Waste incineration device and method with wide calorific value application range

A technology of waste incineration and adaptability. It is applied in the direction of combustion method, incinerator, combustion type, etc. It can solve the problem of unstable temperature field, and achieve the effect of increasing residence time and complete combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

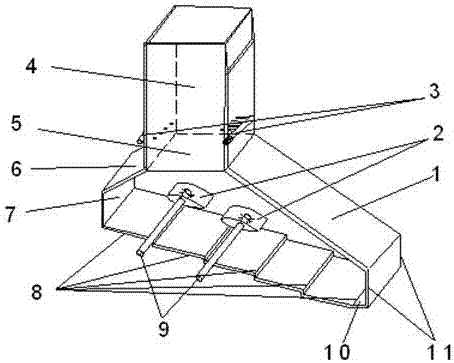

[0026] like figure 1 As shown, a waste incineration device with a wide range of calorific values includes an incineration furnace and a number of rotating airfoil arch mechanisms arranged in parallel. The rear arch 6, the garbage inlet 7, the fire grate 8, the slagging outlet 10, the left and right side walls 11, and the vertical flue 4, the garbage inlet 7 is set at the front end of the fire grate 8, and the slagging outlet 10 is set at the furnace At the end of row 8, the incinerator hearth outlet 5 is located between the rear arch 6 and the highest point of the front arch, and the vertical flue 4 is connected to the incinerator hearth outlet 5. A secondary air component 3 for providing secondary air is arranged on the vertical flue 4 .

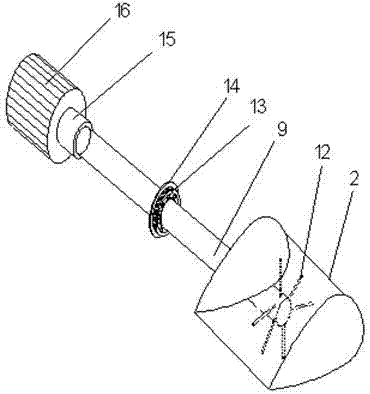

[0027] like figure 2 As shown, the rotating airfoil arch mechanism package is arranged on the rotating airfoil arch 2, transmission shaft 9, bearing 13, sealing component, shaft coupling 15 and motor 16 in the incinerator chamber, and ...

Embodiment 2

[0032] A garbage incineration method for a garbage incinerator with a wide range of heat values, comprising the steps of:

[0033] The garbage enters the grate 8 through the garbage inlet 7, and the primary wind is blown in from the bottom of the grate 8. Under the movement of the grate 8, the garbage undergoes four processes of preheating and drying, pyrolysis, fixed carbon combustion and burnout. The flue gas is discharged from the outlet 5 of the incineration furnace and the vertical flue 4, and the ash is discharged from the slag outlet 10 of the incineration furnace;

[0034] When the calorific value of the garbage is low, the rotating airfoil arch 2 can be turned to a position parallel to the rear arch 6. At this time, the rotating airfoil arch 2 can radiate heat to the garbage material layer, increase the temperature in the furnace, and make the garbage burning more stable , and at the same time force the high-temperature flue gas to wash away the garbage and accelerate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com