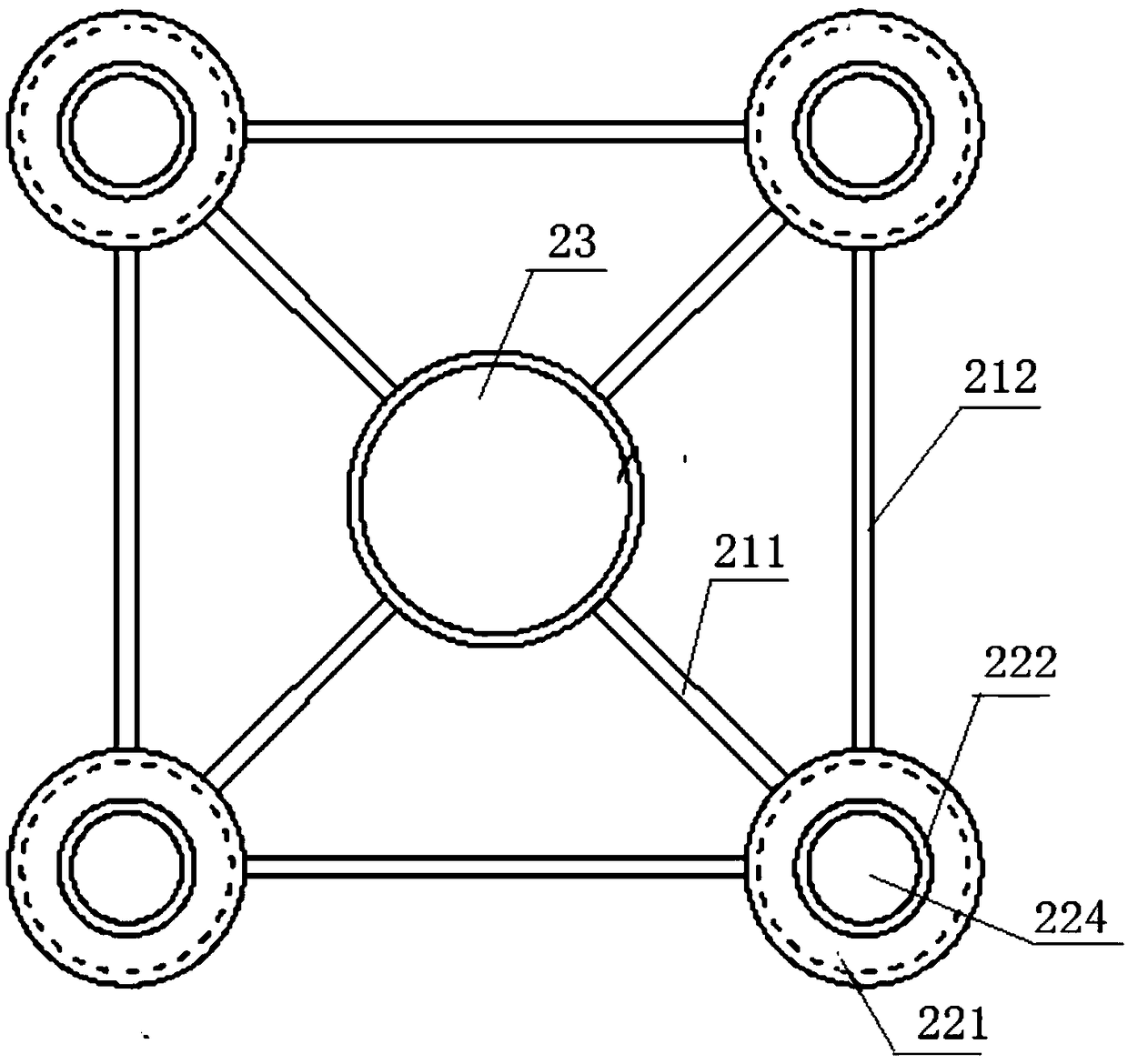

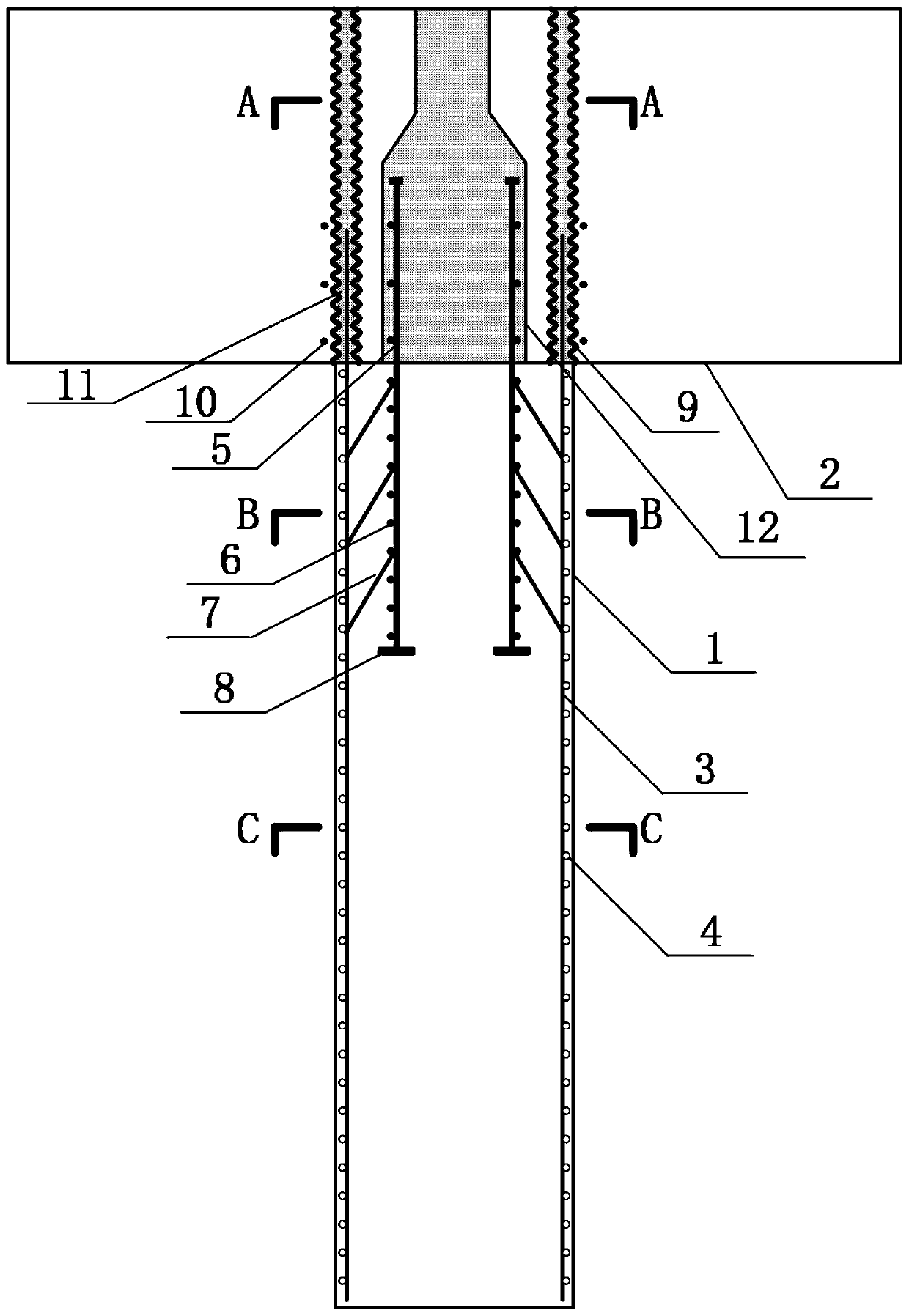

Precast assembled pile foundation pier and construction method thereof

PendingCN109267472AConducive to the realization of prefabricated assembly construction of the whole bridgeRealize the prefabricated assembly construction of the whole bridgeBridge structural detailsFoundation engineeringShear capacityDuctility

The invention relates to a prefabricated pile foundation pier and a construction method thereof, comprising a prefabricated pile, a prefabricated bearing cap and a prefabricated pier column, wherein the pile foundation pier is integrally connected by a first connection structure for connecting the prefabricated pile and the prefabricated bearing cap and a second connection structure for connectingthe prefabricated pier column and the prefabricated bearing cap; the first connection structure connects the precast pile and the bearing cap into a whole, which ensures the reliability of the connection between the pile and the bearing cap, and at the same time satisfies the sufficient compression, bending and shearing capacity and certain tensile capacity at the pile top. The second connectionstructure connects the precast pier column with the cap, and ensures that the bottom of the pier has sufficient compression, bending, shear and ductility seismic capacity. Compared with the prior art,the invention is conducive to realizing the whole bridge segment assembly construction of the concrete bridge, improving the construction quality, greatly accelerating the construction process, shortening the construction period, reducing the adverse impact on the environment, reducing the construction noise and the like.

Owner:TONGJI UNIV +1

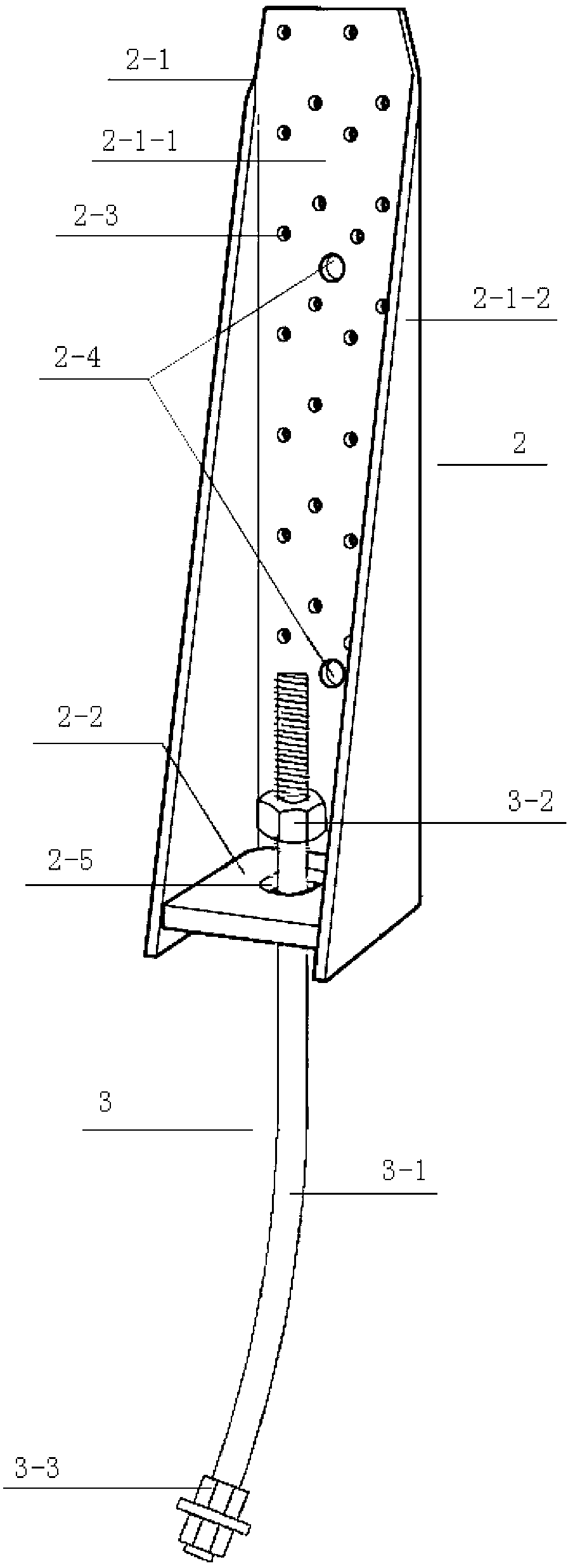

Axial-force rod piece stable lifting piece and operating method thereof

InactiveCN103015553AImprove efficiencyImprove accuracyBuilding material handlingShock proofingArchitectural engineeringAxial force

The invention discloses an axial-force rod piece stable lifting piece, which is characterized by consisting of a stable lifting piece body and an embedded piece, wherein the lower part of the embedded piece is located inside foundation concrete; and the stable lifting piece body is fixedly connected with the foundation concrete by the embedded piece. An operating method for the axial-force rod piece stable lifting piece comprises the following steps: embedding and mounting a wall sleeper slab, mounting an axial-force rod piece, mounting a stable lifting piece body, fastening and adjusting. The axial-force rod piece stable lifting piece and the operating method have the following advantages: 1, the efficiency and accuracy of the structure design are improved; 2, an embedded bolt is allowed to be mounted and fixed without being adjusted when offsetting slightly, so as to improve the allowable value of construction error; and 3, the axial-force rod piece, the stable lifting piece body and the embedded piece form an overall transmission system, so that the anti-seismic property of a timber construction is greatly improved, the mechanical property of the stable lifting piece can be fully achieved even the axial-force rod piece is combined by dimension lumbers, and the shearing behavior of an earthquake-proof shear wall is ensured.

Owner:天津泰明加德投资发展有限公司

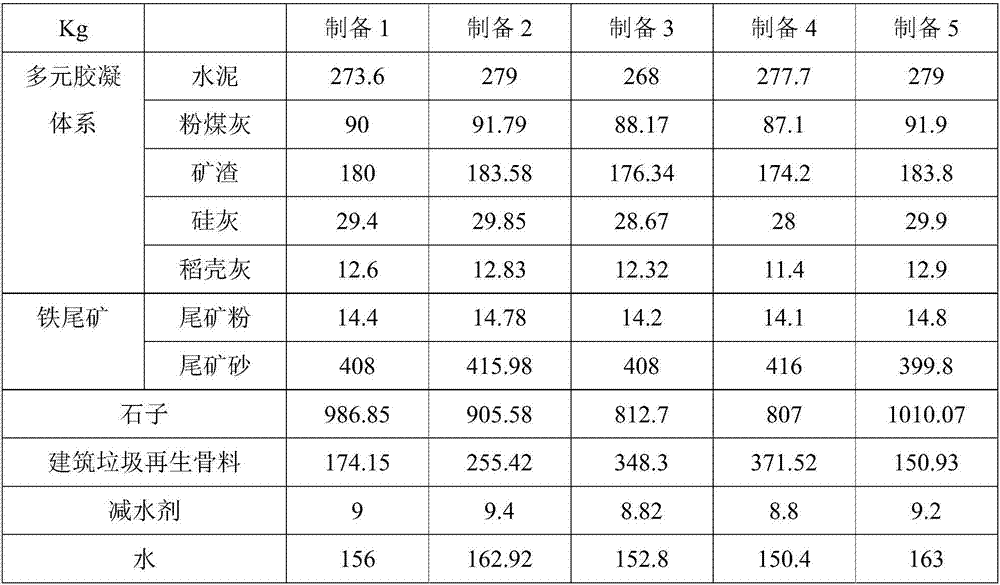

Assembled steel tube high-strength concrete columns and construction method thereof

ActiveCN107460994AIncreased durabilityImprove fire performanceStrutsSolid waste managementHigh strength concreteSteel tube

The invention relates to the technical field of assembled steel tube high-strength concrete columns, and discloses the assembled steel tube high-strength concrete columns and a construction method thereof. The assembled steel tube high-strength concrete columns are formed by sequential connecting of prefabricated standard column joints, and the standard column joints comprise steel tubes, high-strength concrete, stiffening ribs and ordinary concrete, wherein the high-strength concrete is poured in the steel tubes; the stiffening ribs are arranged on the outer side of the steel tubes in a surrounding mode, and the ordinary concrete is poured at the outside of the steel tubes; the high-strength concrete is high-strength concrete with added iron tailings and construction waste; vertical rib groups are fixed to the inner walls of the steel tubes in a welded mode; horizontal end plates are arranged on the outer circumferences of the steel tubes along the section direction in a surrounding mode; through holes are evenly formed in the horizontal end plates at intervals; the stiffening ribs penetrate through the through holes and are arranged in the length directions of the steel tubes in a full-length mode; one ends of the stiffening ribs extend out of the standard column joints, and the other ends of the stiffening ribs are provided with half grouting sleeves which are connected with the stiffening ribs extending out of the adjacent standard column joints. The assembled steel tube high-strength concrete columns are fireproofing, corrosion resisting, high in bearing capacity, and excellent in durability.

Owner:江苏悦港新材料科技有限公司

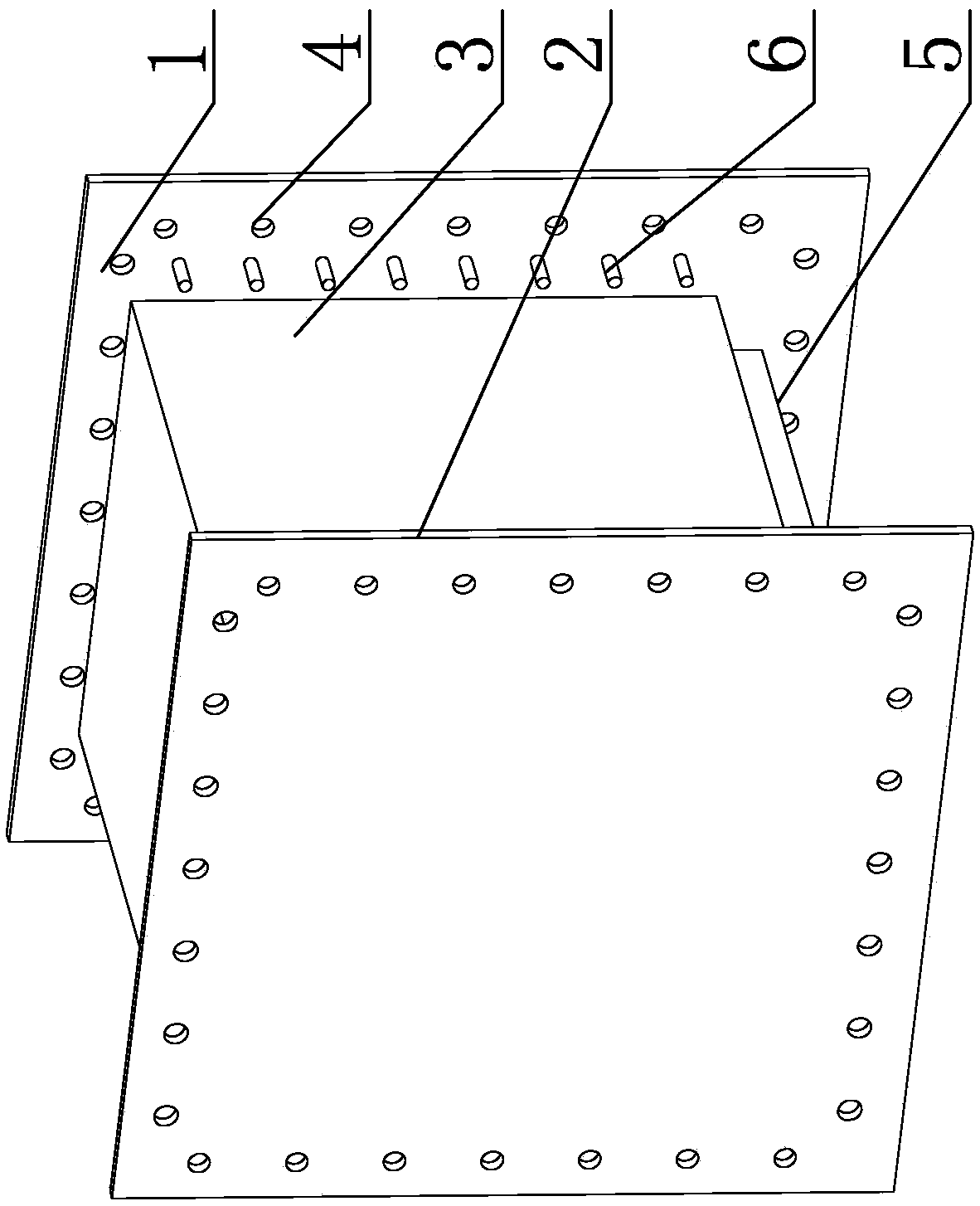

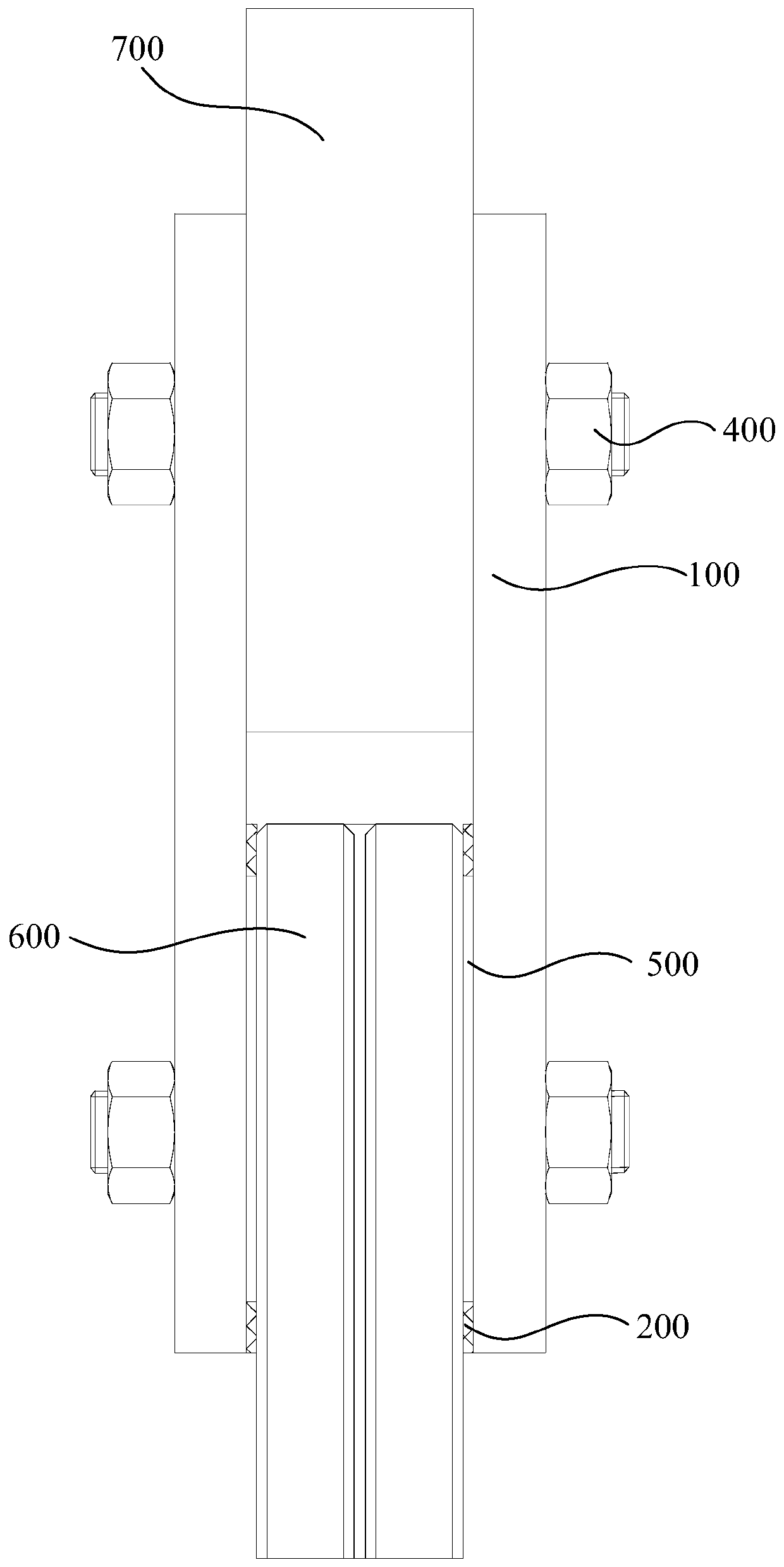

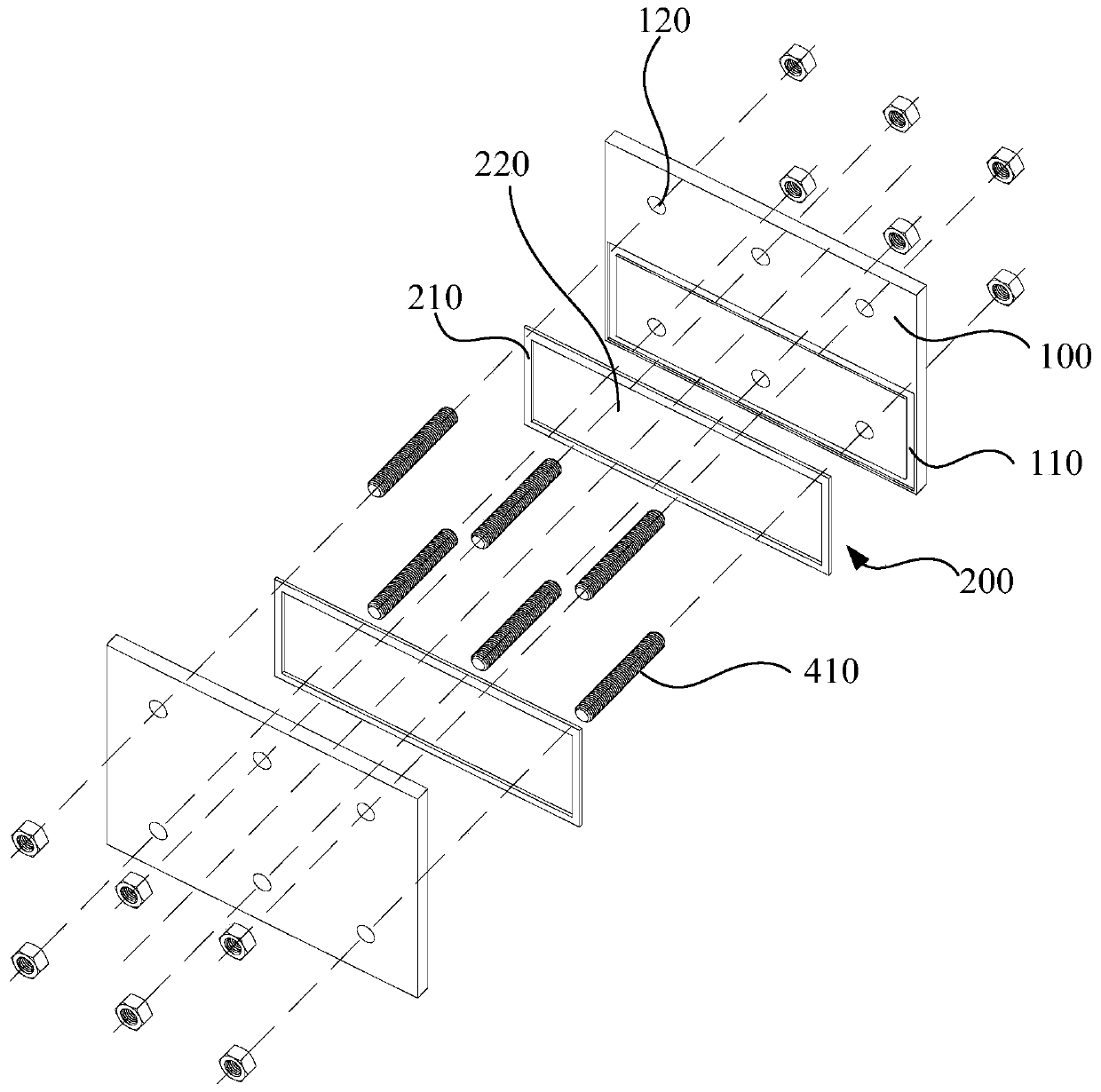

Hollow pier prefabricated inter-segment connecting device and construction method

ActiveCN112301890AAvoid damageEasy to observeBridge structural detailsBridge erection/assemblySteel platesRebar

The invention provides a hollow pier prefabricated inter-segment connecting device and a construction method thereof.The connecting device comprises embedded steel plates, U-shaped steel bars, rubberplates, upper / lower connecting steel plates, upper / lower shear-resistant steel plates and filling plates, the embedded steel plates are embedded in the inner surfaces of prefabricated segments, the U-shaped steel bars are welded to the embedded steel plates, parts of the U-shaped steel bars extend into the prefabricated segments, and parts extend out of the embedded steel plates; threads are arranged on the extending portions, and the rubber plate, the upper connecting steel plate and the lower connecting steel plate are connected with the embedded steel plate through connecting bolts. And after the upper prefabricated segment and the lower prefabricated segment are assembled, the upper shear-resistant steel plate is connected with the upper connecting steel plate through high-strength bolts, the lower shear-resistant steel plate is connected with the lower connecting steel plate through high-strength bolts, filling plates are plugged between the upper shear-resistant steel plate and the lower shear-resistant steel plate, and the upper shear-resistant steel plate is connected with the lower shear-resistant steel plate through high-strength bolts. The connecting device disclosed bythe invention meets the requirements of different procedures in the assembling process of the prefabricated sections, and realizes the functions of hoisting, section position positioning, section linear adjustment, section glue joint prepressing, temporary locking and the like.

