Combustion device for multi-fuel premix swirl-flow combustion

A combustion device and premixed combustion technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as uneven mixing, uneven air distribution, and difficulty in achieving thermal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

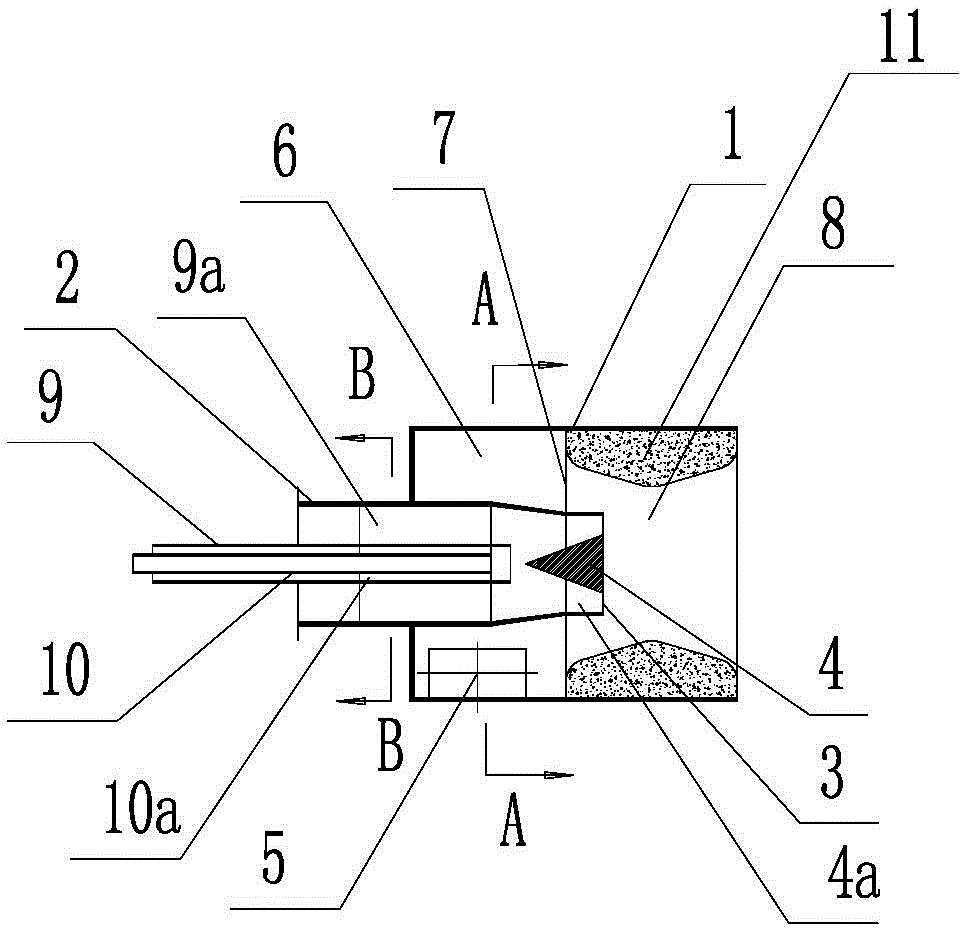

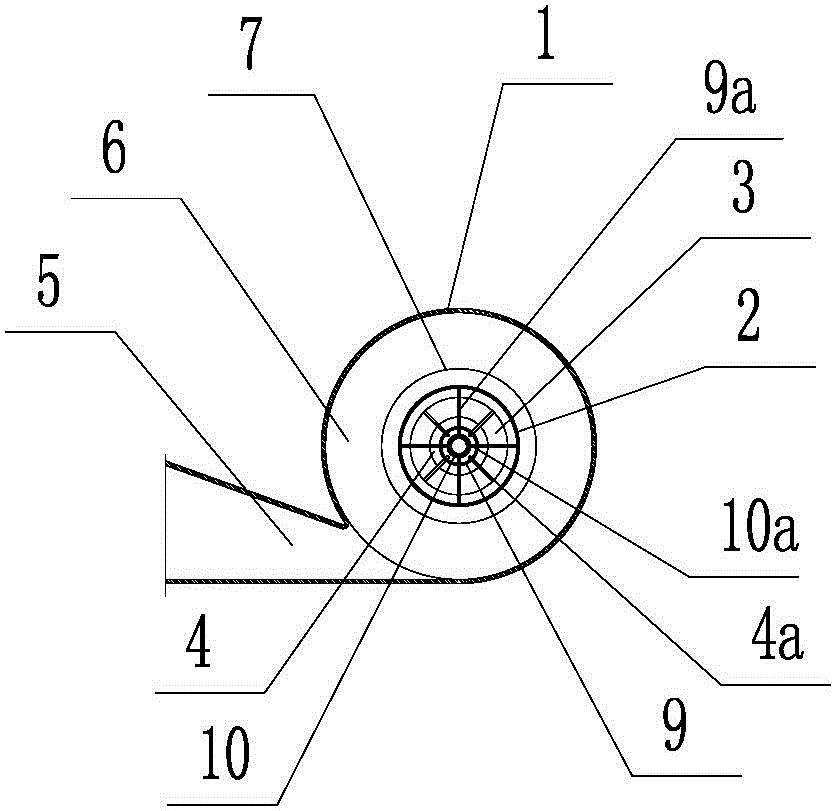

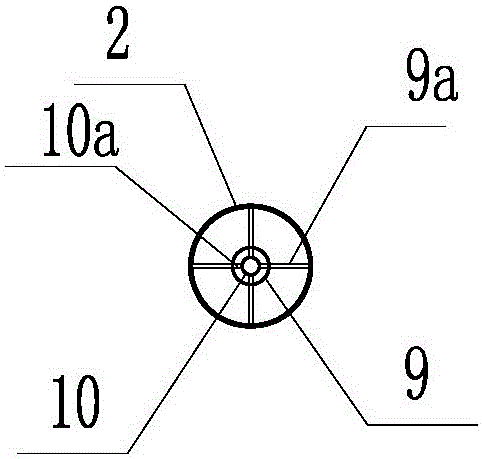

[0009] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] Such as Figure 1-Figure 3 As shown, the present invention includes a combustion device cylinder 1, a gas inlet pipe 2, a gas outlet 3, a blunt body 4, a blunt body support plate 4a, an air inlet pipe 5, an air swirl loop 6, an air outlet 7, a premixed combustion Channel 8, pulverized coal or oil vapor inlet pipe 9, first support deflector 9a, oxygen-enriched air (or pure oxygen) inlet pipe 10 and second support deflector 10a, characterized in that the combustion device cylinder 1 is A cylindrical structure with one end open and the other end closed, a gas inlet pipe 2 is coaxially arranged at the center of the closed end of the combustion device cylinder body 1, and a pulverized coal or oil vapor inlet pipe 9 is coaxially arranged inside the gas inlet pipe, and the gas inlet pipe The inner end is contracted and stretche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com