Dual media atomizing combustor

A dual medium and burner technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of unsuitable combustion flame, increased flame length, difficult control of flame shape and size, etc., and achieve the effect of improving atomization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation

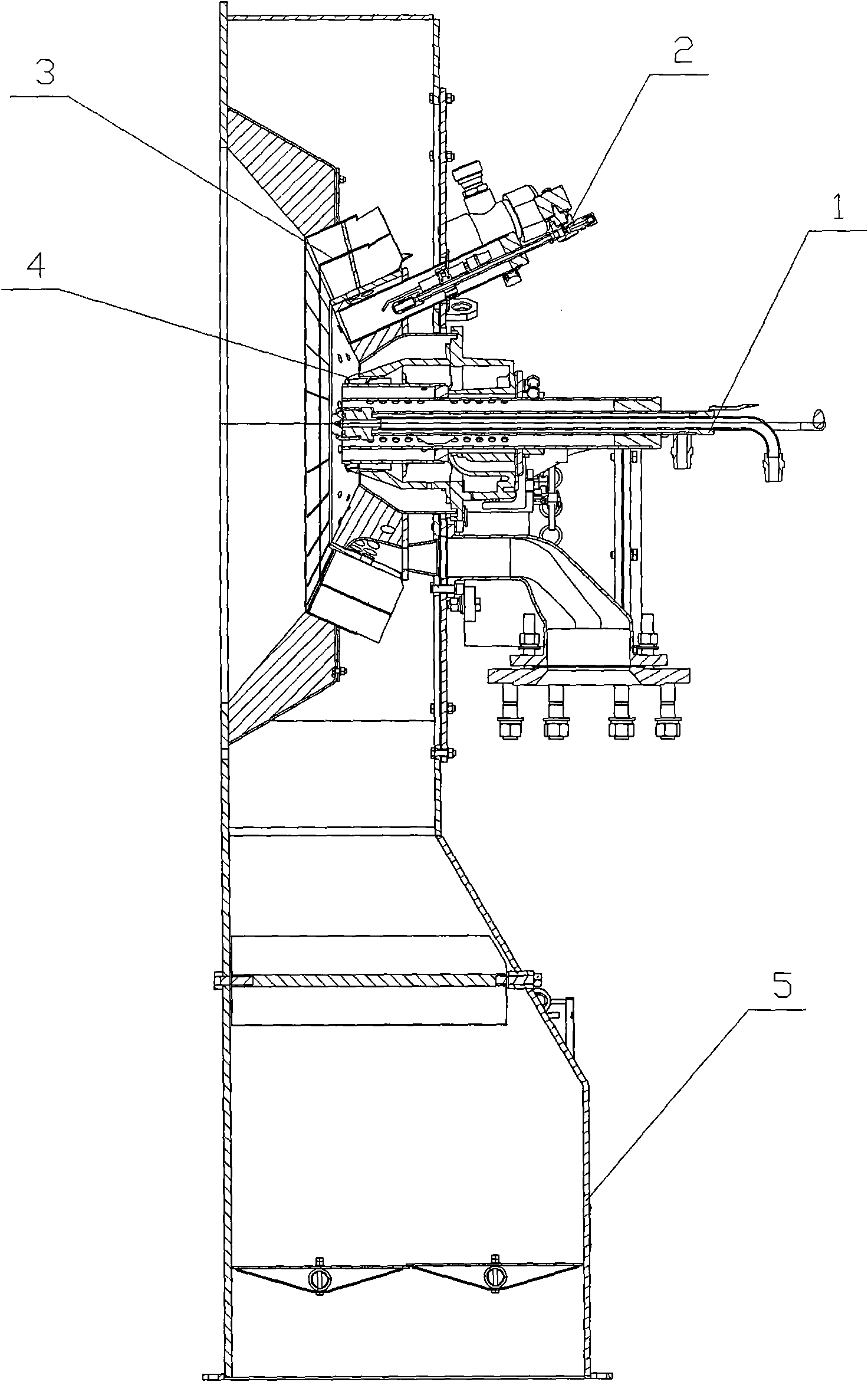

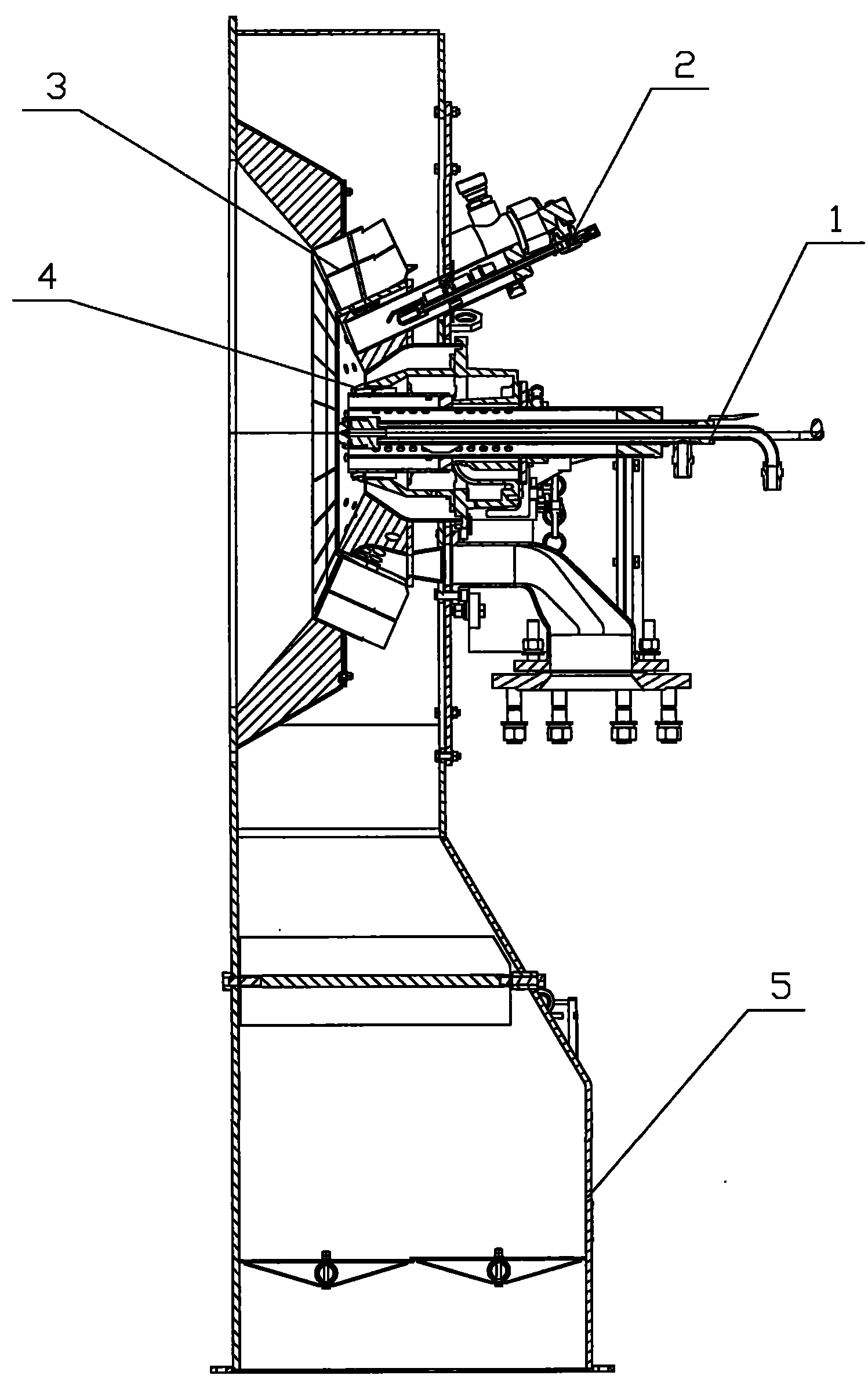

[0009] The embodiment includes a main oil gun 1, a main gas nozzle, an electronic igniter 2, an air box 5, a combustion air swirler 3, and a combustion air servo adjustment mechanism, as shown in the figure, and also includes a medium-pressure atomizing medium nozzle 4 and a fuel and the atomizing medium control valve, the main oil gun nozzle, the medium pressure atomizing medium nozzle 4 and the combustion air cyclone 3 are concentric structures, the main oil gun 1 is in the center position, the medium pressure atomizing medium nozzle 4 and the combustion-supporting air swirler 3 are sequentially arranged in an annular shape on the outer circumference centered on the main oil gun 1, and the main oil gun 1 is provided with liquid fuel and high-pressure atomizing medium.

[0010] The nozzle of the main oil gun 1 is a Y-shaped nozzle.

[0011] The gas nozzle is arranged on the inner wall of the combustion-supporting air swirler 3, and its exit d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com