Owner:CHINA RAILWAYS CORPORATION +1

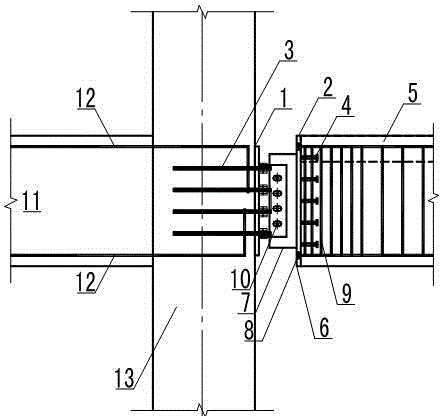

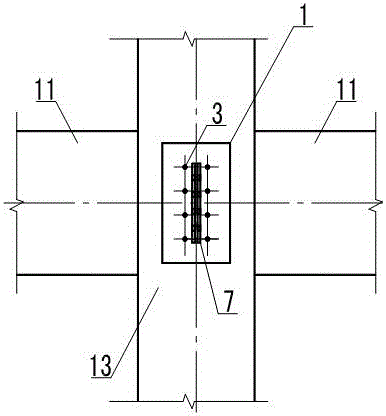

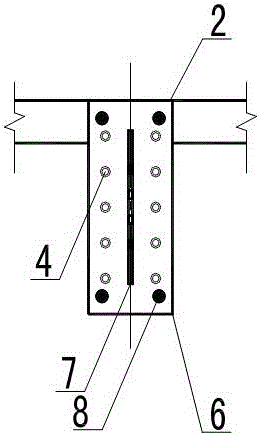

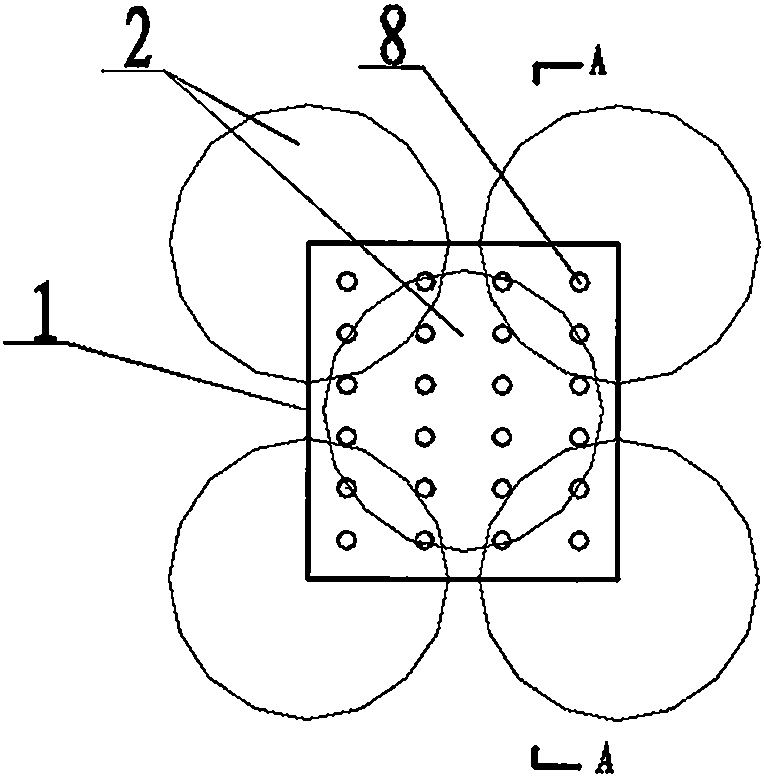

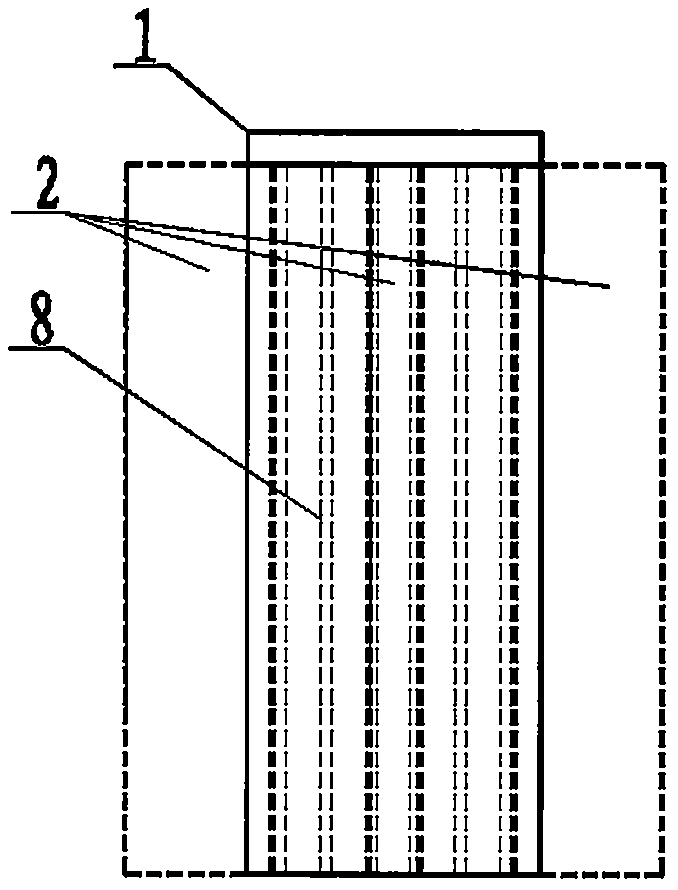

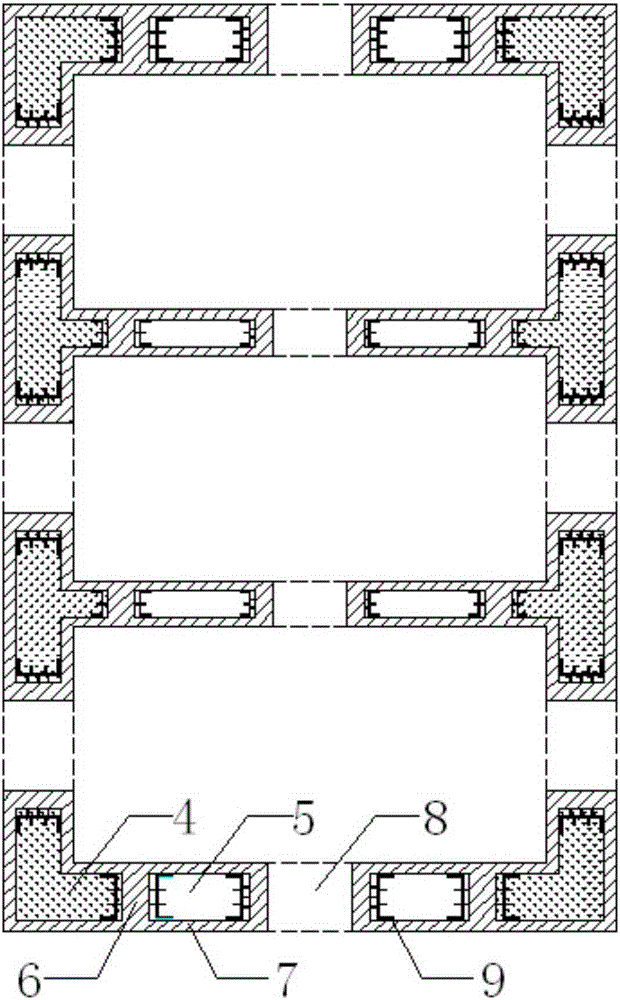

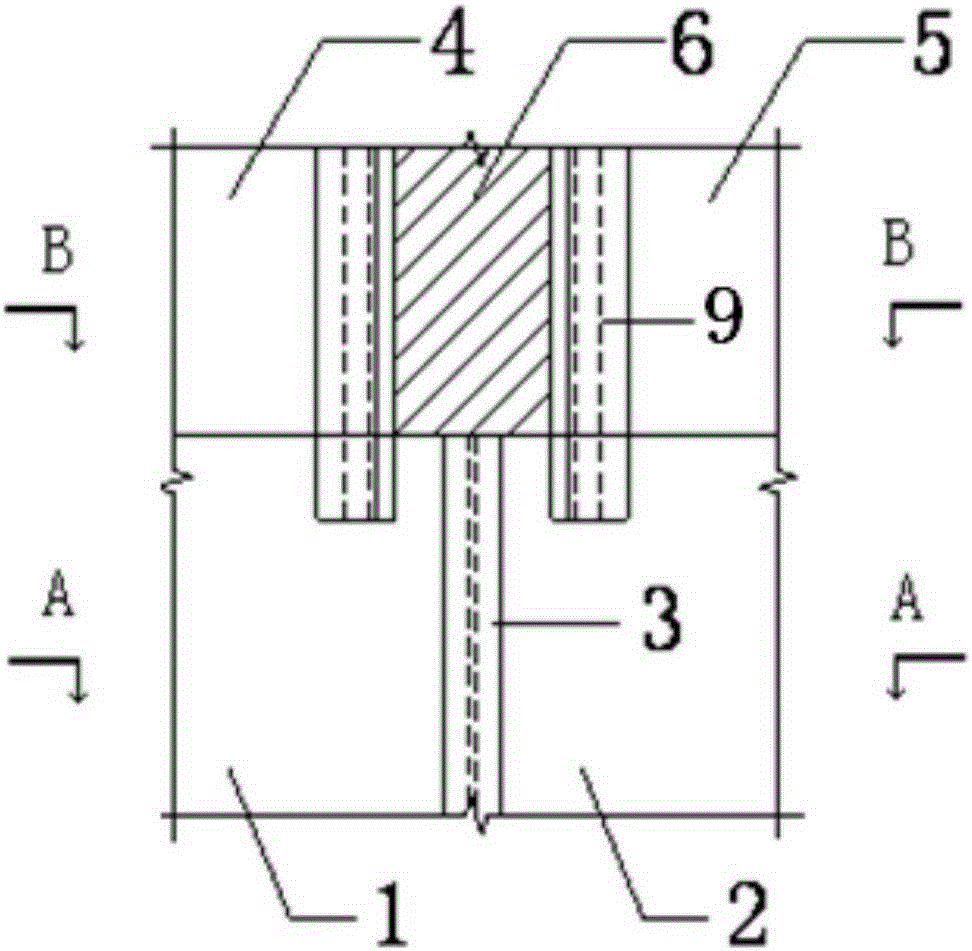

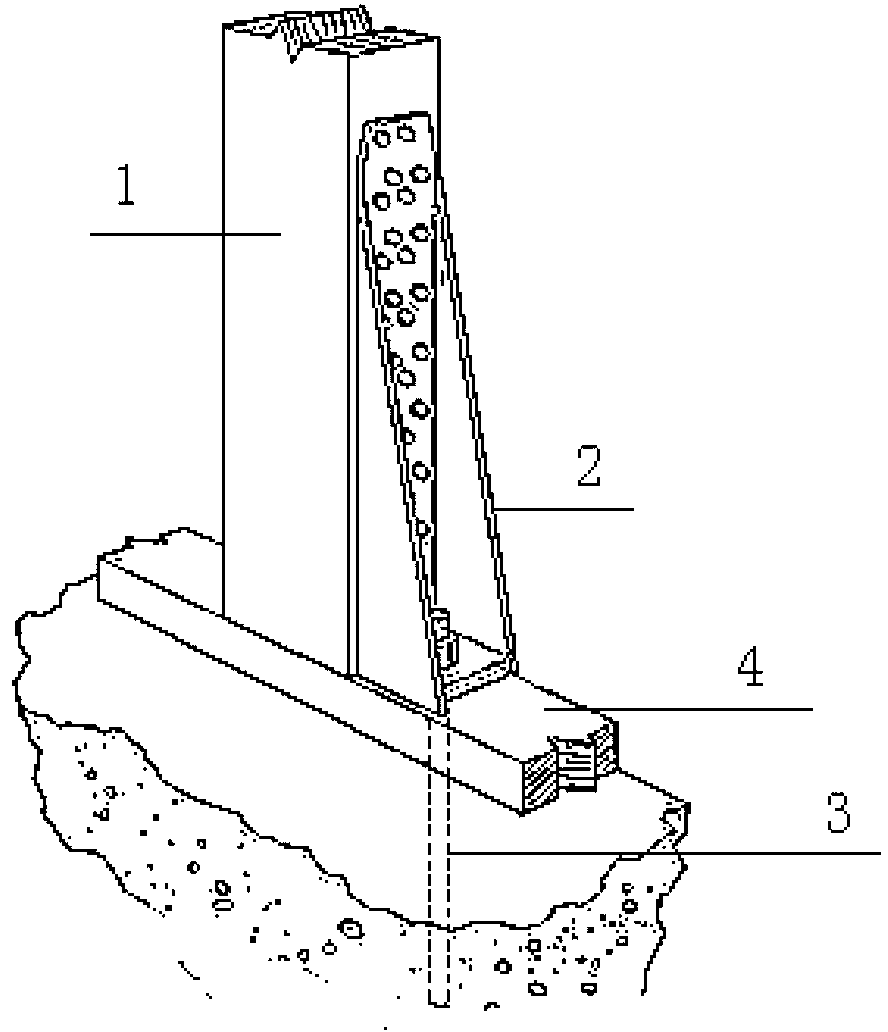

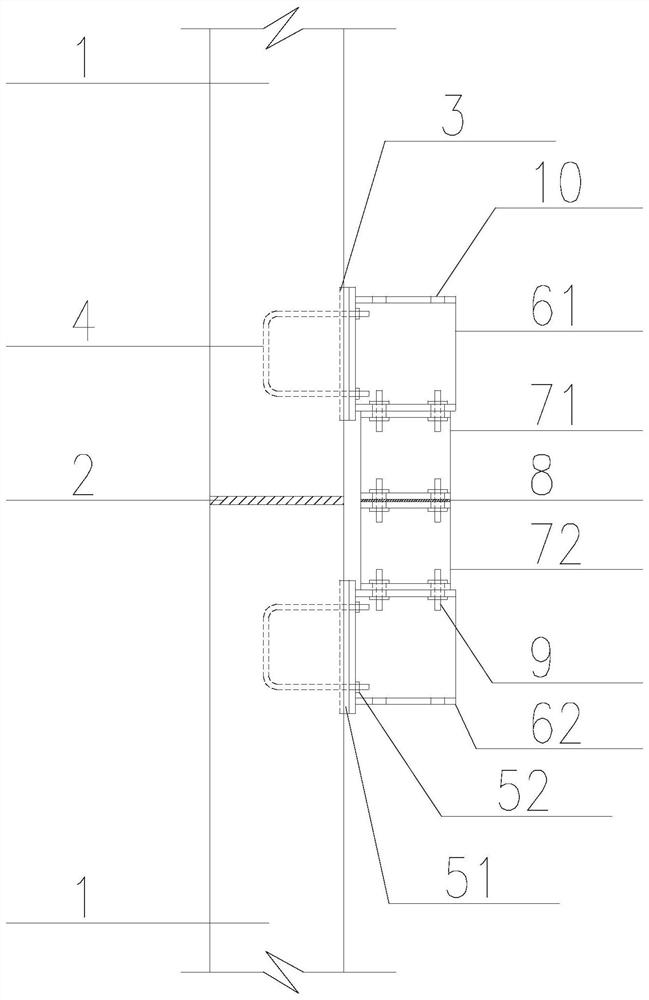

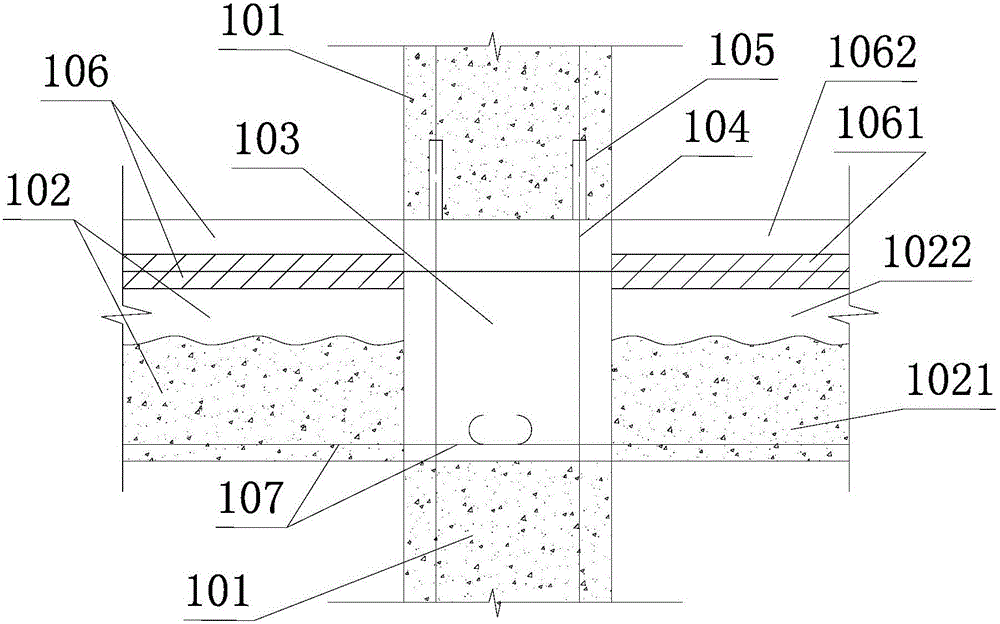

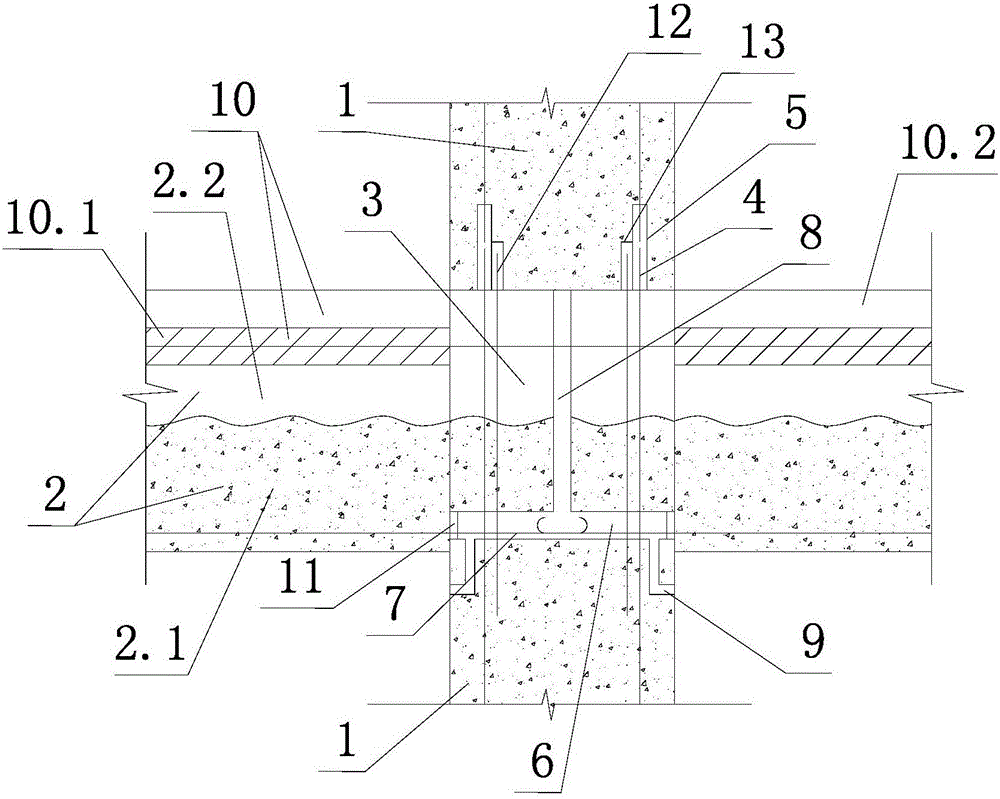

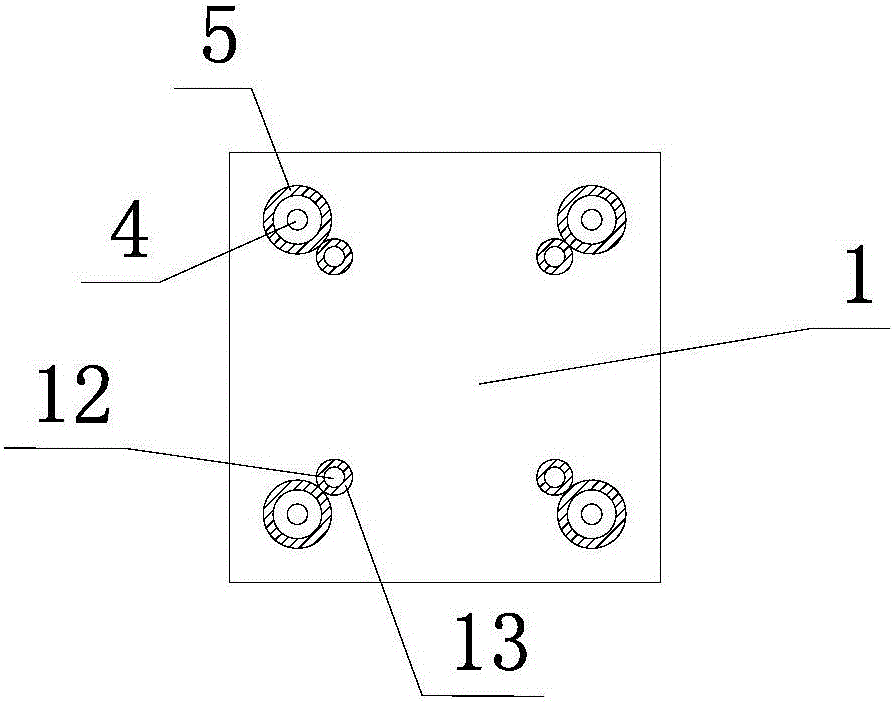

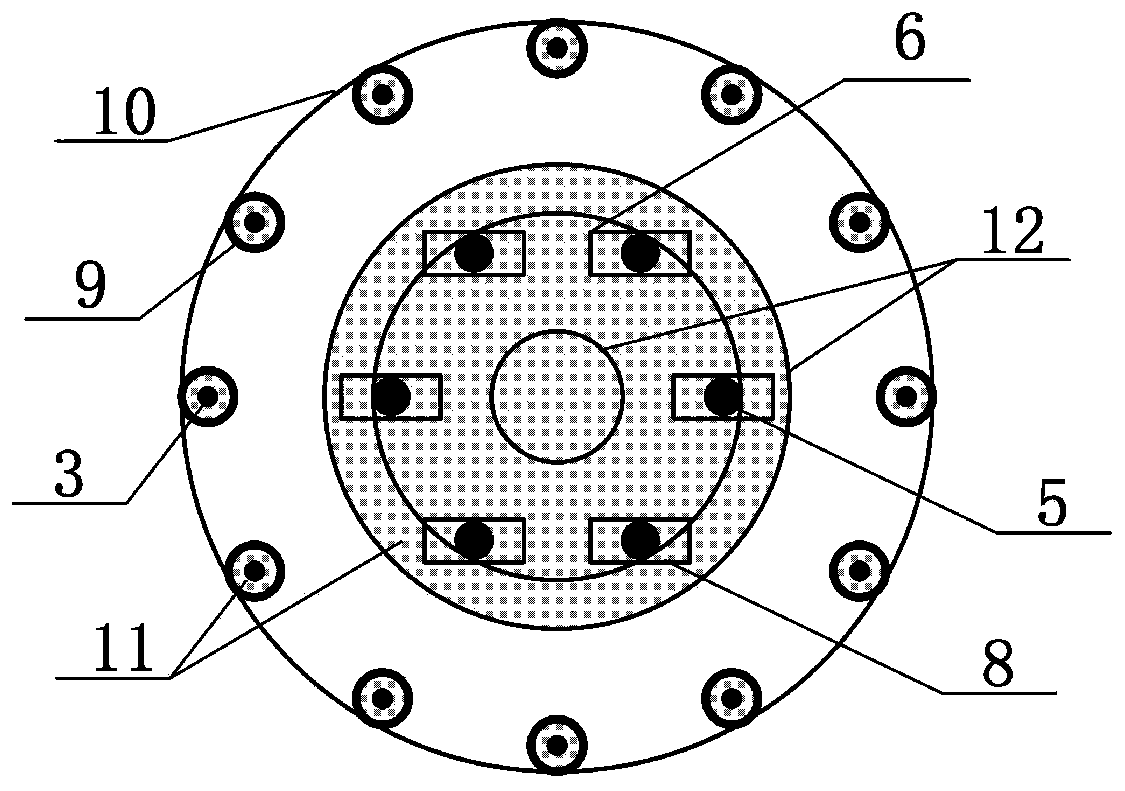

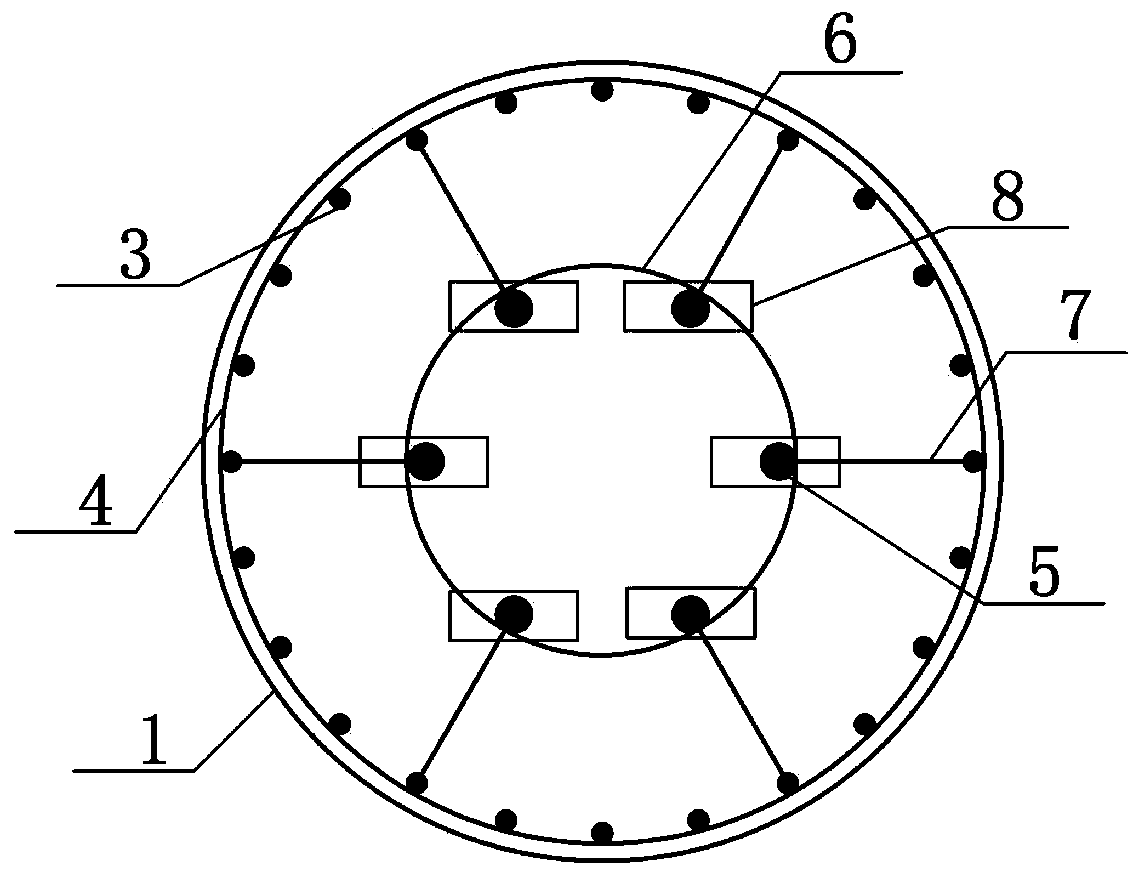

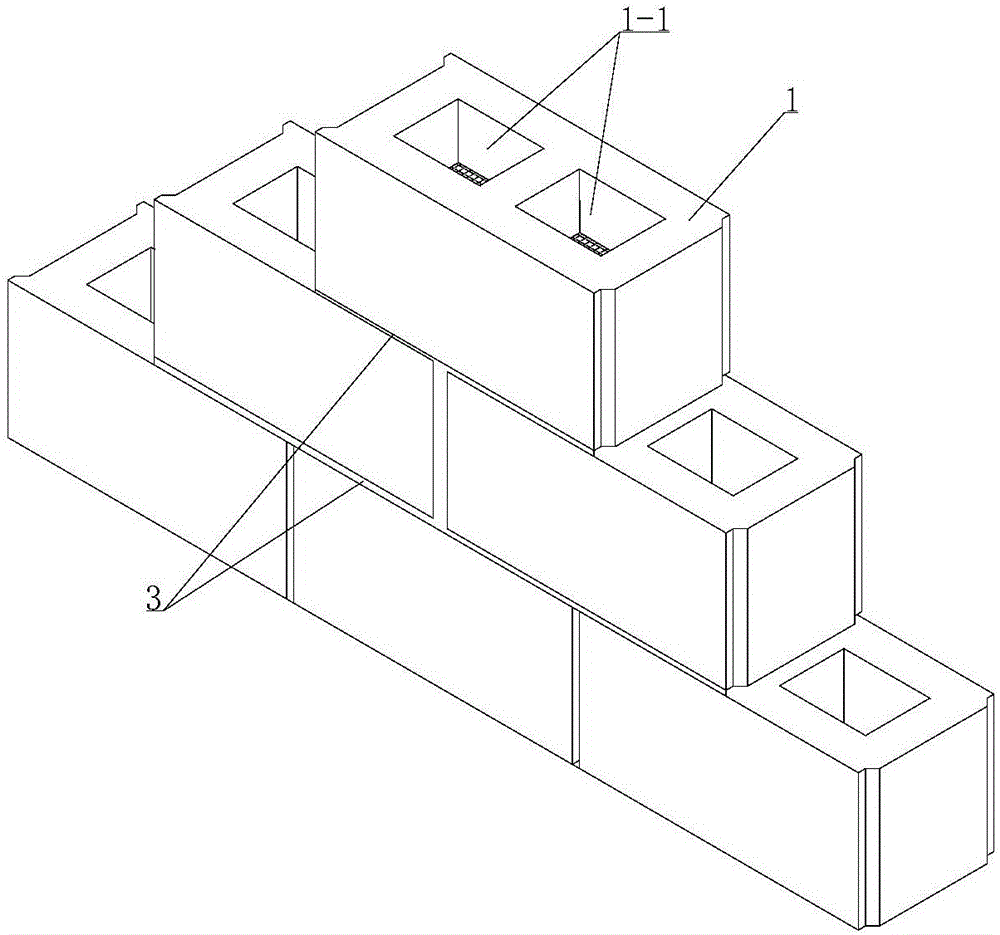

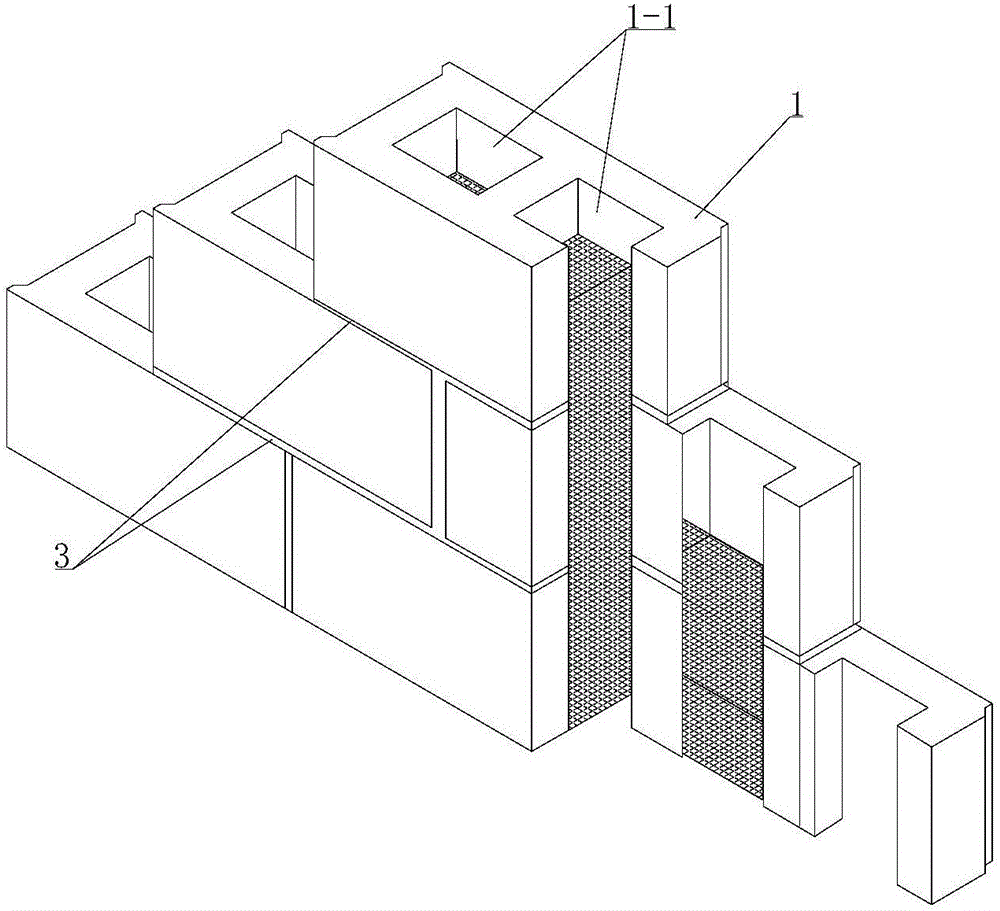

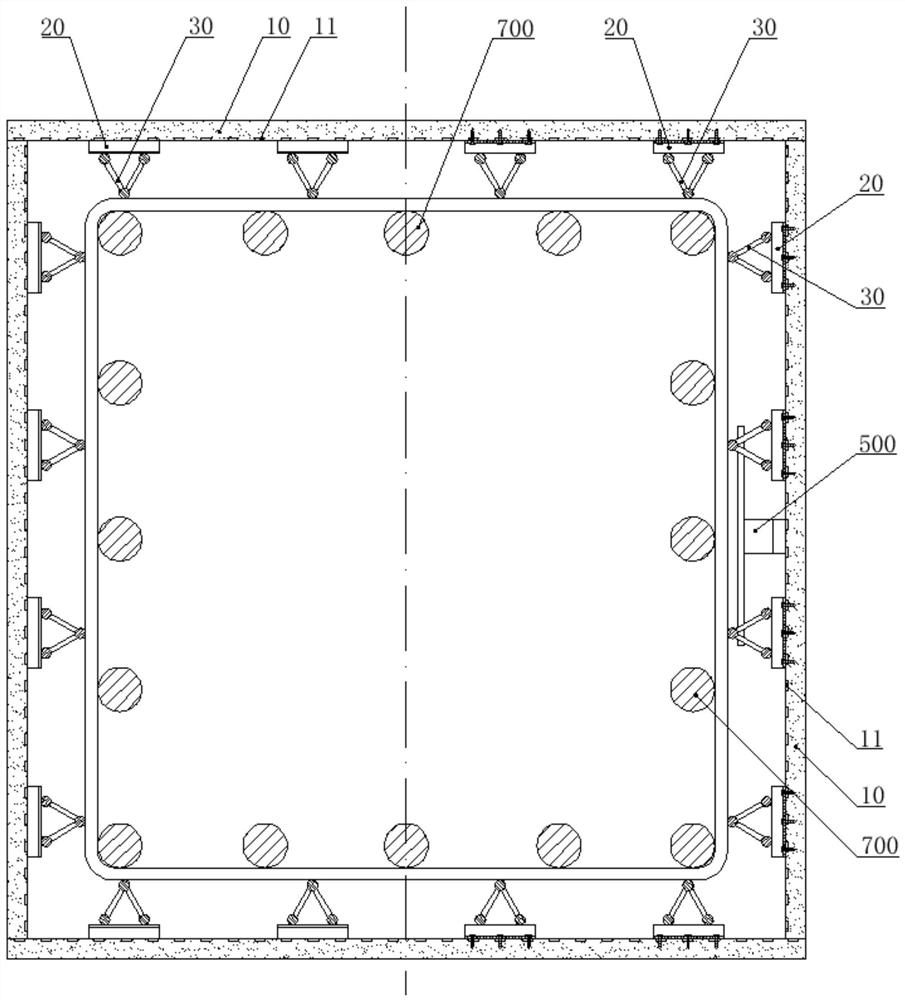

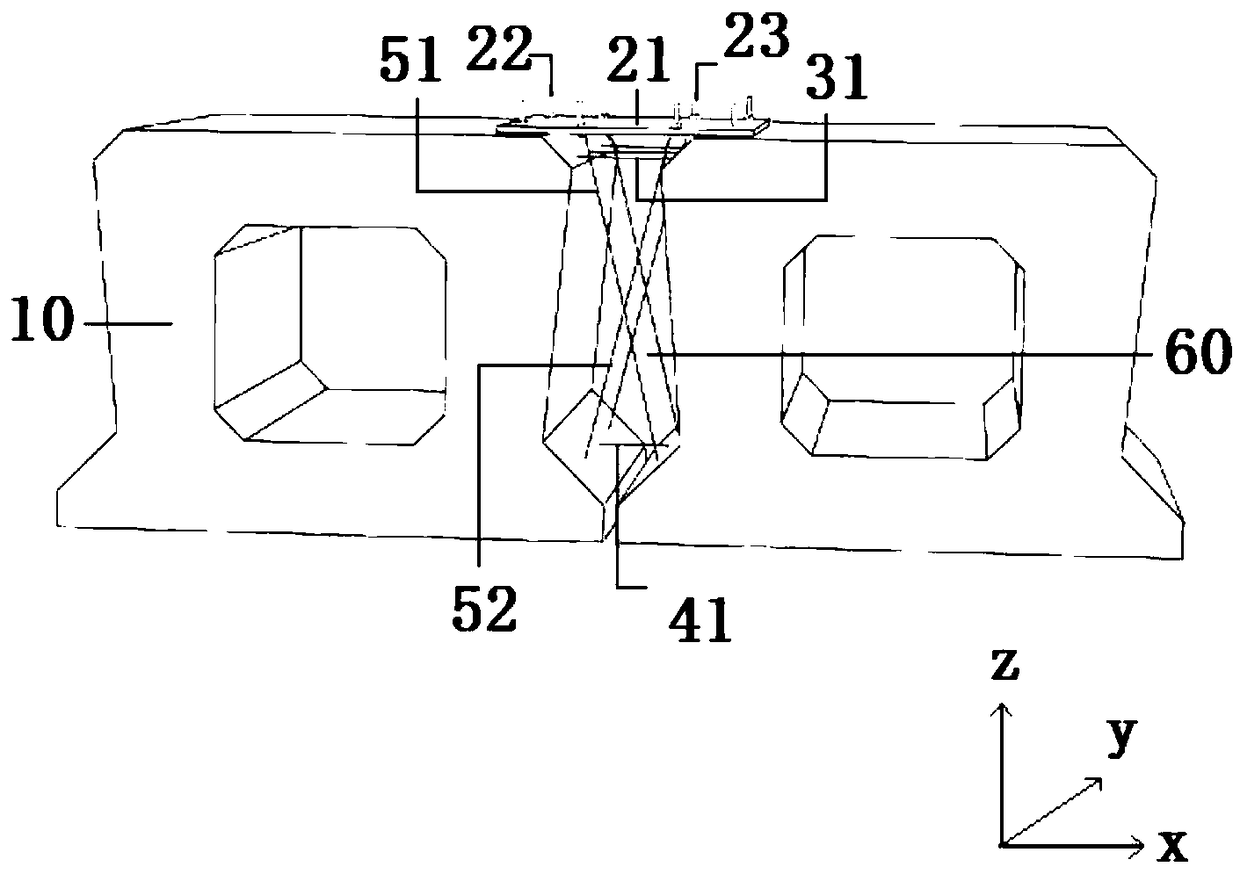

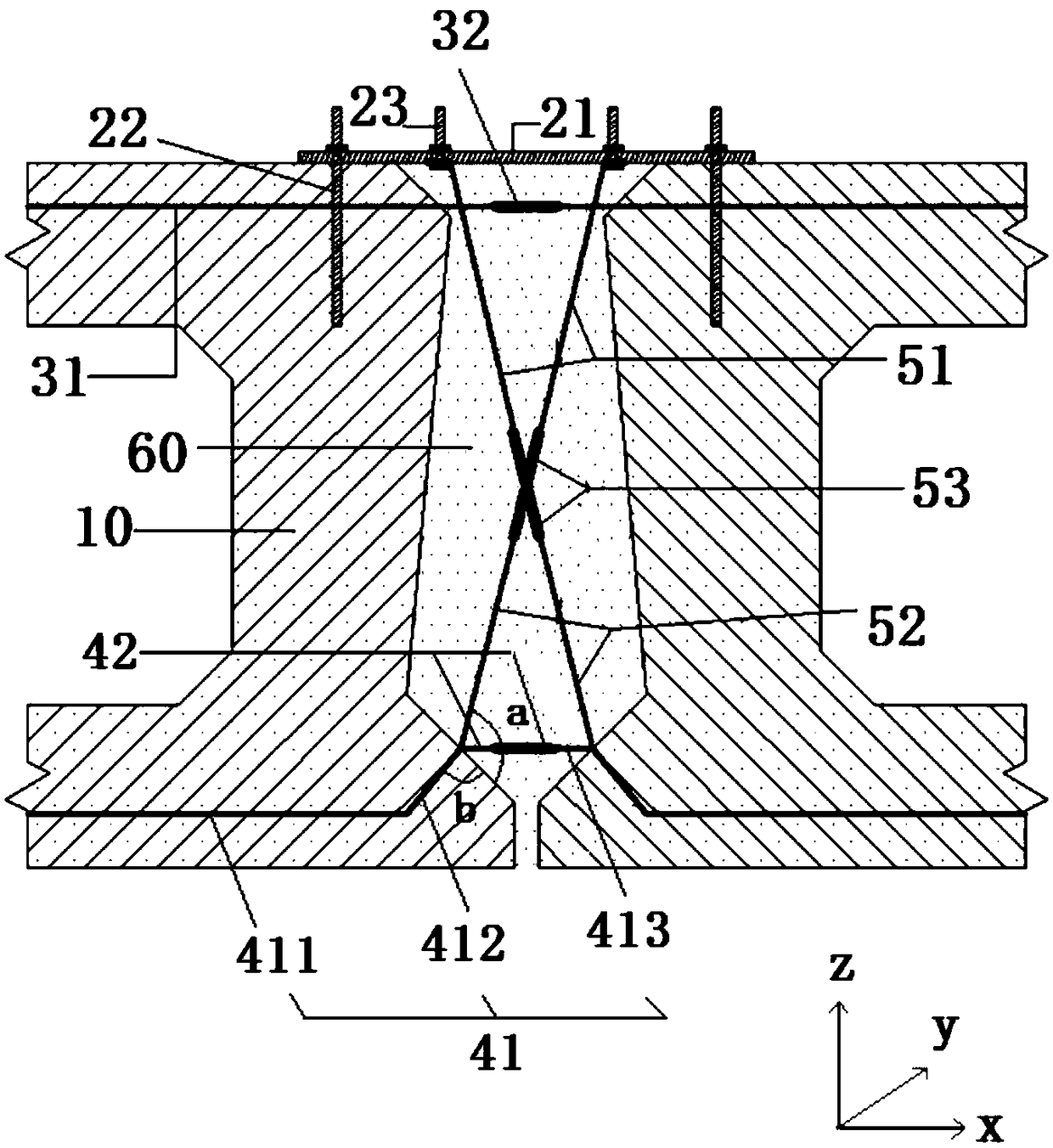

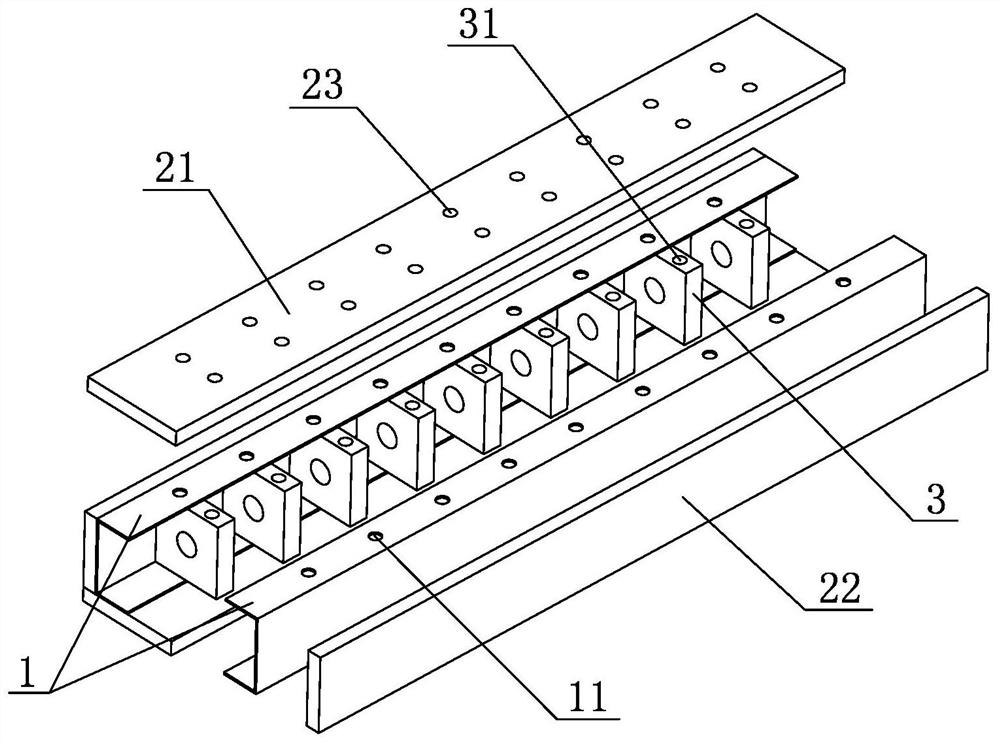

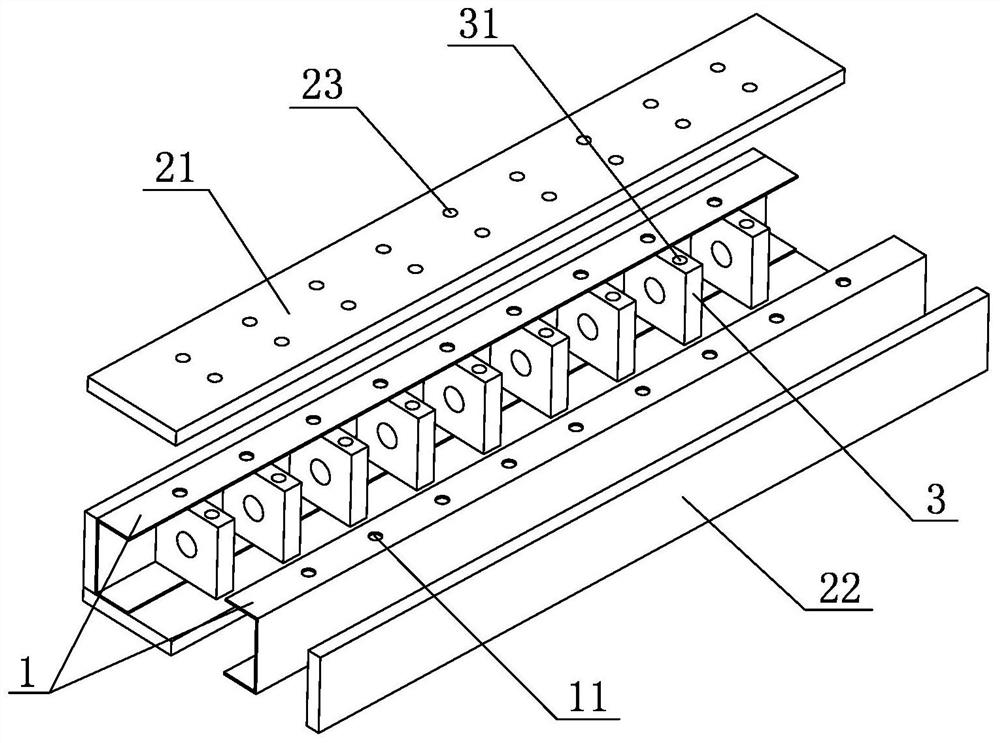

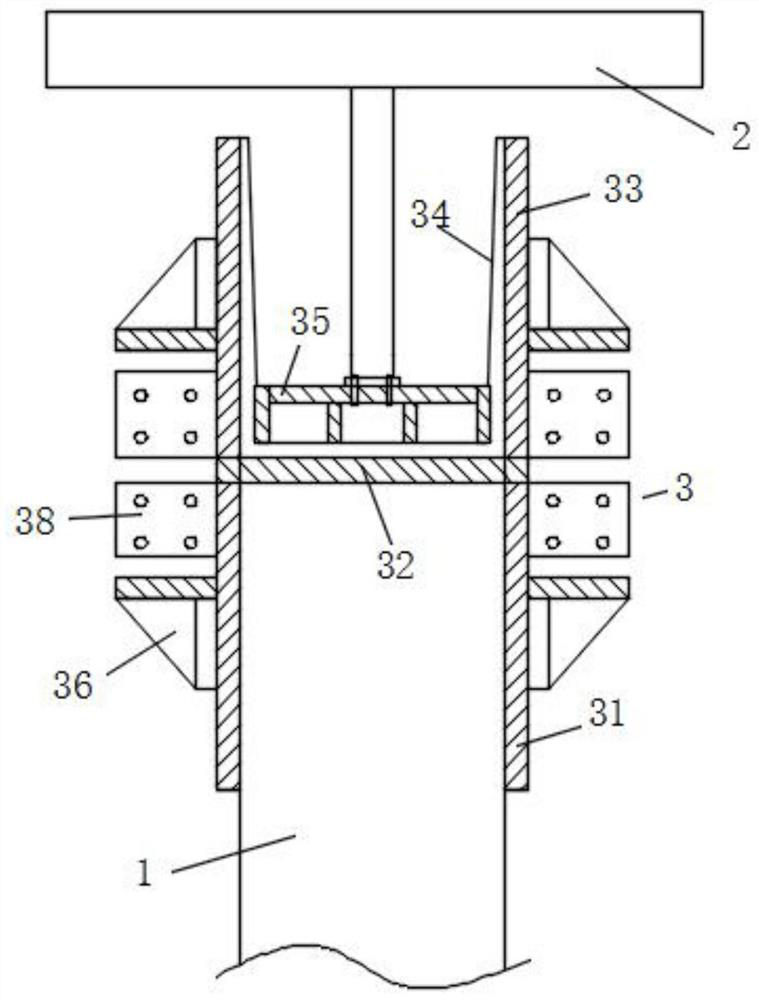

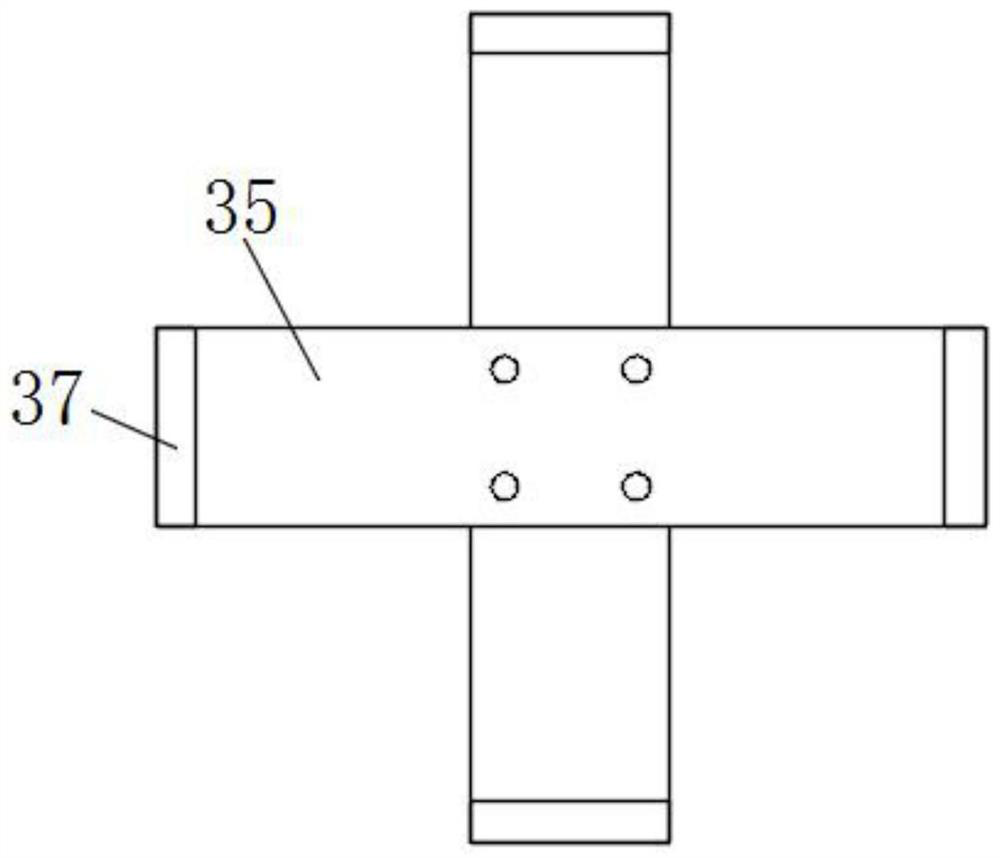

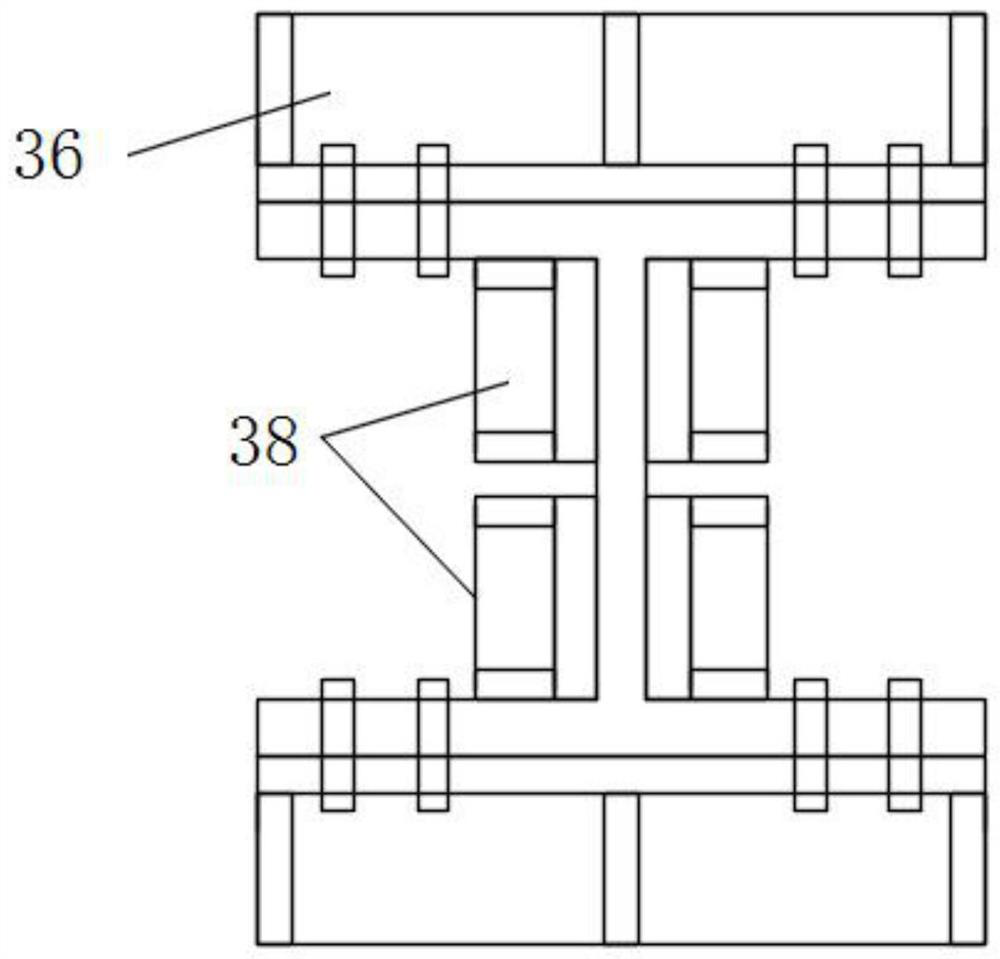

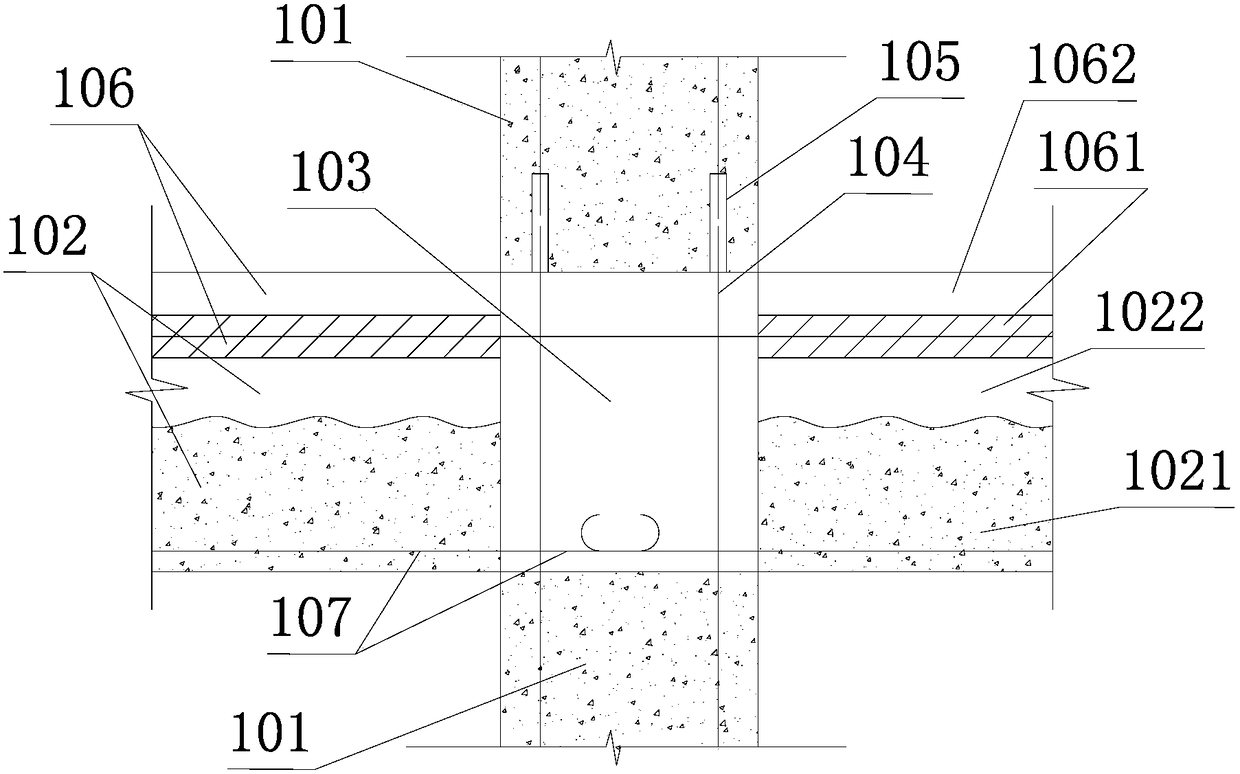

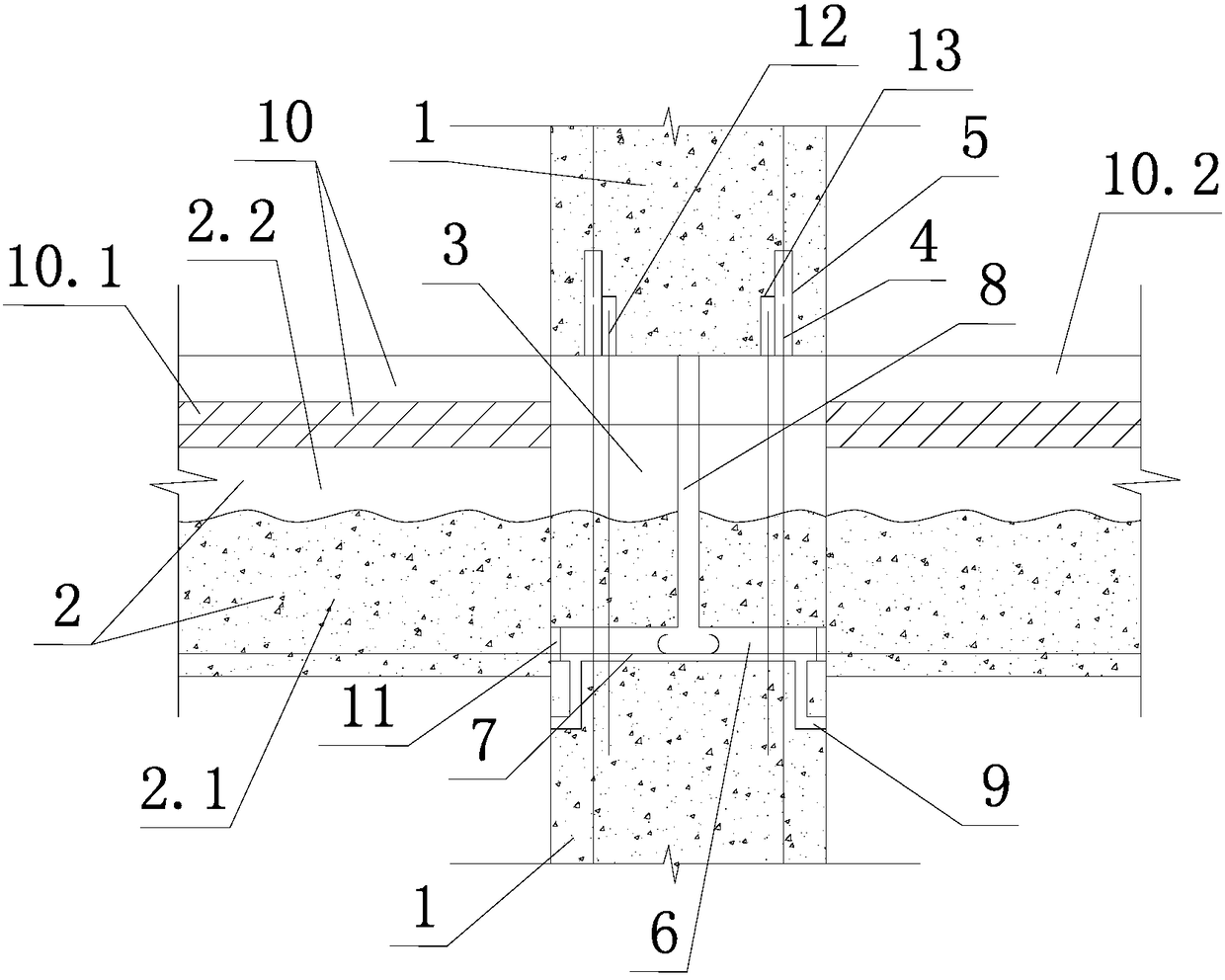

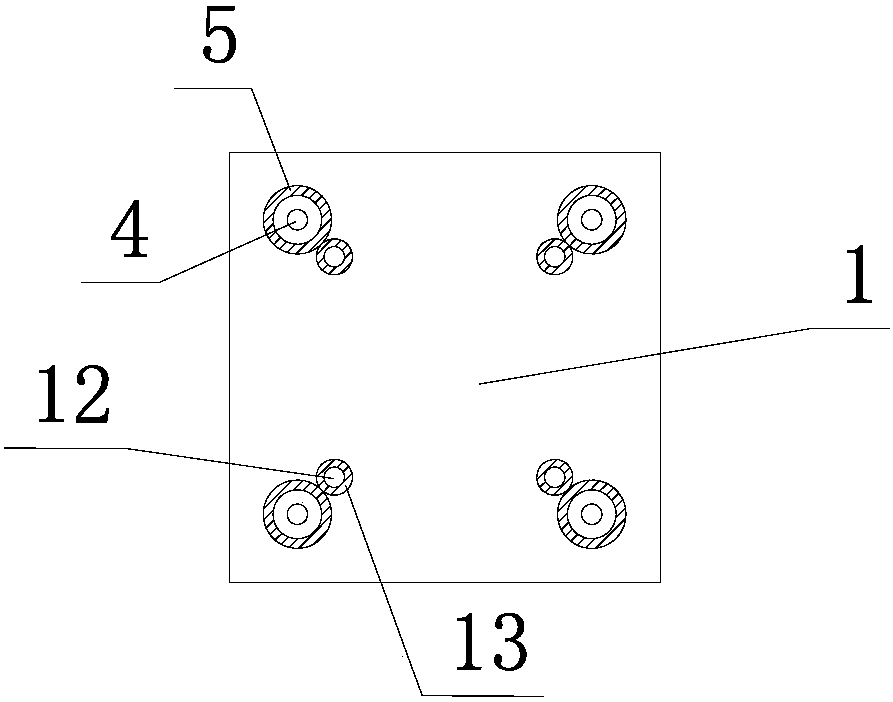

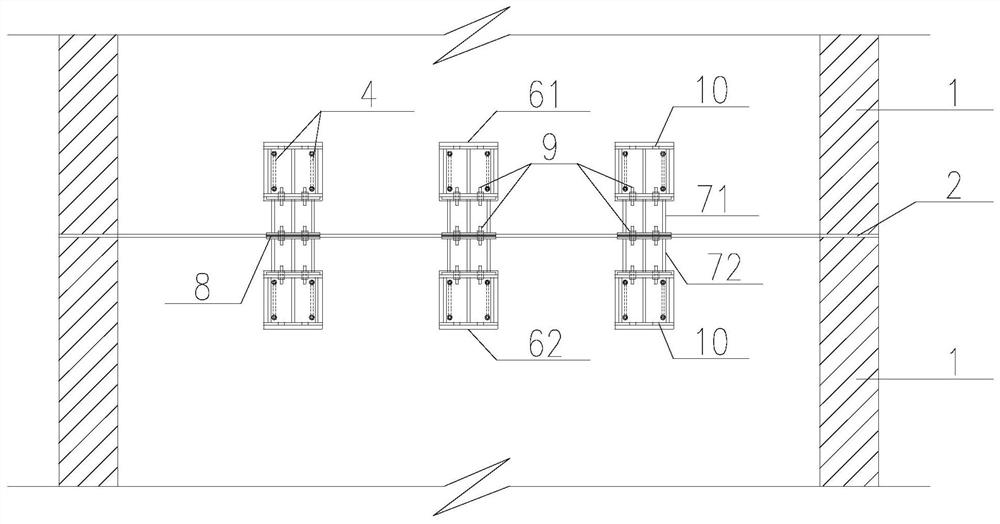

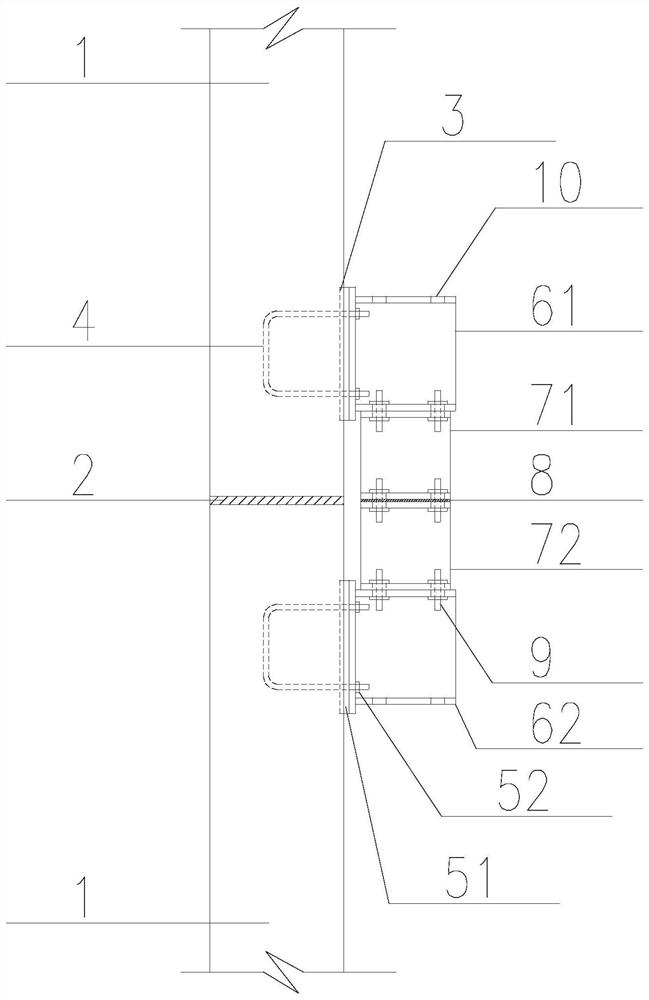

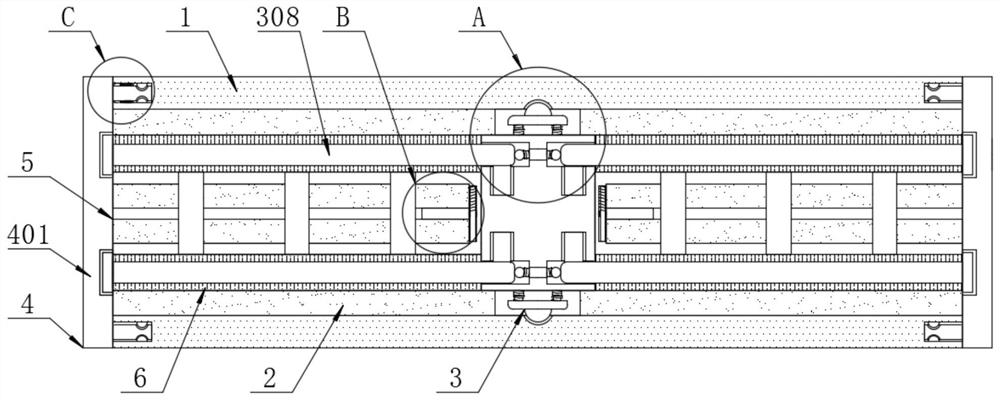

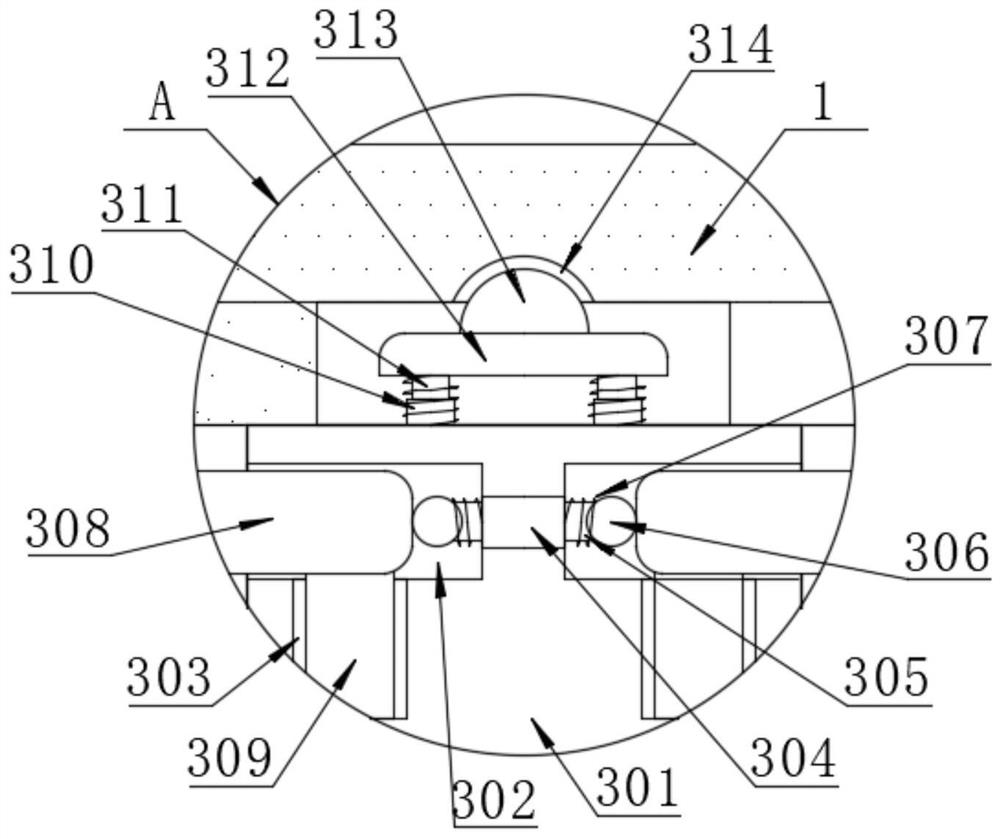

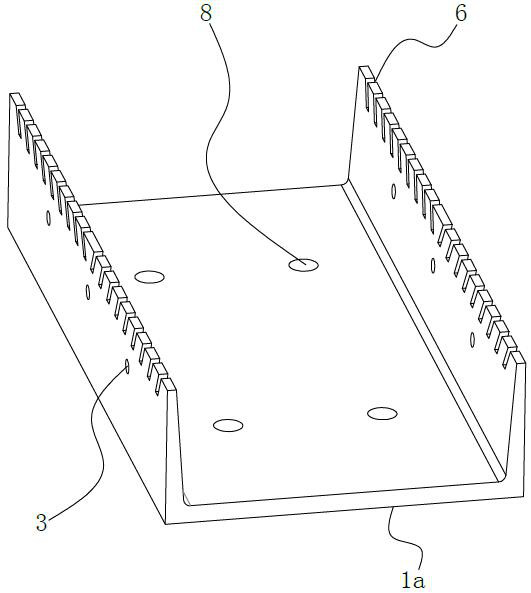

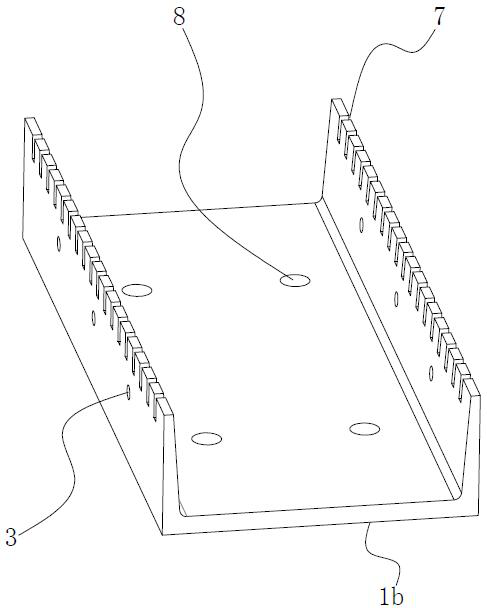

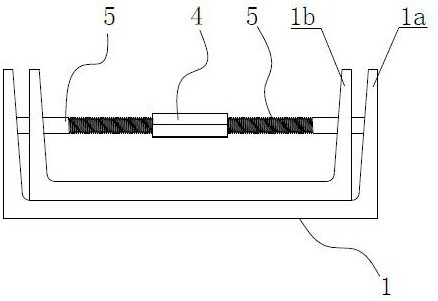

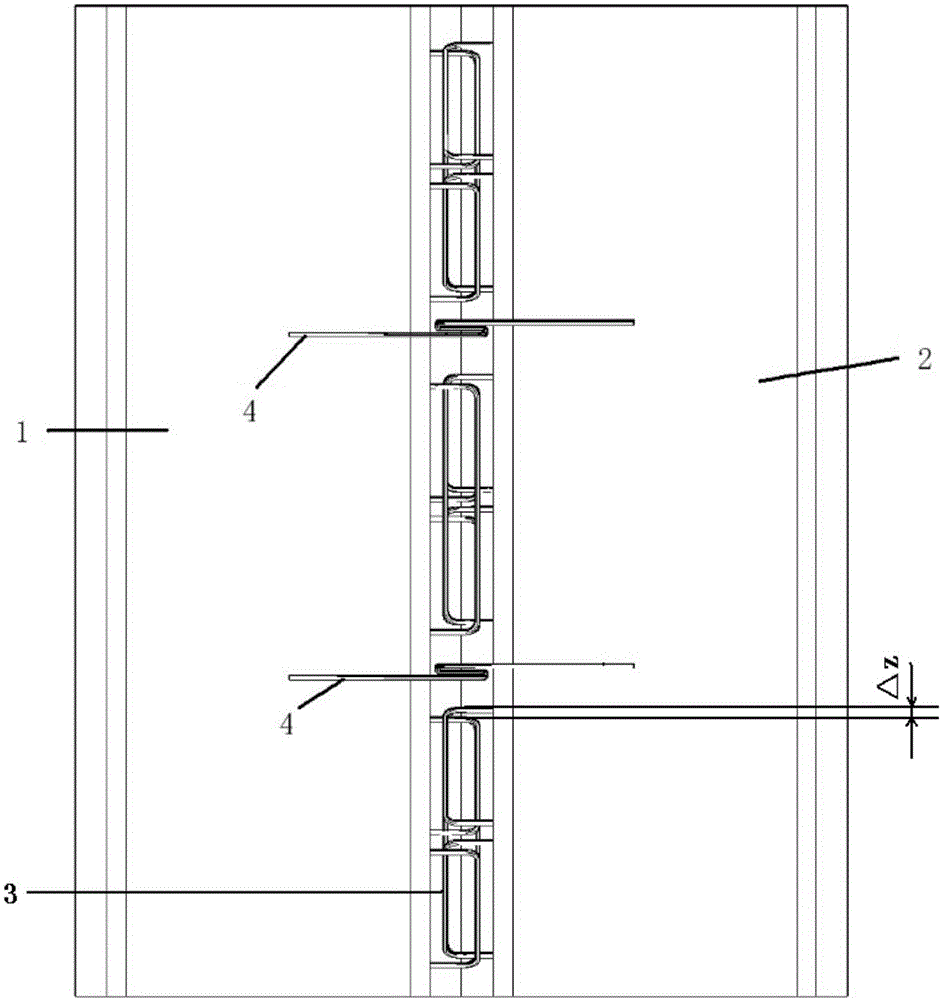

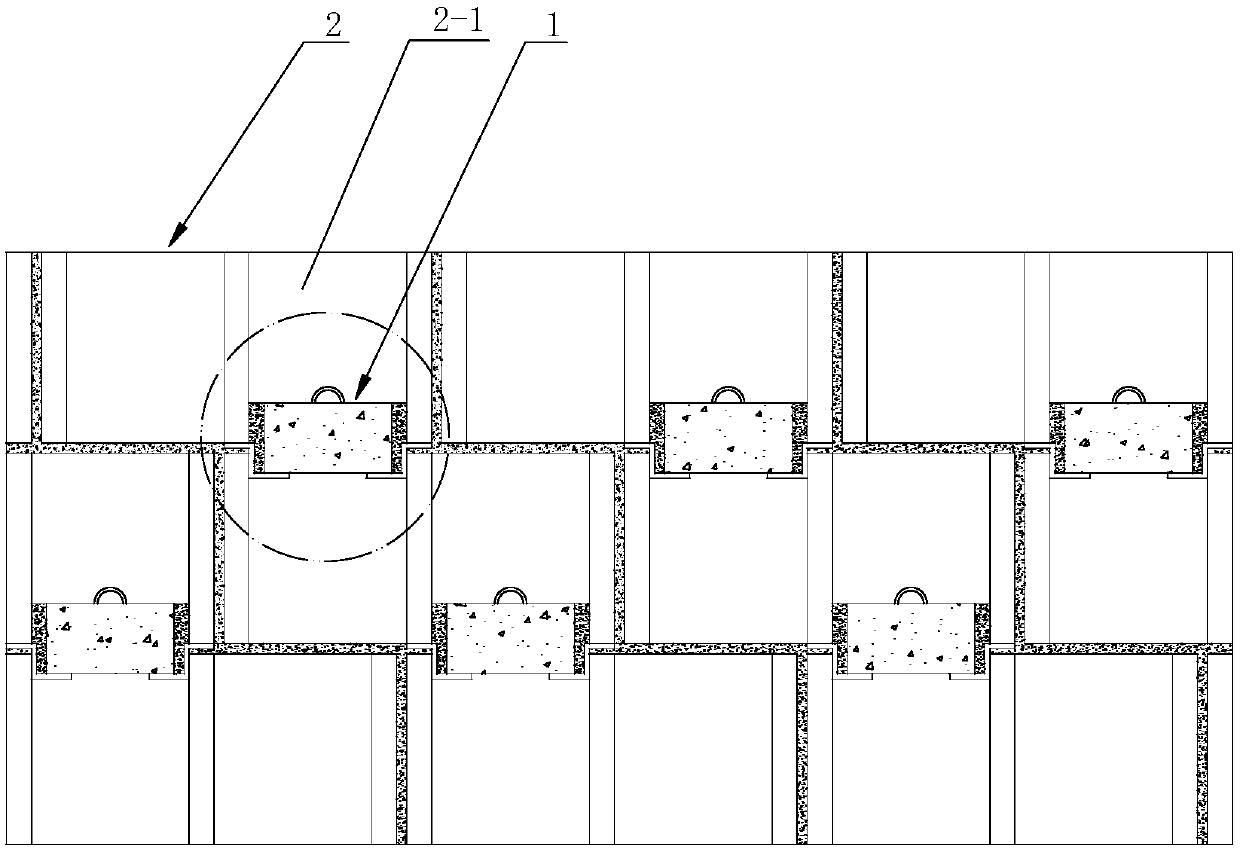

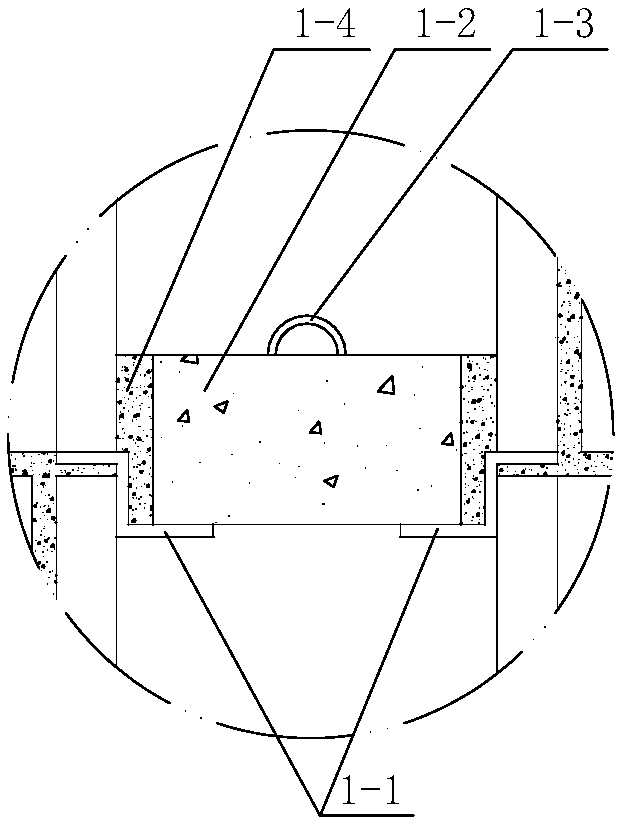

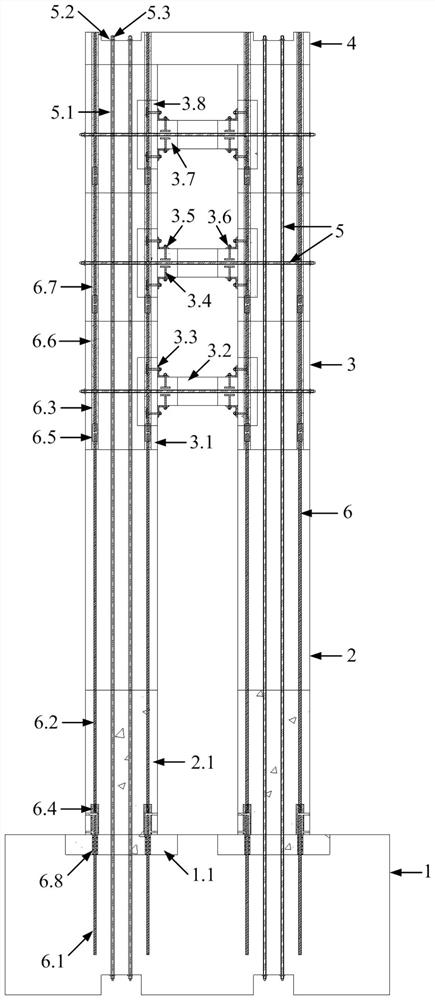

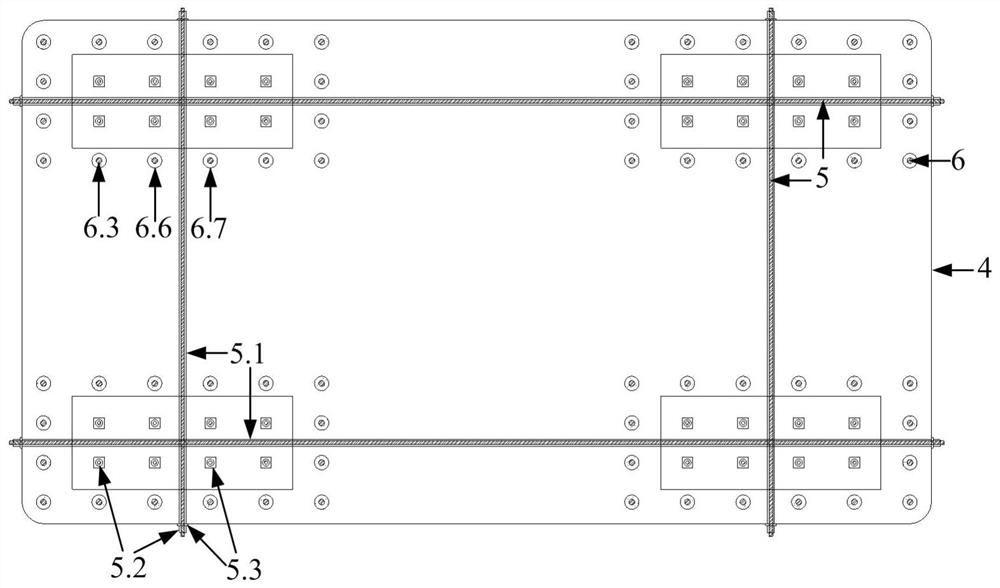

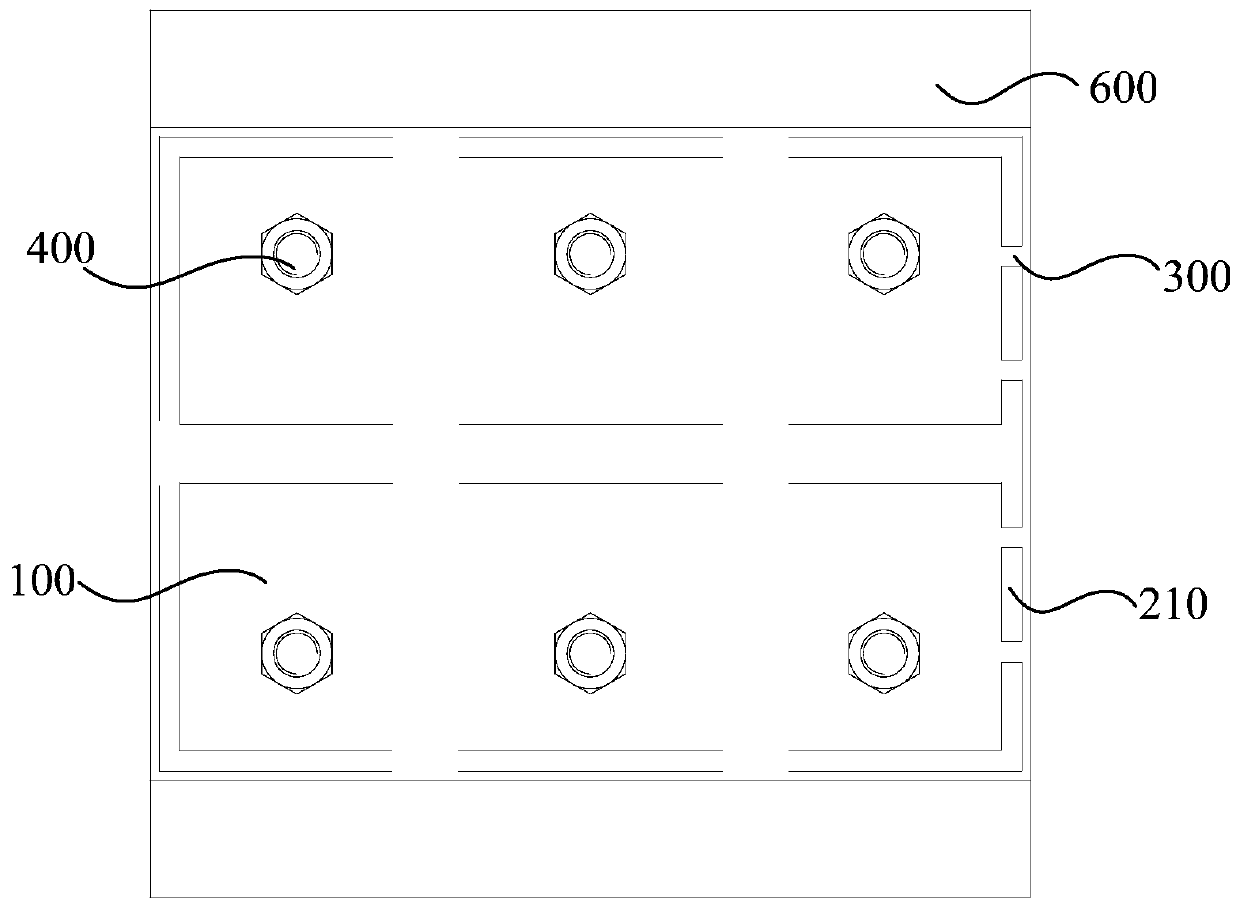

Connecting structure and method for precast column and beam and slab joints of concrete frame structure

ActiveCN106149878APrecise card positioningGuaranteed shear performanceBuilding constructionsGroutLaminated beam

