Core tube inverse superimposed underground diaphragm wall and construction method thereof

A technology of underground diaphragm wall and construction method, which can be applied to artificial islands, sheet pile walls, water conservancy projects, etc., and can solve the problems of not being able to meet the needs of the ground connection wall of the core tube, effectively resisting shear force, and destroying the integrity of the wall. , to achieve the effect of improving construction quality, reducing construction difficulty and ensuring construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention relates to a core tube inverse superimposed underground continuous wall, which includes a core tube underground continuous wall below the elevation of the raft top and a core tube underground continuous wall above the raft top elevation.

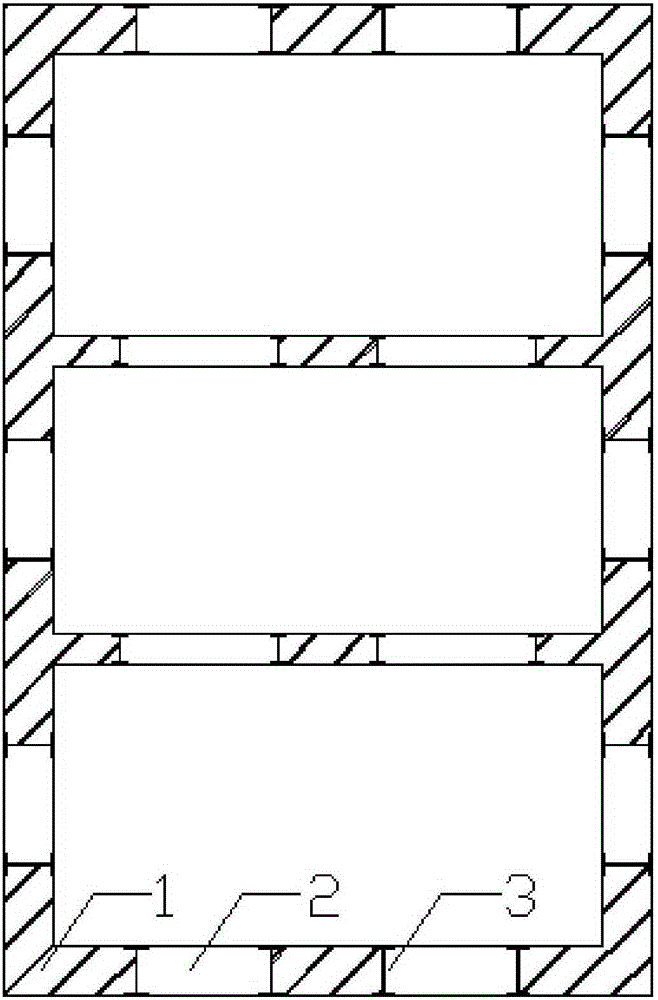

