Sludge incinerator with no auxiliary fuel

A technology of sludge incineration and auxiliary fuel, applied in the field of incinerators, can solve the problems of high investment and operating costs of rotary incinerator equipment, and achieve the effects of easy control of the temperature in the bed, easy control, and low construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

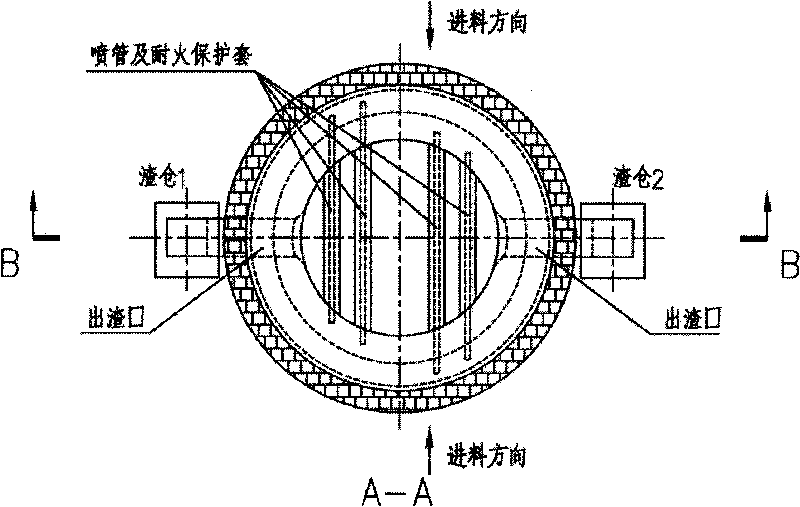

[0056] exist figure 1 In the implementation example, the incinerated material is first placed in the intermediate bin for temporary storage, and is evenly transported into the furnace by the feeder. After the sludge is sent into the incinerator by the feeding device, it is immediately dispersed by a large number of moving high-temperature inert materials and quickly mixed with hot sand particles. Due to the large heat storage capacity of the bed material, the sludge is quickly dried in the fluidized bed. For fire and combustion, in order to avoid the melting of ash in the sludge, the incineration temperature is controlled at 850°C to 950°C.

[0057] The sludge jumps, mixes, squeezes, collides, and breaks in the boiling section of the furnace. The large particles gradually become smaller, and some of the small particles that are not completely burned are blown into the suspension chamber to continue burning until they are completely burned.

[0058] The secondary air nozzle se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com