Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

238results about "Multiple burner assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

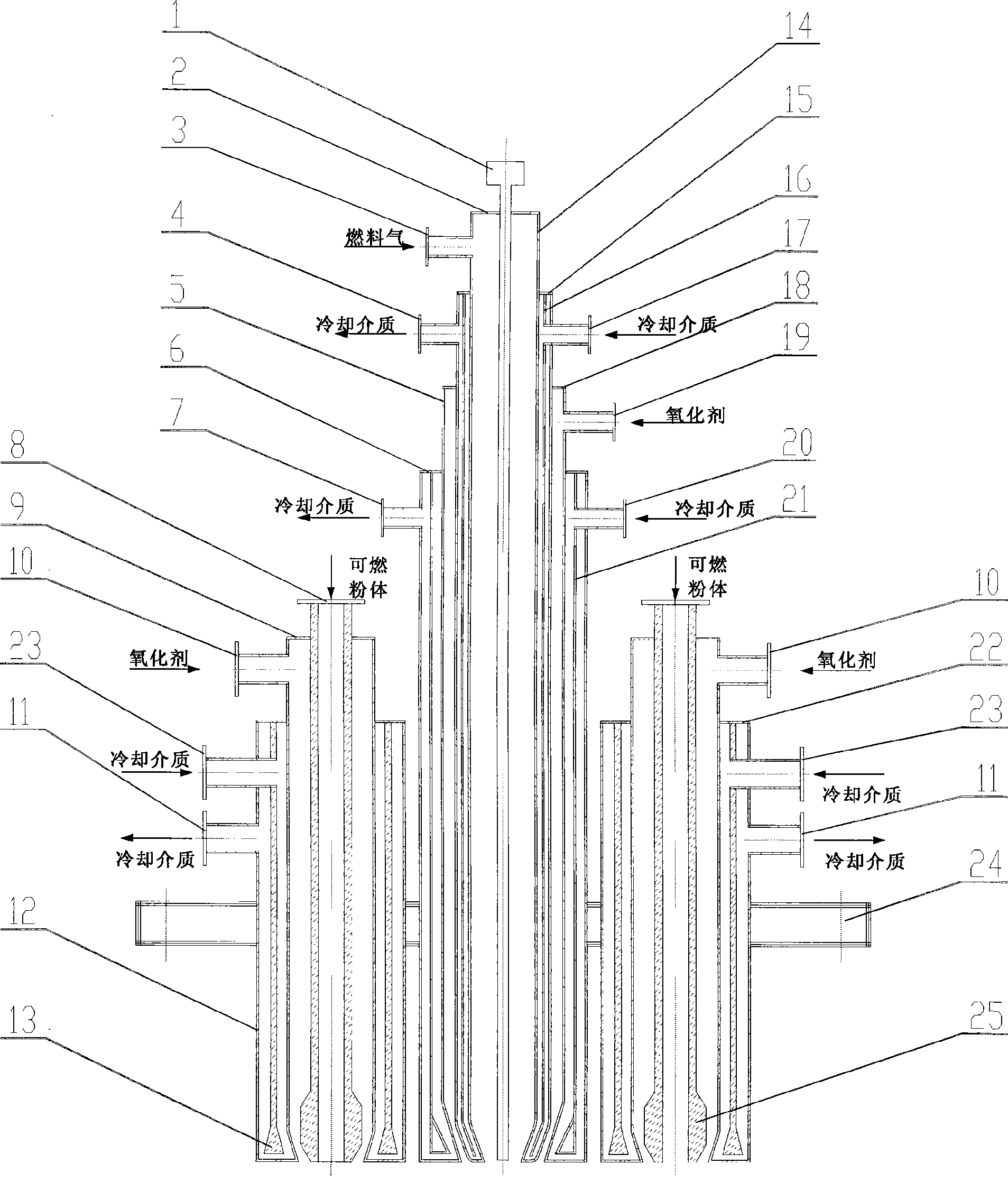

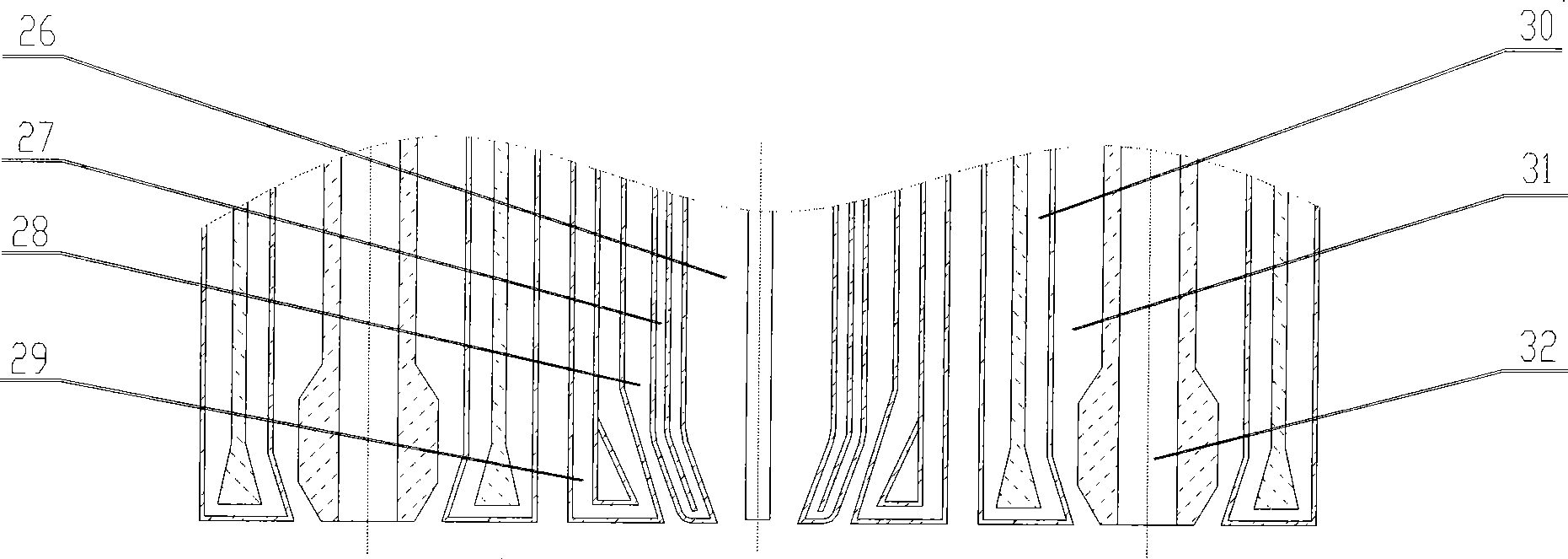

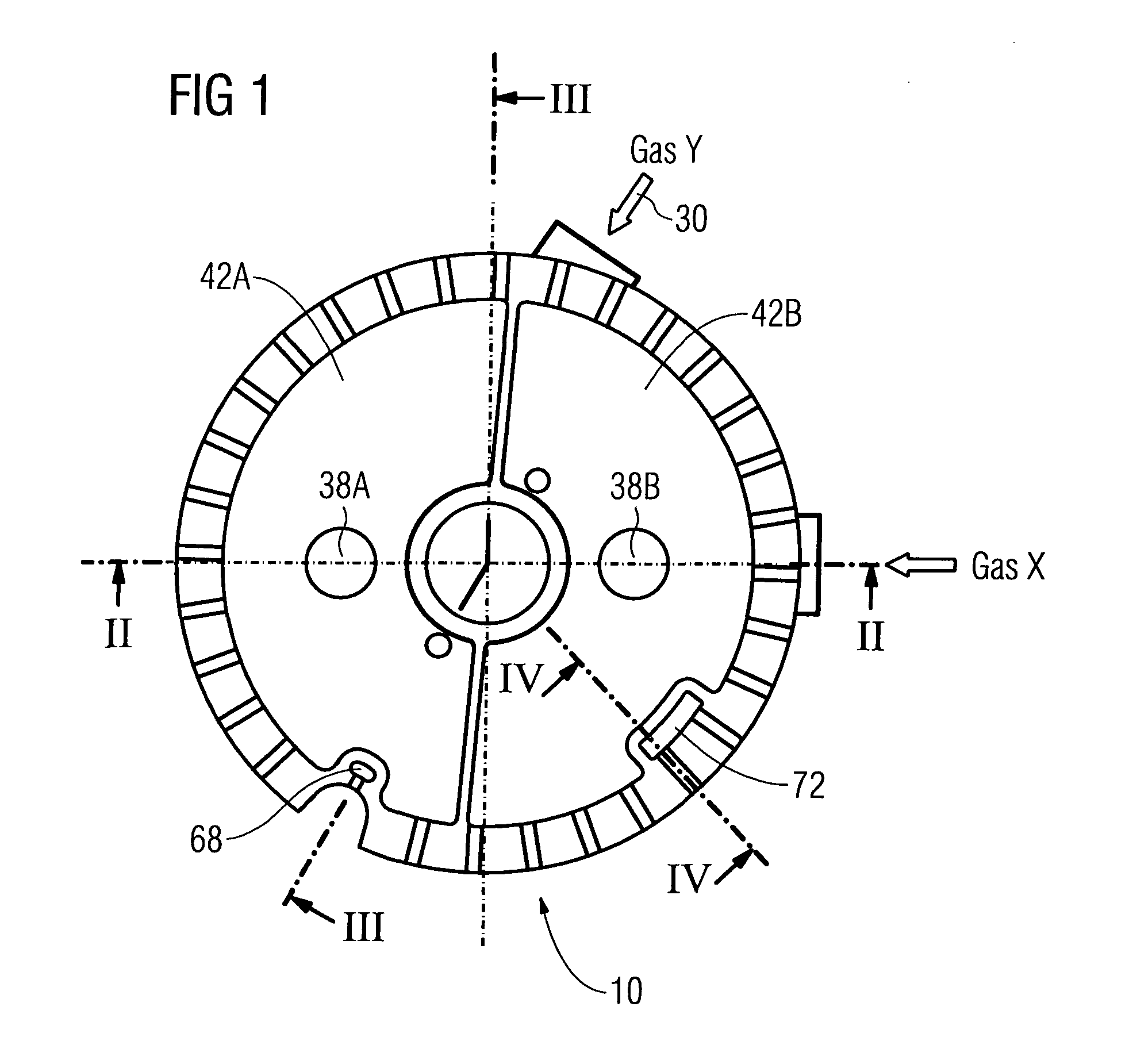

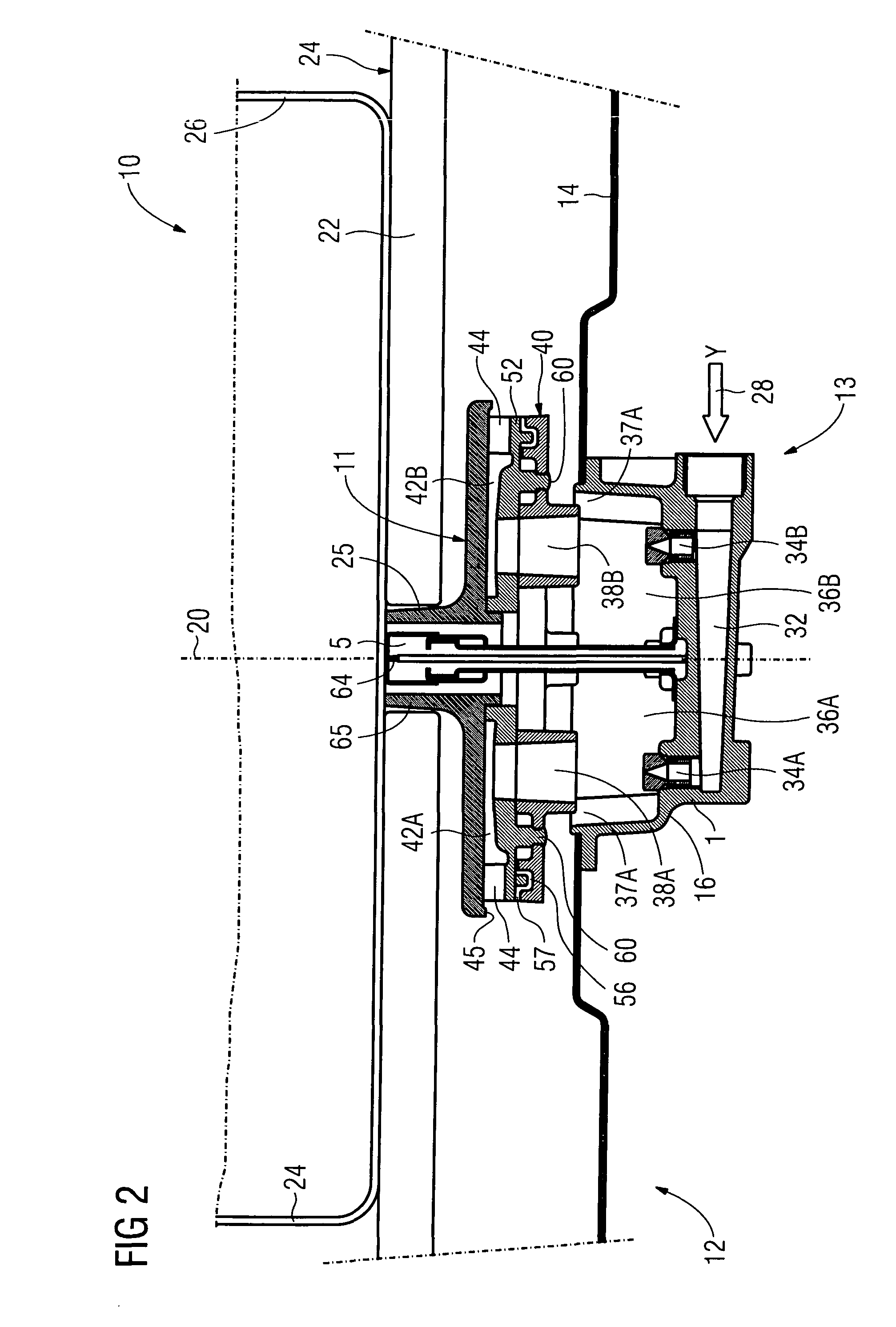

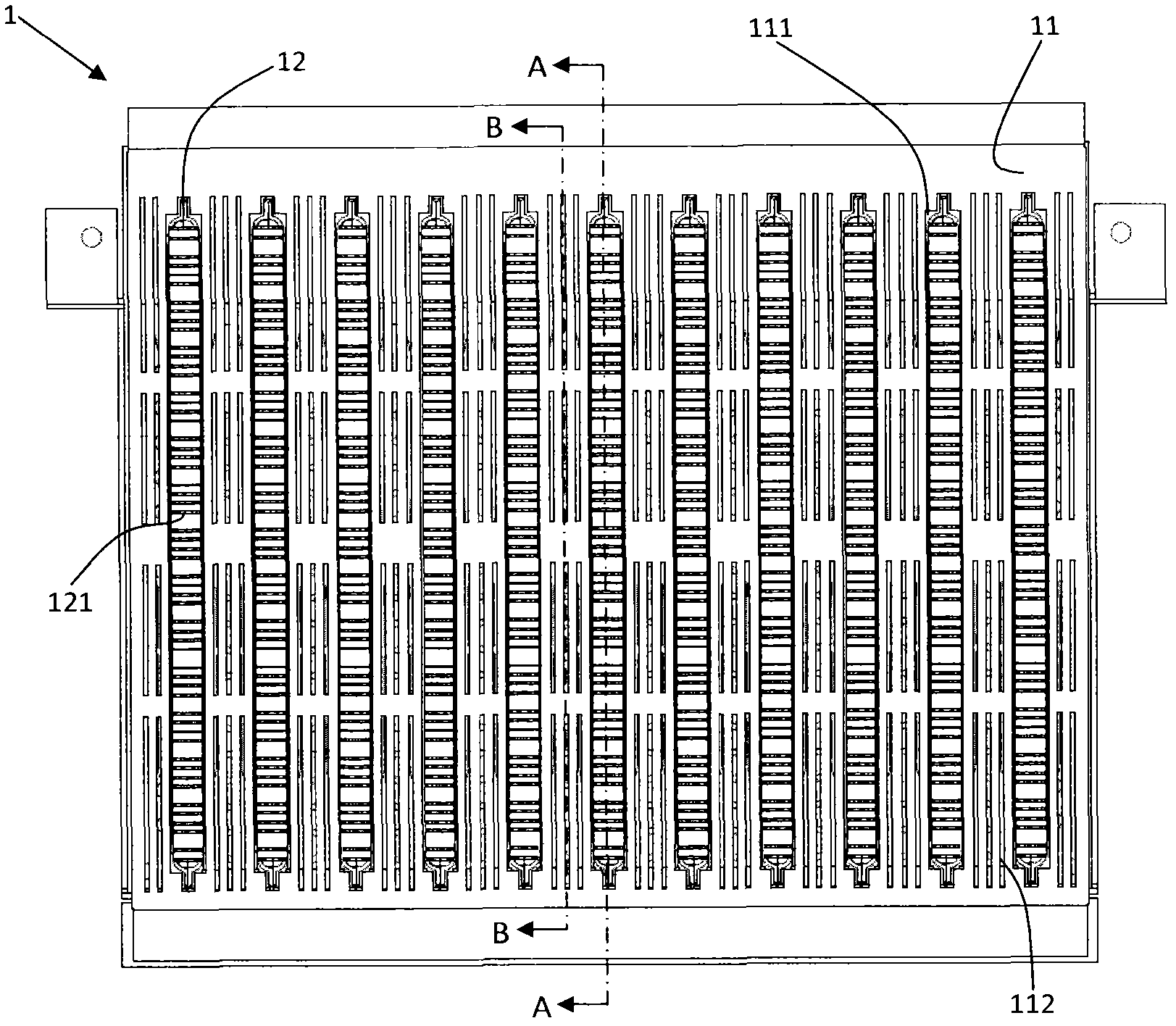

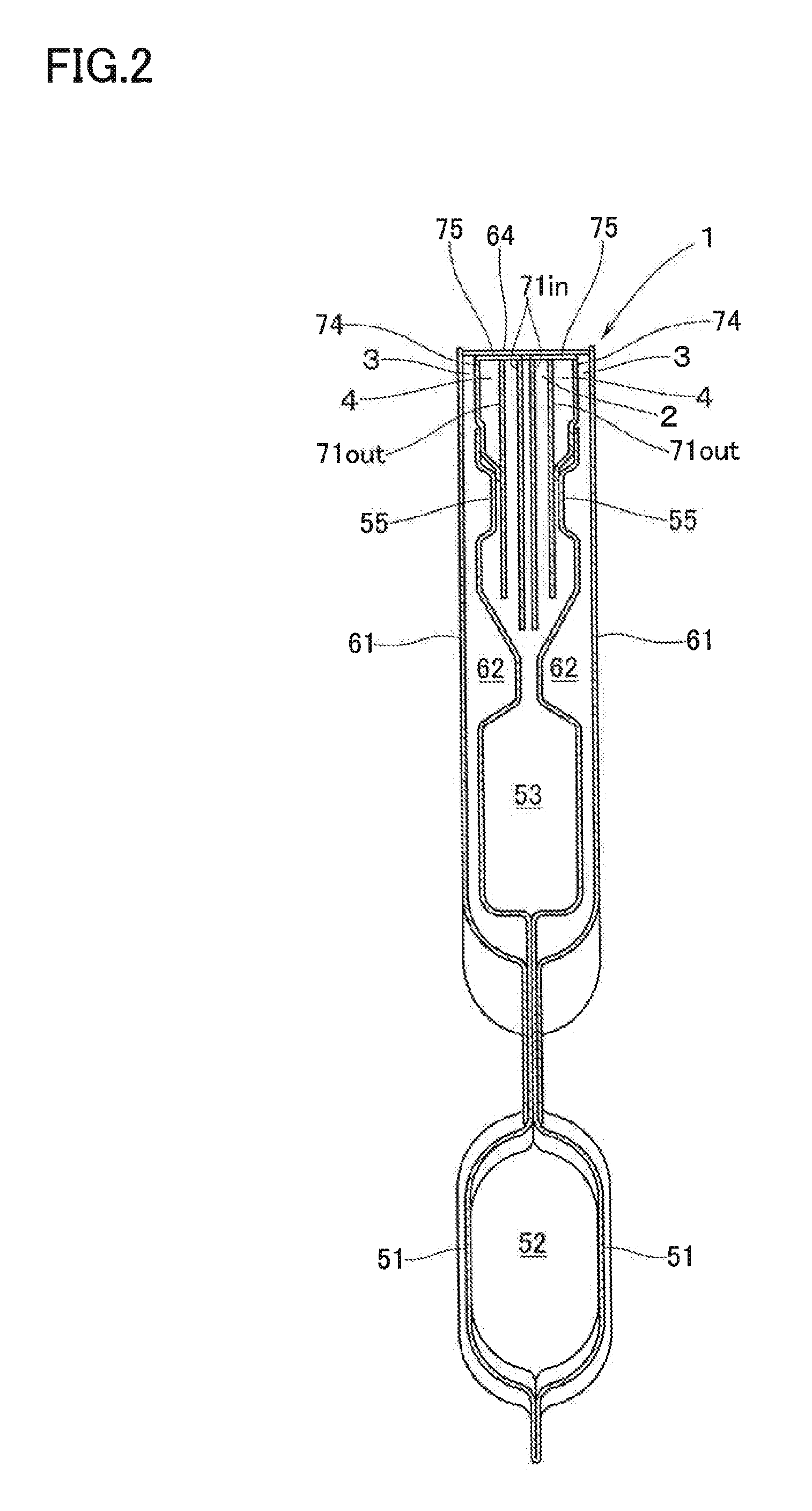

Combined type multi-injector burner

ActiveCN101446413AReduce wearUniform temperature fieldPulverulent fuel combustion burnersMultiple burner assemblyCombustorSingle process

The invention provides a combined type multi-injector burner with a flammable powder body, which comprises an igniter burner positioned at the center of the burner and a plurality of process combustion nozzles which are evenly formed on the periphery of the igniter burner in the circumferential direction, wherein, each process combustion nozzle comprises a coal dust passage positioned at the center of each process combustion nozzle and a first annular oxidizer passage arranged outside the coal dust passage. In the combined type multi-injector burner, a plurality of process combustion nozzles and the igniter burner are assembled together, the structure is compact, and the combustion efficiency as well as the gasification efficiency are increased; the maintenance of each single process combustion nozzle is flexible, and the disassembly and the assembly are convenient; the process combustion nozzles can limberly adjust the load of the burner, mediums in a hearth can be mixed evenly through repeated impacts, the flame fullness degree is good, and a uniform multilayer cooling structure can protect the burner effectively and prolong the service life of the burner.

