Direct flow oil-saving burner faulty coal for combustion

A burner and low-quality coal technology, applied in the direction of combustion ignition, combustion methods, lighting and heating equipment, etc., can solve the problems of low coal combustion rate, high fly ash combustibles, high investment costs, etc., to achieve low investment costs, The effect of broad market prospects and simple transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

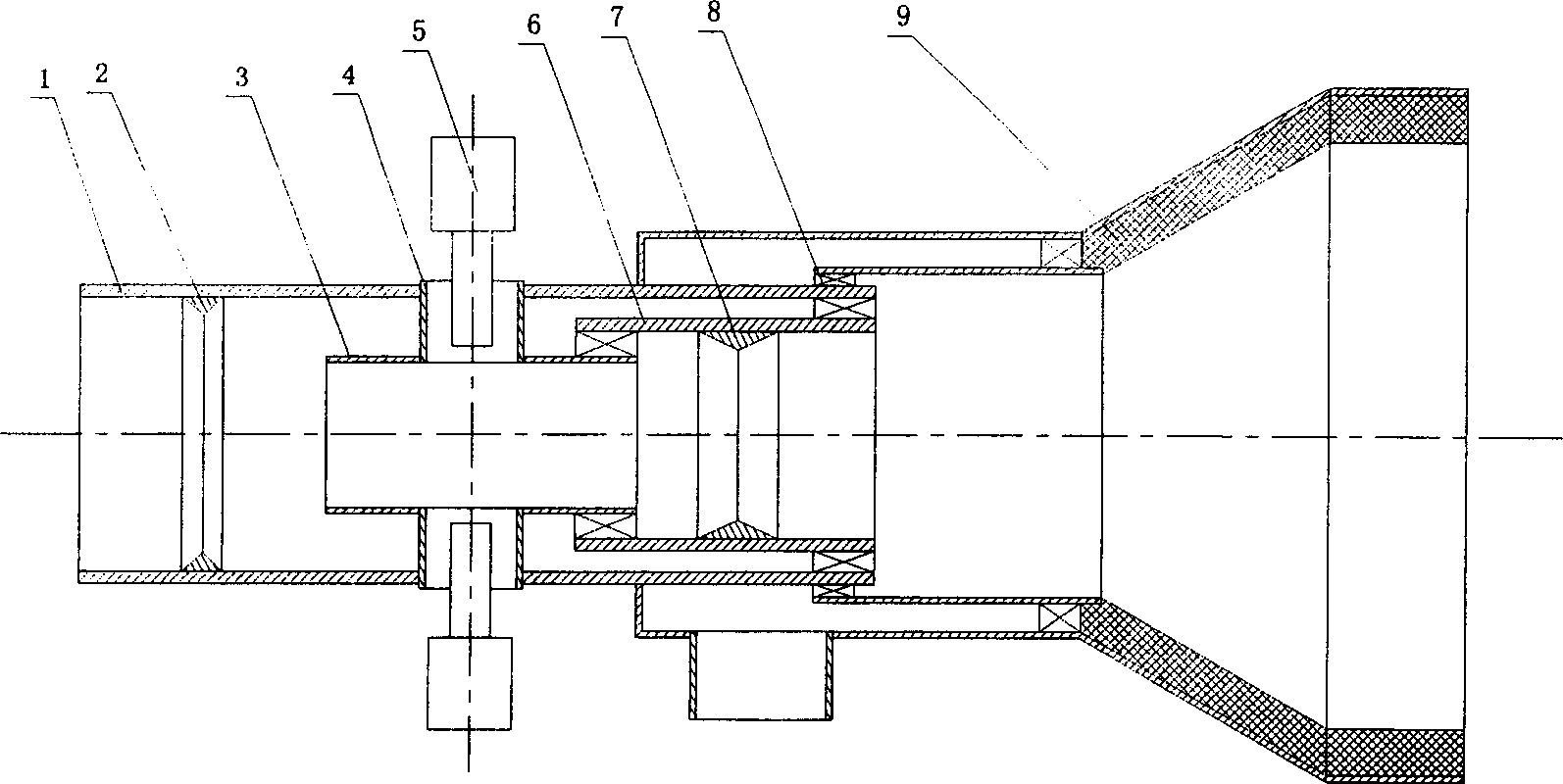

[0015] As shown in the attached figure, the direct-flow oil-saving burner for burning low-quality coal has a pulverized coal combustion chamber 1, and the front end of the pulverized coal pre-combustion chamber 1 is equipped with an impact type pulverized coal concentrator 2, and the pulverized coal pre-combustion chamber 1 is equipped with a primary combustion chamber. Chamber 3, a plurality of oil combustion chambers 4 are arranged on the outside of the middle part of the primary combustion chamber 3, and a small amount of oil burner 5 is arranged in the oil combustion chamber 4, and a secondary combustion chamber 6 is connected to the tail of the primary combustion chamber 3, and the secondary combustion chamber 6 The combustion chamber 6 is provided with a flame-refracting ring 7, and the tail of the pulverized coal pre-combustion chamber 1 is connected with a regenerative pulverized coal combustion chamber 9 through an annular air distributor 8, and the regenerative pulveri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com