High-strength box-type combination column and preparation method thereof

A combined column, high-strength technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of non-disassembly and replacement, troublesome assembly, and large overall weight, so as to facilitate replacement and maintenance, reduce weight and cost, and ensure resistance Effects of Bending and Shear Capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

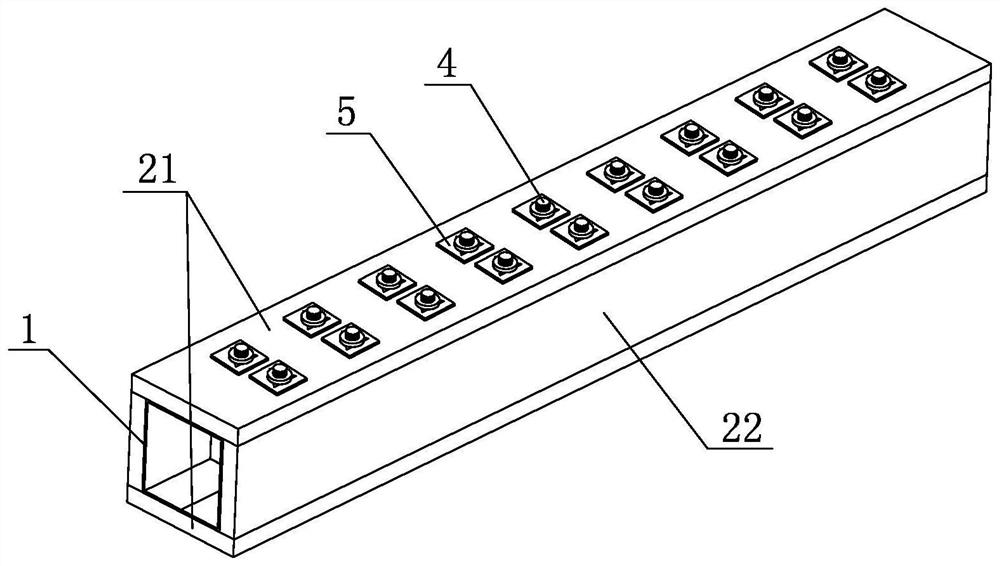

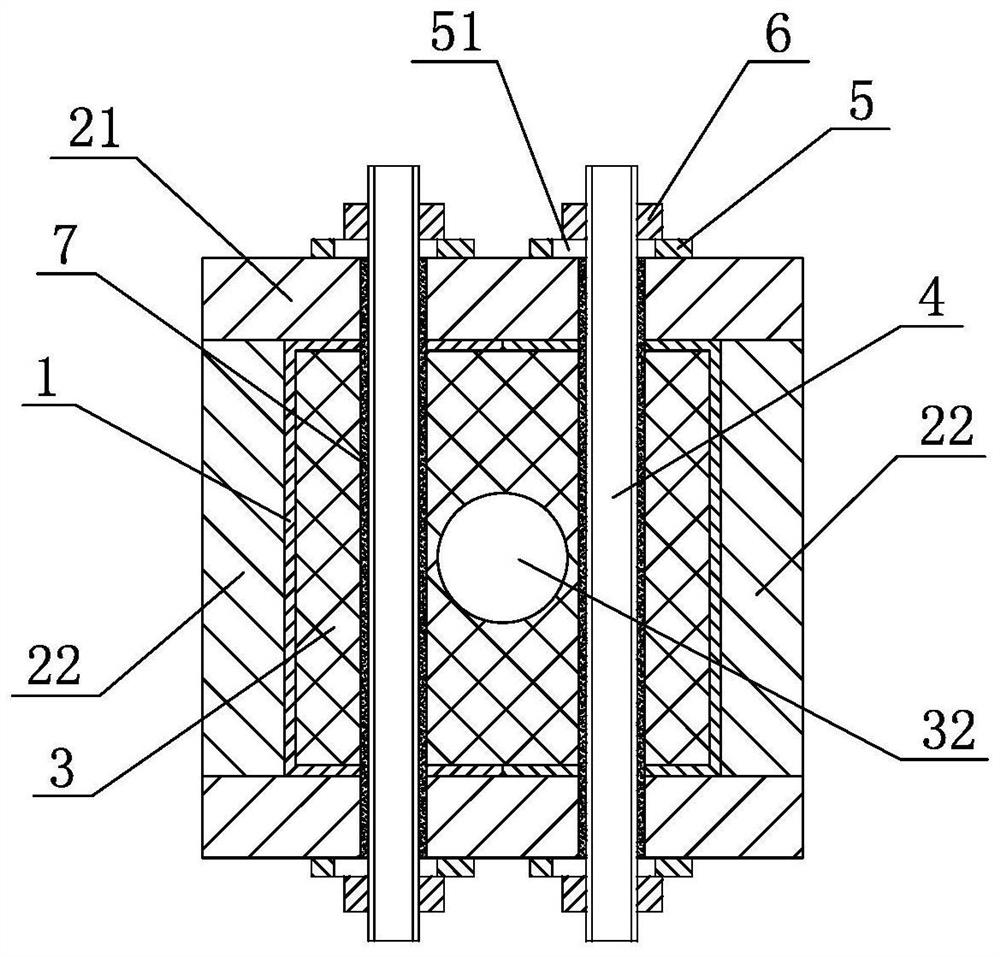

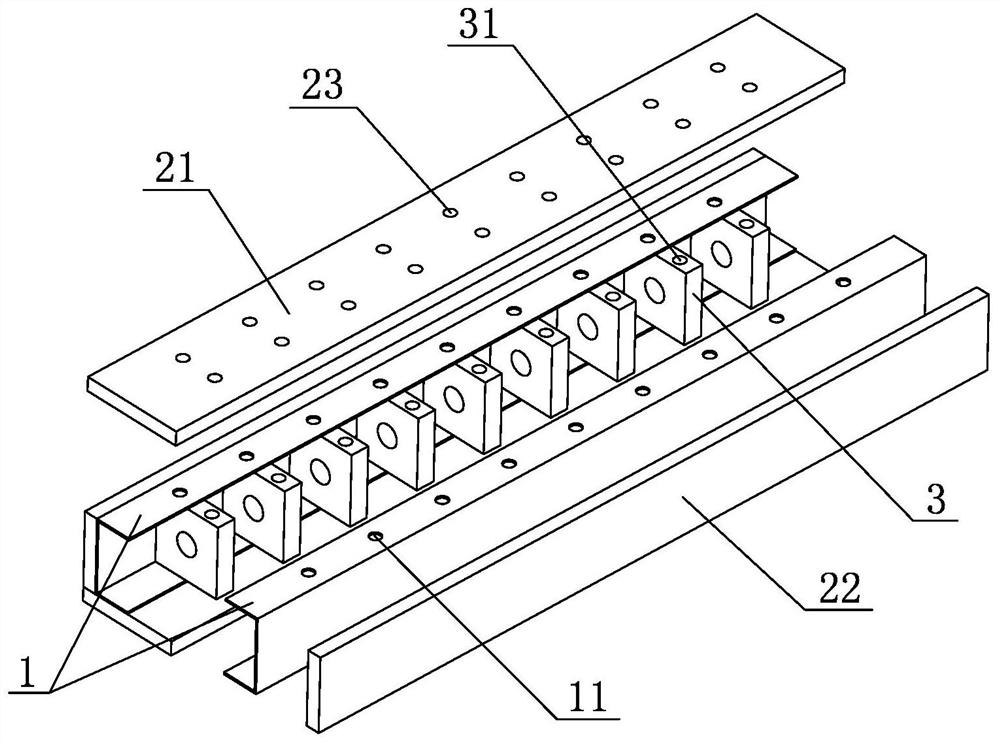

[0026] Embodiment 1: As shown in the figure, a high-strength box-shaped composite column includes two C-shaped steel plates 1 and four column plates 21, 22 made of bamboo / wood, and the openings of the two C-shaped steel plates 1 are opposite to each other. Set and surround a box-shaped framework, four column plates 21, 22 are pasted and fixed on the four outer surfaces of the box-shaped framework respectively, and a plurality of transverse partitions 3 distributed along the length direction are arranged in the box-shaped framework. A first connection hole 23 is provided on the opposite column plate 21, a second connection hole 11 is provided on the flange of the C-shaped steel plate 1, a third connection hole 31 is provided on the diaphragm 3, and the connection screw 4 passes through The rear two ends of the first connection hole 23, the second connection hole 11 and the third connection hole 31 are fixed by pads 5 and nuts 6, so that the diaphragm 3 is fixed to the box-shaped...

Embodiment 2

[0030] Embodiment 2: As shown in the figure, a method for preparing a high-strength box-type composite column includes the following specific steps:

[0031] (1) Take two C-shaped steel plates 1, and drill multiple groups of second connection holes 11 distributed at intervals along the length direction on the flange of the C-shaped steel plates 1. A plurality of groups of first connecting holes 23 equidistant from the second connecting holes 11 are drilled on the column plate 21 of bamboo / wood;

[0032] (2) The column plates 22 made of bamboo / wood are bonded and fixed on the outer surfaces of the webs of the two C-shaped steel plates 1 with an adhesive;

[0033] (3) A third connecting hole 31 is provided on the opposite sides of the transverse partition 3;

[0034] (4) In the same C-shaped steel plate 1 , the position corresponding to the second connection hole 11 is pasted and fixed with an adhesive in order to fix the diaphragm 3 , and the third connection hole 31 on the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com