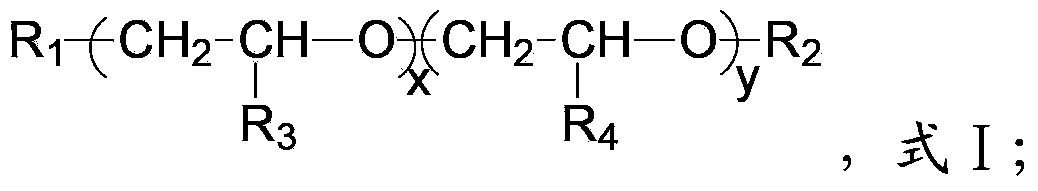

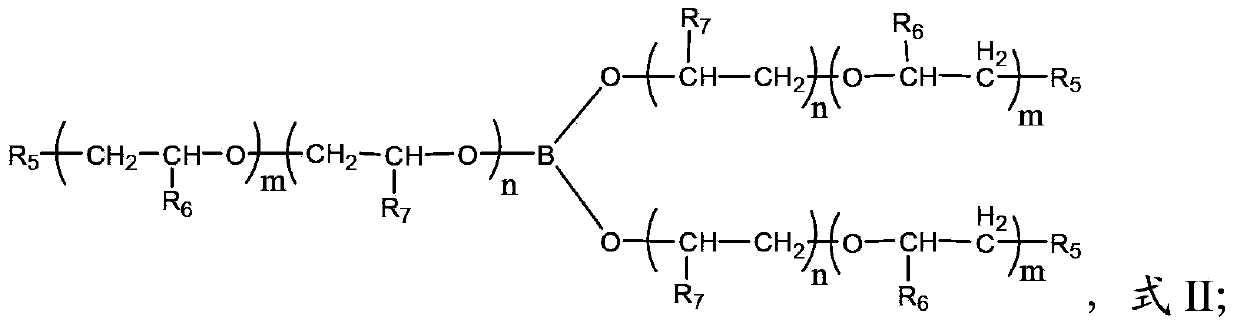

Motor-vehicle brake-fluid composition and preparation method thereof

A composition and brake fluid technology, which is applied in lubricating compositions, petroleum industry, base materials, etc., can solve problems such as poor fluidity and abnormal braking of motor vehicles, and achieve good high temperature stability and excellent flow performance , does not produce the effect of air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a motor vehicle brake fluid composition, which includes the following steps:

[0047] After mixing antioxidants, metal deactivators, corrosion inhibitors, anti-foaming agents, polyalkylene glycol ether borate and polyalkylene glycol ether, and dehydrating, a motor vehicle brake fluid composition is obtained .

[0048] When preparing the automobile brake fluid composition of the present invention, the antioxidant, metal deactivator, corrosion inhibitor, anti-foaming agent, polyalkylene glycol ether borate and polyalkylene glycol There is no special restriction on the mixing method of the ether, and it is preferably prepared according to the following method:

[0049] A) After mixing polyalkylene glycol ether borate and polyalkylene glycol ether, stirring and dehydrating, the first mixed solution is obtained;

[0050] B) After mixing the anti-foaming agent, antioxidant, metal deactivator, corrosion inhibitor, and the fir...