Owner:CHANGZHENG ENG

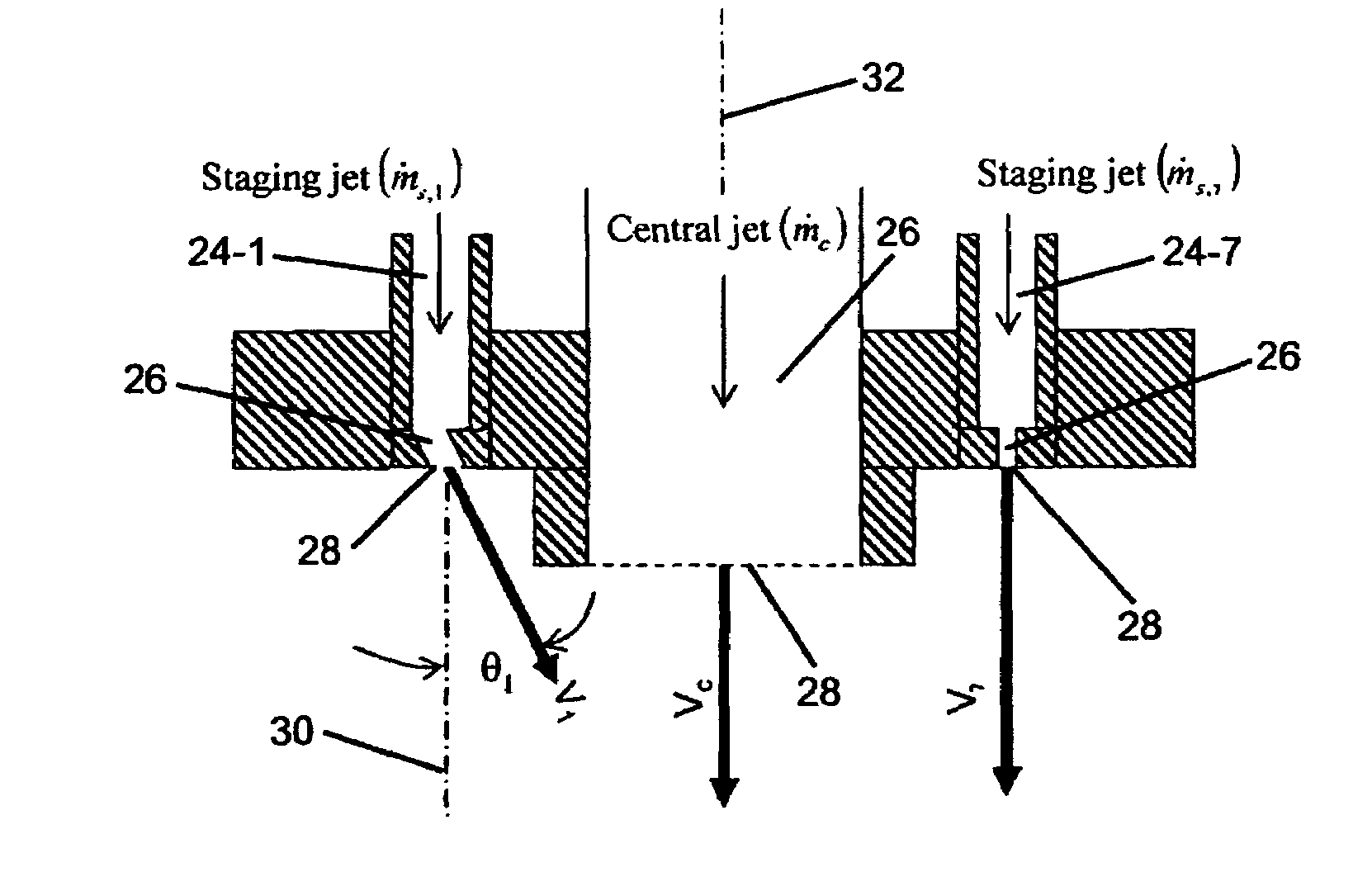

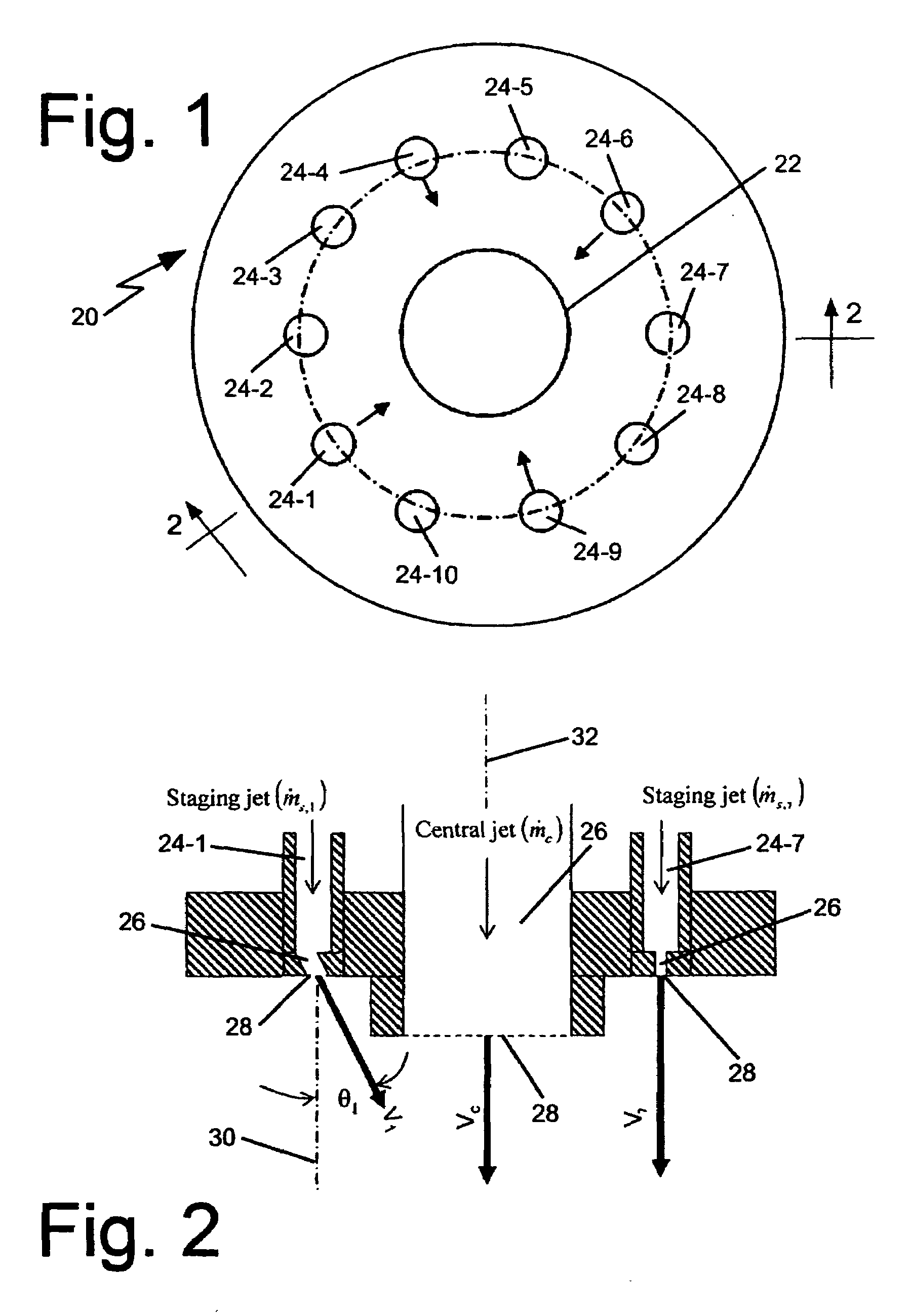

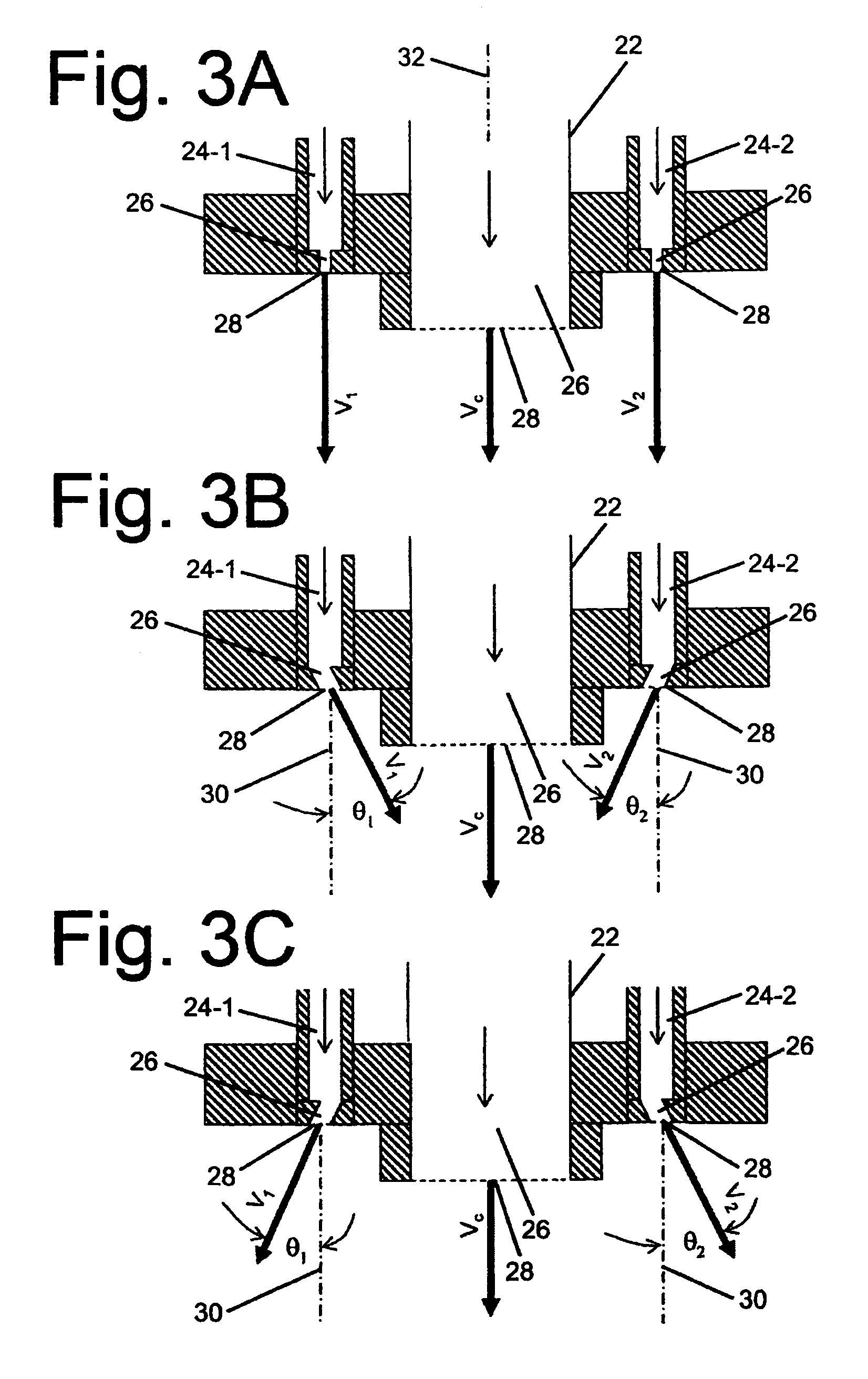

Low NOx staged fuel injection burner for creating plug flow

A burner for producing a plug-like flow and low NOx emissions. The burner has a central air jet and plural staged fuel jets surrounding the central jet. The ratio of the sum of the momentums of vector components of the staged jets along respective axes parallel to the central longitudinal axis of the central jet to the momentum of the central jet along that axis is within the range of 0.5 to 1.5 and most preferably 0.8.

Owner:AIR PROD & CHEM INC

Multiple venture tube gas fuel injector for a combustor

A gas fuel injector includes a first header plate; a second header plate spaced downstream from the upstream header plate; and a plurality of venturi tubes arranged in rows and sealably secured to the first and second header plates. Each of the venturi tubes includes an inlet section, a throat section and an exit. The exit is shaped into a pattern that reduces space between each of the venturi tubes at the exit of each of the plurality of venturi tubes.

