Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Incineration stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

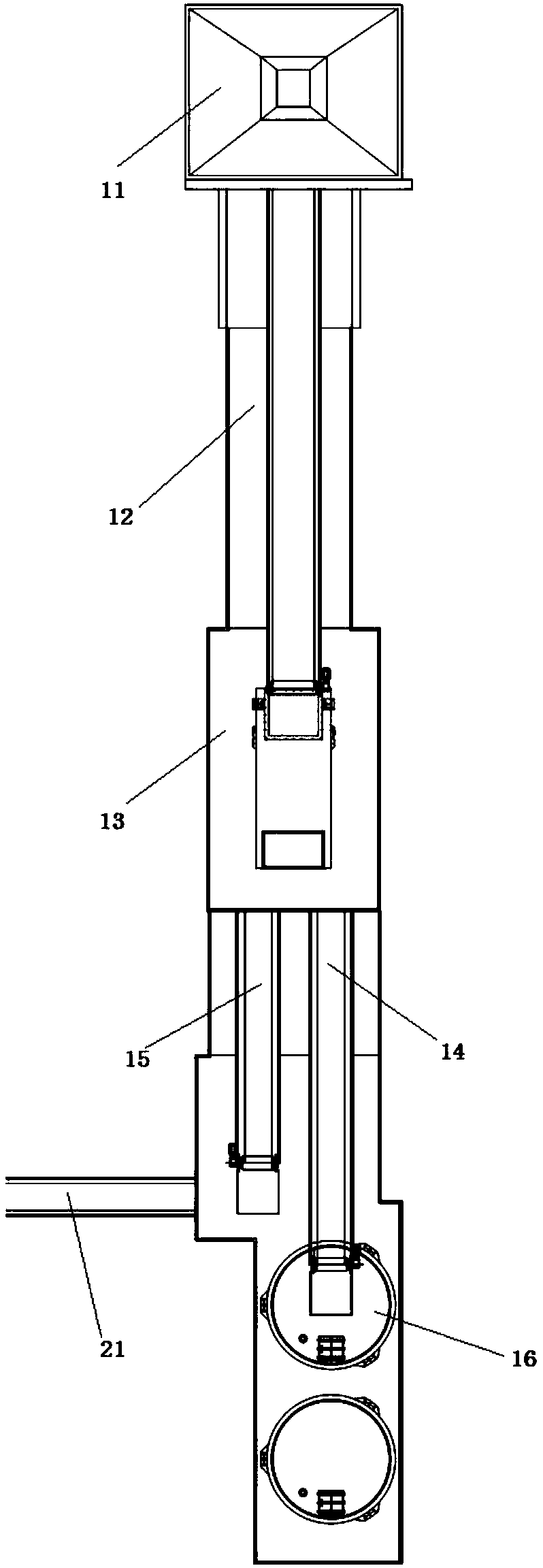

Continuous pyrolysis incineration device for full-scale electronic and electrical product waste

ActiveCN105509062AGuaranteed incineration temperatureGuaranteed incineration efficiencyEmission preventionCombustion technology mitigationEnergy recoverySolvent

The invention relates to a continuous pyrolysis incineration device for full-scale electronic and electrical product waste. The continuous pyrolysis incineration device structurally comprises a feeder, a pulley feed hopper, a pyrolysis gasifier, a pyrolysis gas flue, a combustion furnace, a G-L air heat exchanger, a quenching absorption tower, a bypass flue, a chimney exhaust port, a cat ladder, an activated carbon storage tank and a chimney. The continuous pyrolysis incineration device has the advantages that dangerous electronic and electrical product waste, medical waste, organic waste and other kinds of dangerous combustible solid waste with a certain heat value are treated through a pyrolysis incineration technology, pyrolysis and high-temperature incineration technologies are combined in an optimized mode, low-temperature gas and high-temperature melt are combined together, waste incineration is conducted in the steps of pyrolysis, premixing and incineration, the synthetic technological process and technological conditions of pyrolysis incineration, energy recovery and flue gas cleaning are achieved and have perspectiveness, the overall technology has the outstanding harmless characteristic, compatibility and resourcezation are remarkable, material applicability is high, no hazardous reaction medium or poisonous and harmful solvent is involved in the process, and nature greenization can be achieved.

Owner:NANJING UNIV OF TECH

Sludge incinerator with no auxiliary fuel

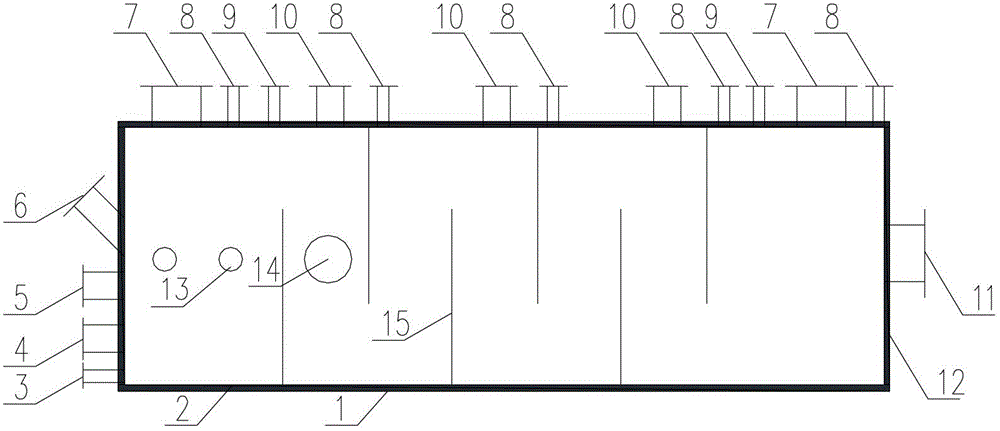

InactiveCN101713543AIncineration stableMass transfer speedSludge treatment by oxidationByproduct vaporizationAir preheaterFailure rate

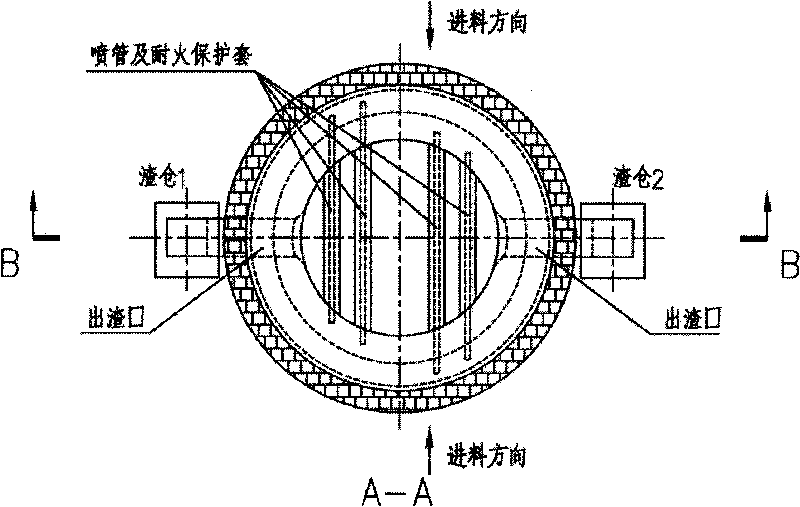

The invention relates to the field of environmental engineering, in particular to sludge incineration technology. The sludge incinerator with no auxiliary fuel overcomes the disadvantage that sludge incineration in the prior art requires the auxiliary fuel such as coal. The sludge incinerator with no auxiliary fuel mainly comprises a boiling section, a suspension chamber, a spray pipe, a gas-guide pipe, a support arch, a slag outlet, a cooling spray nozzle, a combustor, an air chamber and a high-temperature air pre-heater, a slag cabin, a sand hoisting machine, a sand feeder, a middle cabin and a feeding machine. The sludge incinerator with no auxiliary fuel has the following advantages that: the incinerator adopting the technology can realize stable incineration of the sludge under the condition of not adding the coal so as to achieve innocent treatment of the sludge; the sludge incinerator using the technology can store a large amount of heat inside, and a bed has a uniform reaction temperature, so that partial overheat phenomenon is prevented and the temperature in the bed is easy to be controlled; the sludge incinerator is also safe for treating sludge containing a lot of volatile substances (such as oil-containing sludge); a fluidized bed has a simple structure, a low failure rate and a low construction cost, and is provided with a mechanical transmission component; the sludge incinerator can lower the coefficient of excess air and can reduce power consumption; the sludge incinerator has wide fuel adaptability so as to realize controlling harmful gases, such as SO2, NOx and the like easily and to obtain higher combustion efficiency; and ash produced by sludge incineration has a plurality of applications.

