Method for prefabricating assembly type reconstructed and expanded building structure joint and structure node of building

A technology of building structure and prefabrication, which is applied in the direction of building structure, construction, building maintenance, etc., can solve the problems of the loss of the gripping force of the main reinforcement of the original structure, the difficulty of quality control, and the tendency to slip cracks, etc., to ensure the joint resistance Cutting ability, convenient engineering quality, great effect of promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

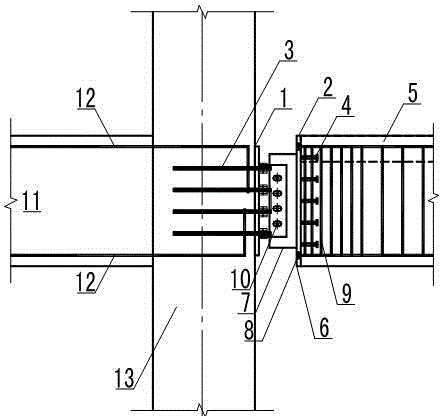

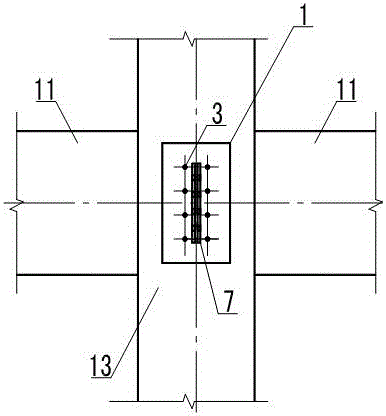

[0037] This embodiment provides a method for prefabricated assembly type reconstruction and expansion of building structure nodes, combining figure 1 , figure 2 with image 3 shown, including the following steps:

[0038] Step 1: Make multiple anchor holes on the built structural column 13 of the built structural beam 11 according to post-anchor technical requirements to avoid conflict with the main reinforcement 12 of the built structural beam, and then fill the post-anchor screw 3 in the anchor holes for anchoring Construction, anchoring screw rod 3 anchoring construction after completion;

[0039] Step 2: After the anchoring construction of the rear anchoring screw 3 is completed, that is, after the maintenance reaches the design bearing capacity, the anchor plate 1 of the rear anchoring connection assembly with screw holes is prefabricated, and then the anchor plate 1 of the rear anchoring connection assembly is attached to the built structural column 13, And make the ...

Embodiment 2

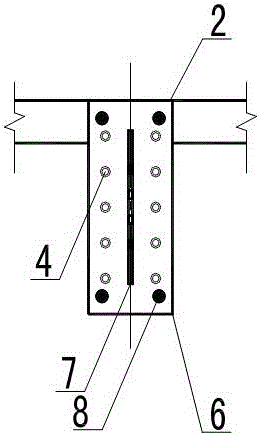

[0046] This embodiment provides a structural node made by a method of prefabricating and rebuilding and expanding a building structural node, including a post-anchor connection component anchor plate 1, a post-anchor screw 3, a shear stud 4, a reinforced concrete beam 5, and a beam end Plate 6, shear connecting plate 7.

[0047] The anchor plate 1 of the post-anchor connection component is attached to the built structural column 13, and is anchored through the post-anchor screw 3, and the interface between the post-anchor connection component anchor plate 1 and the built structural column 13 is treated with structural adhesive and then installed. After positioning, a pre-tightening force is applied to the rear anchoring screw 3. By setting the pre-tightening force, the anchor plate 1 of the prefabricated rear anchoring connection assembly reaches the designed pre-compression and provides reliable shear resistance.

[0048] Bolt holes and main reinforcement perforations 8 are s...

Embodiment 3

[0054] This embodiment further details the connection nodes of the old and new structures (built structures and rebuilt and expanded structures). The connection nodes of the old and new structures are mainly connected by friction-type high-strength bolts 10, which are hinged nodes, and the bending moments of the nodes are released to simplify the original structure. In the state of stress, the load on the original structure is minimized, and the amount of reinforcement work for the original structure is avoided or reduced. In this embodiment, these connecting parts are regularized to form prefabricated parts to realize standardized design, factory prefabrication mass production, and on-site assembly installation and construction. There are mainly two schemes: vertical and horizontal:

[0055] Longitudinal connection scheme: there are multiple anchoring screws 3 penetrating through the anchor plate 1 of the rear anchoring connection assembly, such as figure 1 As shown, it is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com