Owner:GENERAL ELECTRIC CO

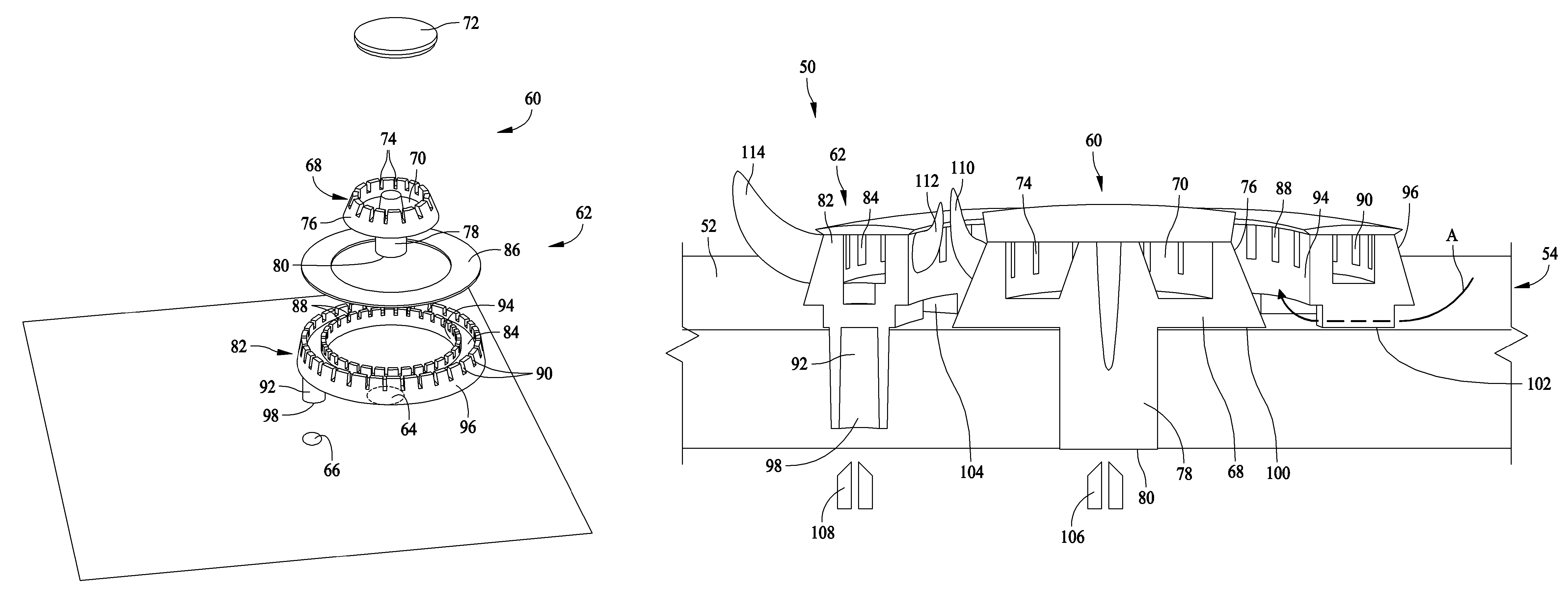

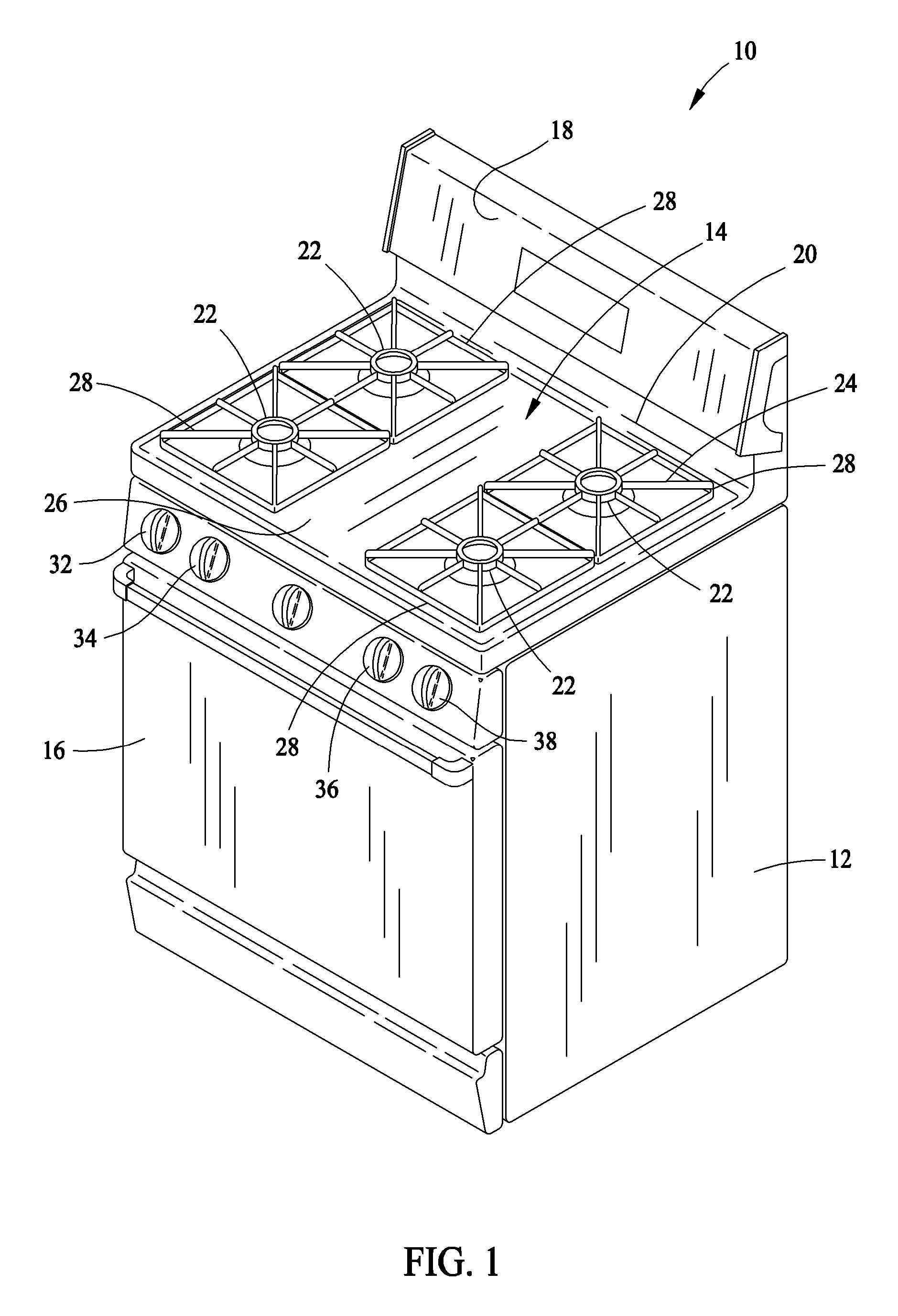

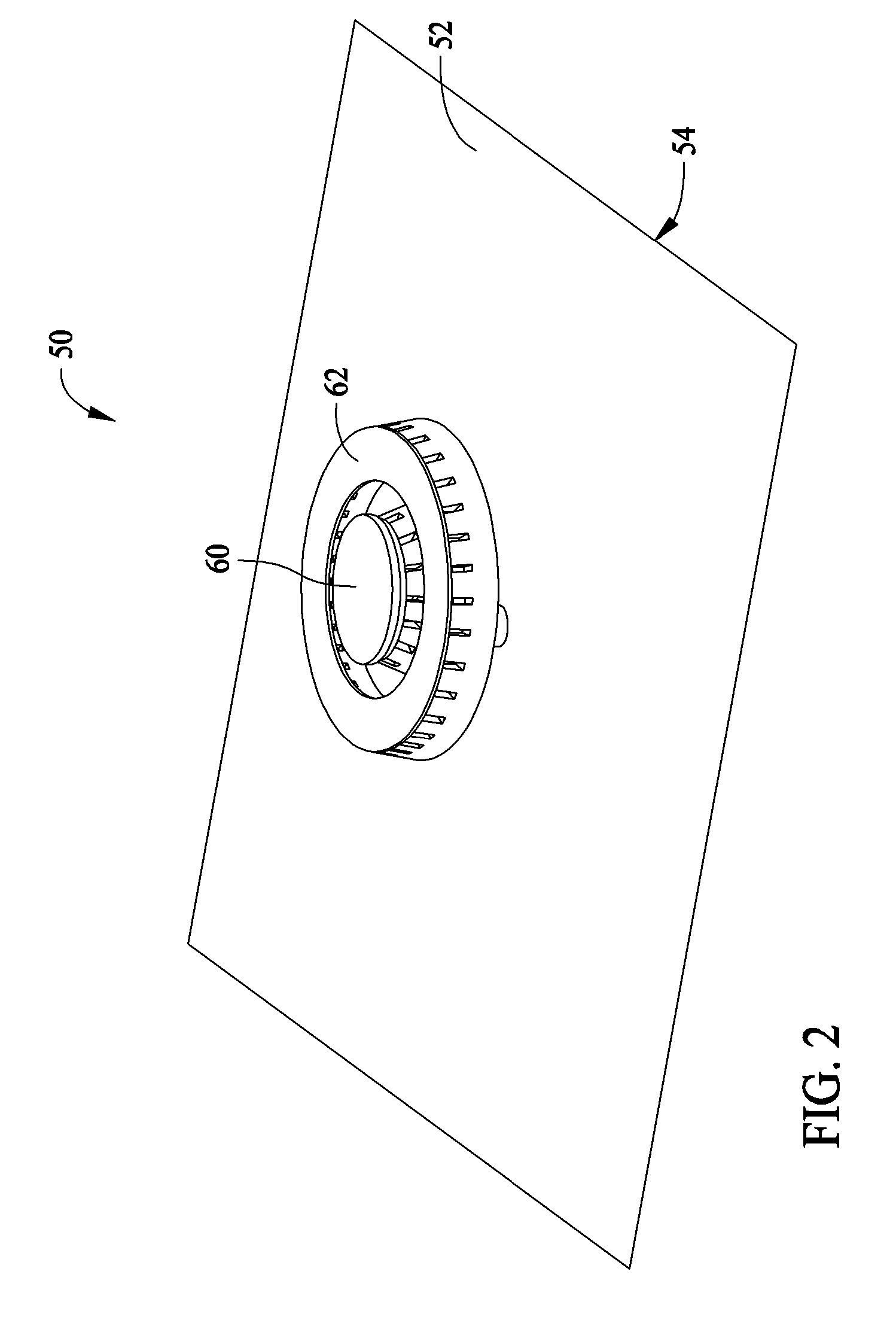

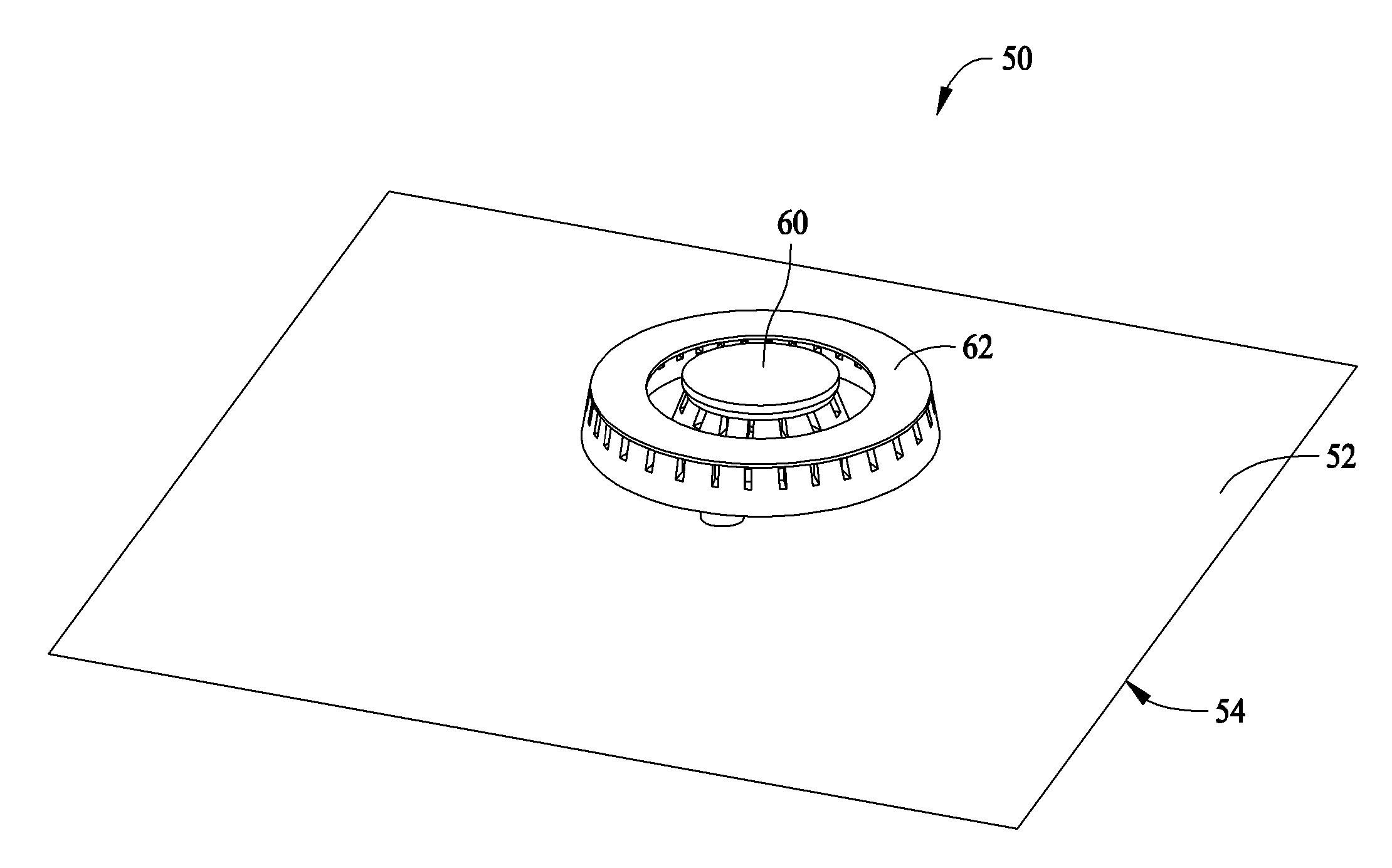

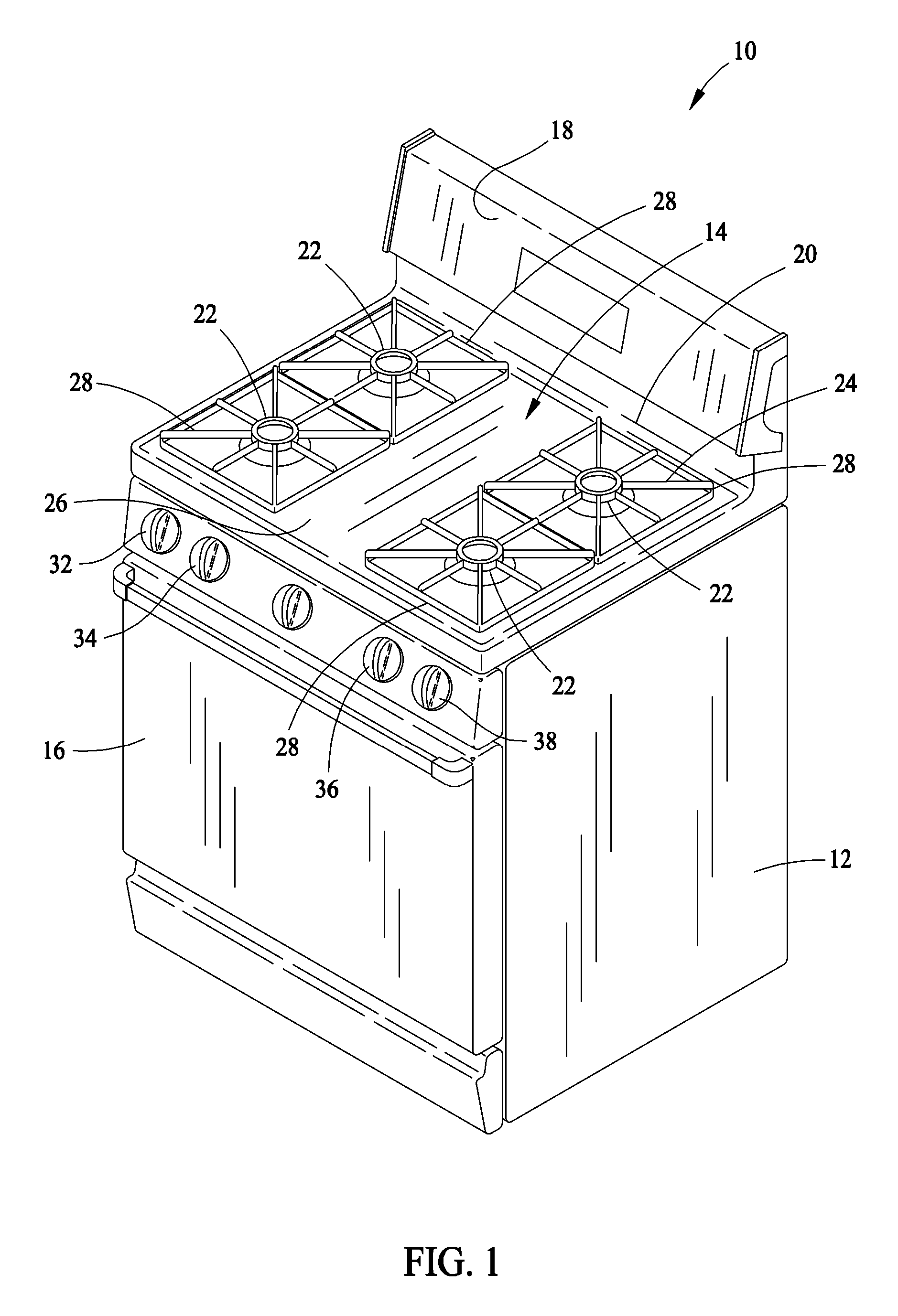

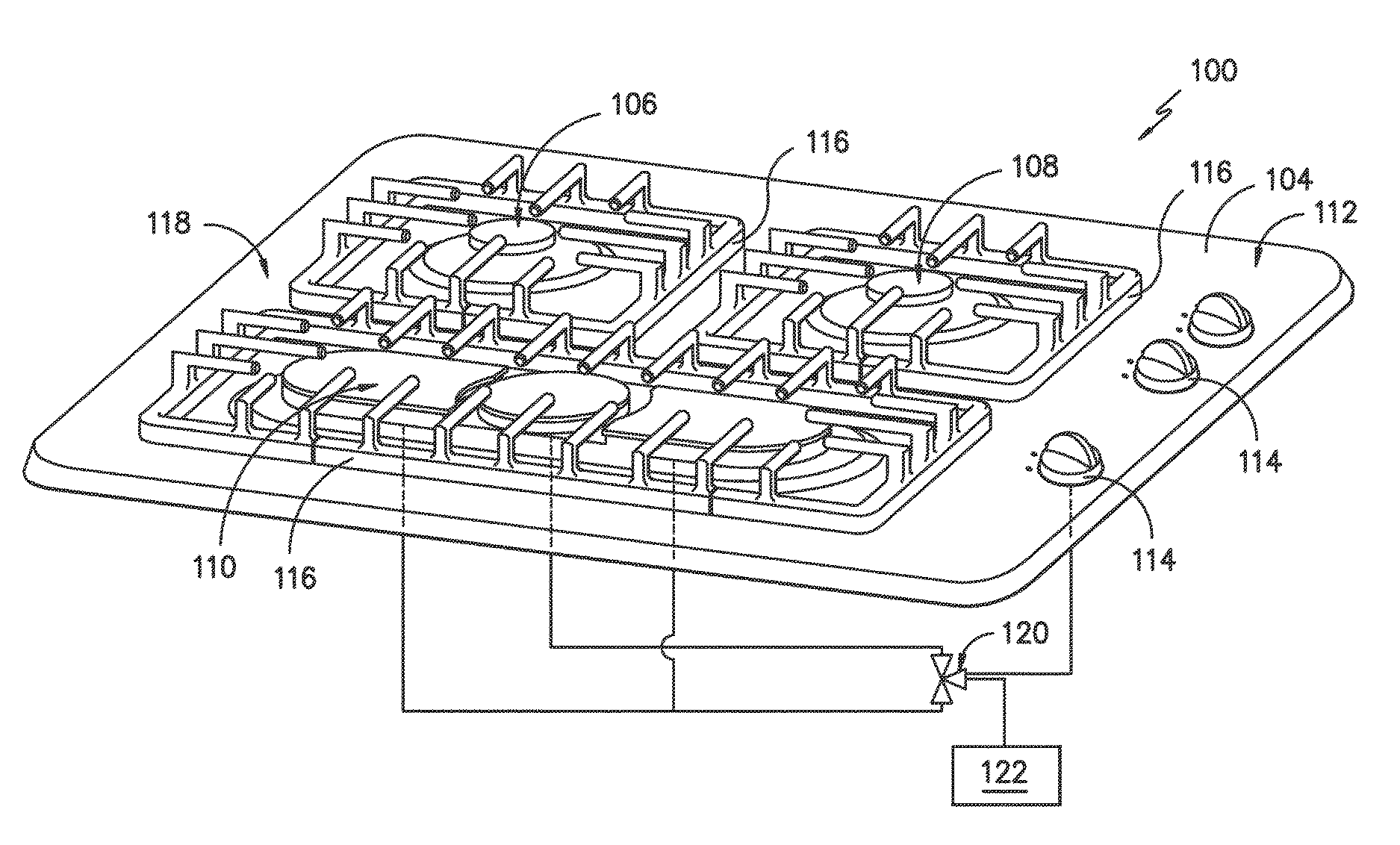

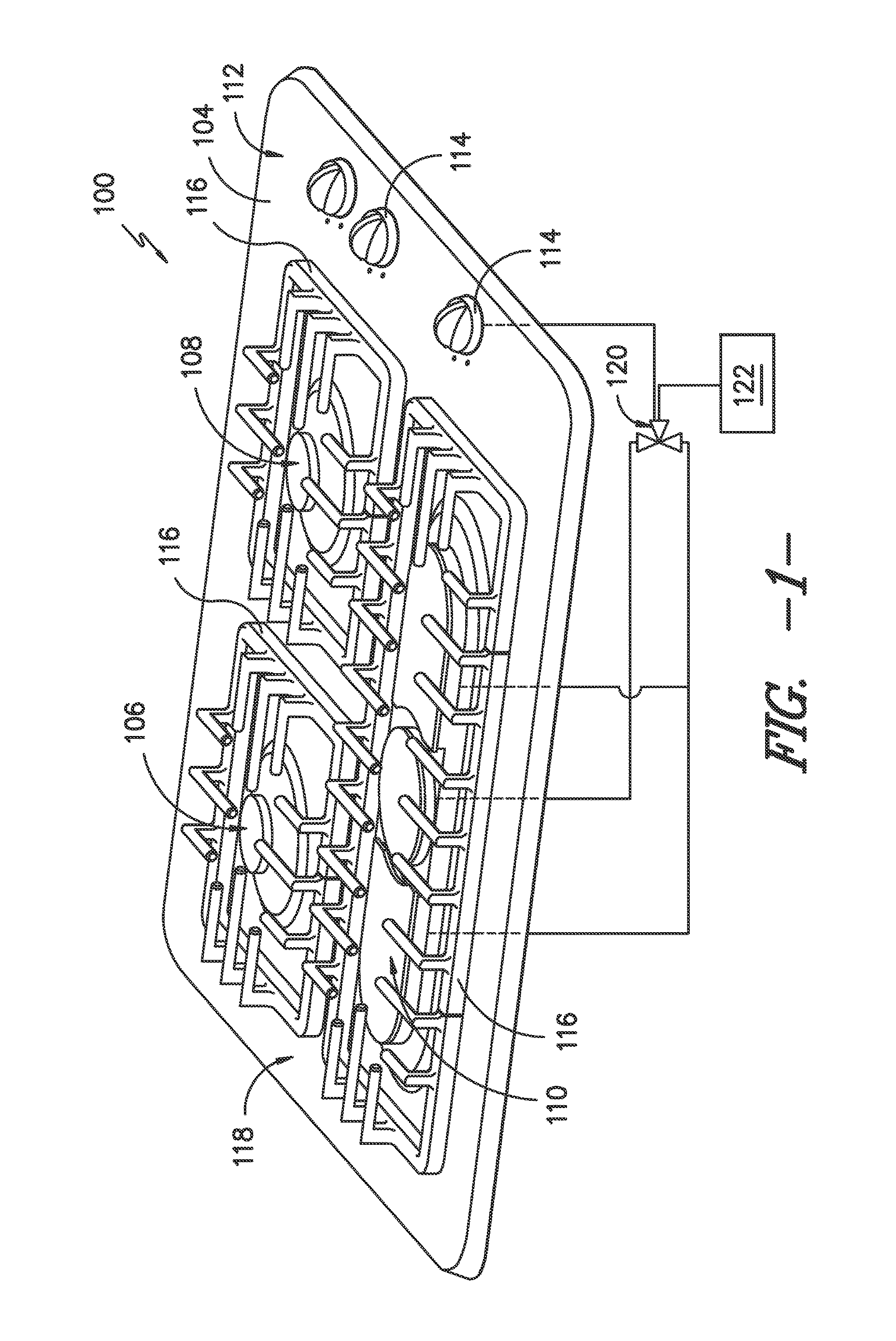

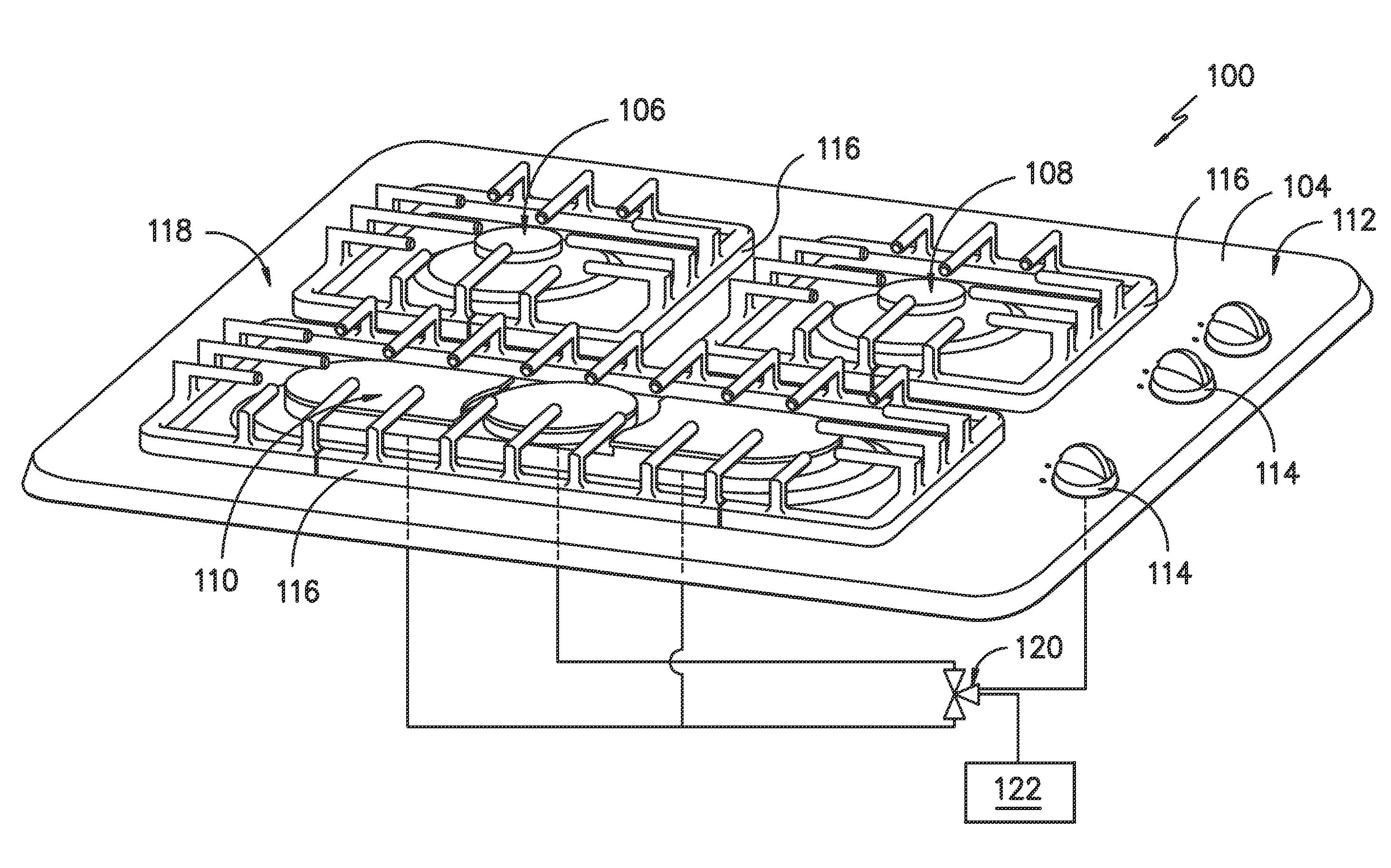

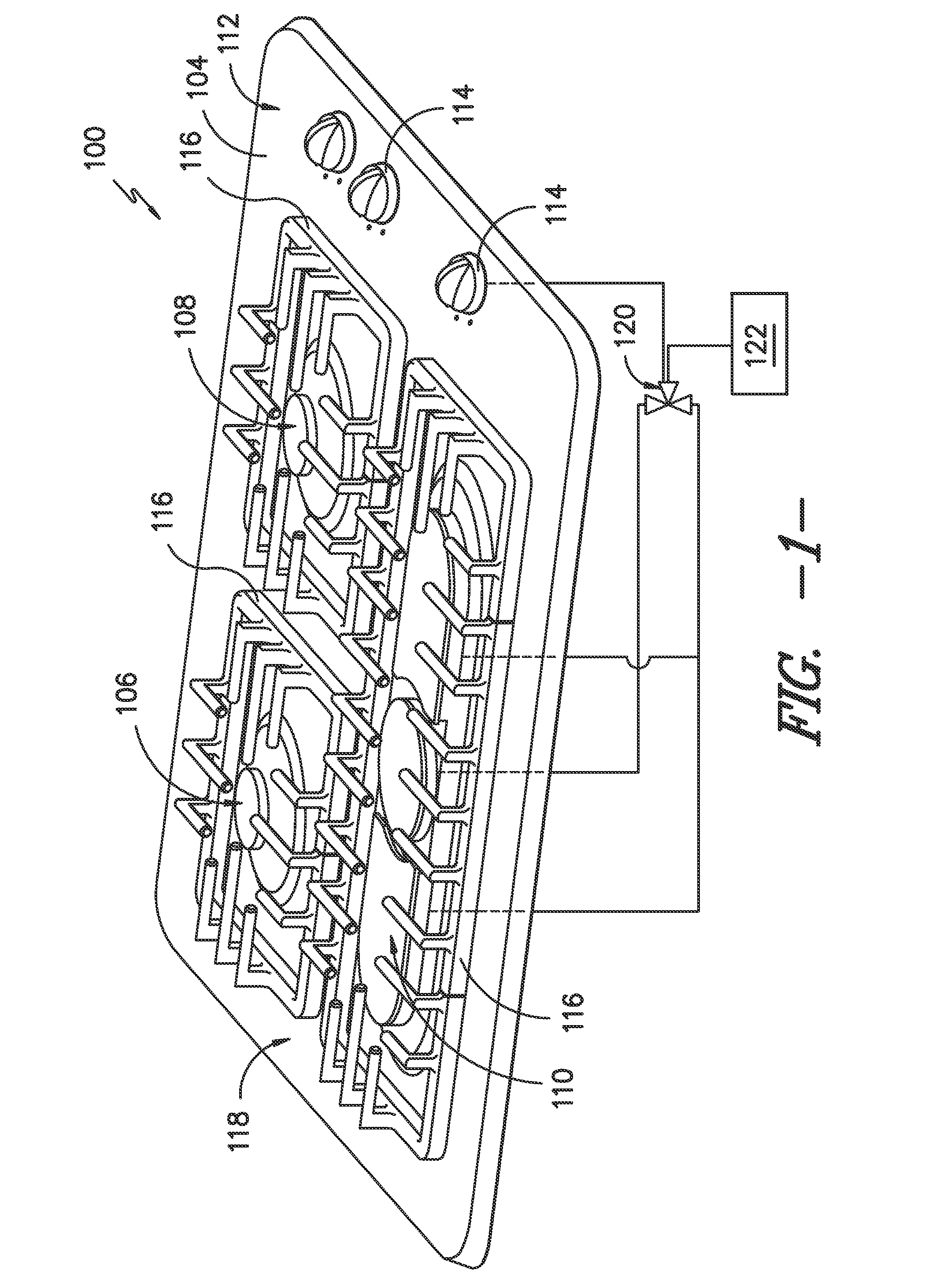

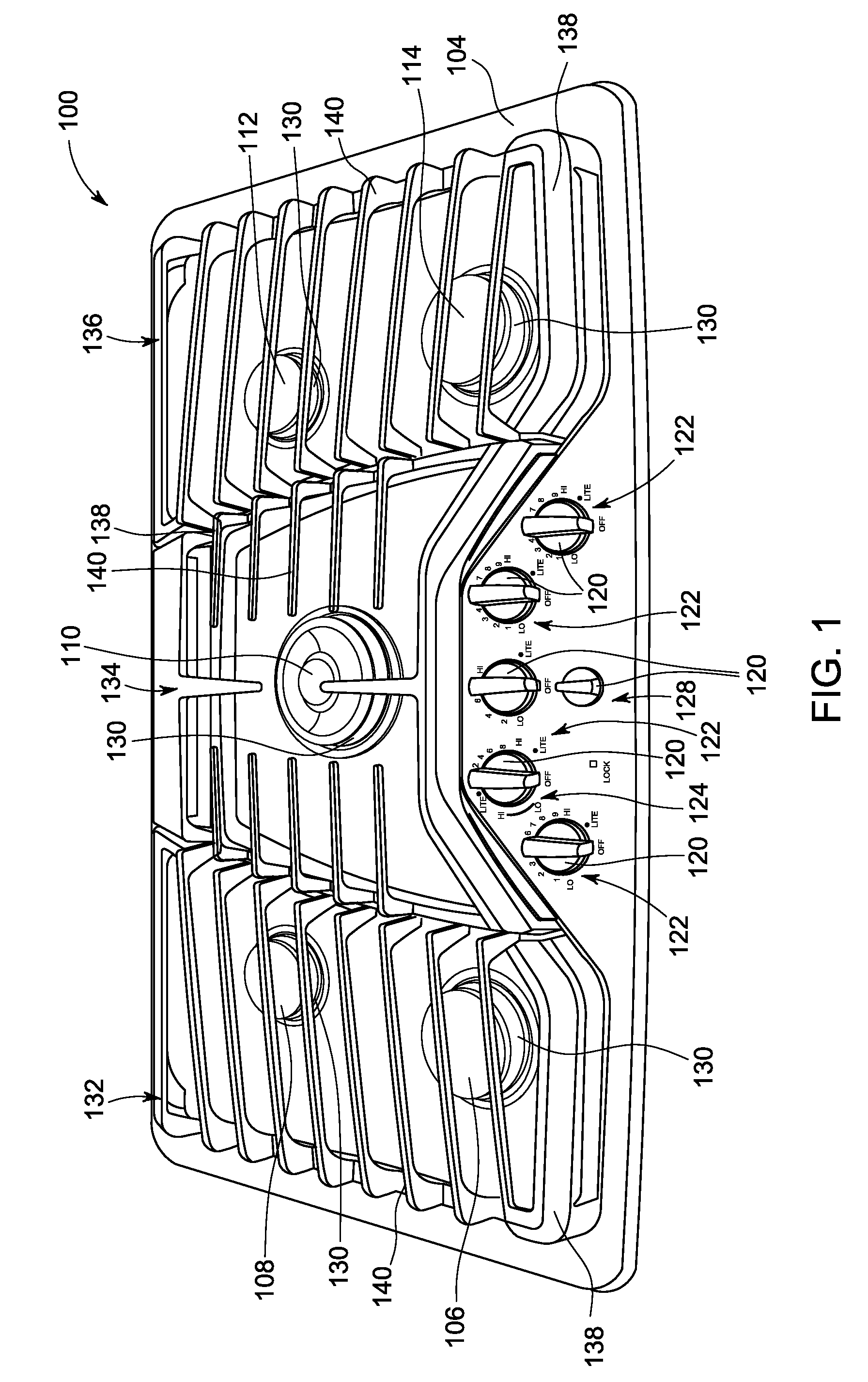