Owner:刘沪滨

Flue gas recirculation type garbage pyrolysis gasification oxygen-rich incinerator

ActiveCN105333440AImprove heat utilization efficiencyReduce consumptionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberFlue gas

The invention discloses a flue gas recirculation type garbage pyrolysis gasification oxygen-rich incinerator which comprises an incinerator main body, a flue gas recirculation type air feeding system, a flue gas filter device, an oxygen-rich air feeding system, a flue gas waste-heat heat exchanger and a flue gas purifying device, wherein the incinerator main body comprises a combustion chamber I and a combustion chamber II which are respectively used for garbage pyrolysis gasification and incineration of combustible materials; the circulated flue gas is injected into the incinerator through the flue gas recirculation type air feeding system, so that turbulivity in the incinerator is improved, garbage incineration is strengthened, incompletely-combusted pollutants such as a dioxin precursor and the like are reduced, and discharge of the pollutants is reduced. The oxygen-rich air feeding system can increase an incineration temperature, and can reduce consumption of auxiliary fuels; the flue gas filter device and the flue gas purifying device can further reduce discharge of pollutants; and the flue gas waste-heat heat exchanger can recycle flue gas waste heat. The flue gas recirculation type garbage pyrolysis gasification oxygen-rich incinerator can effectively solve the problems that a garbage thermal value is low, water content is high, an incineration temperature caused by low oxygen content in air is low, combustion efficiency is poor, consumption of auxiliary fuels is high, discharge of pollutants is not up to standard, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

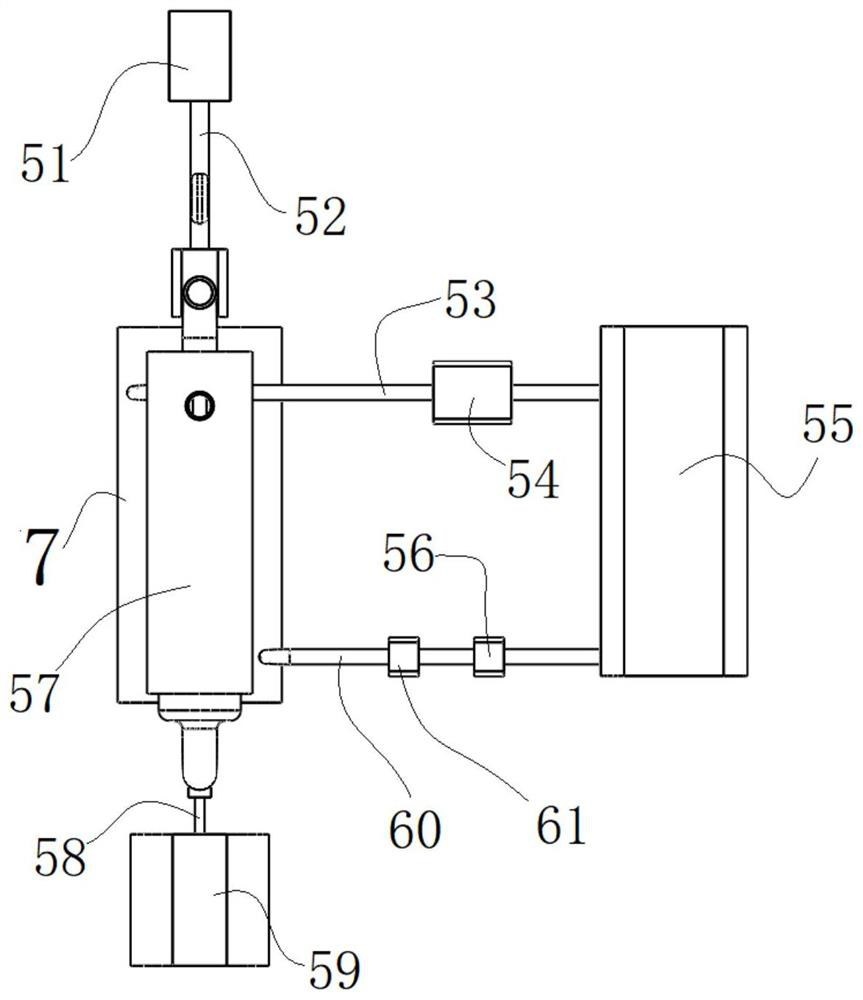

Technology for making acid by combined incineration of waste sulfuric acid and hydrogen sulfide and used incinerator

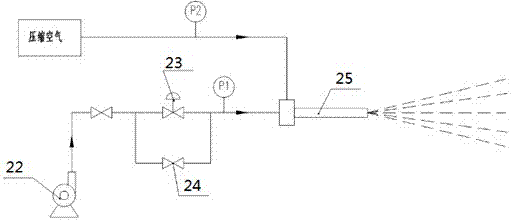

ActiveCN103395750AReduce lossesFull responseChemical industrySulfur compoundsHeat lossesHigh pressure

The invention relates to a technology for making acid by combined incineration of waste sulfuric acid and hydrogen sulfide, and a used incinerator. The technology comprises the following steps: (1) atomizing the waste sulfuric acid, with concentration of greater than or equal to 75%, as a by-product in an oil refinery to form acid mist by combining high pressure pump conveying mechanical atomization with compressed air auxiliary atomization, wherein the grain diameter is smaller than or equal to 80 microns; (2) completely mixing hydrogen sulfide gas, with concentration of 0 to 50%, as the by-product in the oil refinery with hot air in a cyclone air inlet to product mixed gas; and (3) spraying the acid mist into the incinerator by using a waste acid spray gun, meanwhile spraying the mixed gas of hydrogen sulfide gas and hot air into the incinerator by a hydrogen sulfide spray gun and carrying out incineration, pyrolysis and reduction reaction to generate SO2 burner gas, wherein the SO2 burner gas enters an acid making system after the heat is recycled through a heat recovery boiler. During the reaction, the grain diameter of the acid mist is smaller than or equal to 80 microns, and the acid mist is introduced into the incinerator at the same time, so that various reactions can be performed completely and heat loss is reduced furthest at the same time, and produced products meet the requirement of the subsequent acid making technology.

Owner:JIANGSU YONGJI CHEM EQUIP

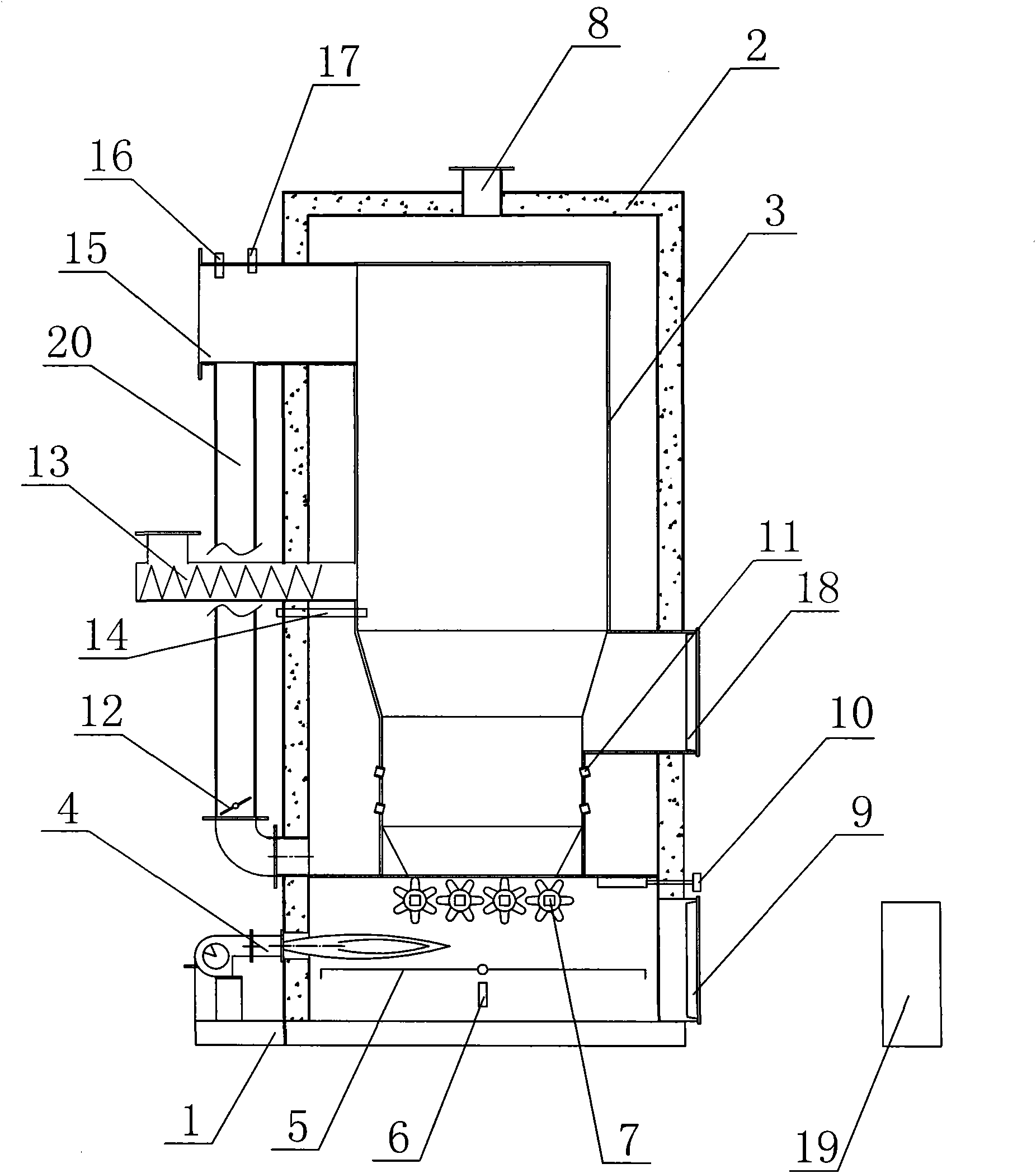

Intelligent sludge incinerator

InactiveCN101956987AIncineration stableHarmless treatmentIncinerator apparatusAutomatic controlCombustion

The invention discloses an intelligent sludge incinerator. The sludge incinerator comprises an outer furnace body, an inner furnace body, a base, an electrically driven automatic slag discharge grate, a screw feeder, an automatic slag discharge device, a diesel oil burner, a primary air inlet system, a secondary air inlet system and a controller, wherein the controller is used for controlling one or more temperature sensors arranged at a hearth, a smoke outlet and a primary inlet, an oxygen quantity sensor arranged at the smoke outlet and a weight sensor for automatic slag discharge. The intelligent sludge incinerator can realize reduction and harmlessness of sludge by adopting a bubbling suspension combustion method, and meanwhile realizes low discharge of pollutants; the combustion is stable by automatic control of parameters of primary and secondary air inlet, and the temperature in the incinerator is controlled at 850 to 950 DEG C all the time for combustion; and the sludge incinerator has high automation degree, saves labor, relieves labor intensity, realizes stable incineration of the sludge, obviously reduces the fault rate, and has low maintenance expense and humanized operation.