The invention discloses a connecting structure and method for precast column and beam and slab joints of a concrete frame structure. The structure comprises upper and lower precast columns (1), laminated beams (2) on the two sides and a joint area (3). The top of the lower precast column (1) is flush with the laminated faces of precast beams (2.1) of the laminated beams (2) on the two sides, a transverse metal bellows (6) is arranged in the lower precast column (1) in a penetrating mode, and negative moment longitudinal force-bearing steel bars (7) at the bottoms of the precast beams (2.1) on the two sides stretch into and are anchored in the metal bellows (6). A grout pipe (8) communicated with the metal bellows (6) is anchored in the joint area (3). The method is characterized in that all the negative moment longitudinal force-bearing steel bars (7) at the bottoms of the precast beams (2.1) on the two sides stretch into the metal bellows (6) of the lower precast column (1) and are anchored. By means of the structure and the method, it can be avoided that operation at joints is difficult due to the narrow space, and the use amount of cast-in-place concrete can be reduced.

Owner:NINGBO PRECA CONSTR TECH CO LTD

Highly seismic region prefabricated assembled bridge central pier stud-cover beam node pouring connection mode and construction

PendingCN110804944ABuild fastImprove construction fault toleranceBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses a highly seismic region prefabricated assembled bridge central pier stud-cover beam node pouring connection mode and construction and belongs to the field of bridge engineering. The construction comprises a prefabricated pier stud and a prefabricated cover beam. The prefabricated pier stud and the prefabricated cover beam are connected into a bridge pier system through pouring of high-performance materials and splicing. The prefabricated pier stud is composed of a pier stud longitudinal bar, a pier stud stirrup, an overlap-joint large-diameter longitudinal bar, an overlap-joint stirrup and an inclined rebar jointly. The prefabricated cover beam comprises a grouting pipeline, a cover beam construction stirrup and a pouring inserting groove. The splicing quantity of the pier stud longitudinal bar is only a half or much less of the total quantity of longitudinal stressed rebars, and high-performance materials are adopted for pouring splicing. Small damage to a post-earthquake pier stud plastic hinge region is ensured while a large-diameter overlap joint longitudinal bar meets