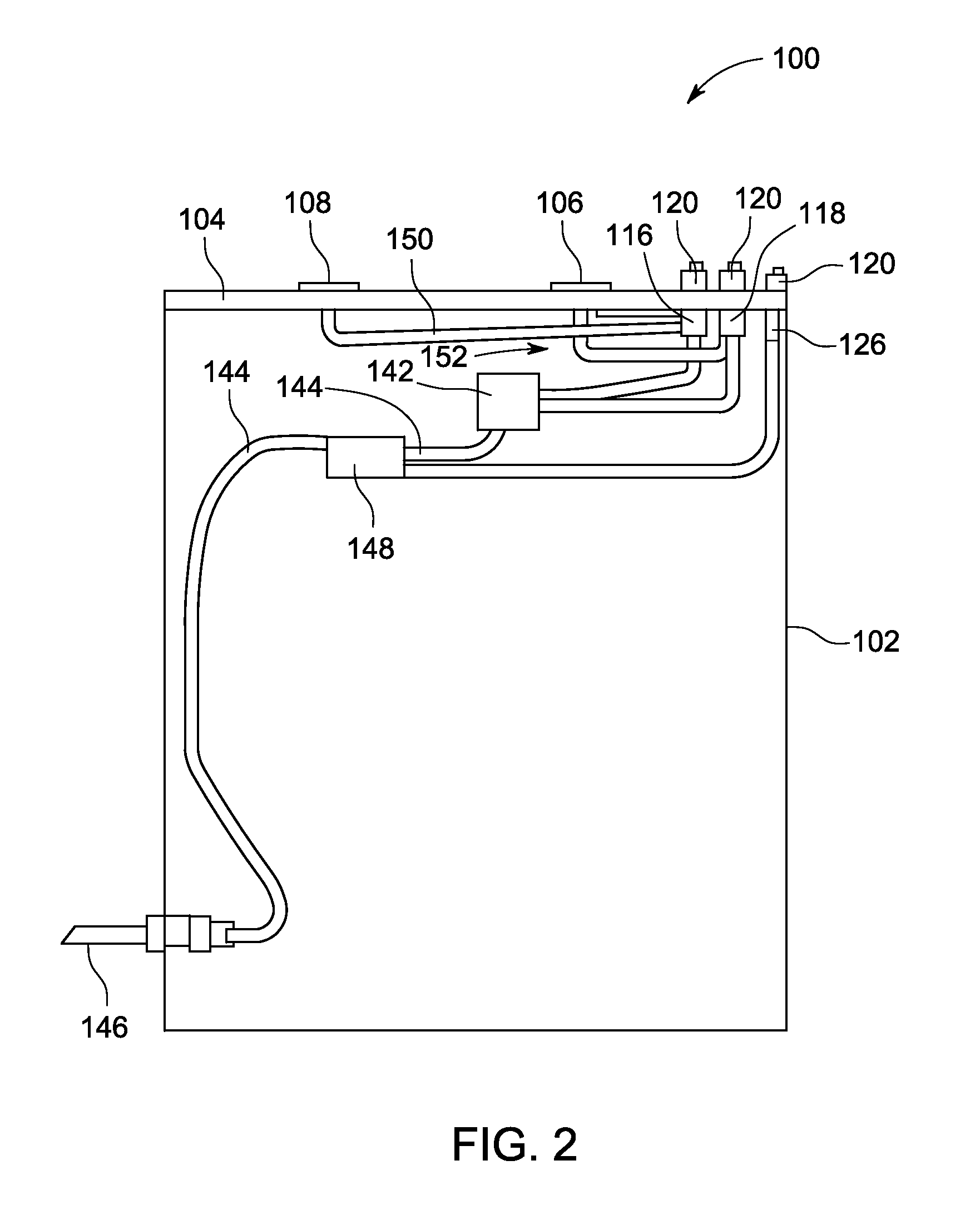

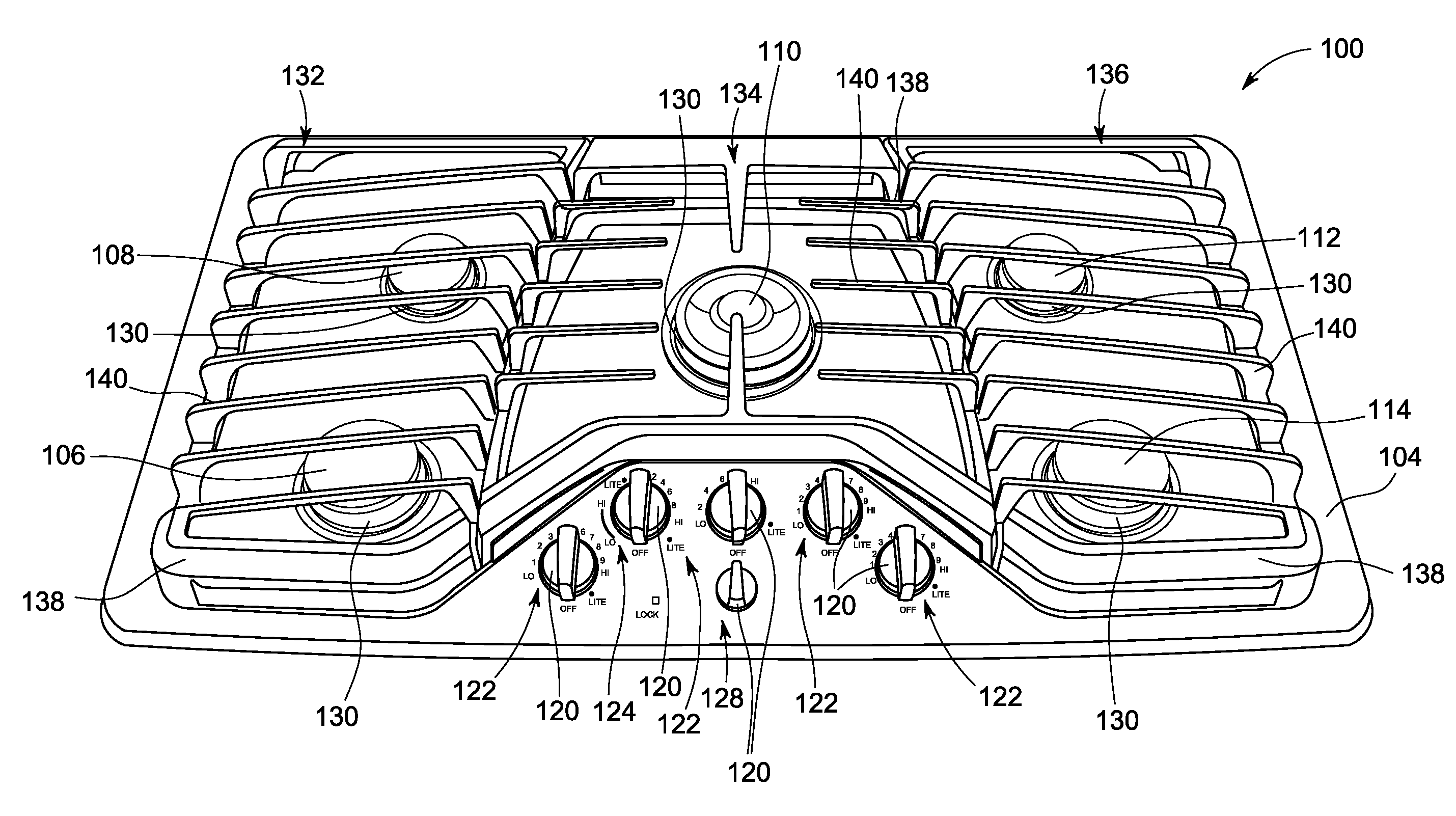

Gas burner assembly including inner and outer burners and methods for implementing same

A gas burner assembly for a cooking appliance that includes a cooktop surface includes a gas burner assembly having a first gas burner including a first burner body. The first burner configured to be mounted on, and contact, the cooktop surface, and provide a cooking flame. The gas burner assembly also includes a second gas burner including a second burner body. The second burner configured to be mounted on, and contact, the cooktop surface. The second burner also configured to be concentric with the first burner and separated from the first burner by a distance at all points along the burners. The second burner body including at least one air passage defined therethrough that is configured to allow air to flow through the second burner and to the cooking flame.

