Soft and clean spinning method

A soft and clean roving technology, applied in the field of textile processing, can solve the problems of lower fiber modulus, poor spinning quality of low- and medium-count yarns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

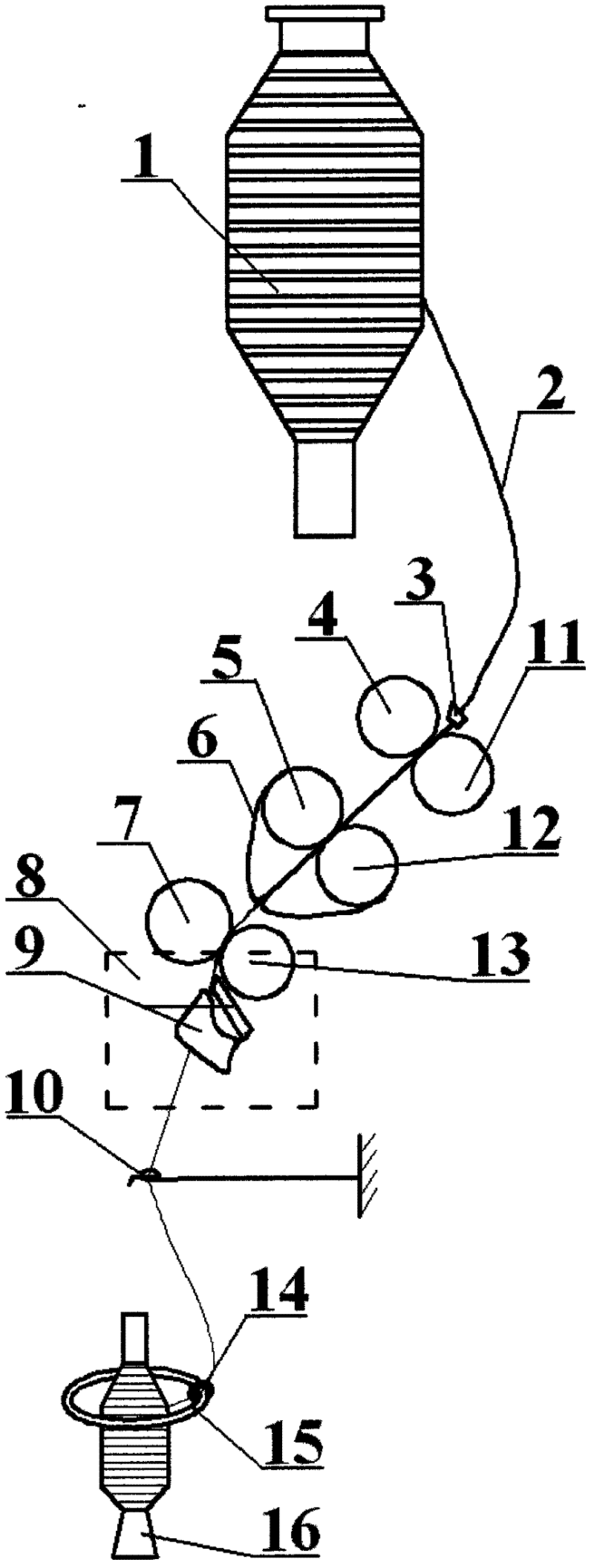

[0018] Example 1 Spinning smooth and low-torque cotton yarn on a cotton ring spinning frame

[0019]On each drafting mechanism of the ring spinning frame, the cotton roving 2 is unwound from the roving package 1, and enters through the yarn guide horn 3 into the rear roller 11, rear rubber roller 4, middle roller 12, middle glue stick 5, leather The drafting zone formed by circle 6, front roller 13 and front rubber roller 7 carries out drafting, and the cotton roving strips after drafting are output from the front nip formed by front roller 13 and front rubber roller 7, and the heat and humidity treatment device 9 is located at the In the twisting triangular area 8, the heat and humidity treatment device 9 performs on-line heat and moisture treatment on the twisted cotton roving strands output from the front jaws and entering the twisting triangle area 8. The on-line heat-moisture treatment can be that in the process of twisting the cotton sliver into yarn, a humidifier is use...

Embodiment 2

[0020] Embodiment 2 spins bright and clean low-torque ramie yarn on hemp spinning ring spinning frame

[0021] On each drafting mechanism of the ring spinning frame, the ramie roving 2 is unwound from the roving package 1, and enters through the yarn guide horn 3 into the rear roller 11, rear rubber roller 4, middle roller 12, middle glue stick 5, leather The hemp spinning drafting zone that circle 6, front roller 13, front rubber roller 7 forms carries out drafting, and the ramie roving sliver after drafting is output from the front nip that front roller 13, front rubber roller 7 form, and heat-moisture treatment device 9 is positioned at In the twisting triangular area 8, the heat-moisture treatment device 9 performs on-line heat-moisture treatment on the twisted ramie roving strands output from the front jaw and entering the twisting triangular area 8. The on-line heat-moisture treatment can be that in the process of twisting the ramie sliver into a yarn, a humidifier is us...

Embodiment 3

[0022] Example 3 Spinning smooth and low-torque ramie wool yarn on wool spinning ring spinning frame

[0023] On each drafting mechanism of the ring spinning frame, the wool roving 2 is unwound from the roving package 1, and enters through the guide horn 3 into the rear roller 11, rear rubber roller 4, middle roller 12, middle glue stick 5, leather 6, front roller 13, and front rubber roller 7 form the wool spinning drafting area for drafting, and the wool roving sliver after drafting is output from the front nip formed by front roller 13 and front rubber roller 7, and the heat and humidity treatment device 9 is located at In the twisting triangular area 8, the heat and humidity treatment device 9 performs on-line heat and moisture treatment on the twisted wool roving sliver that is output from the front jaw and enters the twisting triangle area 8. It can be that, in the process of twisting the wool sliver into yarn, a humidifier is used to directly pass the high-temperature h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com