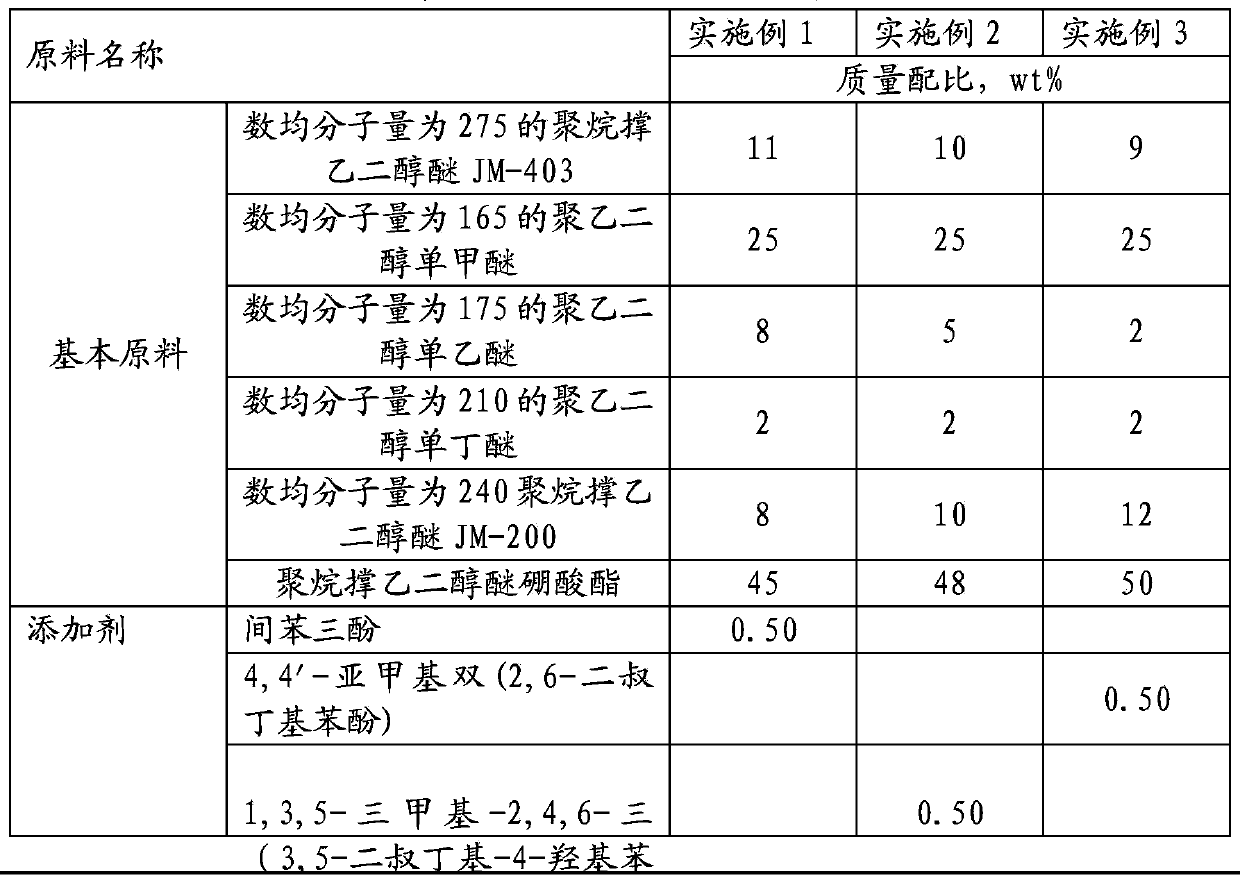

Embodiment 1

[0061] Add appropriate amount of methyl silicone oil with a number average molecular weight of 200 and polyalkylene glycol ether JM220-3 with a number average molecular weight of 2400 to the homogenizer according to the raw material ratio in Table 1, and homogenize 0.5 times at room temperature. Hours, evenly disperse methyl silicone oil with a number average molecular weight of 200 into polyalkylene glycol ether JM220-3 with a number average molecular weight of 2400 to prepare an anti-foaming agent for use;

[0062] According to the raw material ratio in Table 1, polyalkylene glycol ether JM-403 with a number average molecular weight of 275, polyethylene glycol monomethyl ether with a number average molecular weight of 165, and polyethylene glycol mono with a number average molecular weight of 175 Diethyl ether, polyethylene glycol monobutyl ether with a number average molecular weight of 210, polyalkylene glycol ether JM-200 with a number average molecular weight of 240, and pol...

Embodiment 2

[0066] Add appropriate amount of methyl silicone oil with a number average molecular weight of 400 and polyalkylene glycol ether JM220-3 with a number average molecular weight of 2400 to the homogenizer according to the raw material ratio in Table 1, and homogenize 0.5 times at room temperature. After hours, evenly disperse methyl silicone oil with a number average molecular weight of 400 into polyalkylene glycol ether JM220-3 with a number average molecular weight of 2400 to prepare an anti-foaming agent for use.

[0067] According to the raw material ratio in Table 1, polyalkylene glycol ether JM-403 with a number average molecular weight of 275, polyethylene glycol monomethyl ether with a number average molecular weight of 165, and polyethylene glycol mono with a number average molecular weight of 175 Diethyl ether, polyethylene glycol monobutyl ether with a number average molecular weight of 210, polyalkylene glycol ether JM-200 with a number average molecular weight of 240, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com