Owner:WUXI AMDI ENVIRONMENTAL PROTECTION TECH CO LTD

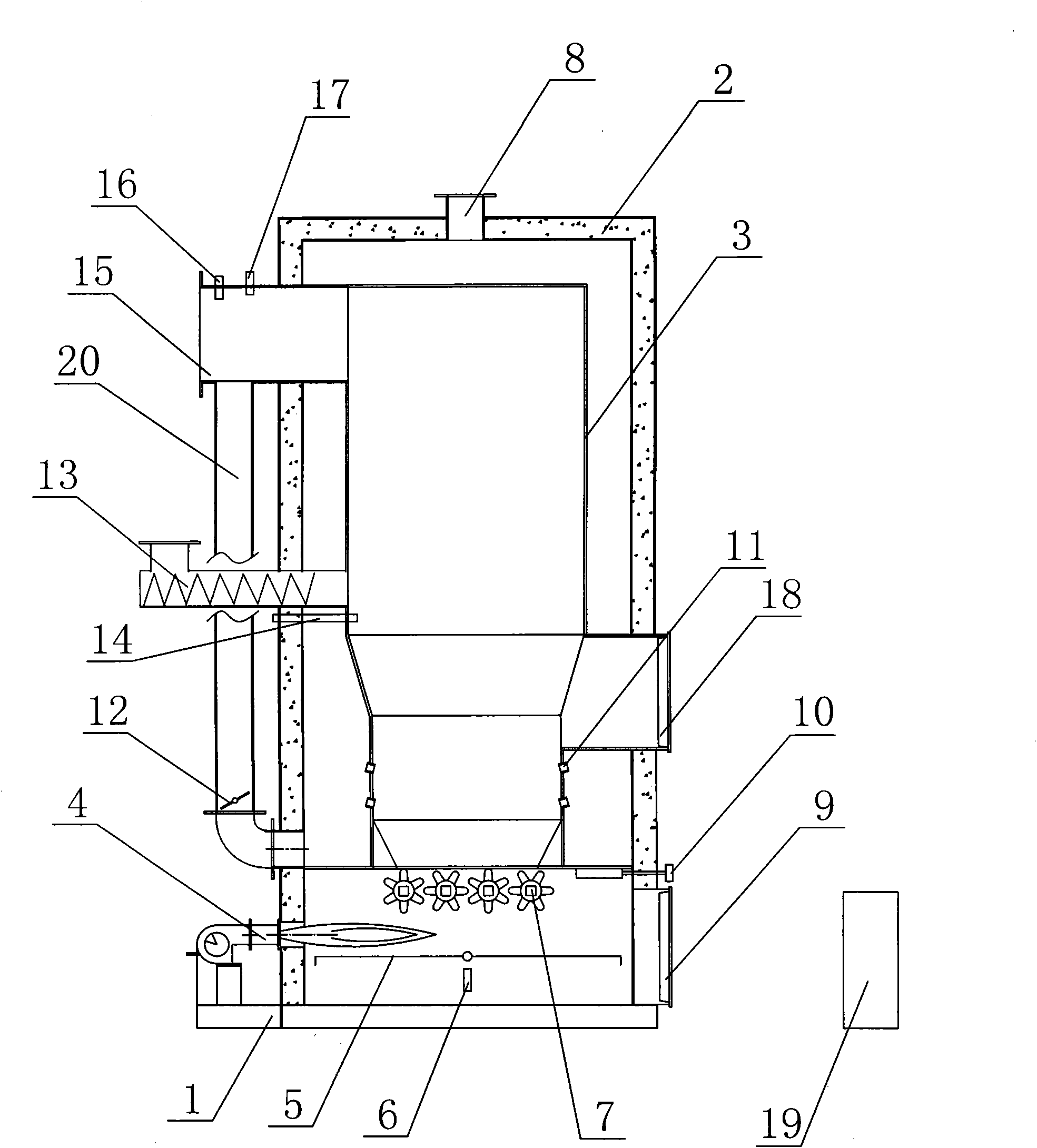

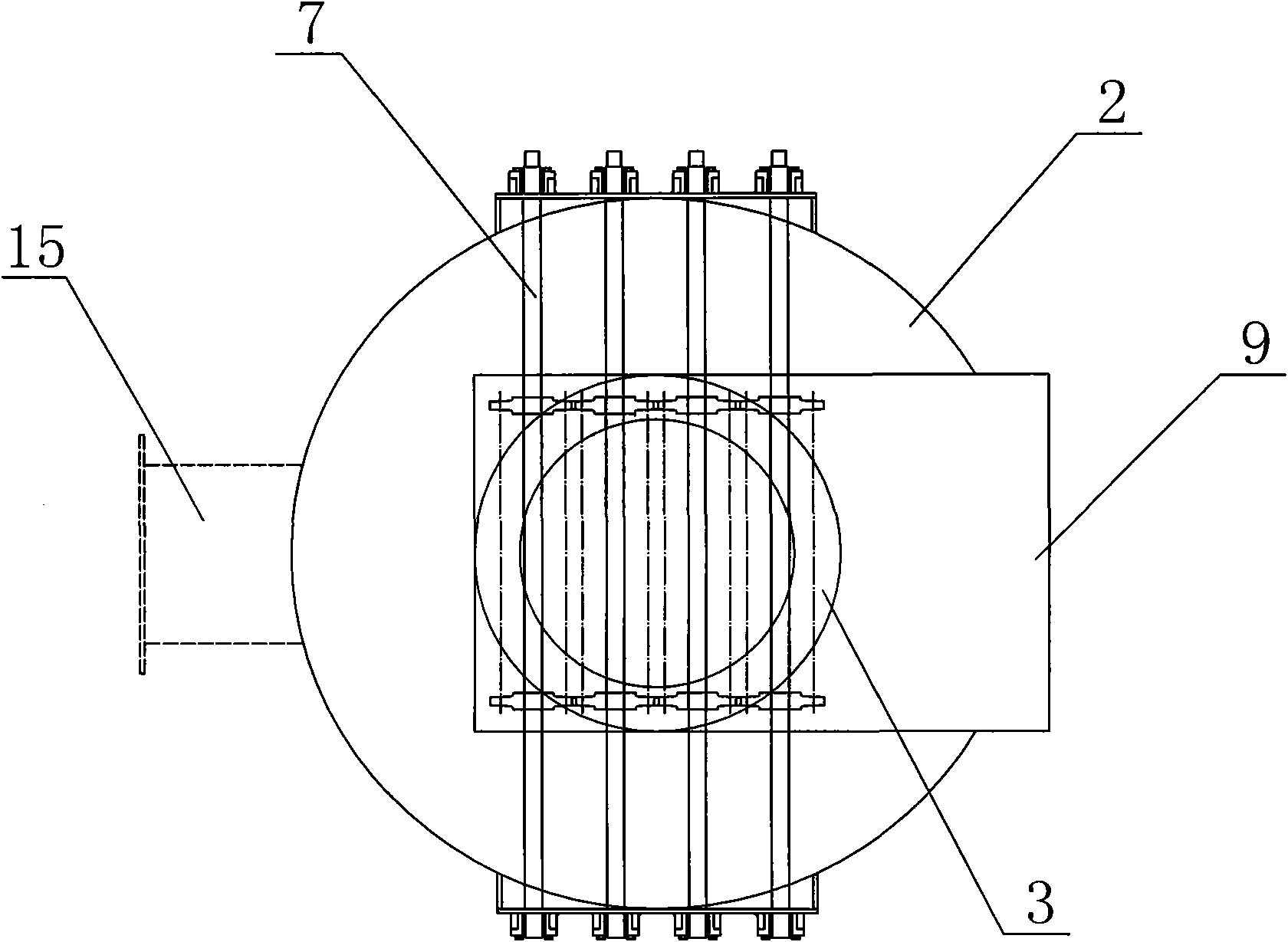

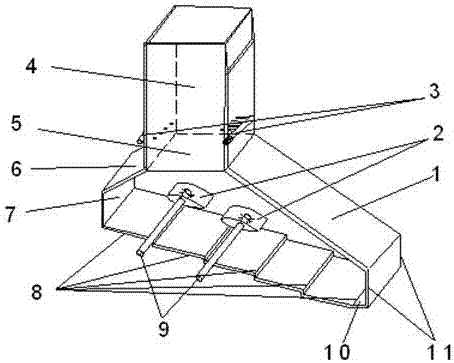

Efficient oil sludge incinerator

ActiveCN103939919AReduce the temperatureHigh thermal efficiencyIncinerator apparatusInlet channelDiesel combustion

An efficient oil sludge incinerator comprises an incinerator body formed by an inner incinerator wall (11) and an outer incinerator wall (10). The efficient oil sludge incinerator is characterized in that an air interlayer (12) is formed between the inner incinerator wall and the outer incinerator wall, a primary air inlet (13) is formed in the outer incinerator wall, an incinerator bottom (5) is arranged on the lower portion of an incinerator chamber (15), an incinerator bottom air outlet (6) communicated with an air outlet of an air distribution plate (4) placed on the outer portion of an incinerator bottom (5) is formed in the incinerator bottom, an air inlet of the air distribution plate (4) is communicated with the air interlayer, a secondary air inlet channel (9) is arranged in the middle of the incinerator body, a screw feeder (8) which conveys oil sludge into the incinerator chamber is arranged on the middle-lower portion of the incinerator body, a diesel combustion-supporting device (1) is arranged on the lower portion of the incinerator body, a smoke outlet channel (14) is arranged on the upper portion of the incinerator body, and a controllable deslagging channel (16) is arranged on the lower portion of the incinerator body. The efficient oil sludge incinerator has the advantages of being high in burning efficiency, stable in incineration and low in mechanical fault rate, and ideal equipment is provided for oil sludge efficient cleaning processing.

