Highly seismic region prefabricated assembled bridge central pier stud-cover beam node pouring connection mode and construction

A technology of prefabricated assembly and connection methods, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of connection accuracy and quality impact between prefabricated assembly nodes, construction difficulties, reduce the technical advantages of prefabricated assembly bridges, etc., to speed up Project construction speed and quality assurance and earthquake resistance, saving on-site working time, and the effect of ecological environment protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

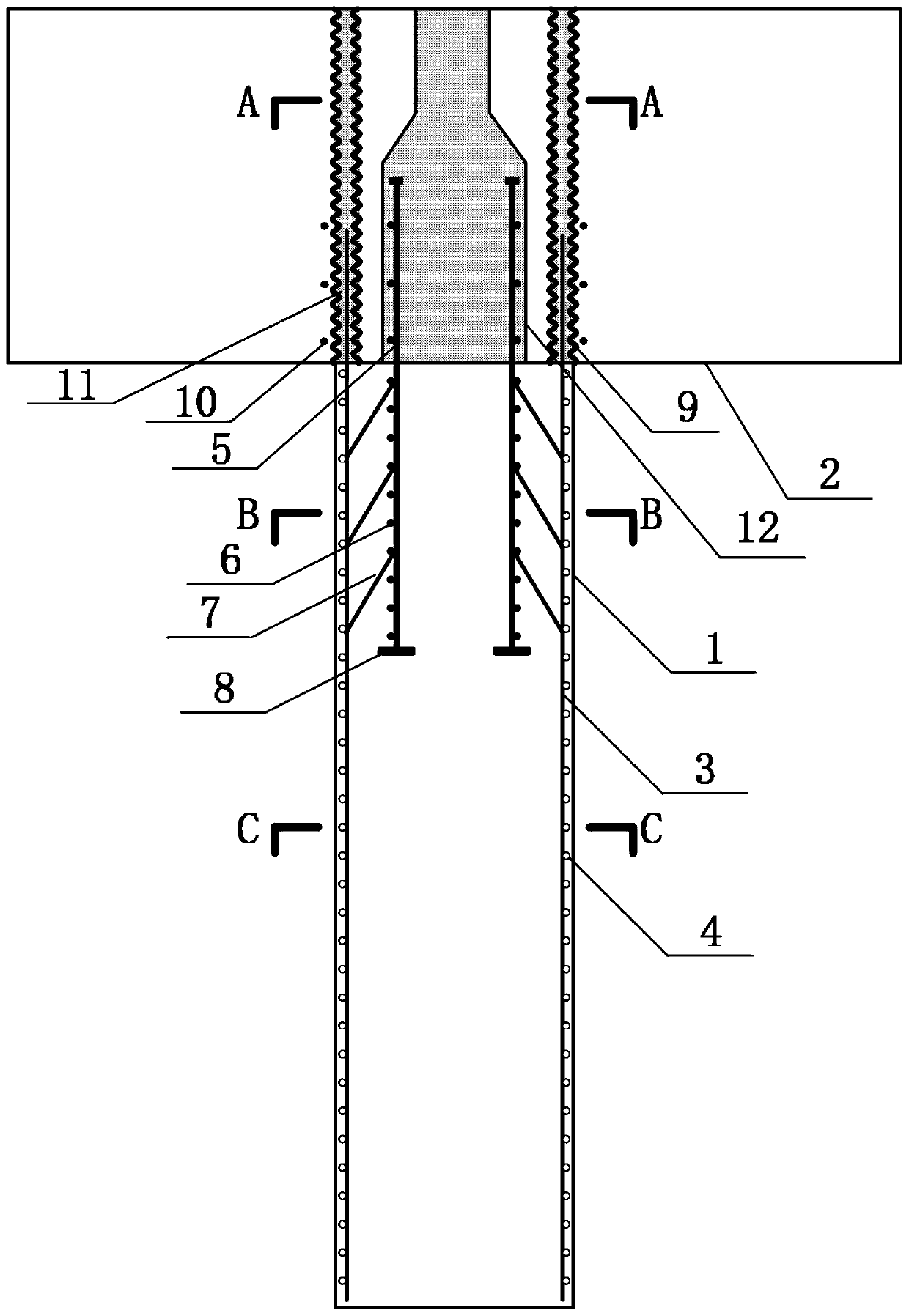

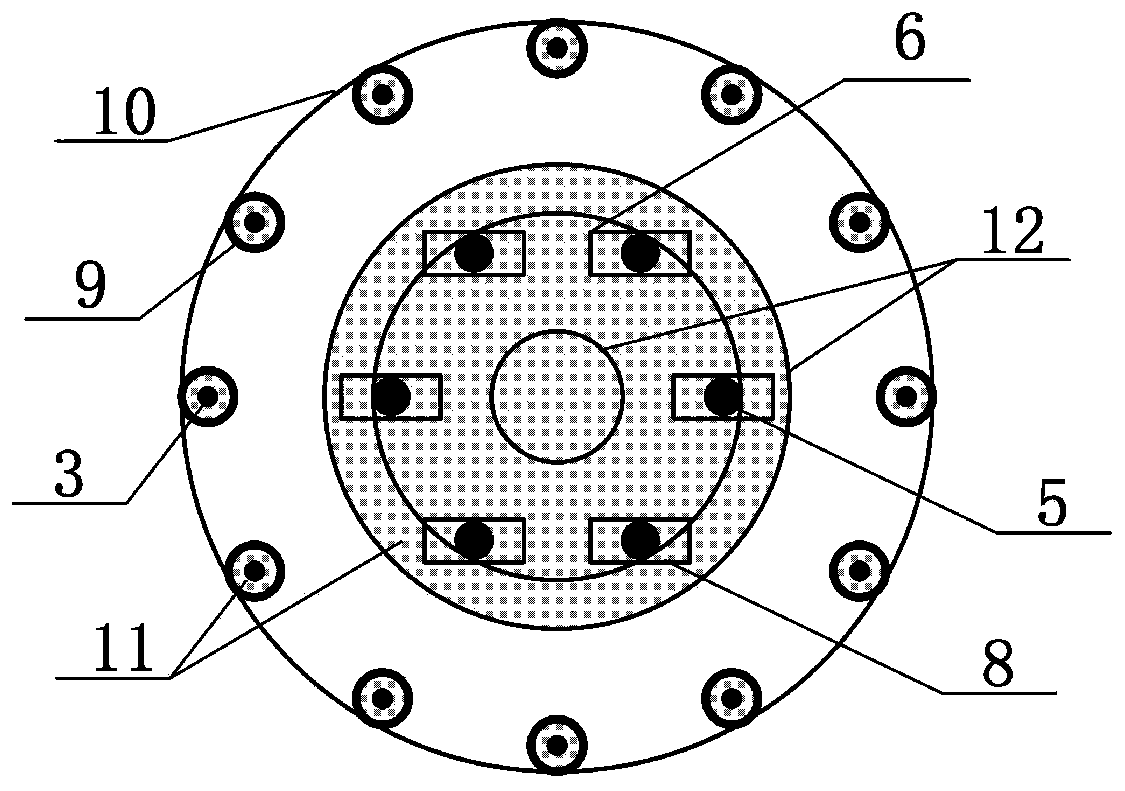

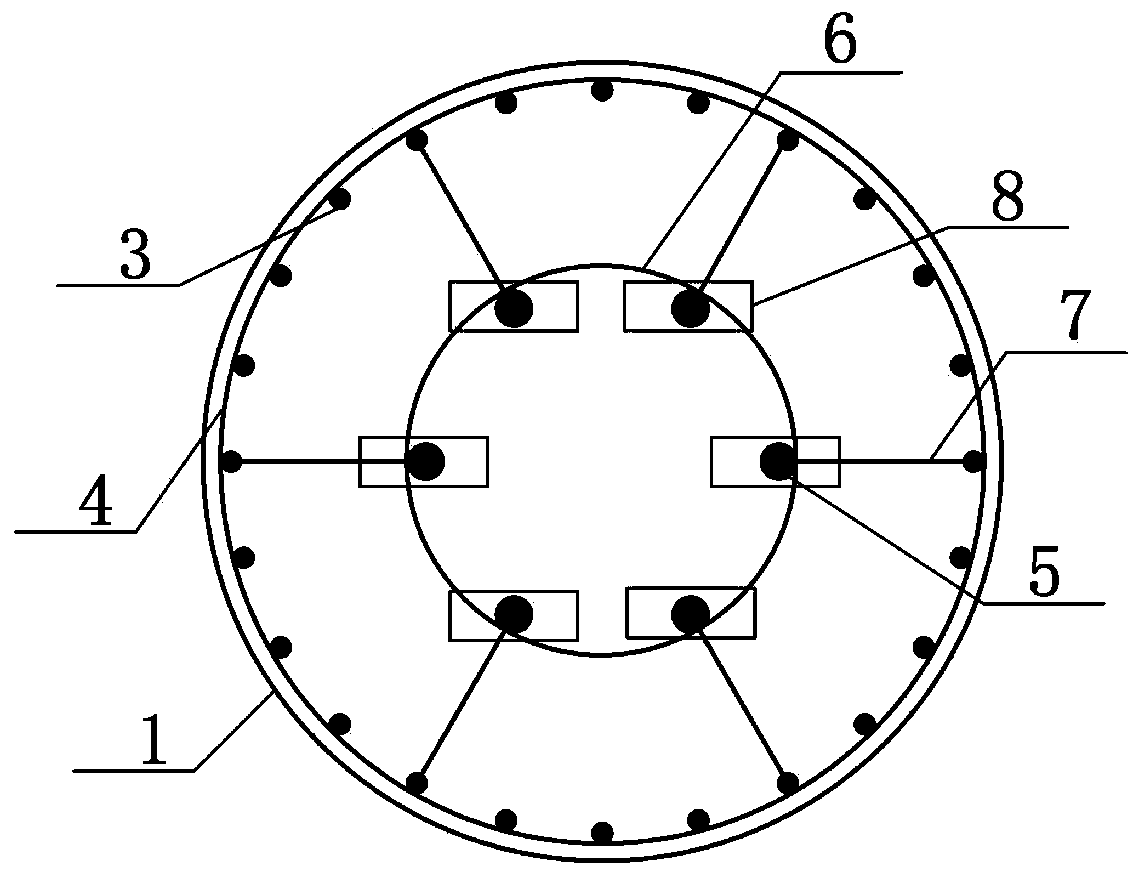

[0035] Below in conjunction with the accompanying drawings and specific embodiments, the pier column-cap beam joint pouring connection mode and structure of the prefabricated assembled bridge in the high-intensity area provided by the present invention will be further described in detail, so as to facilitate a clear understanding of the present invention, but they do not limit the present invention. .

[0036] as attached Figure 1-8 As shown, the present invention provides a perfusion connection method and structure of pier column-cap beam joints in prefabricated assembled bridges in high-intensity areas,

[0037] The connection method and structure are composed of prefabricated pier columns (1) and prefabricated cover beams (2), and the prefabricated pier columns (1) and prefabricated cover beams (2) are connected as a whole by pouring and splicing high-performance materials (11) ; The prefabricated pier column (1) is composed of pier column longitudinal reinforcement (3), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com