the bridge anti-seismic requirement in a highly seismic region. The bridge building speed can be increased greatly and construction convenience is improved greatly while the bridge anti-seismic requirement in the highly seismic region is met and construction quality is ensured, and a completely novel technical solution can be provided for prefabricated assembled bridge engineering application in the highly seismic region.

Owner:BEIJING UNIV OF TECH

Reinforced masonry wall structure filled with rammed earth and construction method thereof

InactiveCN105839811AGuaranteed compactnessGive full play to the effect of shear reinforcementWallsLap jointRare earth

The invention discloses a reinforced masonry wall structure filled with rammed earth and a construction method thereof. The masonry wall structure is formed by bonding a plurality of hollow blocks with mortar, wherein the hollow blocks are arranged in sequence in the vertical direction. Every two hollow blocks adjacent in the vertical direction are connected in a staggered-seam lap joint mode, cavities of the hollow blocks are aligned one by one, and thus through cavities extending from first hollow blocks to the top hollow blocks are formed; all the through cavities are filled with rammed earth, and thus rammed earth core columns are formed. The construction method includes the steps that firstly, bottom mortar is laid, and the first hollow blocks are stacked on the bottom mortar; secondly, mortar is smeared on the upper surfaces of the first hollow blocks, the second hollow blocks are stacked in a staggered-seam lap joint mode, and the cavities are completely aligned in the vertical direction; thirdly, the cavities of the blocks are filled with mixed raw earth, and filling and ramming are performed at the same time till the 1 / 3-1 / 2 height position of the second hollow blocks is reached; fourthly, the third hollow blocks are built and then filled with raw earth, ramming is performed till the 1 / 3-1 / 2 height position of the third hollow blocks is reached, and the process is performed in this way till the last hollow block is built and the cavities are full of the rammed earth. The anti-shear property and integrality of the masonry wall are guaranteed.