Owner:JIANGSU JINDING BOILER

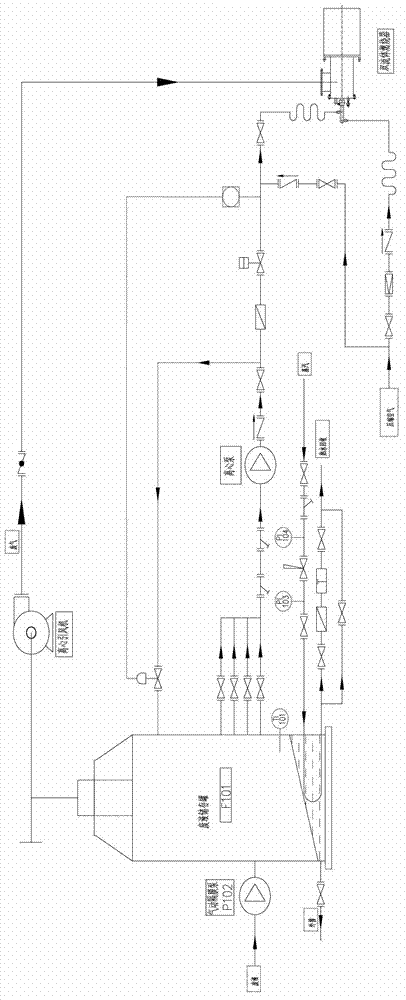

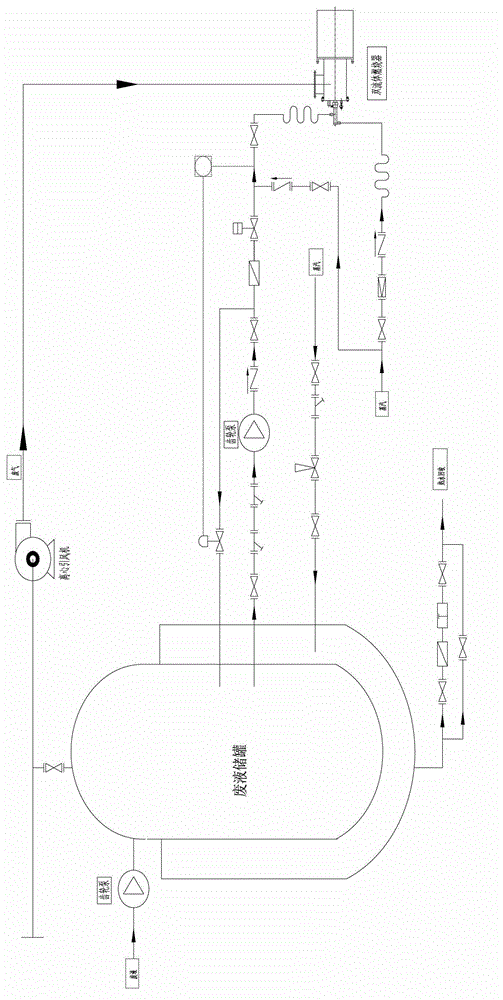

Method for incinerating low-viscosity organic mixed waste liquid

The invention discloses a method for incinerating low-viscosity organic mixed waste liquid. The method comprises the following steps of: injecting an external low-viscosity organic mixed waste liquid into a waste liquid storage tank by using a pneumatic diaphragm pump; controlling the temperature of the waste liquid in the waste liquid storage tank to be30-40 DEG C by using an external steam heat source to guarantee that the waste liquid is in a flowable state; conveying the waste liquid in the waste liquid storage tank to a double-fluid waste liquid combustor through a centrifugal pump, wherein a waste liquid return conduit is arranged between the centrifugal pump and the double-fluid waste liquid combustor and is connected to the waste liquid storage tank; controlling the waste liquid supply pressure to be 0.1-0.4MPa by controlling the reflux quantity of the waste liquid; and before the waste liquid enters the double-fluid waste liquid combustor, introducing compressed air into the waste liquid to guarantee that the waste liquid is atomized, and adjusting the proportioning of the waste liquid to the compressed air through a proportional expression to guarantee that the waste liquid is completely atomized.

Owner:BMEI

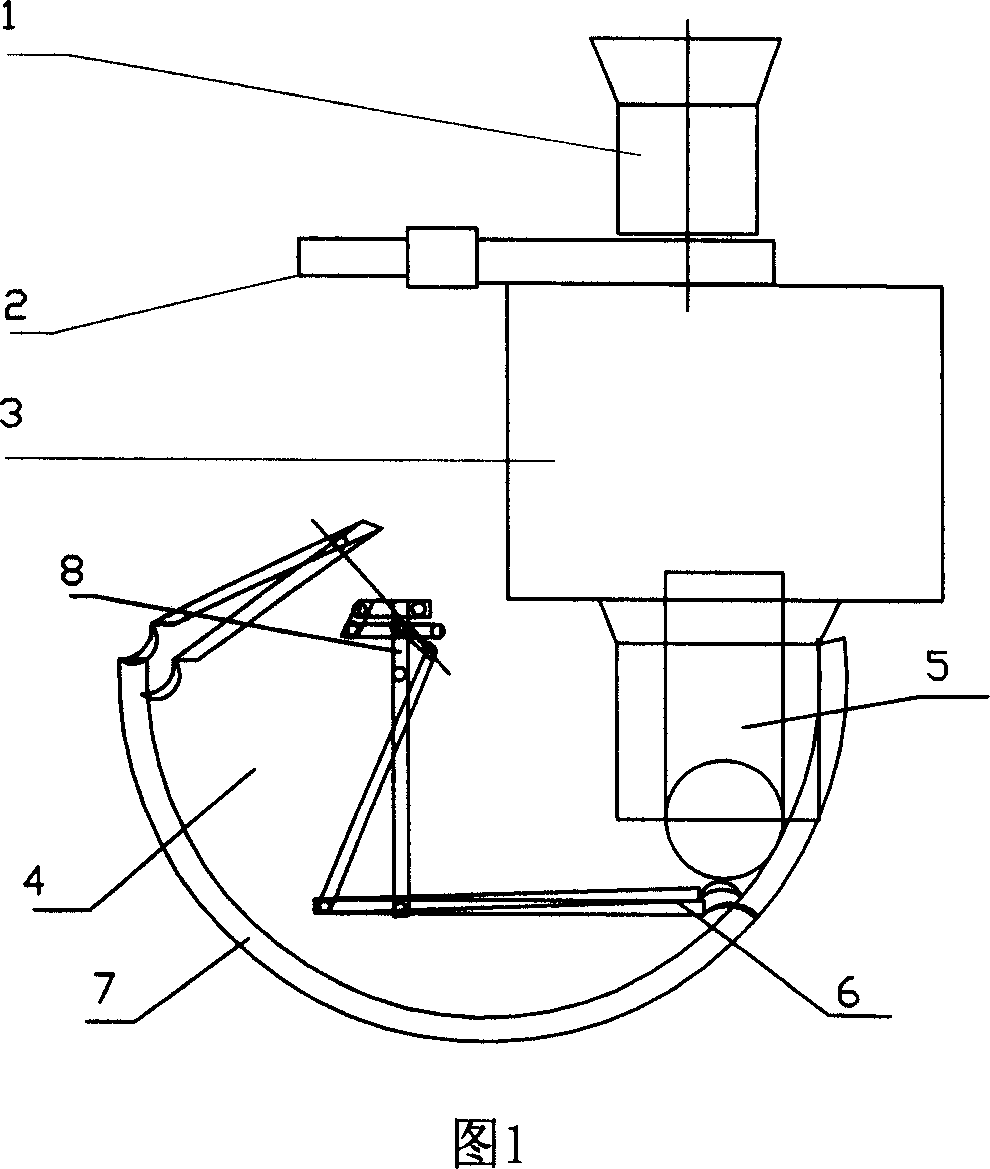

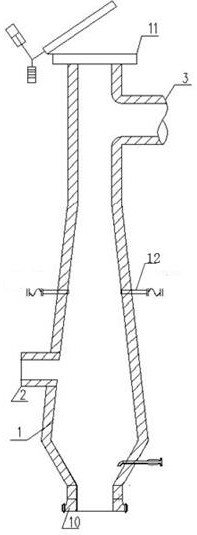

Vertical life refuse heat decomposition incinerator

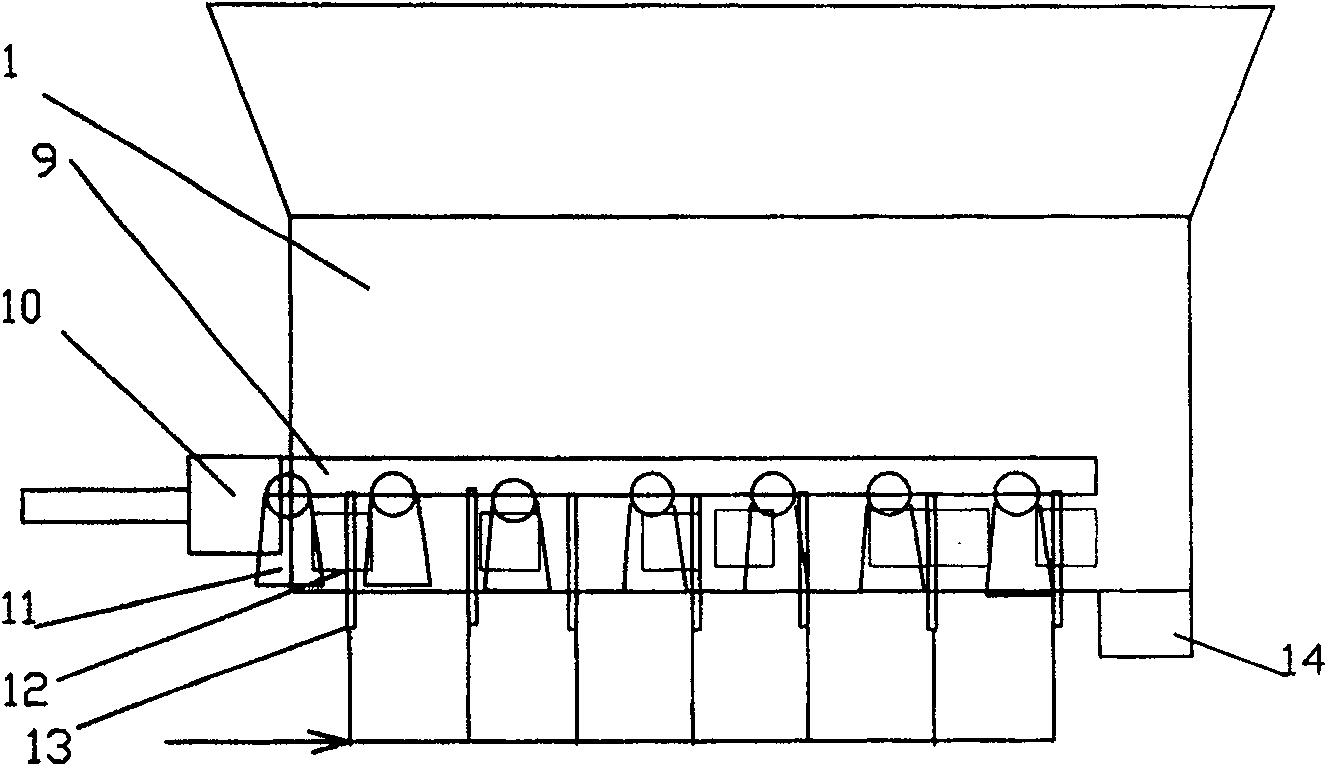

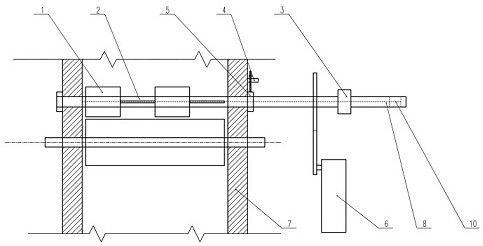

InactiveCN101016990AMeet structural requirementsLow failure rateIncinerator apparatusAir preheaterDecomposition

