Device for supplying garbages to garbage destructor and garbage supplying method

A waste incinerator and waste technology, applied in the combustion method, incinerator, combustion type, etc., can solve the problems of unstable combustion, increase in the proportion of waste, and increase in the supply of waste, so as to suppress the production of dioxins, prevent Generation of unburned substances and reduction of CO generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

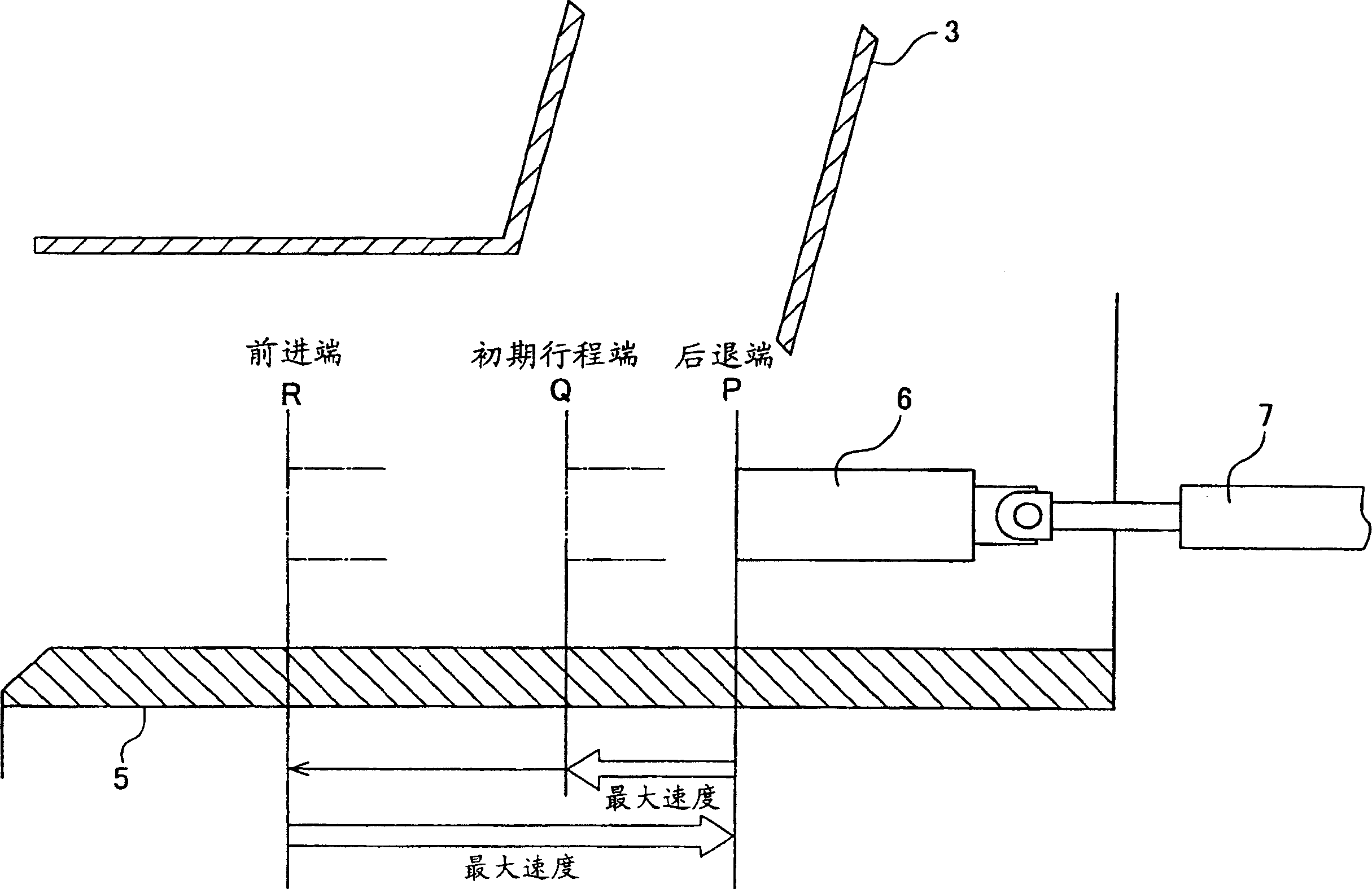

[0037] Figure 4 Shown is a system configuration diagram of a quantitative supply device according to an embodiment of the inventions of Claim 3, Claim 4, and Claim 6.

[0038]In Embodiment 1, the garbage supply device 1 is attached to the bottom of the garbage storage funnel 3 on the motorized grate type garbage incinerator 2 used for burning garbage, etc. The most upstream part of the stepped motorized grate 4 of the row 4b and the post-combustion motorized grate 4c. The refuse supply device 1 is a pusher type device, and it includes a pusher 6 reciprocatingly sliding along the top of a flat plate-like step 5 and a drive mechanism 7 for reciprocating the pusher 6 . In this way, the garbage W thrown in by a crane (not shown) from the top of the hopper 3 sequentially falls on the steps 5, and the garbage on the steps 5 is sequentially given to the drying motor grate 4a by the reciprocating motion of the pusher 6. . In addition, the structure of the motorized grate type garb...

Embodiment 2

[0053] Figure 8 Shown is a system configuration diagram of the quantitative supply device according to the embodiment of the invention of claim 3, claim 5, and claim 6.

[0054] In the second embodiment, the structures of the garbage supply device 1, the garbage incinerator 2, etc. are basically the same as those of the above-mentioned first embodiment. Therefore, the same part as in Example 1 is used with and Figure 8 The same symbols are used, and their detailed descriptions are omitted.

[0055] exist Figure 8 In the second embodiment, the support portion 11 of the hopper 3 is provided with a weighing scale (weight measuring device) 12 such as a sensor, and the weight of the garbage in the hopper 3 can be directly measured by the weighing scale 12 .

[0056] In this structure, when the data on the weight of the garbage measured by the weighing scale 12 is input in the controller 9, the controller 9 calculates the garbage supply weight (t / h) per unit time according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com