Owner:TIANJIN CHENGJIAN UNIV

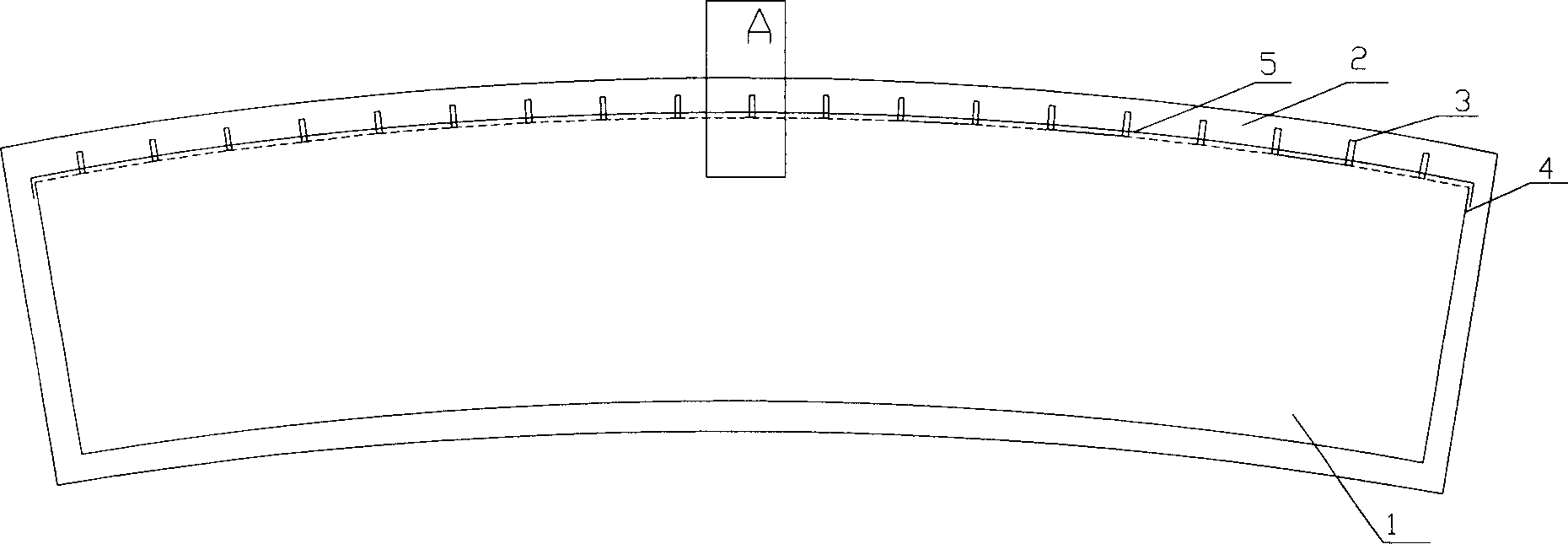

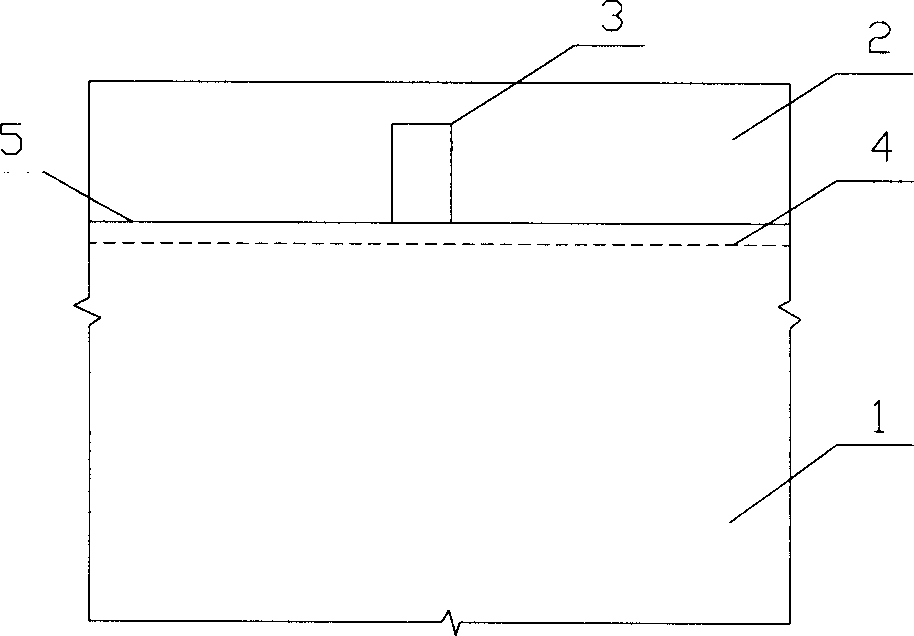

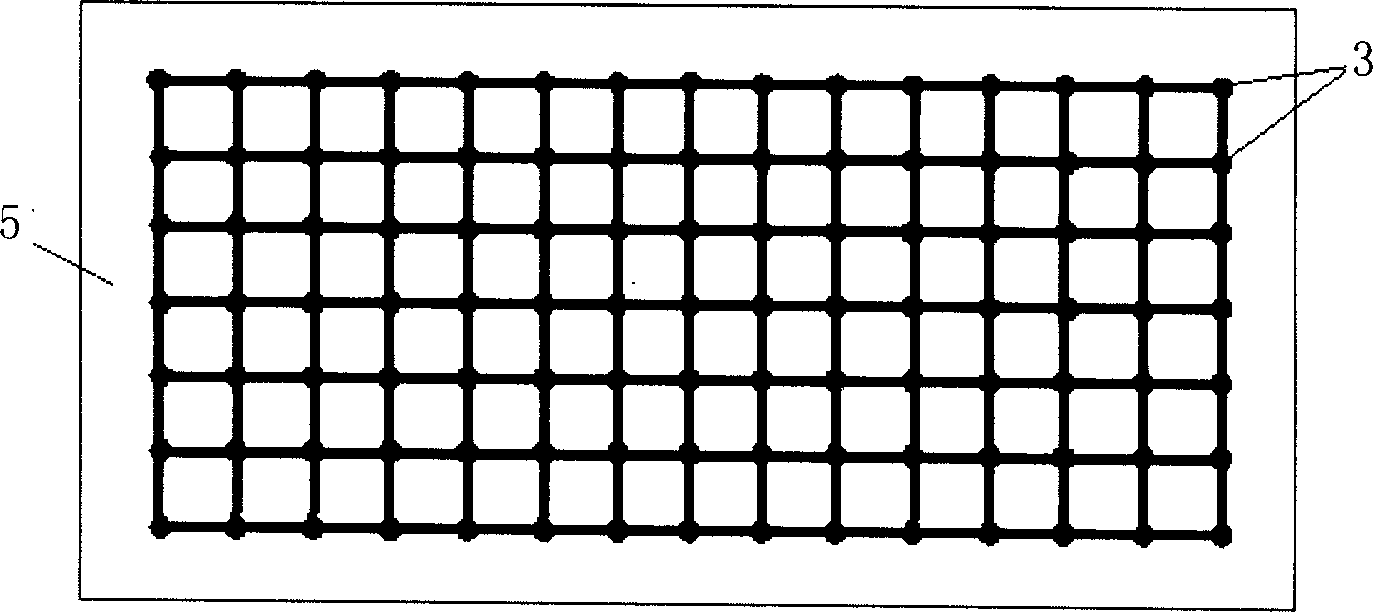

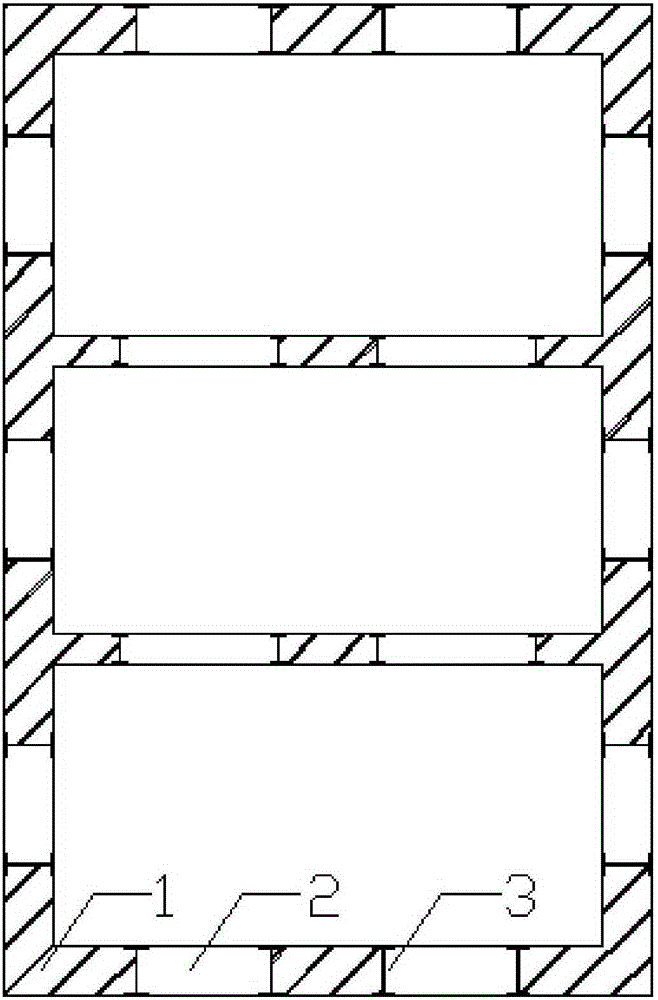

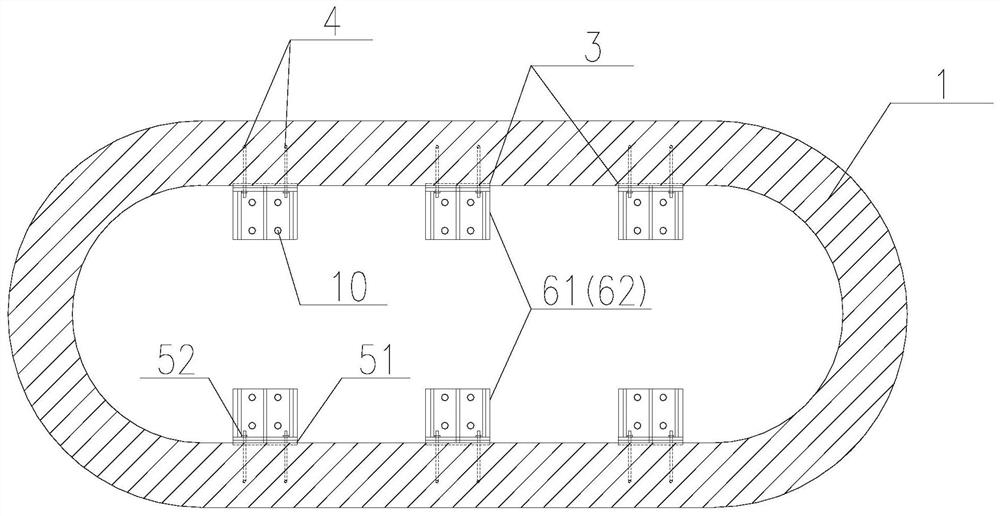

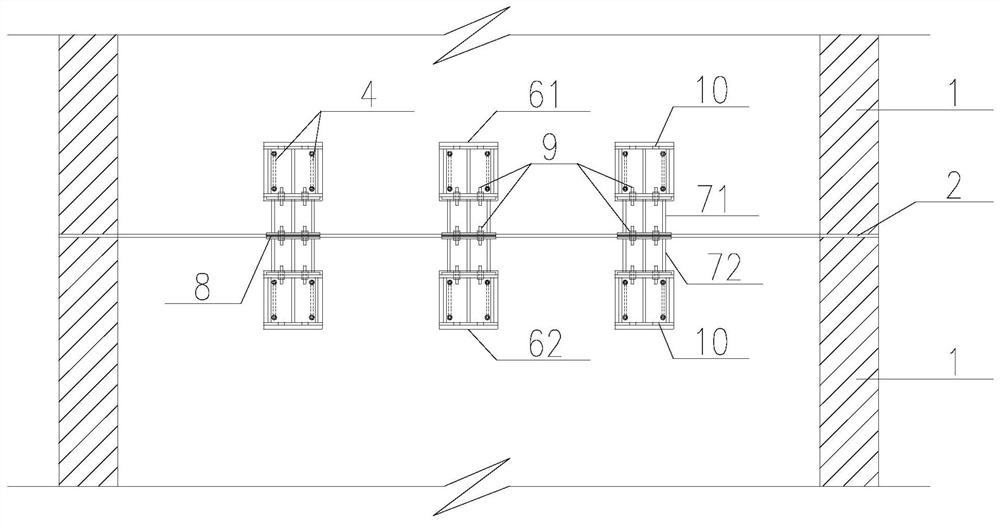

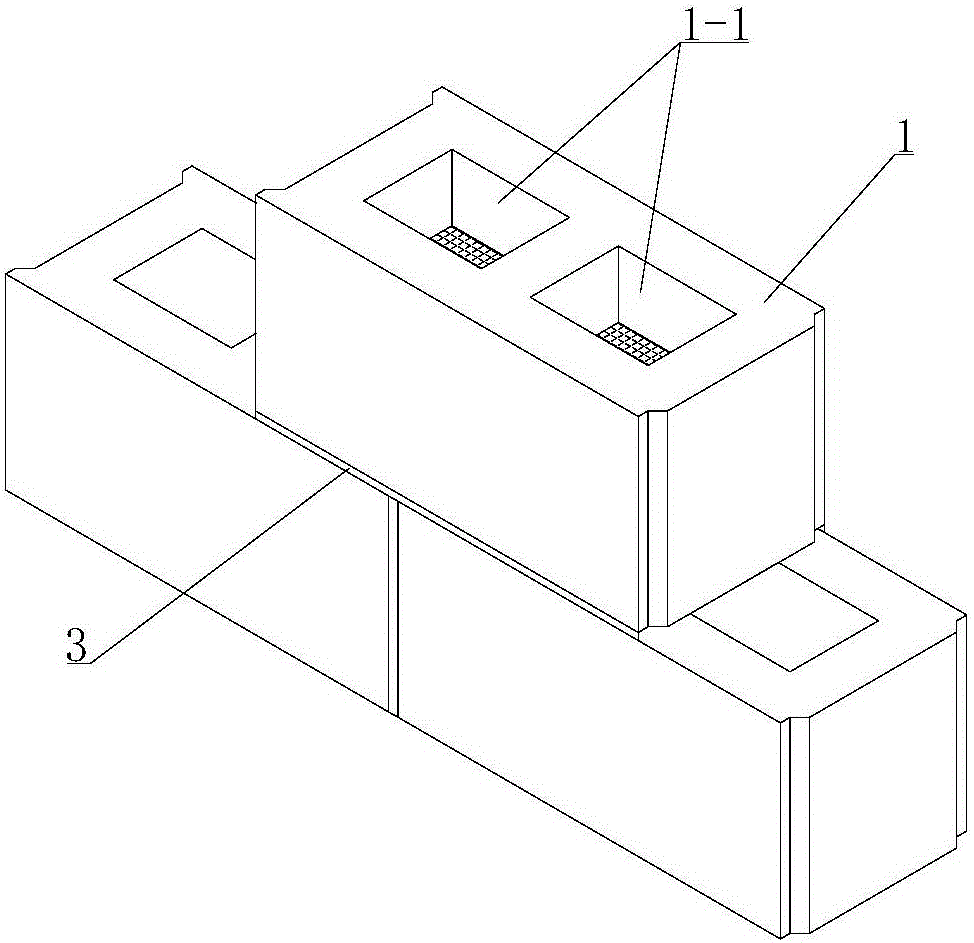

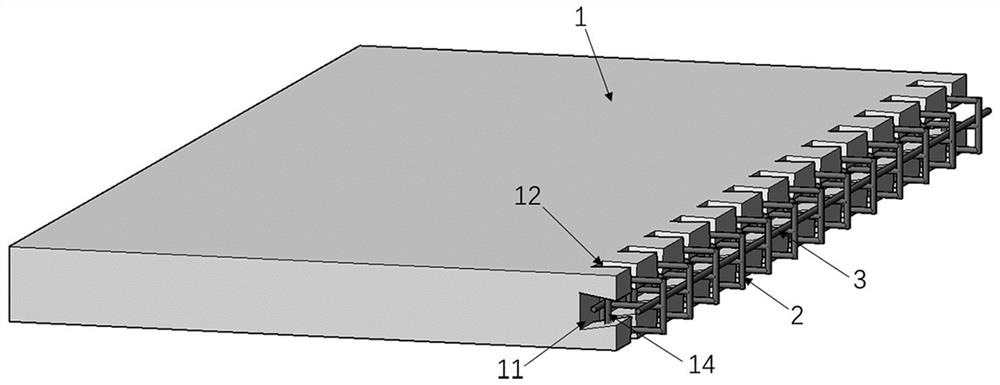

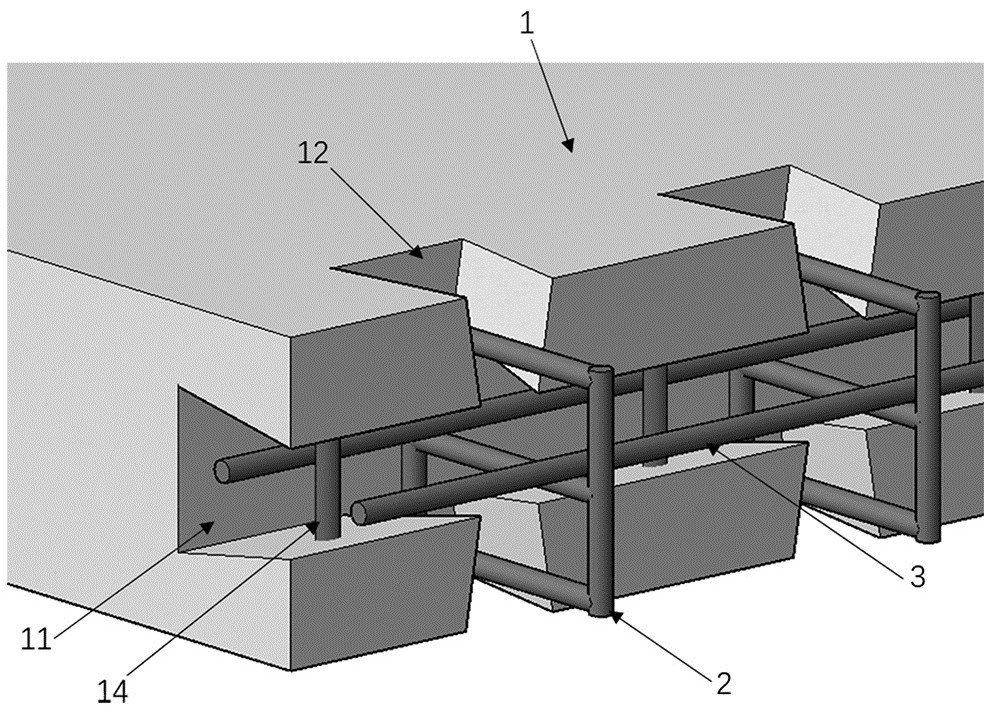

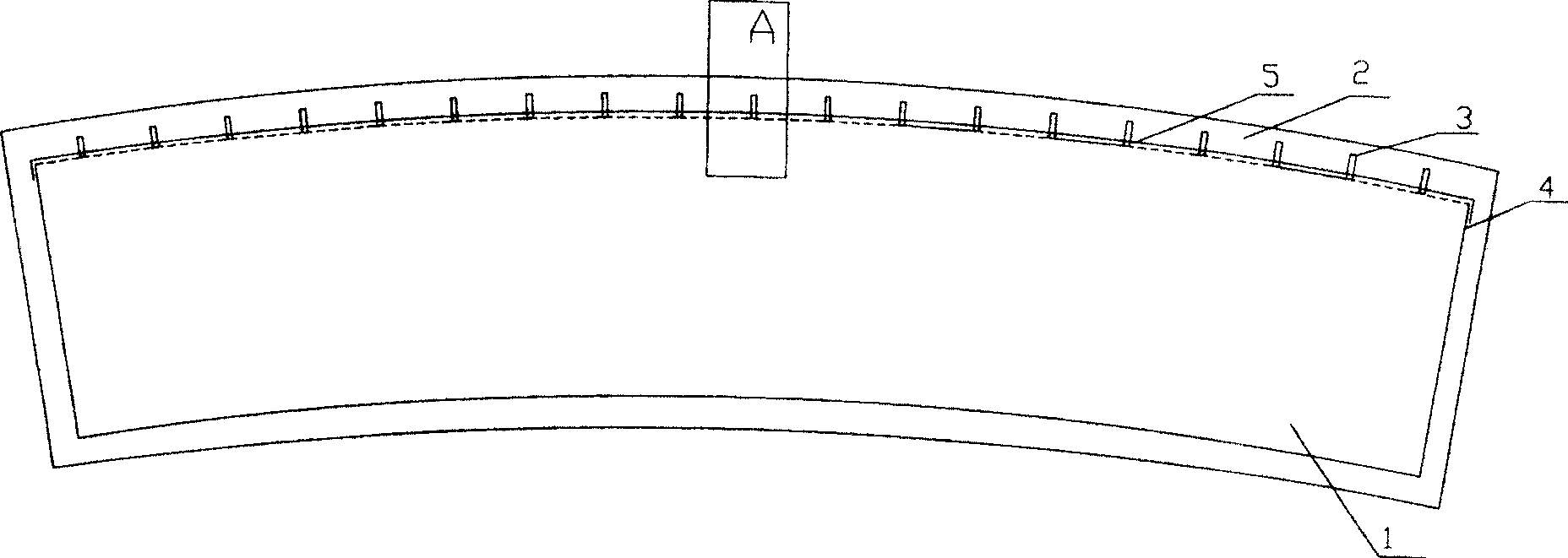

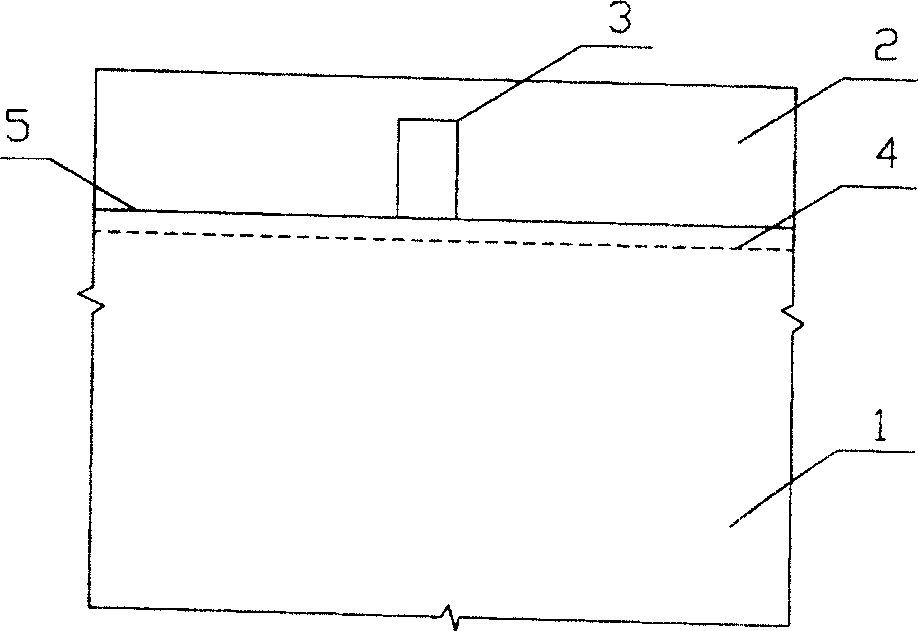

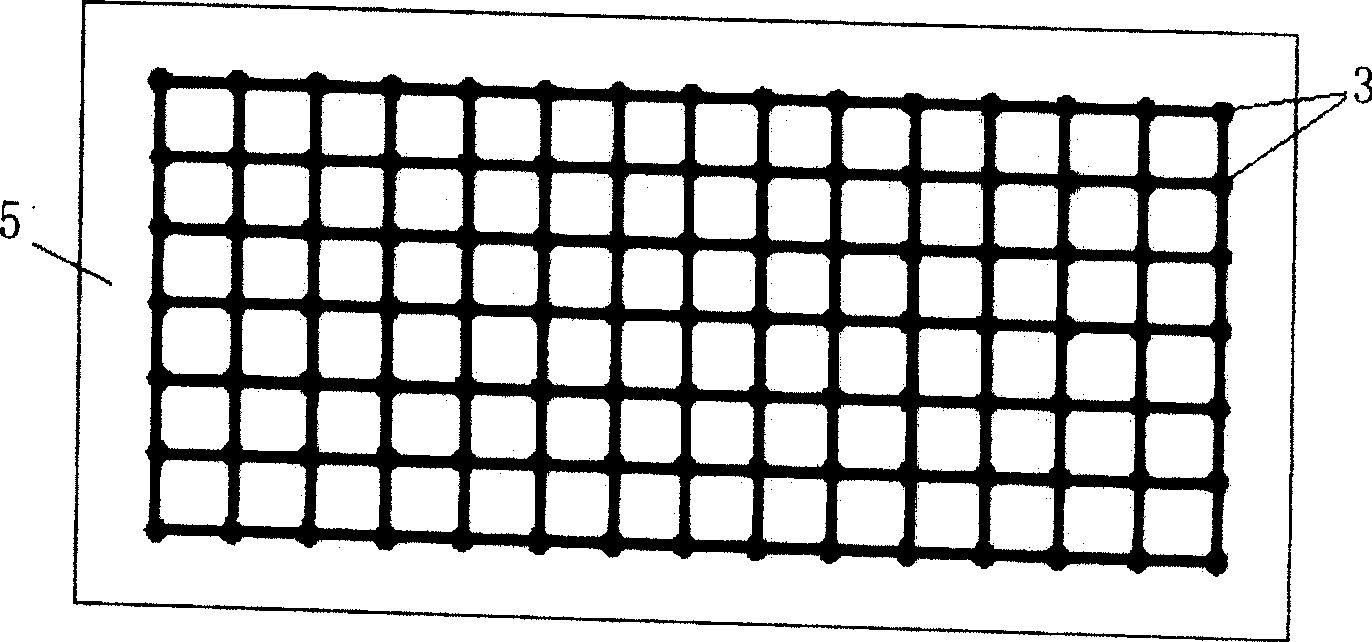

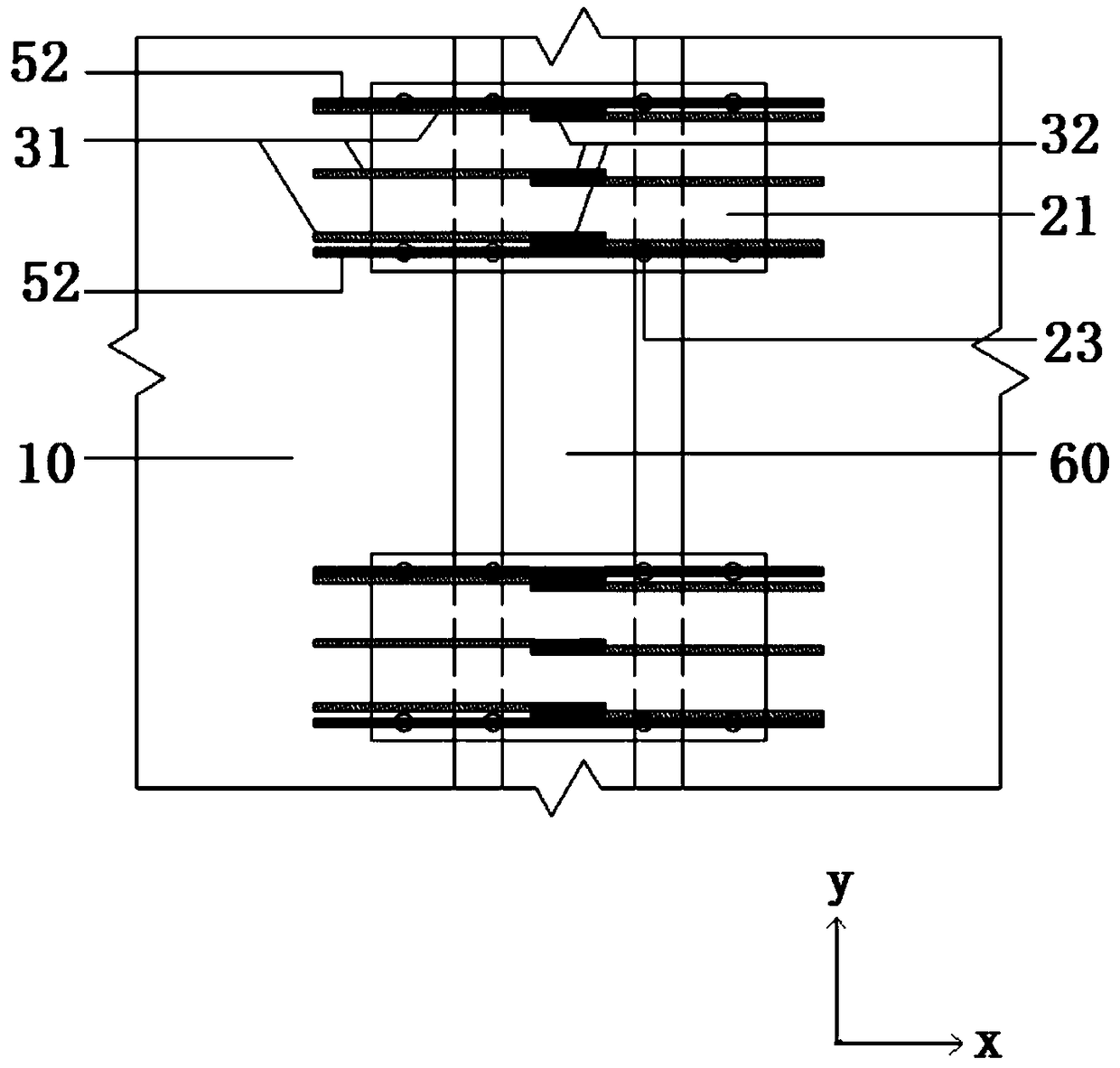

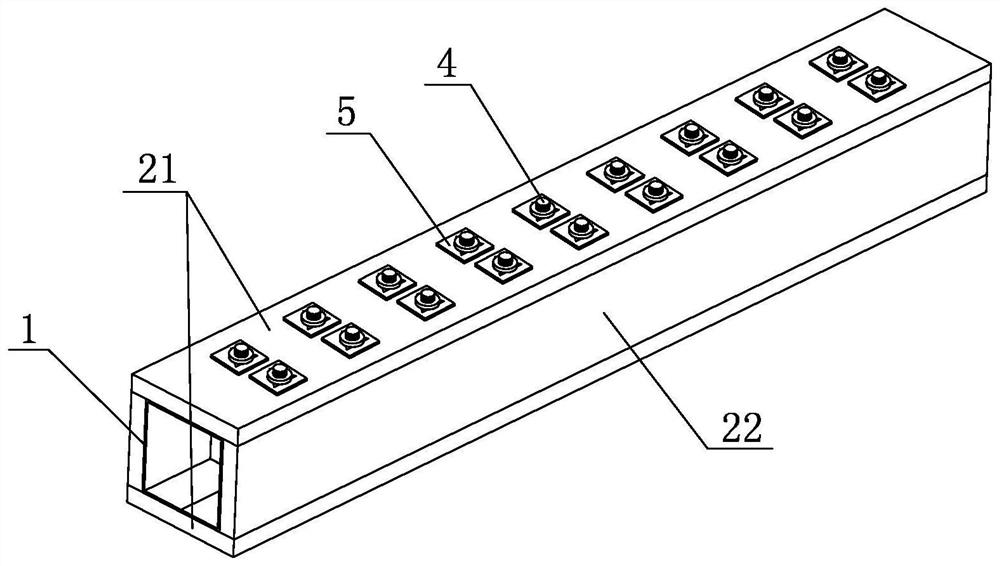

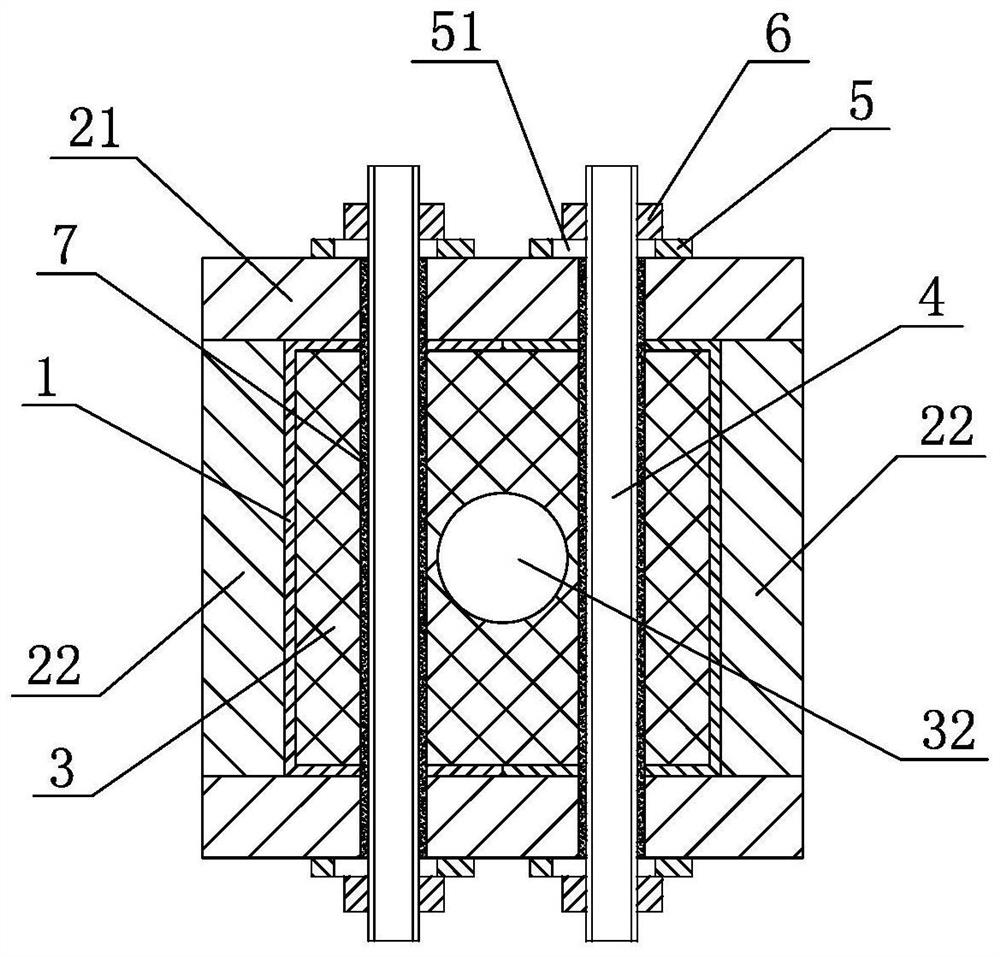

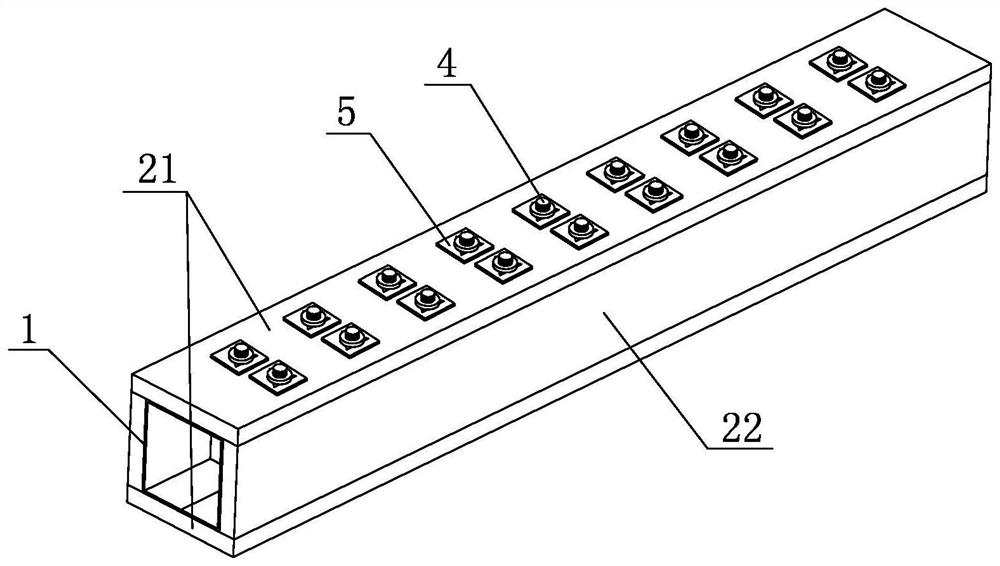

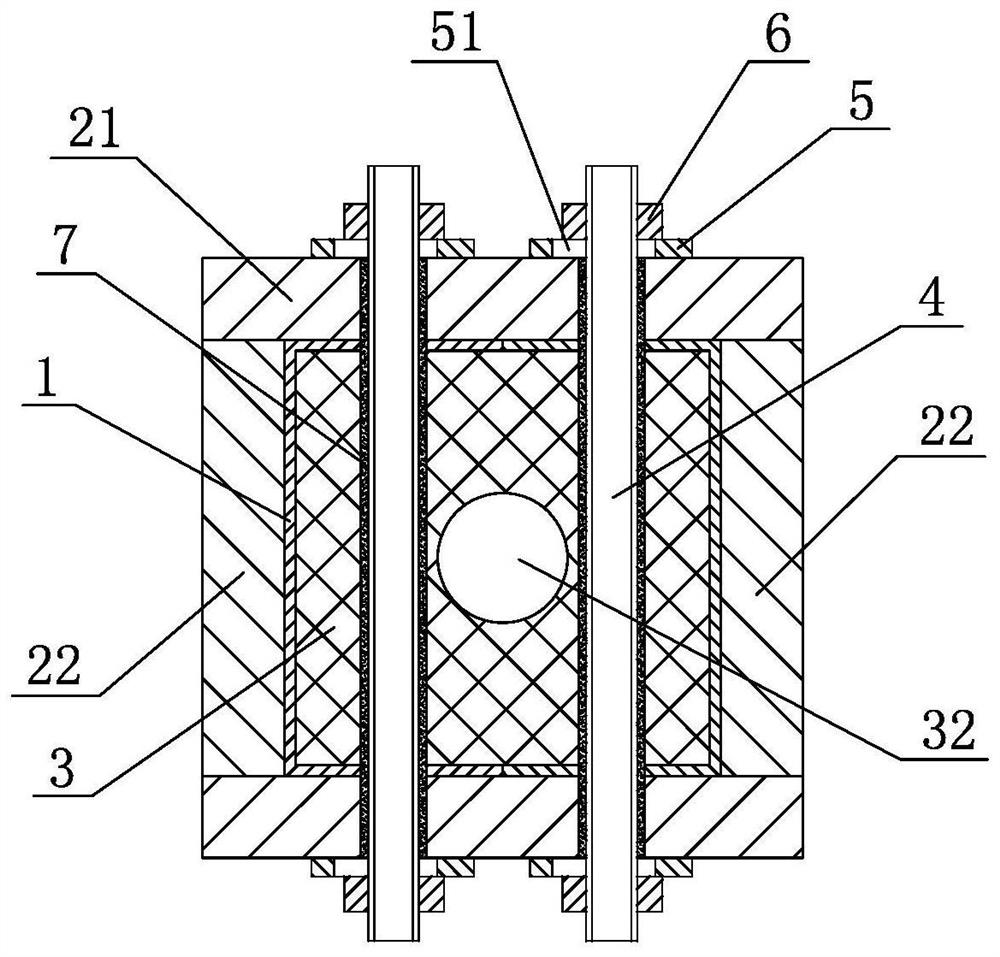

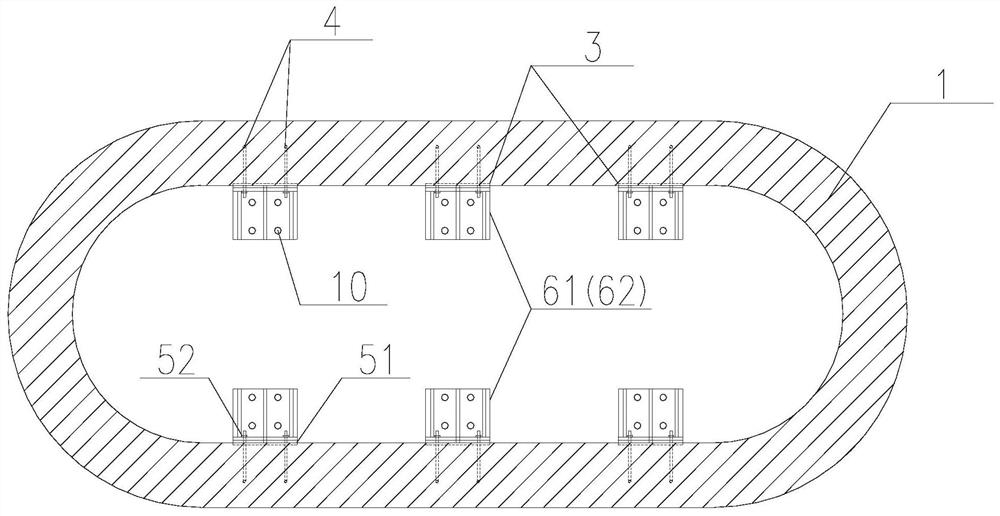

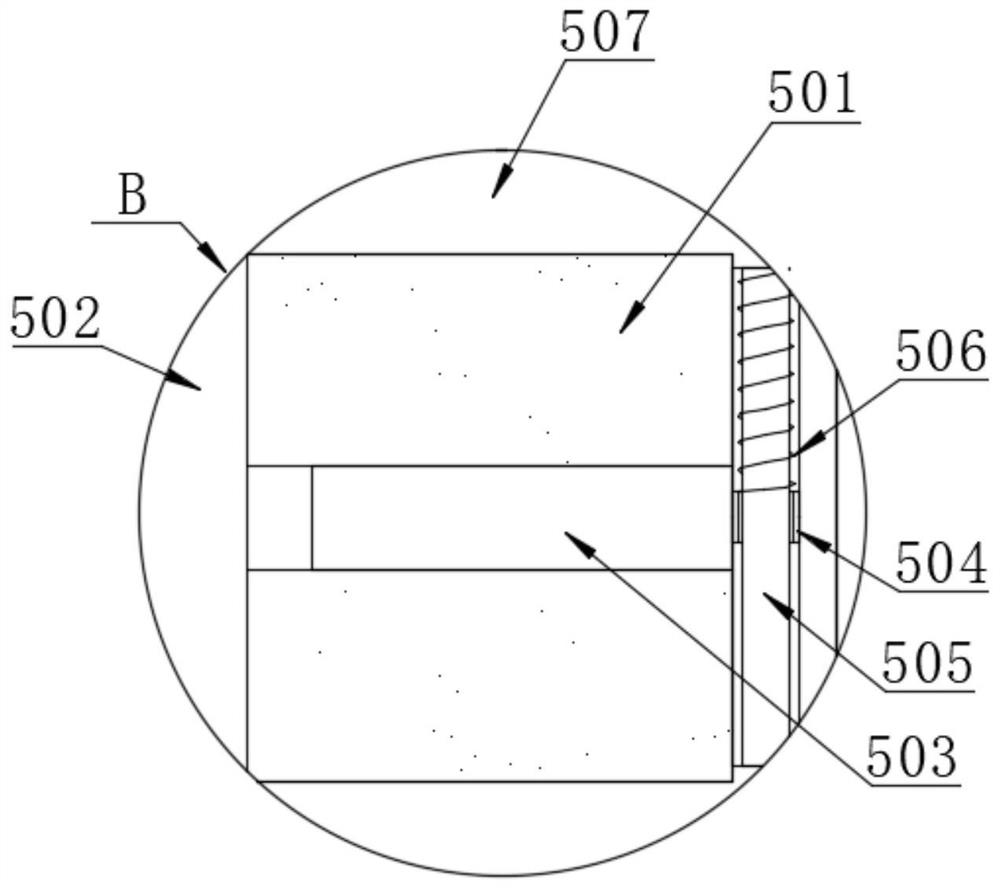

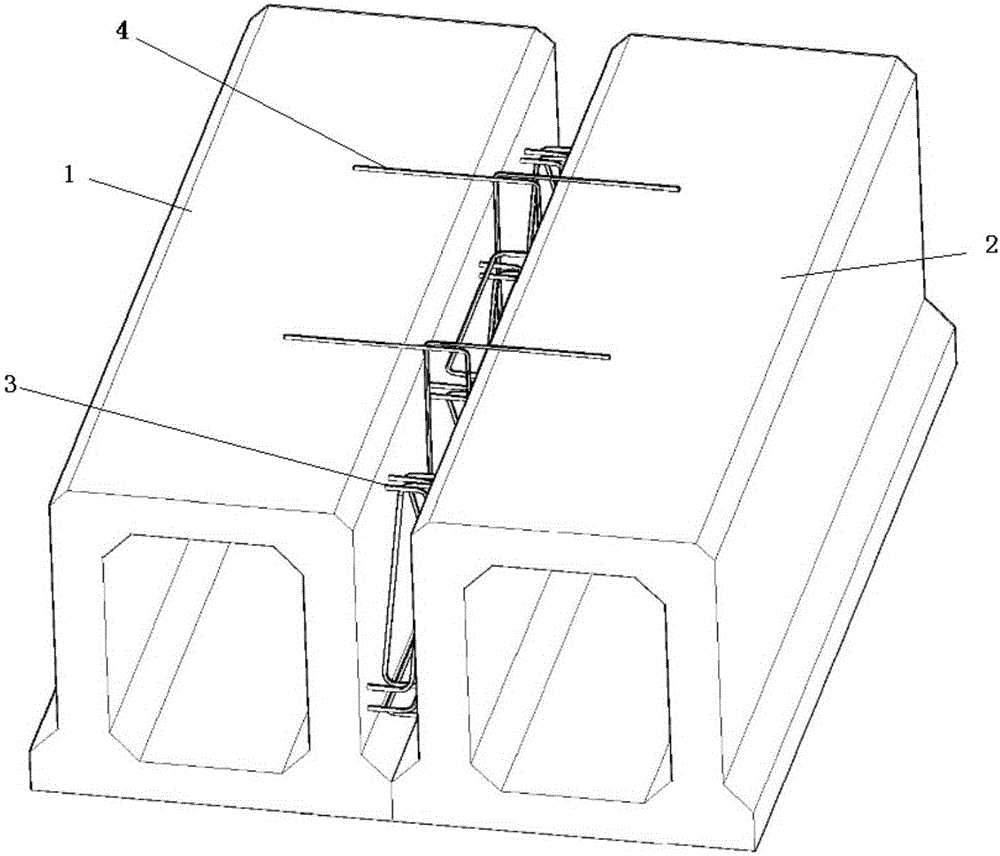

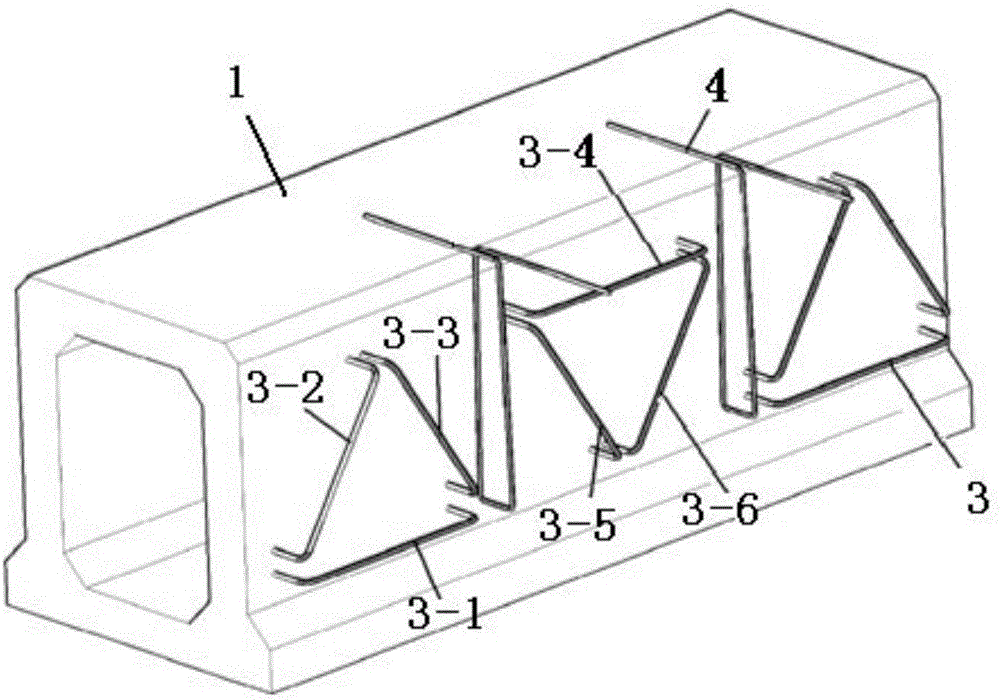

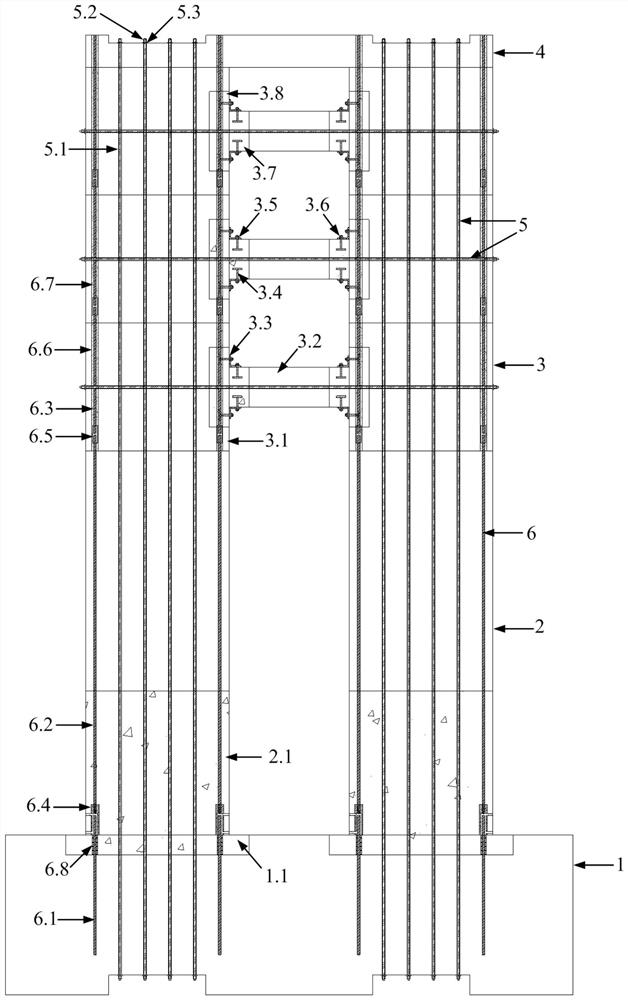

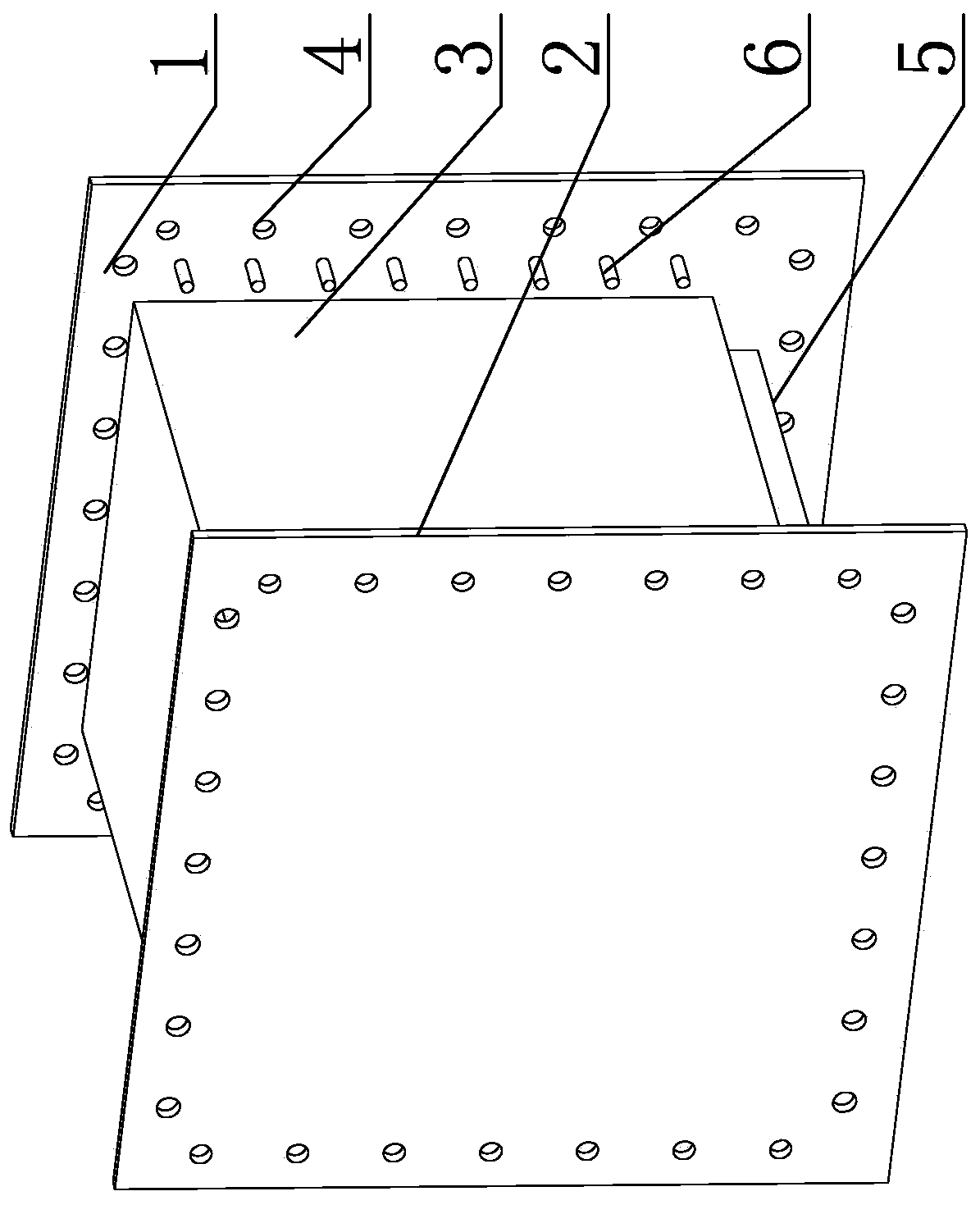

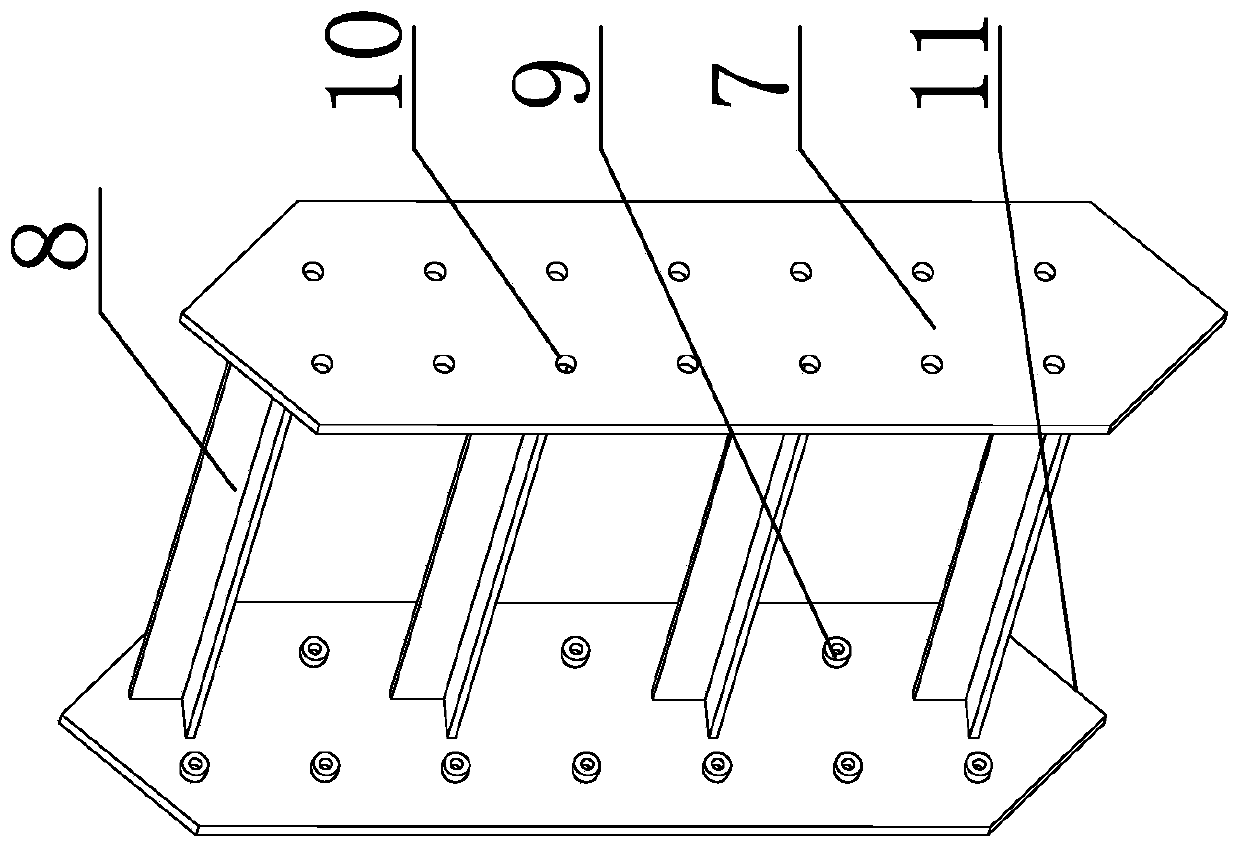

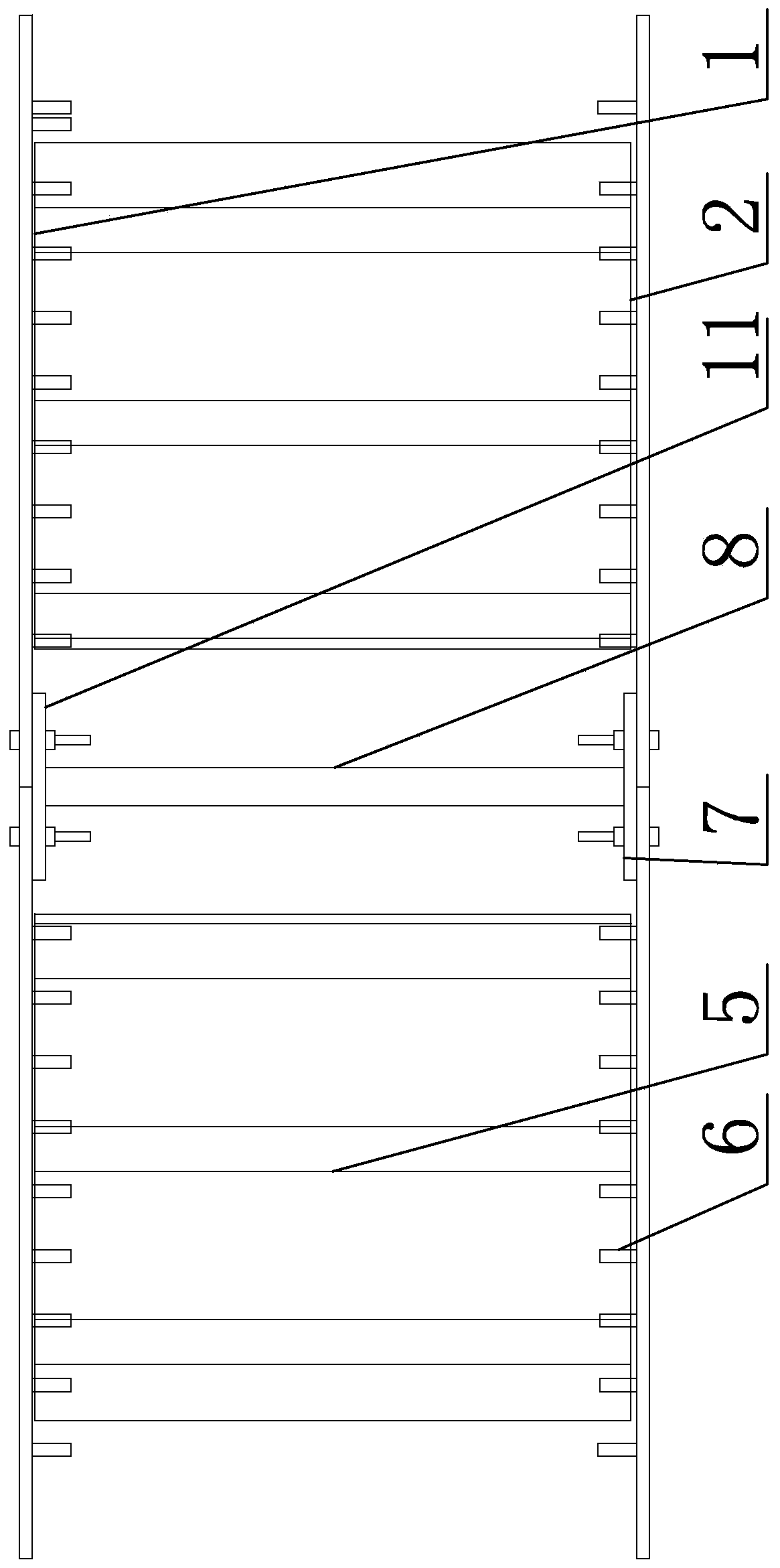

Full-prefabricated concrete floor slab connecting structure and design calculation method

ActiveCN113250359AGuaranteed tensile propertiesGuaranteed shear performanceGeometric CADFloorsFloor slabArchitectural engineering

The invention discloses a full-prefabricated concrete floor slab connecting structure and a design calculation method. The connecting structure comprises prefabricated concrete floor slabs (1) on the two sides, a rear steel bar frame (2), a rear penetrating longitudinal bar (3) and post-poured concrete (4); longitudinal through grooves (11) and a plurality of vertical through grooves (12) are formed in the side faces of the connecting sides of the prefabricated concrete floor slabs (1); the rear steel bar frame (2) is arranged in the vertical through grooves (12) of the floor slabs on the two sides in a centered mode; the rear penetrating longitudinal