The invention discloses an upright life waste thermal decomposition incinerator, comprising a body, a hopper and a feeding chamber at the front of the body, and a slag outlet at the back end, a feeder at the front end of the hopper and the feeding chamber. The feeder is step feeder formed by a taper hopper, a groove, a horizontal step plate, a hydraulic driver and a hot wind drying room. The horizontal step plate is connected with the taper hopper above and the hot wind drying room under, while it is driven by the hydraulic driver, to stepped push waste into an outlet. The hot wind drying room is connected with a smoke air preheater in the tail smoke channel of the boiler. The slag outlet is hydraulic arm slag outlet device, which arranges a slag scrape plate at the bottom of the water sealing groove at the bottom of lower wind inlet tube under a slag hopper, while the plate is driven by an arm connecting rod transmitter. The invention can be used in high-water low-heat waste incinerator.

Owner:深圳京基环保设备有限公司

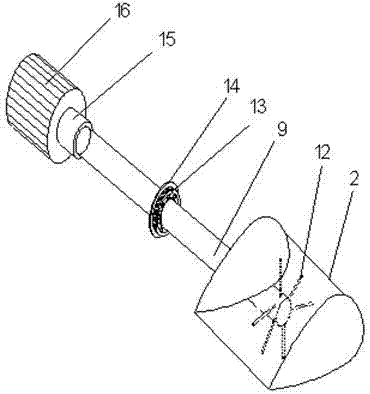

Torch combined with low pressure head by burning buried gas

InactiveCN1786575AIncineration stableSolve the characteristics of large load variation range and air pressure fluctuationIncinerator apparatusMultiple burner assemblyElectricityCombustor

The invention relates to flare tower and its combustion apparatus and unit burner. It includes many circular ring tubes with the same axis but not the same plane. Each of the circular ring tubes is set certain unit burner to form unit burner set. Its features are that each circular ring is connected to landfill gas sub-lateral by U-tube. The sub-lateral can form main. The interval of the U-tube top end is equal to circular ring tube nominal diameter. The vertical section of the former and the horizontal section of the latter are vertical. The sub-lateral is vertically connected to U-tube. It also includes electricity strike fire burning torch. Its accordant adjusting ratio can reach 100:1. The combustion is stable, and not easy to be flameout.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Method and device for chemical-looping incinerating garbage

PendingCN108204593AIncineration realizedPrevent the occurrenceIncinerator apparatusCycloneWater vapor

The invention discloses a method and a device for chemical-looping incinerating garbage. The method comprises the following steps of firstly, pouring the garbage into a fuel reactor, and pretreating;then introducing an oxidation-state oxygen carrier into the fuel reactor, and carrying out oxidation reaction on a treated garbage product and the oxidation-state oxygen carrier; further introducing an oxidation reaction product into a fuel cyclone separator, wherein CO2 and water vapor are used as a fluidizing gas so as to be cyclically imported into the fuel reactor, and a reduction-state oxygencarrier is imported into an air reactor through a classifier; and finally, carrying out reduction reaction on the reduction-state oxygen carrier and air in the air reactor, and re-importing a generated oxidation-state carrier into the fuel reactor for circulating the oxygen carrier. The device comprises the fuel reactor, the air reactor, a first circulator and a second circulator. The method forchemical-looping incinerating the garbage is accomplished through the device, so that the emission of pollutants is reduced, and the garbage can be incinerated fully and stably.

