A trapezoidal high-temperature oxidation chamber for plasma solid waste treatment process

A treatment process, plasma technology, applied in the direction of non-flammable liquid/gas transportation, incinerator, combustion type, etc., can solve the problems of incomplete combustion of combustible gas, easy to produce dead angle areas, uneven distribution of thermal field, etc., to achieve Stable combustion, better effect, uniform flow field and thermal field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

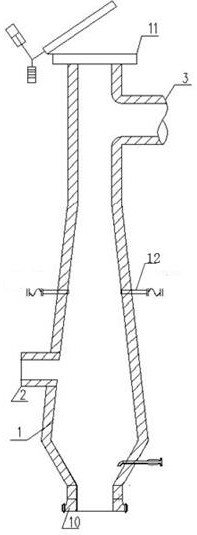

[0020] Such as Figure 1-2 As shown, it is a trapezoidal high-temperature oxidation chamber of the plasma solid waste treatment process of the present invention. The present invention includes a high-temperature oxidation furnace 1, a flue gas inlet 2, a flue gas outlet 3, an oxygen content analyzer 4, a pressure transmitter 5, a thermoelectric Couple 6, desuperheating water valve 7, blower 8, air duct baffle 9, molten salt outlet 10 and explosion-proof door 11.

[0021] The high temperature oxidation furnace 1 of the present invention comprises a straight cylindrical structure at the top, a first conical structure at the middle and a second conical structure at the bottom; the flue gas outlet 3 is arranged on the upper part of the straight cylindrical structure; the flue gas outlet 3 passes through the induced draft fan Connected to the chimn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com