Owner:HAIER US APPLIANCE SOLUTIONS INC

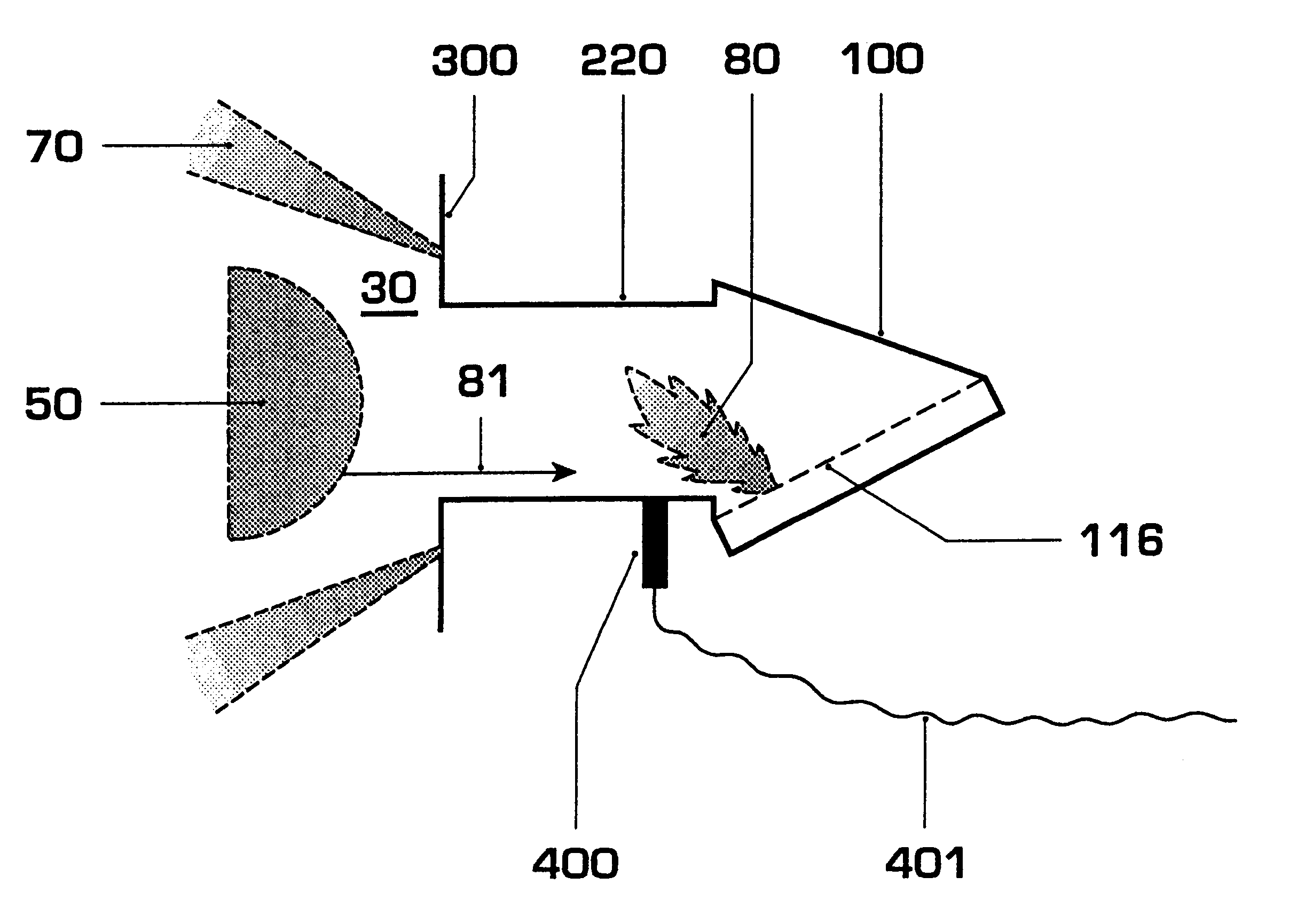

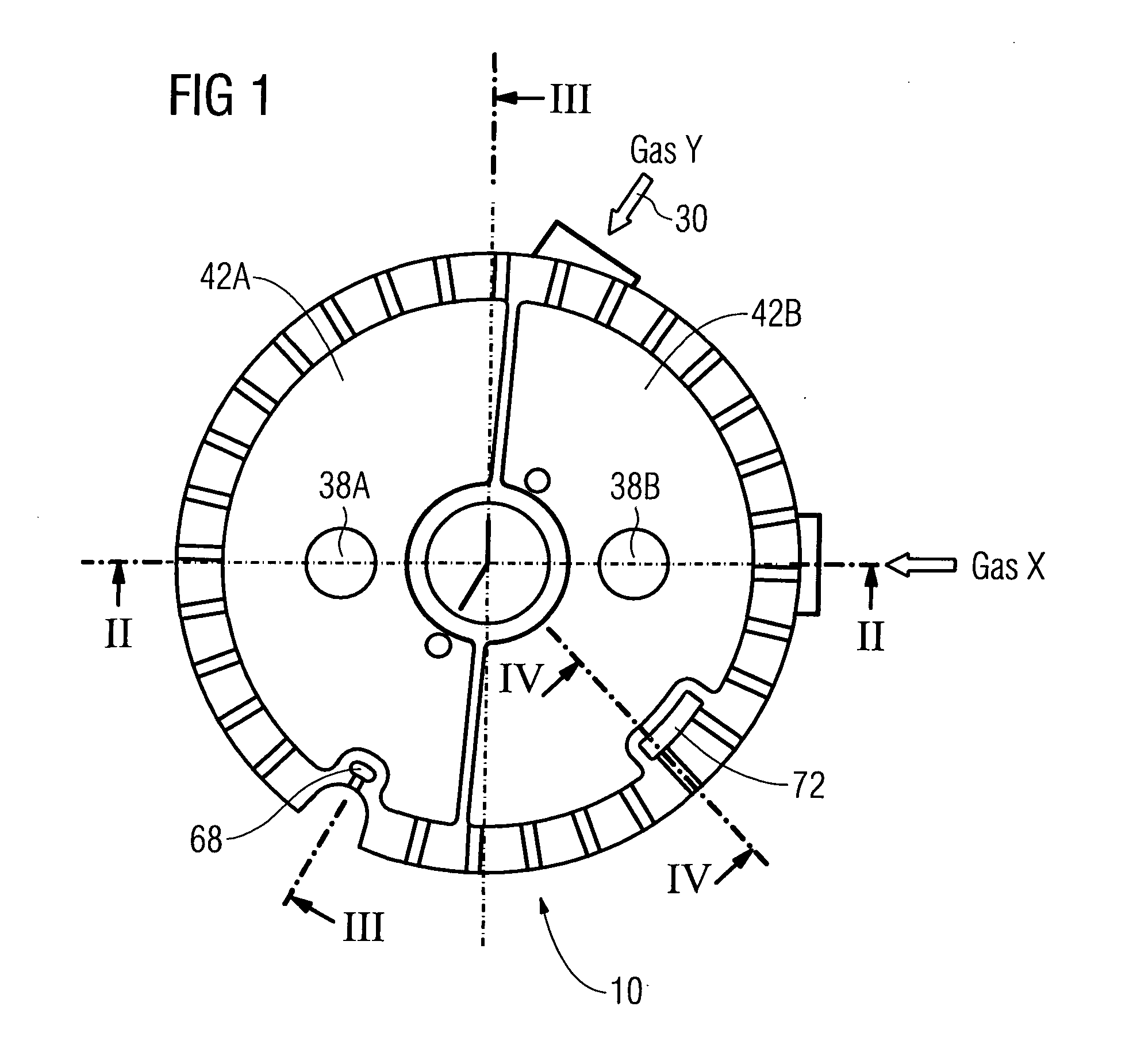

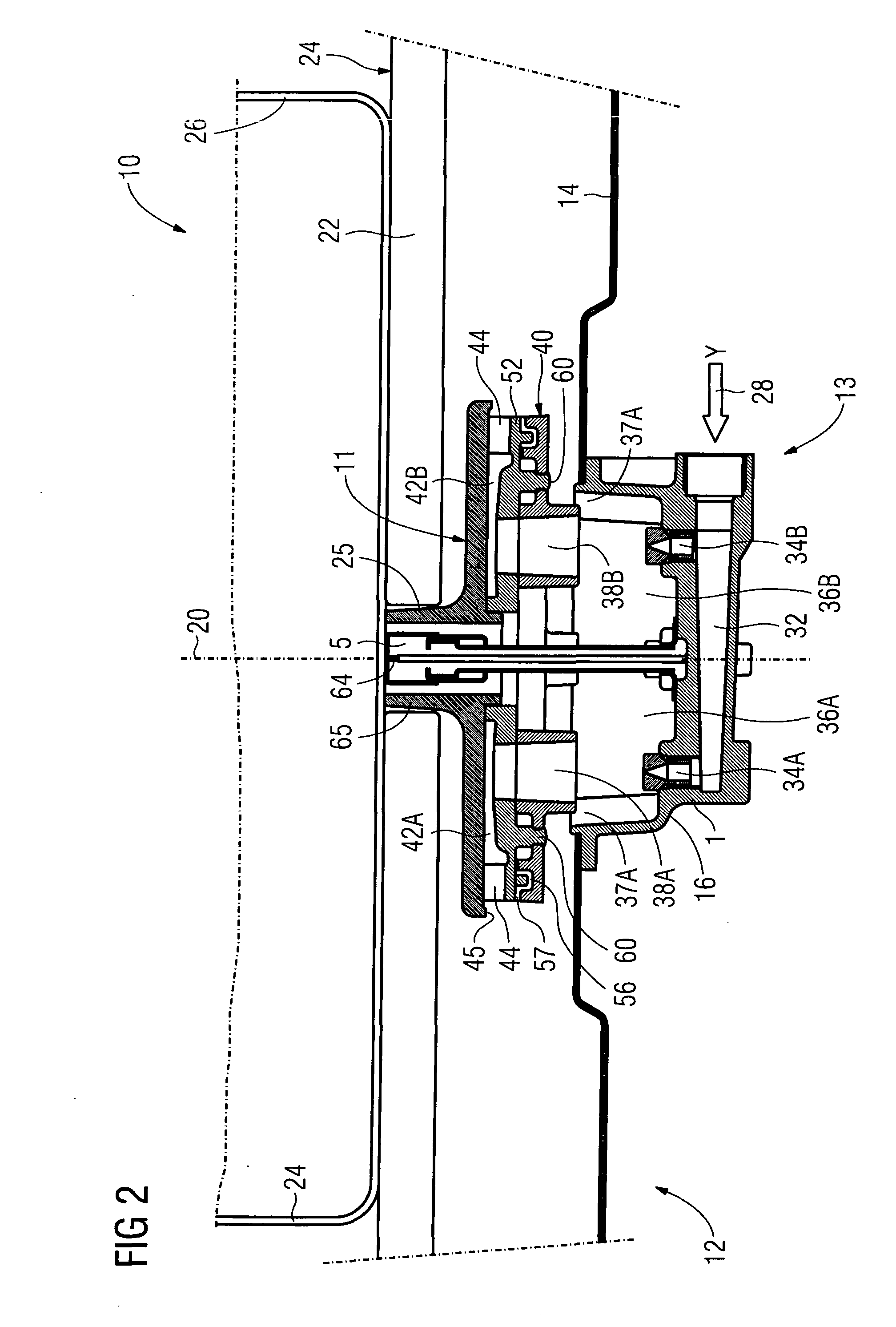

Burner for a heat generator and method for operating the same

InactiveUS6210152B1Avoid destructionBurner safety arrangementsFuel supply regulationCombustorCombustion chamber

In a burner for operating a combustor, the former consists essentially of a rotation generator (100), a transition piece following the rotation generator, and a mixing pipe following this transition piece. Transition piece and mixing pipe form the mixing section (220) of the burner and are located upstream from a combustion chamber (30). In the lower part of the mixing pipe is located a pilot burner system (300) which creates, among other things, a stabilization of the flame front, in particular in the transient load ranges, while minimizing pollutant emissions. A sensor (400) installed in the burner detects a flashback of the flame (80), whereupon the fuel quantity of this flame is at least temporarily reduced and at the same time the fuel quantity for the pilot burner is increased in such a way that the total fuel quantity and thus the turbine output remains constant. This measure prevents a destruction of the burner.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Gas burner assembly including inner and outer burners and methods for implementing same

A gas burner assembly for a cooking appliance that includes a cooktop surface includes a gas burner assembly having a first gas burner including a first burner body. The first burner configured to be mounted on, and contact, the cooktop surface, and provide a cooking flame. The gas burner assembly also includes a second gas burner including a second burner body. The second burner configured to be mounted on, and contact, the cooktop surface. The second burner also configured to be concentric with the first burner and separated from the first burner by a distance at all points along the burners. The second burner body including at least one air passage defined therethrough that is configured to allow air to flow through the second burner and to the cooking flame.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Gas burner

ActiveUS9074765B2Avoids tendencyLarge caliberDomestic stoves or rangesBurner control devicesFuel gasGas burner