Owner:GRANTOP GRP CO LTD

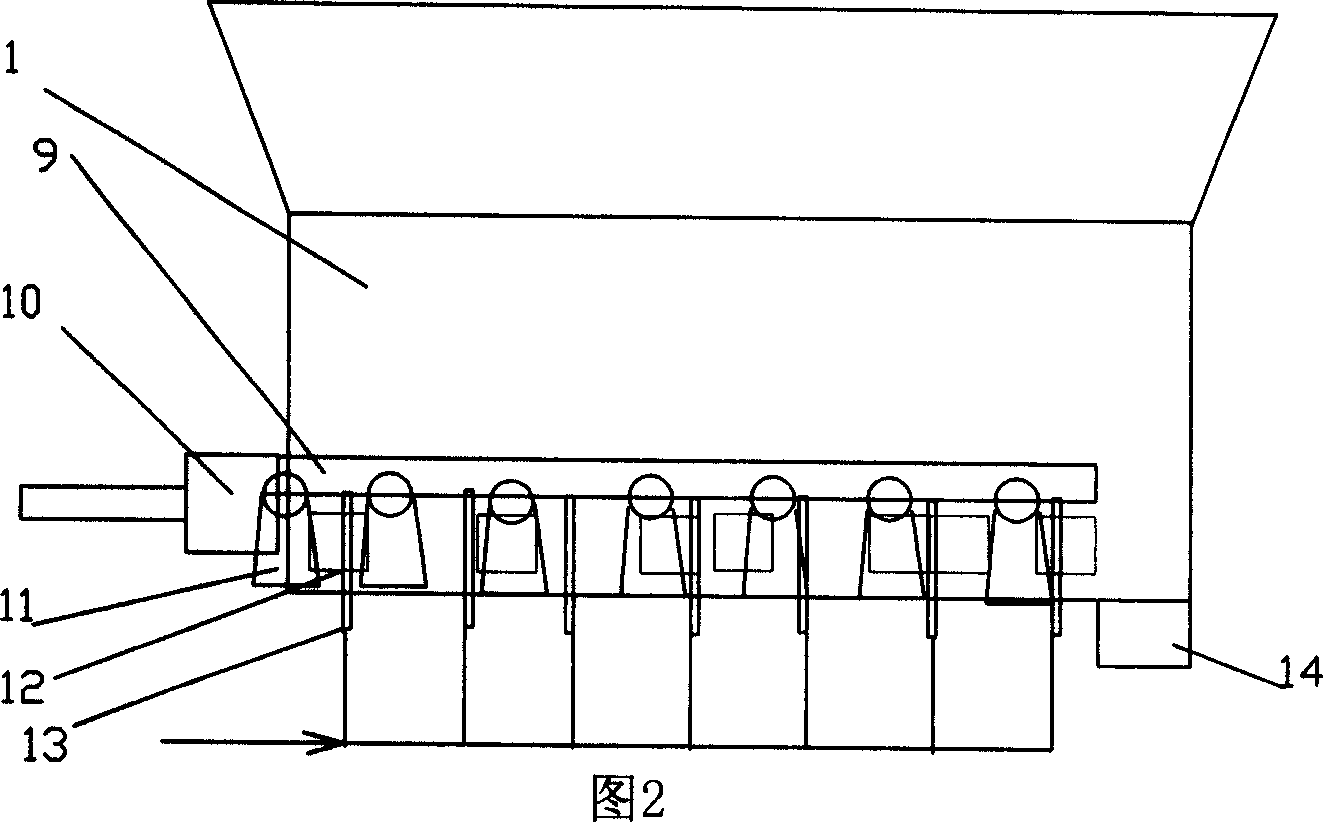

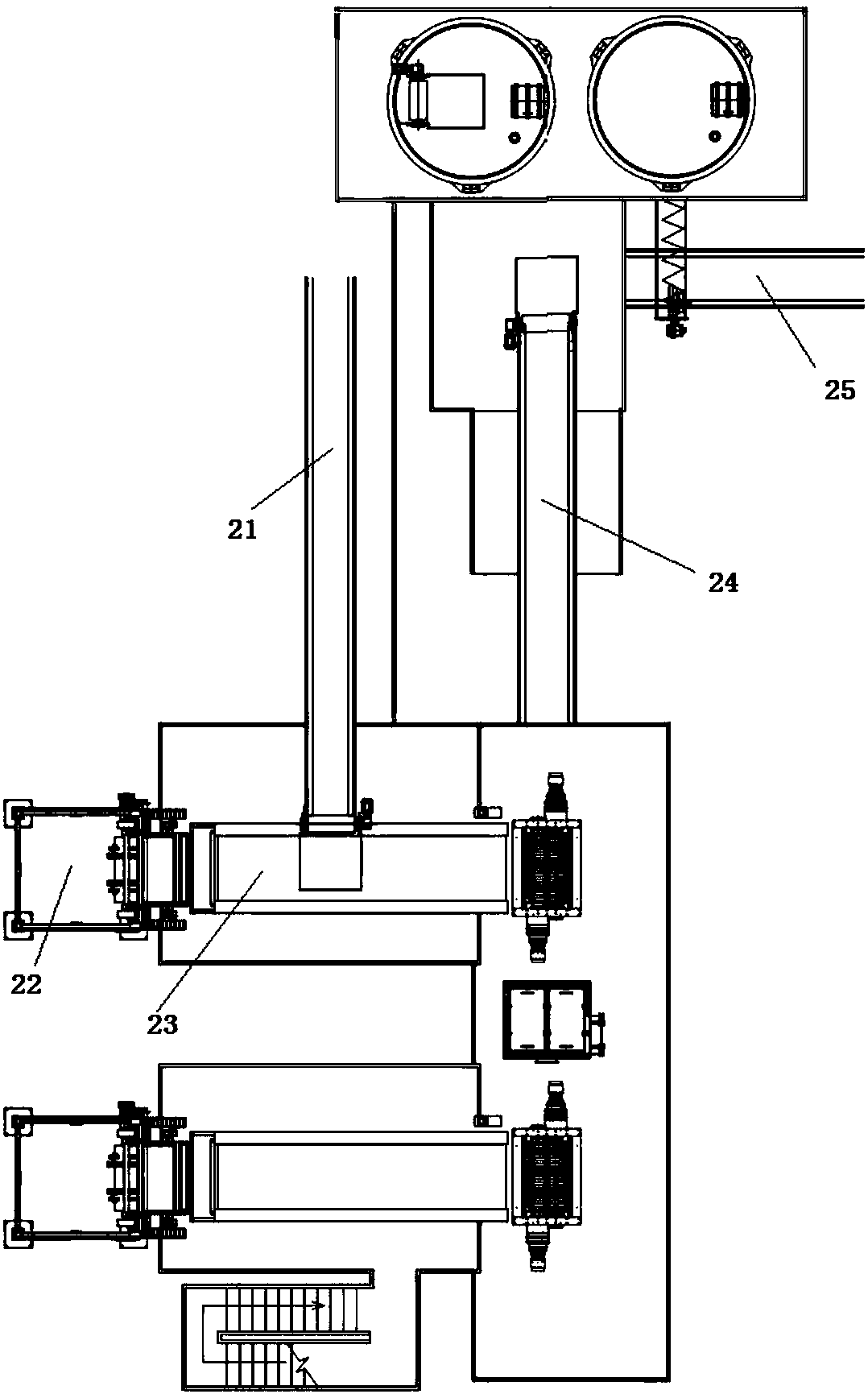

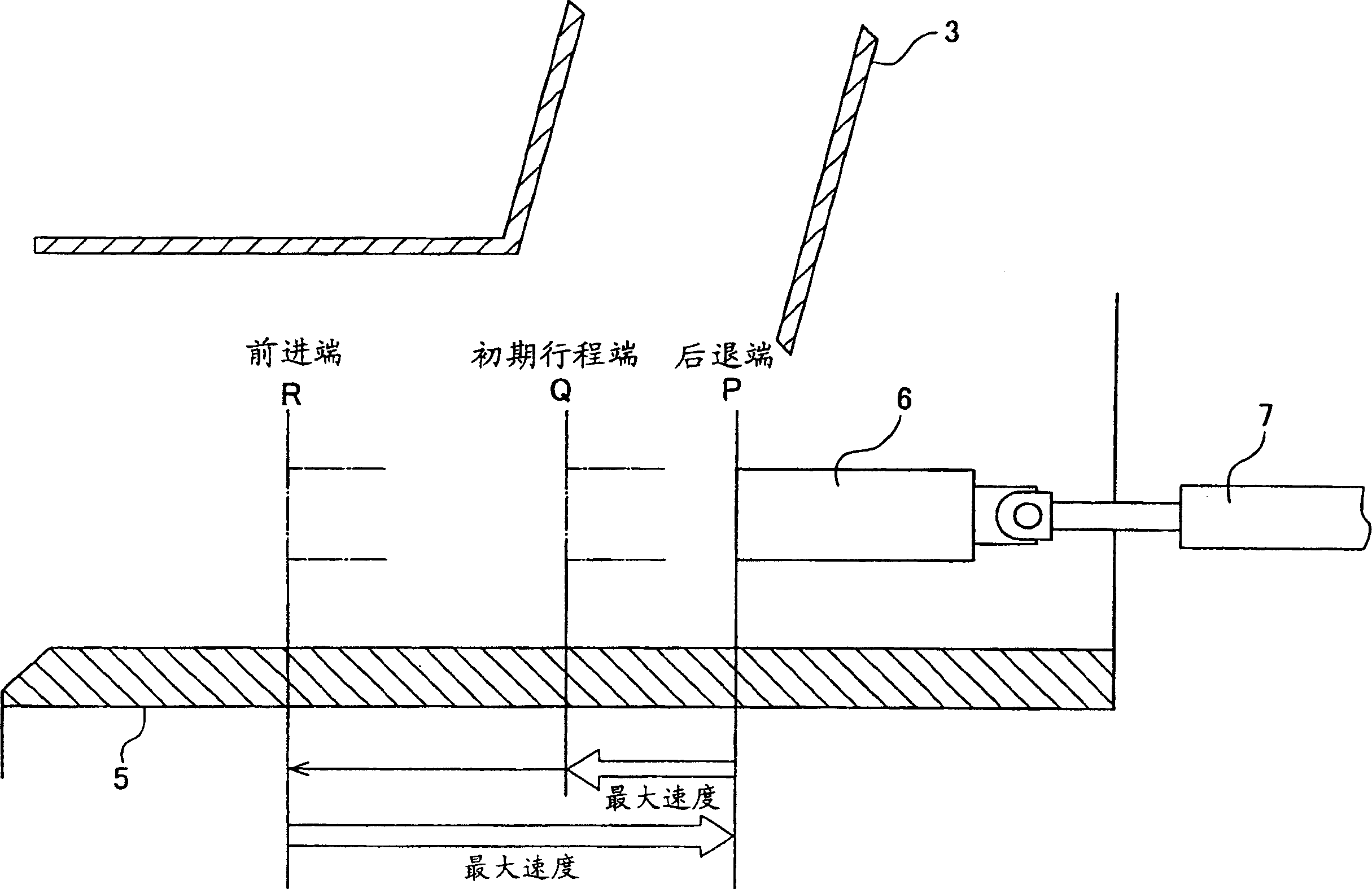

Device for supplying garbages to garbage destructor and garbage supplying method

InactiveCN1521100AContinuous and stable incinerationIncineration stableControl devices for conveyorsIncinerator apparatusCombustionEngineering

The method of supplying garbage to garbage incinerator is to supply garbage through a tunnel to the garbage incinerator quantitatively for stable combustion, reduced CO generated and preventing the generation of un-combusted matter and dioxin. The garbage supplying device has pushing machine with controlled withdrawing speed faster than pushing speed, CCD camera to monitor the status in the upper part of the garbage tunnel, some unit to calculate the weight of supplied garbage in unit time based on the garbage volume inside the tunnel and garbage weight thrown into the tunnel, and some controller to control the constant garbage supplying amount.

Owner:TAKUMA

Full-scale electronic and electrical waste continuous pyrolysis incineration device

ActiveCN105509062BInhibitionTo achieve the purpose of volume reductionEmission preventionCombustion technology mitigationEnergy recoverySolvent

The invention relates to a continuous pyrolysis incineration device for full-scale electronic and electrical product waste. The continuous pyrolysis incineration device structurally comprises a feeder, a pulley feed hopper, a pyrolysis gasifier, a pyrolysis gas flue, a combustion furnace, a G-L air heat exchanger, a quenching absorption tower, a bypass flue, a chimney exhaust port, a cat ladder, an activated carbon storage tank and a chimney. The continuous pyrolysis incineration device has the advantages that dangerous electronic and electrical product waste, medical waste, organic waste and other kinds of dangerous combustible solid waste with a certain heat value are treated through a pyrolysis incineration technology, pyrolysis and high-temperature incineration technologies are combined in an optimized mode, low-temperature gas and high-temperature melt are combined together, waste incineration is conducted in the steps of pyrolysis, premixing and incineration, the synthetic technological process and technological conditions of pyrolysis incineration, energy recovery and flue gas cleaning are achieved and have perspectiveness, the overall technology has the outstanding harmless characteristic, compatibility and resourcezation are remarkable, material applicability is high, no hazardous reaction medium or poisonous and harmful solvent is involved in the process, and nature greenization can be achieved.

Owner:NANJING TECH UNIV

A flue gas circulation type garbage pyrolysis gasification oxygen-enriched incinerator

ActiveCN105333440BImprove heat utilization efficiencyReduce consumptionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberFlue gas

Owner:HUAZHONG UNIV OF SCI & TECH

Household garbage comprehensive disposal and multicomponent utilization method

InactiveCN107617630ALess investmentImprove power generation efficiencySolid waste disposalProduction lineEnvironmental effect

The invention discloses a household garbage comprehensive disposal and multicomponent utilization method, which belongs to the technical field of resources and environmental protection. Municipal household garbage is presorted into two parts including organic combustibles and inorganic muck; after presorting, the organic combustibles are conveyed to a garbage power plant so as to be burnt to generate power, generated slag enters a dry cement production line and is used as cement raw materials so as to be mixed, generated fly ash enters the dry cement production line, and the inorganic muck isconveyed to the dry cement production line so as to be burnt in a cement kiln and then is used as cement raw materials so as to be mixed. According to the household garbage comprehensive disposal andmulticomponent utilization method, the problem of small scale of cooperative garbage disposal of an existing cement kiln is solved, and the problem of slag and fly ash disposal in garbage power is solved; a good environmental effect is guaranteed, the high household garbage disposal capability is provided, recycling is realized during household garbage disposal, and a good economic effect is achieved.

Owner:成都建筑材料工业设计研究院有限公司 +2

Vertical life refuse heat decomposition incinerator

InactiveCN100549521CHigh calorific valueIncineration stableIncinerator apparatusAir preheaterDecomposition

The invention discloses a vertical domestic waste thermal decomposition incinerator, which comprises an incinerator body, a hopper and a feeding bin at the front end of the incinerator body, and a slag discharging device at the rear end; a feeding device is arranged at the rear end of the hopper and the feeding bin; The feeding device described above is a stepping type, mainly composed of a conical hopper, a trough, a horizontal stepping plate, a hydraulic drive device and a hot air drying chamber; room; the horizontal stepping plate is driven by a hydraulic drive device, and the garbage is pushed into the discharge port in a step-by-step manner. The hot air drying chamber is connected to the flue gas air preheater in the tail flue of the boiler of the incinerator body with pipelines. The slag discharge device adopts a hydraulic bucket arm type slag discharge machine; its structure is to set a dust scraper at the bottom of the water seal groove at the bottom of the air inlet pipe under the outlet of the ash hopper, and the dust scraper is driven by the bucket arm linkage transmission mechanism. It is suitable for waste incinerators with high moisture content and low calorific value.