bar (3) is arranged in the rear steel bar frame (2) in a penetrating mode; and the post-poured concrete (4) is poured in the longitudinal through grooves (11) and the plurality of vertical through grooves (12). The in-slab shear resistance, flexural rigidity and bearing capacity of the full-prefabricated floor slabs can be remarkably improved, deformation coordination of slab joints during vertical load bearing is guaranteed, and the using performance similar to that of an overall cast-in-place floor system can be achieved. The full-prefabricated concrete floor slab connecting structure is reliable in performance, simple in structure, rapid in construction and environmentally friendly.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Technique for strengthening boundary face of functional gradient material of shield duct piece by using FRP rib

InactiveCN100464056CGuaranteed shear performanceReduce processUnderground chambersCeramic shaping apparatusReinforced concreteGradient material

The present invention relates to a technical process for reinforcing functional gradient material interface of shield-driven tunnel concrete segment by utilizing FRP rib. Said technical process includes the following steps: (1), creating FRP rib anchorage reinforcement transition zone; laying and sticking flexible FRP mesh fabric on the surface of reinforcing cage in reinforced concrete segment steel mould, on the mesh fabric distributing FRP ribs according to the point lattice form to form FRP rib anchorage reinforcement transition zone, in which the FRP ribs and FRP mesh fabric are adhered together and formed into an integral structure; (2), in the reinforced concrete segment steel mould pouring the high-performance concrete whose strength grade is greater than C50 to upper surface of reinforcing cage to form reinforced concrete structure layer; and (3), utilizing pumping process to pour high-antipermeable protective concrete to surface of steel mould on the reinforced concrete structure layer to form high-antipermeable protective layer.