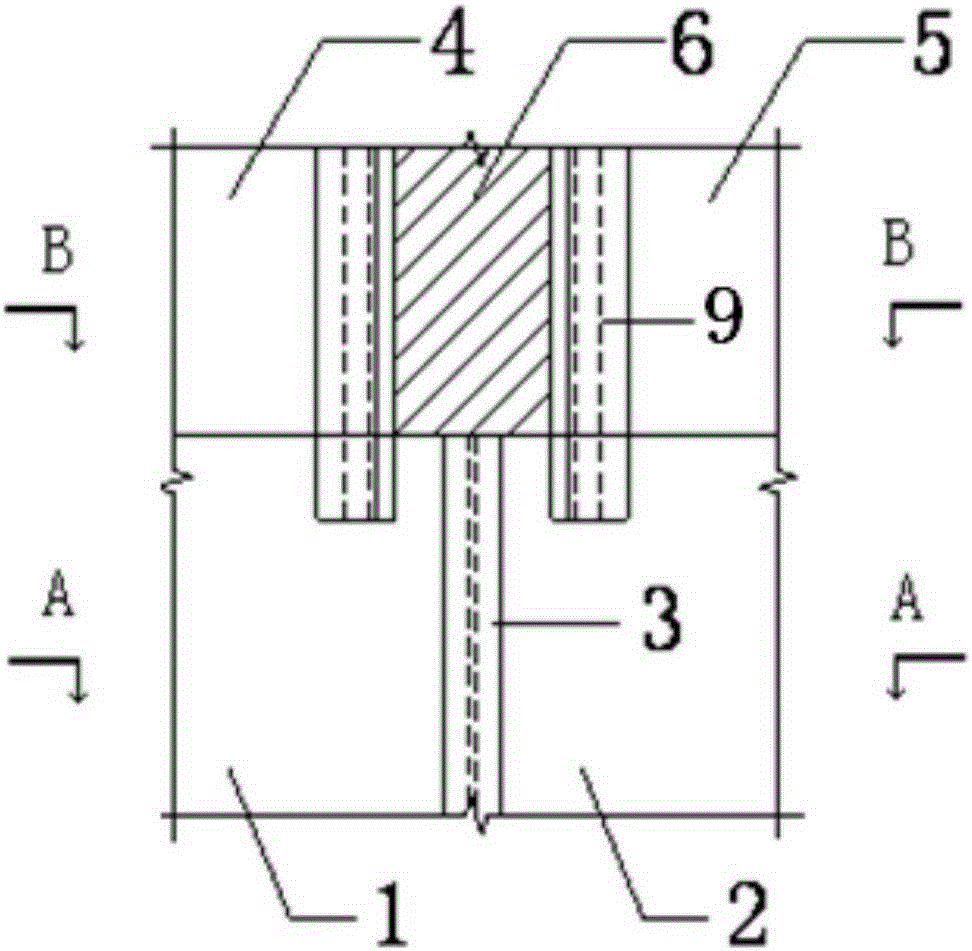

[0037] Refer to the attached figure 1 , 3 It can be seen from and 4 that the underground diaphragm wall of the core tube below the elevation of the top of the raft includes a first leading section 1 and a first subsequent section 2, and the first leading section 1 and the first subsequent section 2 are rigidly connected, Such as the use of I-shaped steel 3 connection.

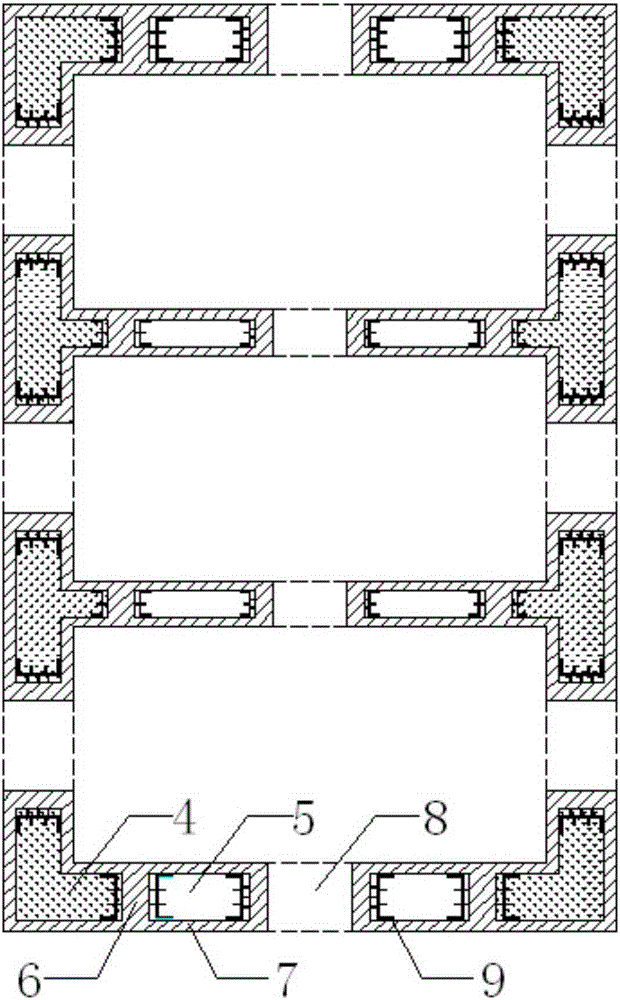

[0038] Refer to the attached figure 2 , 3 It can be seen from and 5 that the underground diaphragm wall of the core tube above the elevation of the top of the raft includes the second leading section 4, the second subsequent section 5, the connecting beam 8, the space between the second leading section 4 and the second subsequent section 5 and The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com