Owner:深圳京基环保设备有限公司

High efficiency oil sludge incinerator

ActiveCN103939919BReduce the temperatureHigh thermal efficiencyIncinerator apparatusInlet channelDiesel combustion

An efficient oil sludge incinerator comprises an incinerator body formed by an inner incinerator wall (11) and an outer incinerator wall (10). The efficient oil sludge incinerator is characterized in that an air interlayer (12) is formed between the inner incinerator wall and the outer incinerator wall, a primary air inlet (13) is formed in the outer incinerator wall, an incinerator bottom (5) is arranged on the lower portion of an incinerator chamber (15), an incinerator bottom air outlet (6) communicated with an air outlet of an air distribution plate (4) placed on the outer portion of an incinerator bottom (5) is formed in the incinerator bottom, an air inlet of the air distribution plate (4) is communicated with the air interlayer, a secondary air inlet channel (9) is arranged in the middle of the incinerator body, a screw feeder (8) which conveys oil sludge into the incinerator chamber is arranged on the middle-lower portion of the incinerator body, a diesel combustion-supporting device (1) is arranged on the lower portion of the incinerator body, a smoke outlet channel (14) is arranged on the upper portion of the incinerator body, and a controllable deslagging channel (16) is arranged on the lower portion of the incinerator body. The efficient oil sludge incinerator has the advantages of being high in burning efficiency, stable in incineration and low in mechanical fault rate, and ideal equipment is provided for oil sludge efficient cleaning processing.

Owner:JIANGSU JINDING BOILER

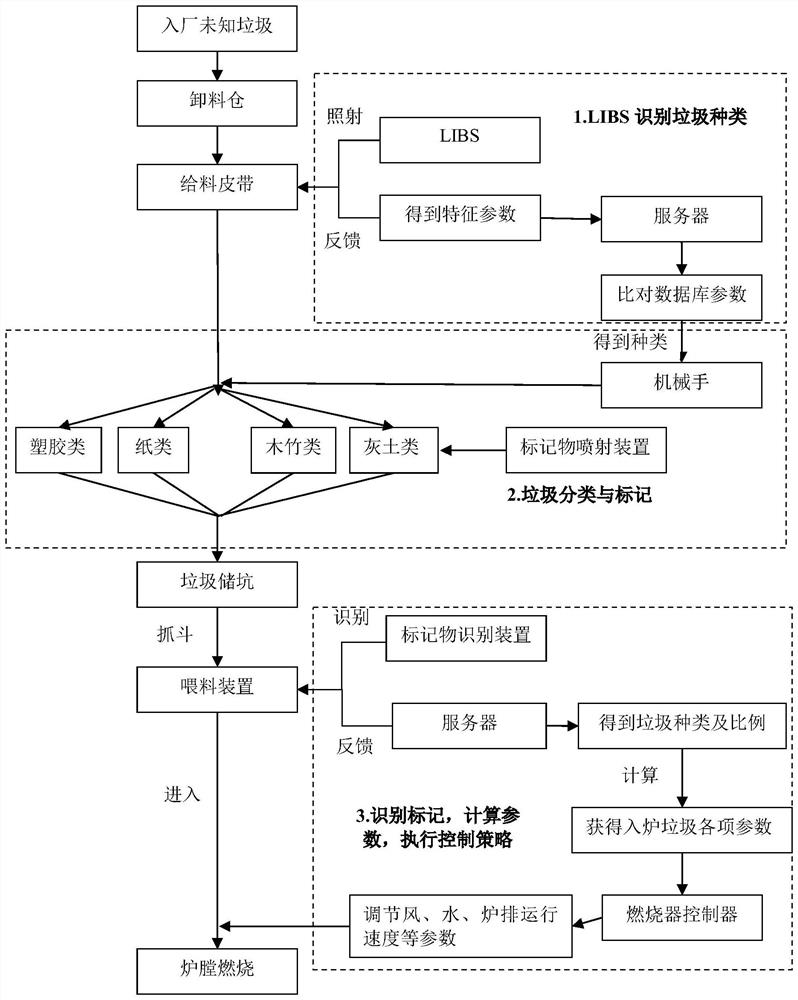

Waste incineration prediction and feedforward control method

The invention relates to a waste incineration prediction and feedforward control method. The method comprises the following steps that the types of furnace-entering waste are obtained; the furnace-entering waste is classified based on the waste types, and then each type of classified waste is marked; the marked furnace-entering waste is mixed and then identified, and the types and the mass ratio of the furnace-entering waste are obtained; based on the types and the mass ratio of the furnace-entering waste, one or more parameters including the heat value, the water content, the fixed carbon and the ash content of the furnace-entering waste are calculated; and according to the parameters of the furnace-entering waste, one or more parameters including the air volume, the water supply flow and the fire grate running speed of an incinerator are adjusted. According to the method, the waste is subjected to fine classification and marking, then the data of the real-time furnace-entering waste are obtained, the parameters including the heat value, the water content, the fixed carbon and the ash content of the furnace-entering waste are obtained based on the data, the boiler combustion parameters are adjusted in advance, the combustion condition is prejudged, the problem of control lag is avoided, and combustion in the incinerator is optimized.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

A kind of incineration method of high-viscosity organic mixed waste liquid

The invention discloses a method for incinerating high-viscosity organic mixed waste liquid. The method comprises the following steps of: injecting external high-viscosity organic mixed waste liquid into a waste liquid storage tank by using a gear pump; controlling the temperature of the waste liquid in the waste liquid storage tank to be between 60 and 130 DEG C by utilizing an external steam heat source, and ensuring the waste liquid to be in a flowable state; conveying the waste liquid in the waste liquid storage tank to a two-fluid waste liquid combustor, wherein a waste liquid reflux pipe is arranged between the gear pump and the two-fluid waste liquid combustor and is connected to the waste liquid storage tank, and the waste liquid supply pressure is controlled to be between 0.1 and 0.4 MPa by controlling the reflux amount of the waste liquid; and before the waste liquid enters the two-fluid waste liquid combustor, introducing steam into the waste liquid to atomize the waste liquid, and proportionally adjusting the ratio of the waste liquid to the steam to completely atomize the waste liquid.

Owner:BMEI

Hazardous Waste Pretreatment System

The invention discloses a hazardous waste pretreatment system. The hazardous waste pretreatment system comprises a coarse powder hazardous waste pretreatment unit, a solid hazardous waste pretreatment unit, a paste hazardous waste pretreatment unit, a special hazardous waste pretreatment unit and a liquid hazardous waste pretreatment unit, wherein the coarse powder hazardous waste pretreatment unit is used for pretreating coarse powder hazardous waste, the solid hazardous waste pretreatment unit is used for pretreating solid hazardous waste, the paste hazardous waste pretreatment unit is used for pretreating paste hazardous waste, the special hazardous waste pretreatment unit is used for pretreating special hazardous waste, the liquid hazardous waste pretreatment unit is used for pretreating liquid hazardous waste, and the hazardous waste is fed into an incineration system for incineration treatment after being subjected to physical form shaping, material compatibility matching and calorific value adjustment. According to the hazardous waste pretreatment system, the materials which will enter the incineration system can be subjected to physical form unification beforehand and processed through compatibility and calorific value matching, so that the materials burn sufficiently in the incineration system, the sources of fuel are stable, and the efficiency is improved.

Owner:北京北控环保工程技术有限公司

Combustion treatment method for carbonyl nickel-containing waste gas

ActiveCN102012033BIncrease continuous processing timeContinuous incineration processIncinerator apparatusCombustionMixed flow

The invention discloses a combustion treatment method for carbonyl nickel-containing waste gas and relates to improvement of a combustion treatment method for the carbonyl nickel-containing waste gas generated in the carbonyl metallurgical production process. The method is characterized in that: by utilizing the Venturi principle of fluid for the combustion treatment of the carbonyl nickel-containing waste gas, a sleeve is arranged on an air inlet pipe of an incinerator; and a compressed air inlet pipe is arranged at the front end of the sleeve; therefore, the temperature of an exhaust pipe is reduced, and the distribution of the waste gas and air is realized. The method comprises the following steps of: opening a compressed air valve to introduce air into the sleeve, and opening a carbonyl nickel-containing waste gas inlet valve to perform mixed flow distribution combustion. By utilizing the Venturi principle of fluid, mixed flow distribution is performed before the waste gas is combusted, a negative pressure area is formed at the waste gas inlet, the rate for decomposing the carbonyl nickel in the waste gas at the air inlet to form nickel plating is delayed and the continuous treatment time of the waste gas is prolonged; therefore, the process of combusting the waste gas is continuously and stably performed, and the aim of timely disinfection is fulfilled.

Owner:JINCHUAN GROUP LIMITED

A preparation system and operation method of solid recovered fuel

ActiveCN110358603BReasonable structural designEmission reductionBiofuelsSolid fuelsThermodynamicsProcess engineering

The invention provides a solid recovery fuel preparation system and a running method thereof, wherein light combustible substances, heavy incombustible substances and recoverable metals can be separated while the moisture content of domestic garbage can be reduced and the calorific value of the garbage can be increased. According to the method, garbage enters a coarse breaking machine by a sortingline material receiving hopper, and the coarse breaking machine breaks the domestic garbage; the coarsely broken garbage is conveyed to a dish-type sieve by a coarse breaking machine material discharge belt conveyor, and before the garbage enters the dish-type sieve, part of the iron metal carried in the garbage is removed by a dish-type sieve feeding pre-iron removing device; the domestic garbage is sieved into an oversize material and an undersize material; the light combustible substances in a light substance buffer warehouse are fed to a drying line material receiving hopper by a substance buffer warehouse bridge type grab crane, and then the light combustible substances are conveyed to a drying machine by a double screw conveyor; and the light combustible substances being subjected to air drying treatment is conveyed to a solid recovery fuel warehouse by a finished product fuel warehousing conveyor.