Owner:WUHAN UNIV OF TECH

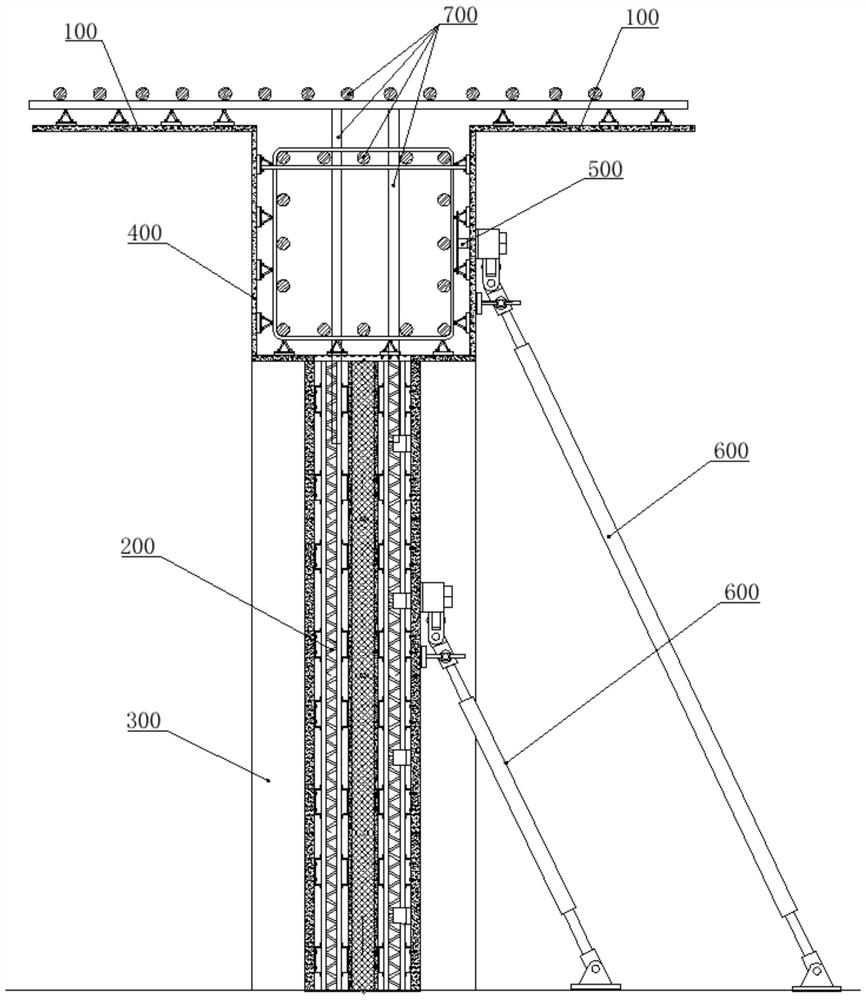

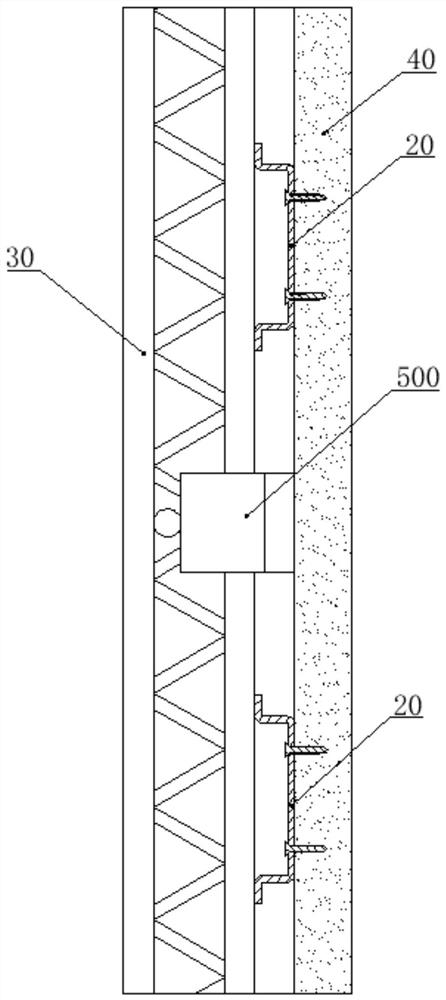

Integrated formwork-removal-free building system and construction method thereof

InactiveCN113338430AImprove appearance qualityGuaranteed shear performanceStrutsWallsReinforced concreteArchitectural engineering

The invention provides an integrated formwork-removal-free building system and a construction method thereof, and belongs to the technical field of fabricated buildings. The system comprises a floor support plate, a shear wall, a structural column and a structural beam. A bottom face of the floor support plate, two side faces of the shear wall, side faces of a periphery of the structural column and side faces and a bottom face of the structural beam are all of an integrated formwork-removal-free face structure. The integrated formwork-removal-free face structure comprises a removal-free formwork, a plurality of first connecting strips and a plurality of trusses sequentially arranged from outside to inside; the trusses on the floor support plate, the structural column and the structural beam are all connected with structural main reinforcements; two sets of second connecting strips and a heat preservation plate are further arranged between two side faces of the shear wall; and the floor support plate, the shear wall, the structural column and the removal-free formwork of the structural beam are all spliced in a sealed mode. The construction method is used for constructing the system. The whole structure of the integrated formwork-removal-free building system belongs to a fabricated structure, the reinforced concrete structure can be continuously poured, such that the whole structure is integrated, the structural strength can be guaranteed, construction can be facilitated, and forming quality is good.

