Waste incineration prediction and feedforward control method

A technology of feed-forward control and waste incineration, which is applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems that operators are difficult to control stable combustion, easy to lag, and easy to coke in the furnace, so as to ensure economical, efficient and environmentally friendly operation, optimization Combustion in the incinerator, which is conducive to the effect of stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

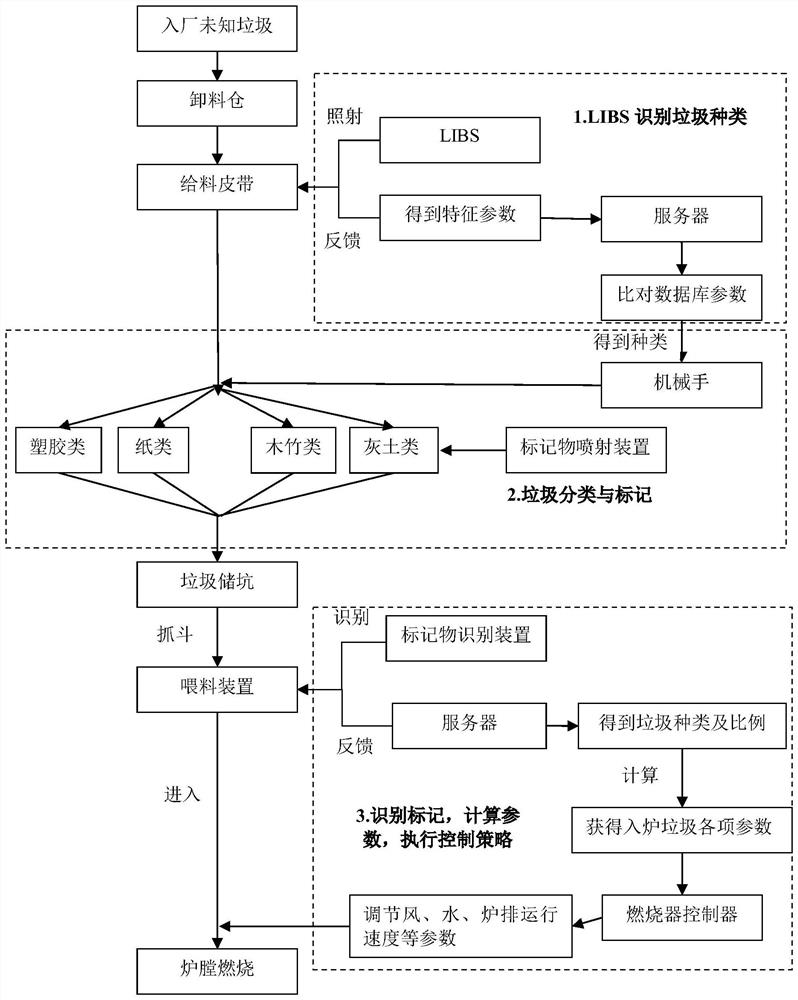

[0041] The device used in the waste incineration prediction and feed-forward control method provided by the present invention includes a discharge bin, a feeding belt, LIBS, a server, a classification controller, a manipulator, a classification belt, a marker injection device, a marker identification device, and a burner control unit. device.

[0042] The waste incineration prediction and feed-forward control method provided by the present invention can be found in figure 1 , including the following steps:

[0043] S1. Obtain the type of garbage entering the furnace; preferably, the LIBS is used to detect the garbage before entering the incinerator to obtain the type of garbage entering the furnace. Specifically, LIBS irradiates the garbage into the furnace through laser pulses to obtain the spectral characteristic parameters of the real-time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com