Owner:CHINA UNITED ENG

Combustion treatment method for carbonyl nickel-containing waste gas

ActiveCN102012033AIncrease continuous processing timeContinuous incineration processIncinerator apparatusCarbonyl groupExhaust fumes

The invention discloses a combustion treatment method for carbonyl nickel-containing waste gas and relates to improvement of a combustion treatment method for the carbonyl nickel-containing waste gas generated in the carbonyl metallurgical production process. The method is characterized in that: by utilizing the Venturi principle of fluid for the combustion treatment of the carbonyl nickel-containing waste gas, a sleeve is arranged on an air inlet pipe of an incinerator; and a compressed air inlet pipe is arranged at the front end of the sleeve; therefore, the temperature of an exhaust pipe is reduced, and the distribution of the waste gas and air is realized. The method comprises the following steps of: opening a compressed air valve to introduce air into the sleeve, and opening a carbonyl nickel-containing waste gas inlet valve to perform mixed flow distribution combustion. By utilizing the Venturi principle of fluid, mixed flow distribution is performed before the waste gas is combusted, a negative pressure area is formed at the waste gas inlet, the rate for decomposing the carbonyl nickel in the waste gas at the air inlet to form nickel plating is delayed and the continuous treatment time of the waste gas is prolonged; therefore, the process of combusting the waste gas is continuously and stably performed, and the aim of timely disinfection is fulfilled.

Owner:JINCHUAN GROUP LIMITED

Device for supplying garbages to garbage destructor and garbage supplying method

InactiveCN1294381CContinuous and stable incinerationIncineration stableControl devices for conveyorsIncinerator apparatusCombustionCcd camera

The method of supplying garbage to garbage incinerator is to supply garbage through a tunnel to the garbage incinerator quantitatively for stable combustion, reduced CO generated and preventing the generation of un-combusted matter and dioxin. The garbage supplying device has pushing machine with controlled withdrawing speed faster than pushing speed, CCD camera to monitor the status in the upper part of the garbage tunnel, some unit to calculate the weight of supplied garbage in unit time based on the garbage volume inside the tunnel and garbage weight thrown into the tunnel, and some controller to control the constant garbage supplying amount.

Owner:TAKUMA

A trapezoidal high-temperature oxidation chamber for plasma solid waste treatment process

ActiveCN110296434BGood effectUniform flow fieldBlast-producing apparatusIncinerator apparatusThermodynamicsFlue gas

The invention discloses a trapezoidal high-temperature oxidation chamber for plasma solid waste treatment process, which comprises a high-temperature oxidation furnace, a pressure control system, an oxygen content control system and a water spray cooling system; A conical structure and a second conical structure at the bottom, and the longitudinal section of the first conical structure is a trapezoidal structure with a narrow top and a wide bottom, and the longitudinal section of the second conical structure is a trapezoidal structure with a wide top and a narrow bottom; the pressure control system The pressure of the high temperature oxidation furnace is controlled to be ‑20~‑30Pa; the oxygen content control system maintains the normal oxygen content of the flue gas outlet; the water spray cooling system controls the normal incineration temperature of the high temperature oxidation furnace. The flow field and heat field in the high temperature oxidation chamber of the present invention are more uniform, the incineration is more stable, the effect is better, and the NO can be significantly reduced. X emission; the setting of double blowers reduces the possibility of interlock shutdown; in terms of structure, the trapezoidal design is also more stable.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Agricultural waste environment-friendly incineration device

InactiveCN110986057AIncineration stableBig burning surfaceAir/fuel supply for combustionIncinerator apparatusEnvironmental engineeringPolluted environment

The invention relates to the field of agricultural environmental protection equipment, in particular to an agricultural waste environment-friendly incineration device. The agricultural waste environment-friendly incineration device comprises a vertically-arranged support mounting barrel, wherein supporting foot pads are arranged at four corners of the lower end of the support mounting barrel; material guide mounting holes are horizontally formed in the lower half part of the support mounting barrel in a penetrating manner; a material guide mounting frame is horizontally arranged between the material guide mounting holes; a movable combustion barrel is arranged at the upper end of the material guide mounting frame; and a lifting mounting frame is horizontally arranged in the support mounting barrel above the material guide mounting holes. Through the cooperation of a synchronous lifting adjusting structure and a clearance fit pressing structure, crop wastes can be stably incinerated, the problems of polluting the environment and wasting resources since incineration ash is directly led out and difficult to recycle are avoided, the crop wastes have large incineration area, high incineration efficiency and good incineration quality by means of an active incineration structure of active flow guiding and multi-point combustion, the incineration residues are completely recycled, the recycling is facilitated, and the whole agricultural waste environment-friendly incineration device is more environmentally friendly.

Owner:赵权

Preparation method of rotary kiln type continuous carbonization pyrolysis gasification incinerator

ActiveCN105114955BSolve the problem of high consumptionReduce operating costsIncinerator apparatusCycloneCombustion chamber

The rotary kiln type continuous dry distillation pyrolysis gasification incinerator includes a feeding device, a kiln body rotary device, a dry distillation pyrolysis gasification device, and a tail gas purification device. The right end of the kiln body rotary device is provided with a feeding device, the left end of the kiln body rotary device is provided with a dry distillation pyrolysis gasification device, and the left end of the dry distillation pyrolysis gasification device is provided with a tail gas purification device; the kiln body rotary device includes a rotary kiln, dry distillation pyrolysis gasification device The gasification device includes a dry distillation gasification chamber and a secondary combustion chamber, and the tail gas purification device includes a cyclone dust collector, a waste heat boiler, a quenching tower, a neutralization tower, a bag filter, an induced draft fan, and a spray washing tower; the preparation method includes the following operation steps: Initial combustion of material → dry distillation and gasification of material → initial combustion of flue gas → preliminary dust removal of flue gas → heat exchange of flue gas → quenching of flue gas → neutralization of flue gas → secondary dust removal of flue gas → acid removal of flue gas → discharge of flue gas up to standard. The invention can use high temperature flue gas to dry, dry distillation and pyrolyze medical waste or industrial waste, save fuel, discharge environmental protection and reduce the operating cost of enterprises.

Owner:江苏鼎新环保科技有限公司

A process for making acid by combined incineration of waste sulfuric acid and hydrogen sulfide and the incinerator used

Owner:JIANGSU YONGJI CHEM EQUIP

A waste gas treatment system and its purification treatment process

ActiveCN109611871BBurn completelyIncineration stableLiquid fuel feeder/distributionIncinerator apparatusFlue gasExhaust fumes

The invention discloses a waste gas treatment system, an organic waste gas incinerator, an organic waste gas preheater and a diverter; the smoke exhaust end of the organic waste gas incinerator is connected to a smoke guide pipe, and the smoke outlet end of the smoke guide pipe The hot smoke inlet end of the organic waste gas preheater is connected, and the cold smoke discharge end of the organic waste gas preheater is connected with a smoke exhaust pipe; the invention can fully incinerate the organic waste gas, and can also stably utilize its The energy contained in the organic waste gas, and the organic waste gas preheater can make full use of the waste heat of the flue gas to achieve the effect of energy saving and emission reduction.

Owner:TAICANG CITY LVDIAN INFORMATION TECH CO LTD

Waste incineration device and method with wide calorific value application range

The invention discloses a waste incineration device with a wide calorific value application range. The waste incineration device comprises an incineration hearth and a rotary wing type arch mechanism, wherein the rotary wing type arch mechanism comprises a rotary wing type arch, a transmission shaft, a bearing, a sealing part, a shaft coupler and a motor which are arranged in the incineration hearth; one end of the transmission shaft is fixed with the rotary wing type arch; the other end of the transmission shaft passes through a furnace wall and is in driving connection with the motor through the shaft coupler; the bearing is arranged between the transmission shaft and the furnace wall; the sealing part is arranged in a seam between the transmission shaft and the furnace wall; and the rotary wing type arch rotates by a proper angle under driving of the motor. The invention further discloses a waste incineration device with a wide calorific value application range. According to the waste incineration device and method disclosed by the invention, the design of the rotary wing type arch is adopted, a proper angle is rotated, radiation heat during waste incineration can be adjusted, temperature fields in the hearth are kept stable, and waste is guaranteed to stably combust; and flue gas disturbance in the hearth and retention time, in the hearth, of the flue gas also can be increased, and a waste calorific value is wide in application range, so that the waste incineration device and method are worthy of being popularized in the waste incineration field.

Owner:SOUTH CHINA UNIV OF TECH

Movable incinerator grate turning device

PendingCN114321938AIncineration stableMeet compactnessIncinerator apparatusNon-combustible gases/liquids supplyEngineeringCombustion

A movable incinerator fire grate turning device is arranged at the front end, the middle end and the rear end of a fire grate respectively, the turning device at the front end is arranged in the middle of a drying area, and the turning device at the rear end is arranged at the 1 / 3 position of a burnout area. Comprising a material turning shifting piece, an air cooling hollow shaft, a rotary joint, an adjusting structure, a high-temperature-resistant bearing, a speed reducer, a furnace wall, an air supply and exhaust pipeline, a secondary fan and an air supply cooling structure, the air cooling hollow shaft is fixed to the furnace wall through the adjusting structure and the high-temperature-resistant bearing, and a hollow shaft of the speed reducer is connected with one end of the air cooling hollow shaft; a plurality of material turning shifting pieces are evenly arranged on the shaft section, located between the furnace walls, of the air cooling hollow shaft, the secondary fan is connected with the end, close to the speed reducer, of the air cooling hollow shaft through an air supply and exhaust pipeline and a rotary connector, and nozzles are formed in the positions, located on the material turning shifting pieces, of the air cooling hollow shaft. According to the device, an original combustion mode is reserved, stable incineration of low-calorific-value large-particle-size garbage is achieved through the enhanced turbulent flow technology, and the compact and mobile requirements of the device are met.

Owner:CSSC NANJING LUZHOU ENVIRONMENT PROTECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com