Owner:韩宇彤

Hinge joint sealing connection device

PendingCN109235253AImprove integrityIncrease lateral stiffnessBridge structural detailsCross connectionHinge joint

A hinge joint sealing connection device comprises a connection part for connecting two adjacent hollow plates, a filling part filled in the hinge joint and a bridge deck pavement layer laid on the topsurface of the hollow plates. The hinge joint sealing connection device comprises a connection part for connecting two adjacent hollow plates, a filling part filled in the hinge joint and a bridge deck pavement layer laid on the top surface of the hollow plates. The connecting part comprises a plurality of sets of connecting pieces arranged in the hinge joint at intervals along the width direction of the bridge; The connector comprises a connecting plate which is laid on the top surfaces of two adjacent hollow plates and covers the hinge joints along the bridge length direction, and the two ends of the connecting plate along the bridge length direction are fixed on the top surfaces of the two adjacent hollow plates by fixing devices respectively. The connectors also include an upper horizontal connection group, a lower horizontal connection group, and a cross connection group. The filling portion is a first concrete filled in the hinge joint. The pavement layer comprises a concrete layer formed by pouring a second concrete on the top surface of the hollow slab, and the concrete layer is paved with a reinforcing steel mesh which is fixedly connected with the connecting part.

Owner:ZHEJIANG UNIV OF TECH

High-strength box-type combination column and preparation method thereof

ActiveCN113047525AGuaranteed bending resistanceGuaranteed shear performanceStrutsBio-packagingEpoxyEngineering

The invention discloses a high-strength box-type combination column and a preparation method thereof. The high-strength box type combination column is characterized in that the high-strength box-type combination column comprises two C-type steel plates and four column plates made of bamboo / wood, the two C-type steel plates define a box-type framework, the four column plates are respectively pasted and fixed on four outer surfaces of the box-type framework, a plurality of transverse partition plates distributed at intervals in the length direction are arranged in the box-type framework, a connecting screw rod penetrates through a first connecting hole, a second connecting hole and a third connecting hole, then the two ends of the connecting screw rod are fixed through cushion blocks and nuts, and polygonal holes are formed in the cushion blocks. The high-strength box-type combination column has the advantages that the overall weight and cost are reduced, and meanwhile the bending resistance and the shearing resistance of the box-type column are guaranteed; and in addition, due to the fact that the transverse partition plates are fixedly connected with the box-type framework through the connecting screw rod, later replacement and maintenance of the box-type combination column are facilitated, when the box-type combination column is damaged due to stress, the box-type combination column can be conveniently disassembled only by heating to melt epoxy resin glue, and repeated use can be achieved by replacing the damaged part of the box-type combination column.

Owner:NINGBO UNIV

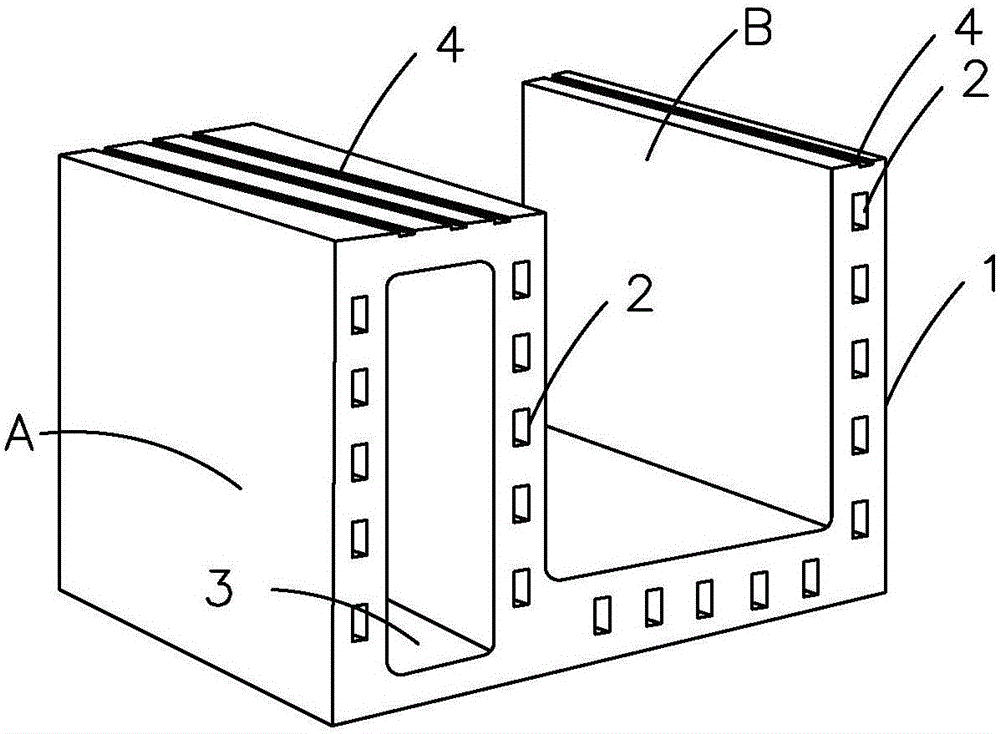

Hollow brick with U-shaped section

InactiveCN105155759AGuaranteed seismic performance and shear performanceReduce building construction timeConstruction materialHollow coreBrick

The invention discloses a hollow brick with a U-shaped section. The hollow brick comprises a main body, wherein the section of the main body is a U-shaped section; the U-shaped section is divided into a vertical wall A and a vertical wall B, wherein the wall A is 3-4 times thicker than the wall B; a heat-preserving-material filling hole is formed in the inner part of the wall A; through holes are formed in the inner part of the wall B, surrounding the heat-preserving-material filling hole, and the bottom of the main body. The hollow brick disclosed by the invention has the benefits that because the section of the main body of the hollow brick is the U-shaped section, when concave wall bodies are needed during building construction, a formed hollow-brick structure does not need to be damaged by building workers, so that the anti-shock performance of the hollow brick and the anti-shear performance of the hollow brick are guaranteed; besides, the heat-preserving-material filling hole is formed in the inner part of the wall A, and the heat preserving materials can be directly added in the heat-preserving-material filling hole during production to realize factory prefabrication, so that the time for building construction is greatly shortened.

Owner:成都市凤庭环能科技有限公司

A high-strength box-type composite column and its preparation method

Owner:NINGBO UNIV

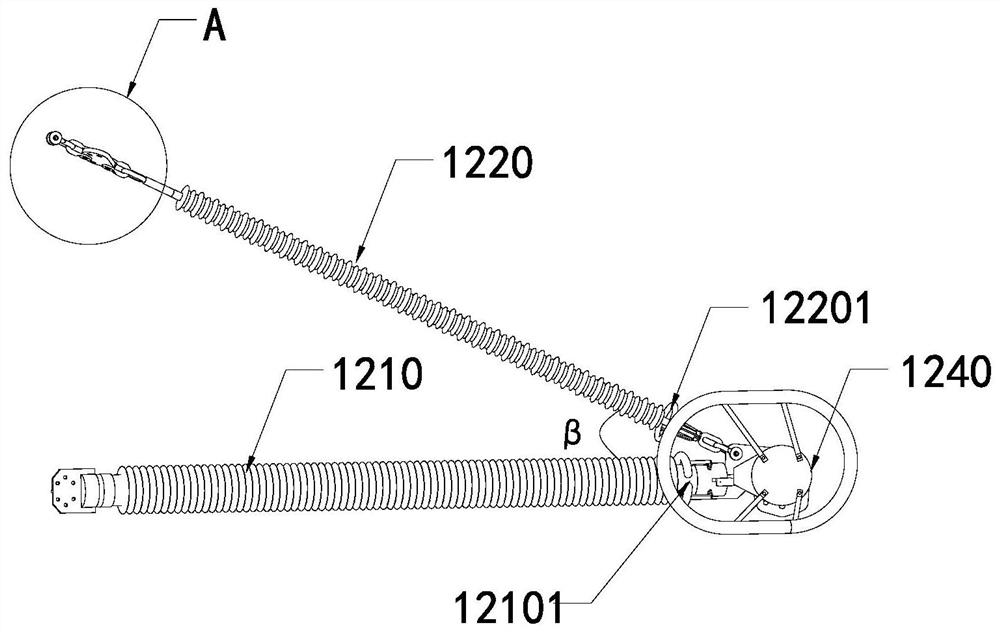

Comprehensive steel structure lifting appliance based on BIM technology and construction method

InactiveCN113104718AGuaranteed shear performanceImprove mechanical propertiesBuilding material handlingLoad-engaging elementsConstruction engineeringMechanical engineering

The invention discloses a comprehensive steel structure lifting appliance based on a BIM technology and a construction method, and belongs to the technical field of steel structure installation. The lifting appliance comprises a steel structure column and further comprises a hanging bracket body connected with the steel structure column and a hanging arm detachably connected with the hanging bracket body, and a positioning structure used for connecting the steel structure column on the upper side and the steel structure column on the lower side is fixedly installed on the hanging bracket body. The hanging bracket body, the hanging arm and the positioning structure are arranged, the hanging bracket body is used for hanging a steel structure, meanwhile, the hanging bracket body and the positioning structure can be used for assembling an upper steel structure column and a lower steel structure column, the torsion resistance and the shear resistance of a connecting joint can be guaranteed, the mechanical property of the comprehensive steel structure lifting appliance is greatly improved, and the construction efficiency can also be remarkably improved.

Owner:CHINA MCC17 GRP

Connection structure and method of prefabricated column and beam-slab joints in concrete frame structure

ActiveCN106149878BPrecise card positioningGuaranteed shear performanceBuilding constructionsSteel barPrecast concrete

Owner:NINGBO PRECA CONSTR TECH CO LTD

A hollow pier prefabricated inter-segment connection device and construction method

ActiveCN112301890BAvoid damageEasy to observeBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention provides a connection device and a construction method between prefabricated segments of a hollow pier, the connection device includes a pre-embedded steel plate, a U-shaped steel bar, a rubber plate, an upper / lower connecting steel plate, an upper / lower shear resistant steel plate and a filling plate, and a pre-embedded steel plate Pre-buried on the inner surface of the prefabricated segment, U-shaped steel bars are welded on the pre-embedded steel plate, part of which extends into the pre-fabricated segment, and part of which protrudes from the pre-embedded steel plate. Threads are set on the protruding part, and the rubber plate, upper / The lower connecting steel plate is connected with the embedded steel plate. After the assembly of the upper and lower prefabricated sections is completed, the upper shear steel plate and the upper connecting steel plate, the lower shear steel plate and the lower connecting steel plate are connected by high-strength bolts, and then a filler plate is inserted between the upper shear steel plate and the lower shear steel plate. The upper shear steel plate and the lower shear steel plate are connected by high-strength bolts. The connecting device of the present invention meets the needs of different processes in the prefabricated segment assembly process, and realizes functions such as hoisting, segment position positioning, segment linear adjustment, segment glue seam pre-pressing, and temporary locking.

Owner:CHINA RAILWAYS CORPORATION +1

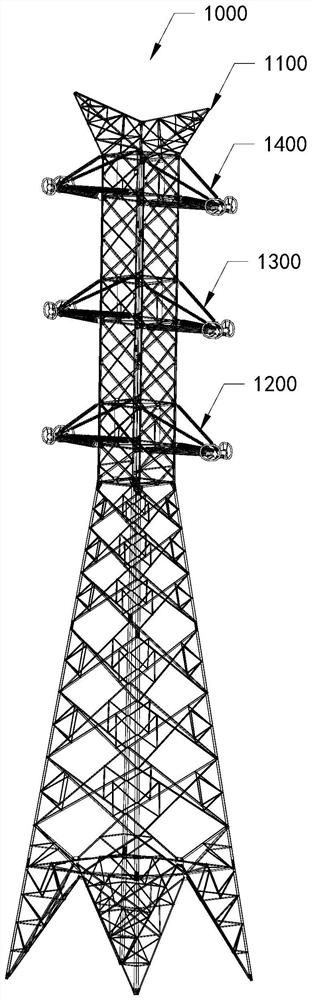

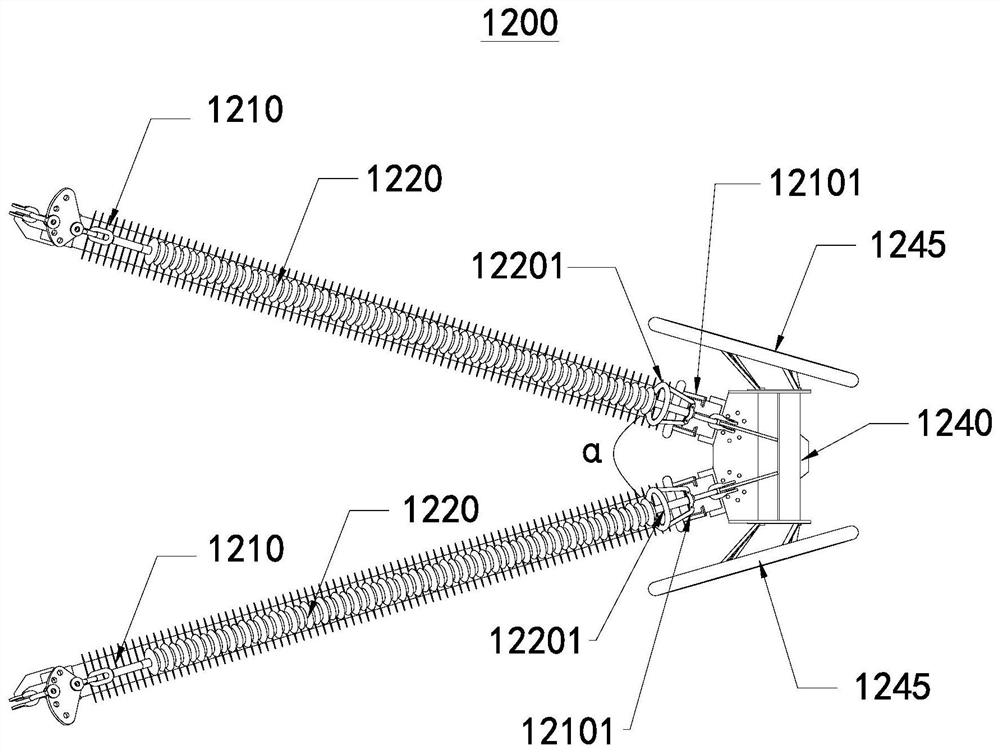

Post insulator and composite cross arm

PendingCN112885544AGuaranteed StrengthGuaranteed shear performanceTowersSupporting insulatorsEngineeringFlange

The invention discloses a post insulator and a composite cross arm. The post insulator comprises: an insulator; an umbrella skirt wrapping the periphery of the insulator; and a first connecting fitting connected with the end of the insulator and comprising a flange cylinder, wherein the flange cylinder is of a hollow structure in the axial direction and is arranged at the end of the insulator in a sleeving mode, the inner wall of the flange cylinder is provided with a plurality of cementing grooves formed in the axial direction at intervals, the cementing grooves are equal in width, and the width of each cementing groove is smaller than the width of the interval between every two adjacent cementing grooves. Through the arrangement, the strength of the post insulator can be improved.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

PC and ALC combined type integrated wallboard

The invention discloses a PC and ALC combined type integrated wallboard, and belongs to the technical field of wallboards. The PC and ALC combined type integrated wallboard comprises a PC wallboard, wherein a first lightweight wallboard and a support frame are clamped in an inner cavity of the PC wallboard through an assembly mechanism, sandwich members are arranged on both sides of the assembly mechanism, and clamping mechanisms are fixedly connected to both sides of the PC wallboard. According to the PC and ALC combined type integrated wallboard, the first lightweight wallboard and a secondlightweight wallboard are arranged in the PC wallboard, and the first lightweight wallboard and the second lightweight wallboard which are made of ALC materials are installed in the PC wallboard, so that the PC and ALC combined type integrated wallboard is formed, the weight reduction effect can be achieved by filling ALC members, the wallboard has good heat preservation and heat insulation performance and good sound insulation performance and impermeability, the assembly difficulty is obviously reduced, and the overall use requirement is met.

Owner:苏州良浦节能新材料股份有限公司

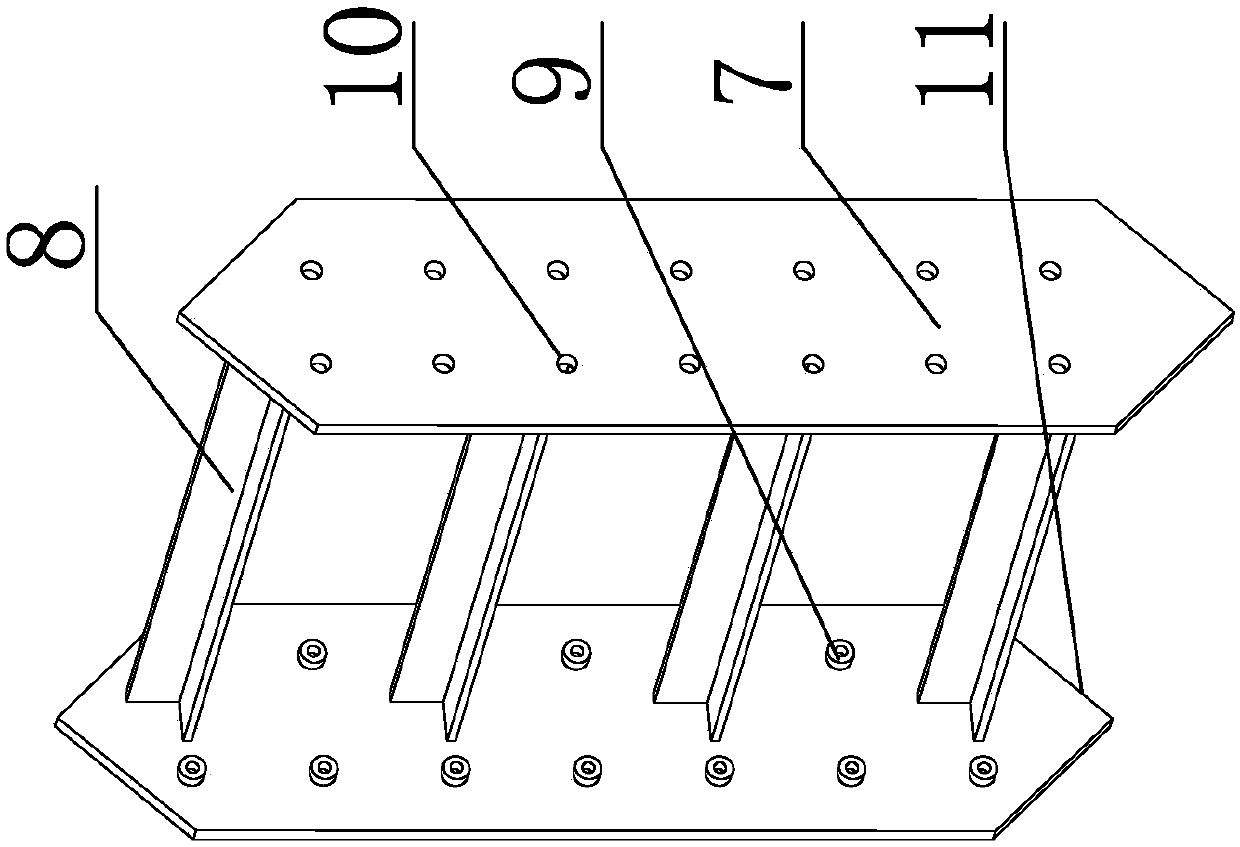

Channel steel-concrete composite beam and manufacturing method thereof

ActiveCN112049007ASimple structureImprove carrying capacityBridge structural detailsBridge materialsBridge engineeringReinforced concrete

The invention relates to a channel steel-concrete composite beam and a manufacturing method thereof, and belongs to the technical field of bridge engineering. The channel steel-concrete composite beamcomprises a steel beam and a bridge deck, wherein the steel beam comprises an outer beam and an inner beam which are made of large channel steel and small channel steel respectively; the inner beam is placed in a groove cavity of the outer beam, a bottom plate of the inner beam is abutted with a bottom plate of the outer beam, and series connection holes are respectively formed in side plates onthe left and right sides of the outer beam and the inner beam and are connected in series through series connection ribs; inclined notches and vertical notches which are in one-to-one correspondence are formed in the top ends of the side plates of the inner beam and the outer beam; and the bridge deck stretches across the steel beam, at least one part of steel bars at the bottom of the bridge deckpenetrate through the inclined notches and the vertical notches, and concrete of the bridge deck wraps the steel bars, the series connection bars and the top end of the steel beam, so that the steelbeam and the reinforced concrete bridge deck are connected into a whole. The channel steel-concrete composite beam has the advantages of the simple structure, no need of welding and high bearing capacity.

Owner:HUNAN INST OF TECH

A joint structure and arrangement method of hinged steel bar connectors for concrete girder bridges

ActiveCN106049258BGuaranteed shear performanceImprove shear resistanceBridge structural detailsBridge erection/assemblyConcrete beamsInverted triangle

Owner:HEBEI PROVINCIAL COMM PLANNING & DESIGN INST

Bolt connection structure for manufacturing tank body and manufacturing method thereof

InactiveCN107939131AEasy constructionHigh degree of standardizationBuilding material handlingBulk storage containerNuclear powerComputer module

The invention relates to a bolt connection structure for manufacturing a tank body and a manufacturing method thereof and belongs to the field of civil engineering. The bolt connection structure for manufacturing the tank body and the manufacturing method thereof are used for solving the problems that tank body structures of nuclear power station containments and oil storage tanks in large energystructure engineering in the prior art are high in site construction difficulty, long in period, high in construction cost, inconvenient to construct during site welding construction and low in safetycoefficient. The bolt connection structure comprises four square modules and four hexagonal joint modules; the four square modules are spliced into a square block body, and every two adjacent squaremodules are fixedly connected through a corresponding hexagonal joint module and a plurality of bolts; and the connection positions of the square modules and the hexagonal joint modules are fixedly connected through self-compacting concrete.

Owner:HARBIN INST OF TECH

Anti-shear connecting structure used for hollow block masonry, masonry wall and construction method

The invention discloses an anti-shear connecting structure used for hollow block masonry, a masonry wall and a construction method. The anti-shear connecting structure is arranged at the layered position of upper skin and lower skin of a masonry structure and is composed of two L-shaped supporting angle plates and a concrete anti-shear block, the two supporting angle plates are symmetrically arranged in a cavity of the hollow block in a paired manner, upper transverse sides of the two supporting angle plates are supported on rib walls of two sides of the cavity and are bonded with two side rib walls through mortar, and the concrete anti-shear block is arranged between the two supporting angle plates and is supported on the lower transverse sides of the two supporting angle plates in a lap-joint manner; the upper half portion and the lower half portion of the concrete anti-shear block are embedded in an upper skin building block cavity and a lower skin building block cavity, and are bonded with the two supporting angle plates and the inner cavity wall of the hollow block through mortar arranged outside the periphery in a filling manner. According to the anti-shear connecting structure, cracking on the wall mortar joint can be reduced, the anti-shear strength of the masonry wall structure is improved, the wall has the higher integrality, the masonry wall with the anti-shear connecting structure has the higher anti-shear strength and the higher integrality, and the construction method of the masonry wall is simple and reliable.

Owner:TIANJIN CHENGJIAN UNIV

Self-resetting prefabricated bidirectional coupled high-speed rail pier with local UHPC (Ultra High Performance Concrete) restorable function

PendingCN114319084AReasonable divisionGuaranteed lateral stiffnessBridge structural detailsBridge erection/assemblyEarthquake resistancePre stress

The invention discloses a local UHPC (Ultra High Performance Concrete) recoverable function self-resetting prefabricated bidirectional coupled high-speed rail pier which comprises a bearing platform and a cover beam supported above the bearing platform through a vertical supporting structure, and the cover beam is a prefabricated part; the vertical supporting structure comprises a prefabricated pier bottom section, a prefabricated pier-coupling beam section and an unbonded prestressed steel strand; the prefabricated pier bottom sections are fixed on the bearing platform in a matrix arrangement manner; a prefabricated pier-coupling beam section is arranged on the top surface of the prefabricated pier bottom section; the prefabricated pier-coupling beam section comprises a prefabricated pier section and a prefabricated coupling beam; a feasible structural form is provided for applying a prefabrication construction technology to the high-speed rail bridge pier, by means of the structural form, the structural rigidity requirement and the rapid construction requirement can be both considered, the shear state of the bridge pier is improved, it can be guaranteed that the bridge pier has good deformation capacity under the earthquake action, and only replaceable damage elements are damaged; the prefabricated high-speed rail pier is further developed into a post-earthquake function recoverable structure, and the requirement for toughness and earthquake resistance is met.

Owner:SOUTHEAST UNIV

Glass connection structure and its construction method

The invention relates to a glass connecting structure and a construction method thereof. The glass connecting structure is used for connection between two glass ribs or between a glass rib and a main structure and comprises clamping plates arranged on two side faces of the glass ribs respectively, fasteners, elastic gaskets and injection and drainage holes, the fasteners penetrate through the glass ribs or the main structure and are connected with the clamping plates, the elastic gaskets are arranged between the glass ribs and the clamping plates, at least one sealing cavity for being filled with an adhesive is defined by the elastic gaskets, the clamping plates and the glass ribs jointly, and the injection and drainage holes are formed in the clamping plates or the elastic gaskets and communicated with the sealing cavity. When the adhesive is injected into the sealing cavity, the adhesive is evenly distributed in the area defined by the sealing cavity, certain thickness is formed, any part on the clamping plates is connected with the glass ribs through the adhesives, therefore, the shear capacity of the glass connecting structure is guaranteed, shear loads can be transferred, it is avoided that the glass ribs are damaged due to stress concentration, and meanwhile fast construction and installation are guaranteed.

Owner:GUANGDONG KIN LONG HARDWARE PROD CO LTD

Bolt connection structure for making tank body and method for making bolt connection structure

InactiveCN107939131BEasy constructionHigh degree of standardizationBuilding material handlingBulk storage containerNuclear powerComputer module

The invention relates to a bolt connection structure for manufacturing a tank body and a manufacturing method thereof and belongs to the field of civil engineering. The bolt connection structure for manufacturing the tank body and the manufacturing method thereof are used for solving the problems that tank body structures of nuclear power station containments and oil storage tanks in large energystructure engineering in the prior art are high in site construction difficulty, long in period, high in construction cost, inconvenient to construct during site welding construction and low in safetycoefficient. The bolt connection structure comprises four square modules and four hexagonal joint modules; the four square modules are spliced into a square block body, and every two adjacent squaremodules are fixedly connected through a corresponding hexagonal joint module and a plurality of bolts; and the connection positions of the square modules and the hexagonal joint modules are fixedly connected through self-compacting concrete.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com