Owner:ELECTROLUX HOME PROD CORP NV

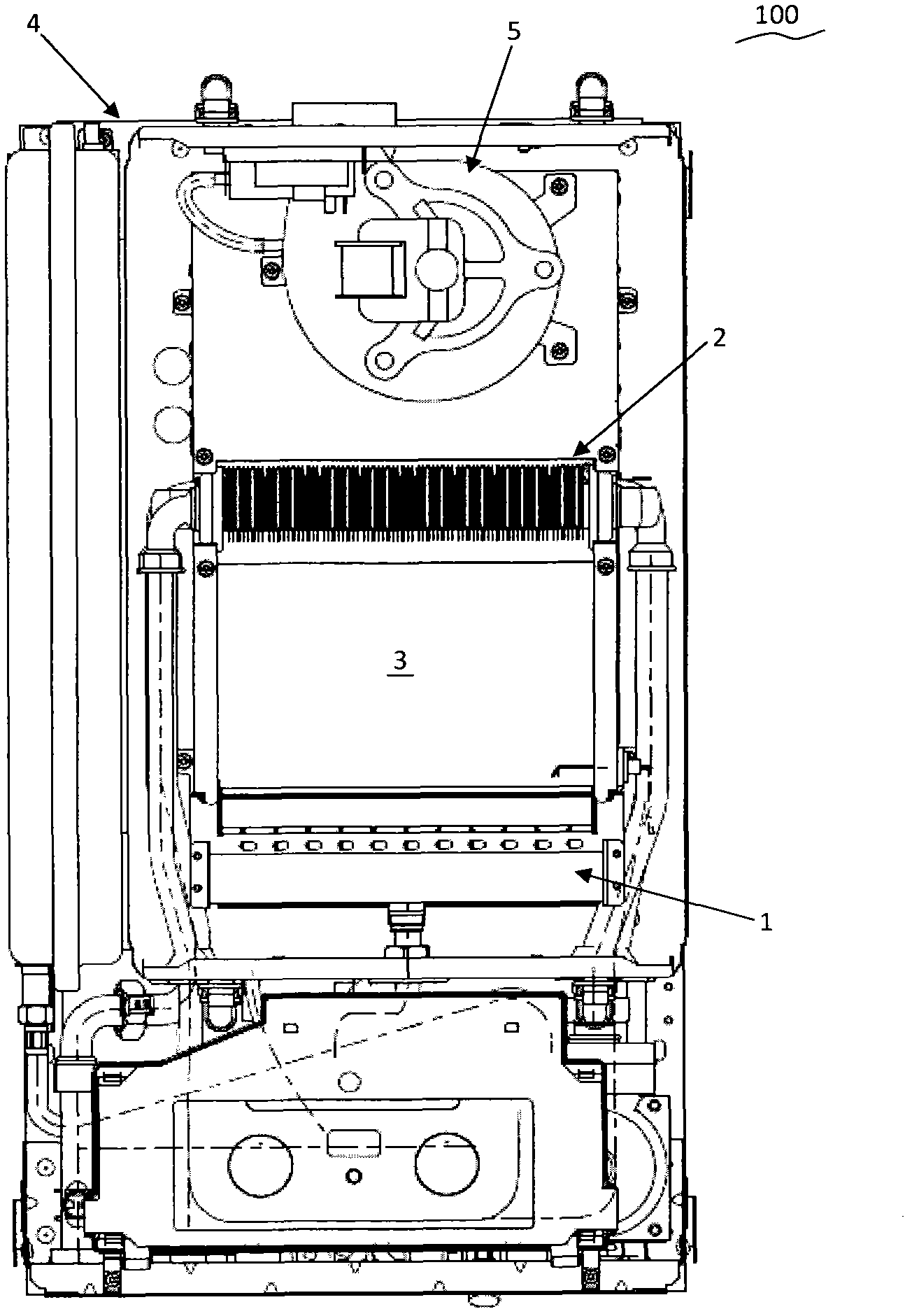

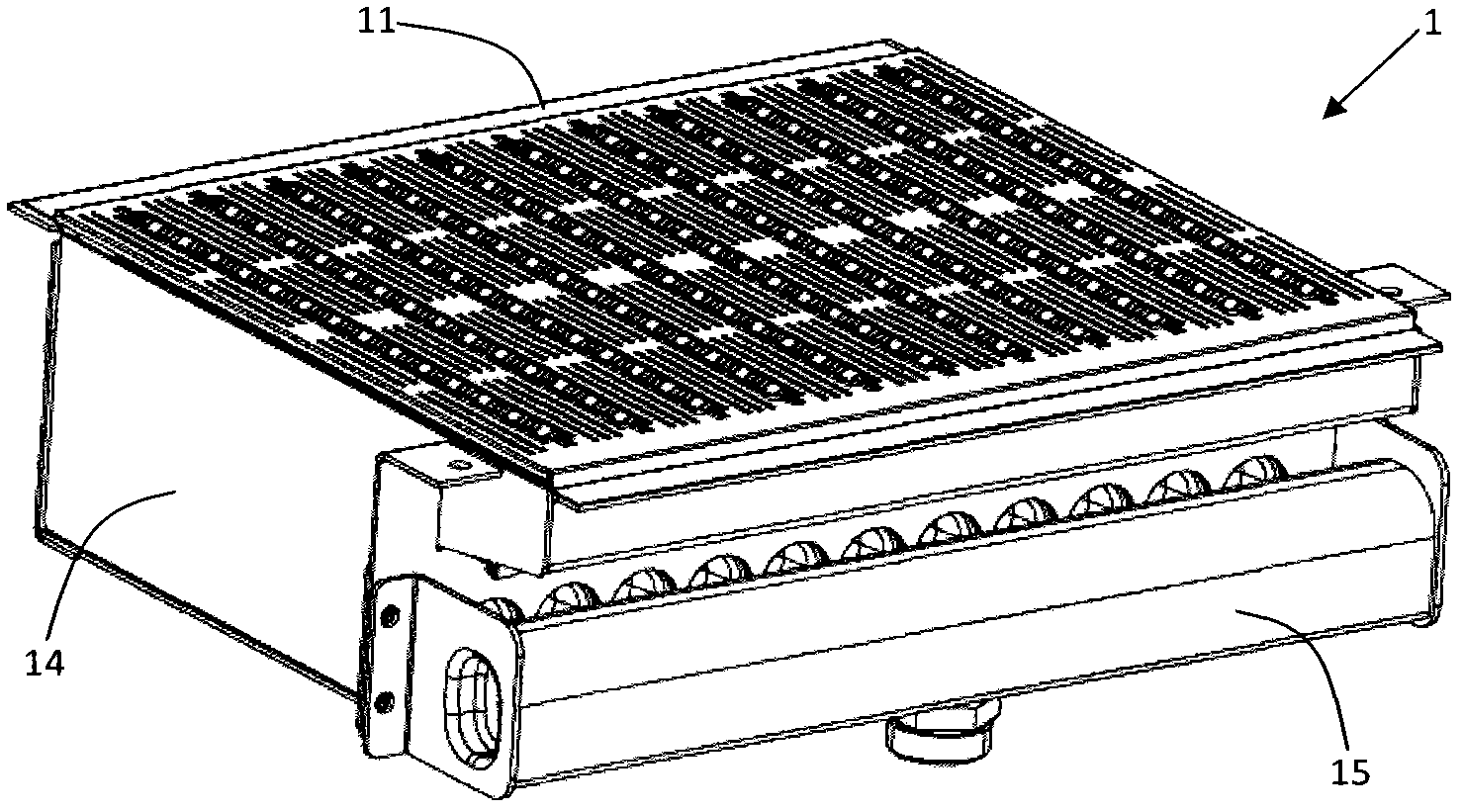

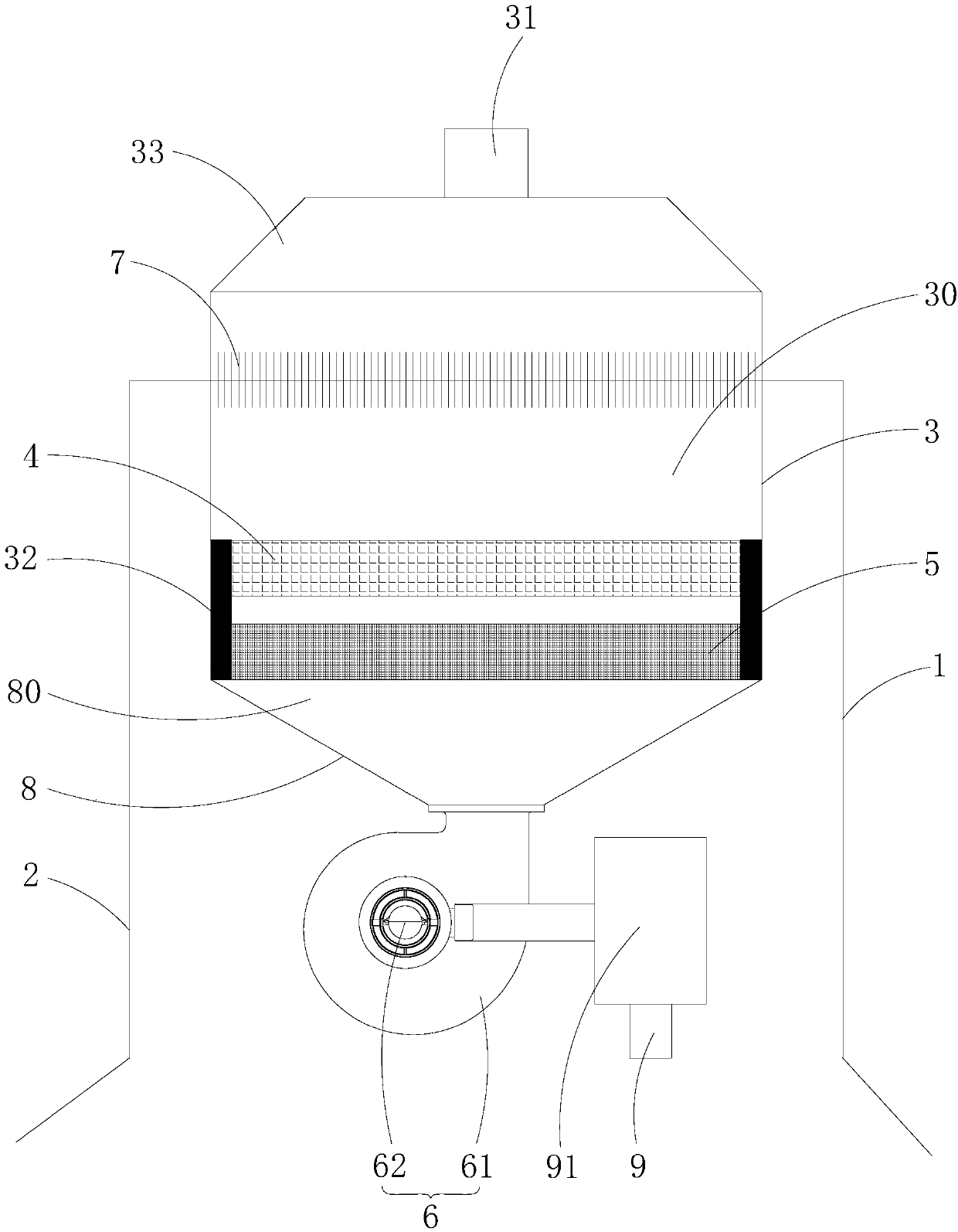

Burner and fuel gas hot water equipment adopting same

ActiveCN102635863AEmission reductionImprove flammabilityFluid heatersMultiple burner assemblyCombustorNitrogen oxide

The invention provides a burner which comprises at least two burner units, a second fuel-air mixing cavity as well as at least one fuel-air mixture distributing port, wherein each burner unit comprises a plurality of fire holes which are arranged in a lengthwise manner and a first fuel-air mixing cavity, and each first fuel-air mixing cavity is used for generating and transferring a first fuel-air mixture to the fire holes; at least two burner units are arranged side by side along a transverse direction and a gap is formed between the upper parts of the burner units, and the second fuel-air mixing cavity is used for generating a second fuel-air mixture; and at least one fuel-air mixture distributing port is arranged independently relative to at least two burner units and is communicated with gas in the second fuel-air mixing cavity so as to distribute the second fuel-air mixture to a gap between at least two burner units. Through the arrangement, the discharge of nitrogen oxide is effectively reduced and simultaneously the good burning effect is ensured, and the reconstruction of the fire discharge piece of the existing burner is reduced as much as possible.

Owner:VAILLANT WUXI HEATING EQUIP

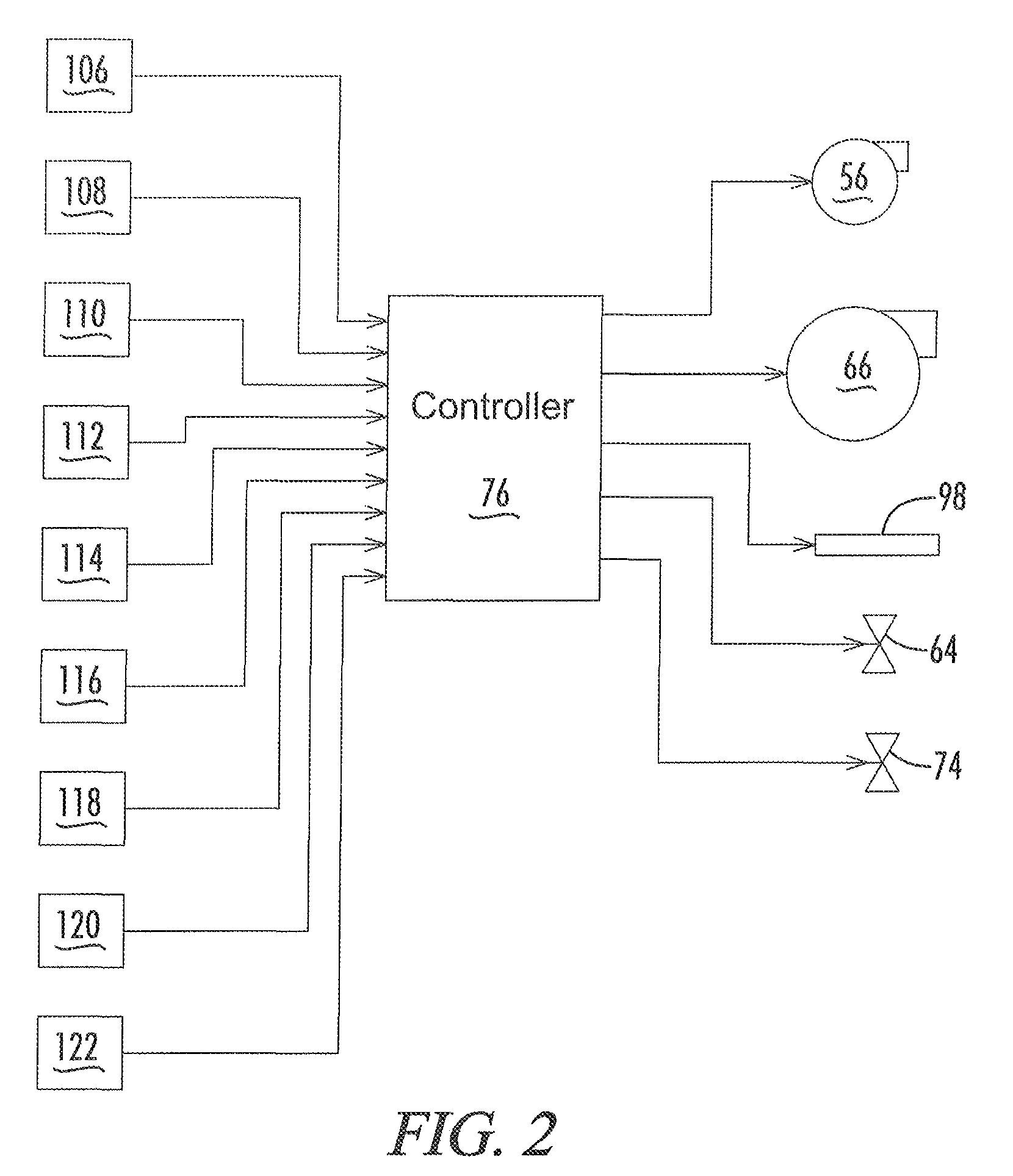

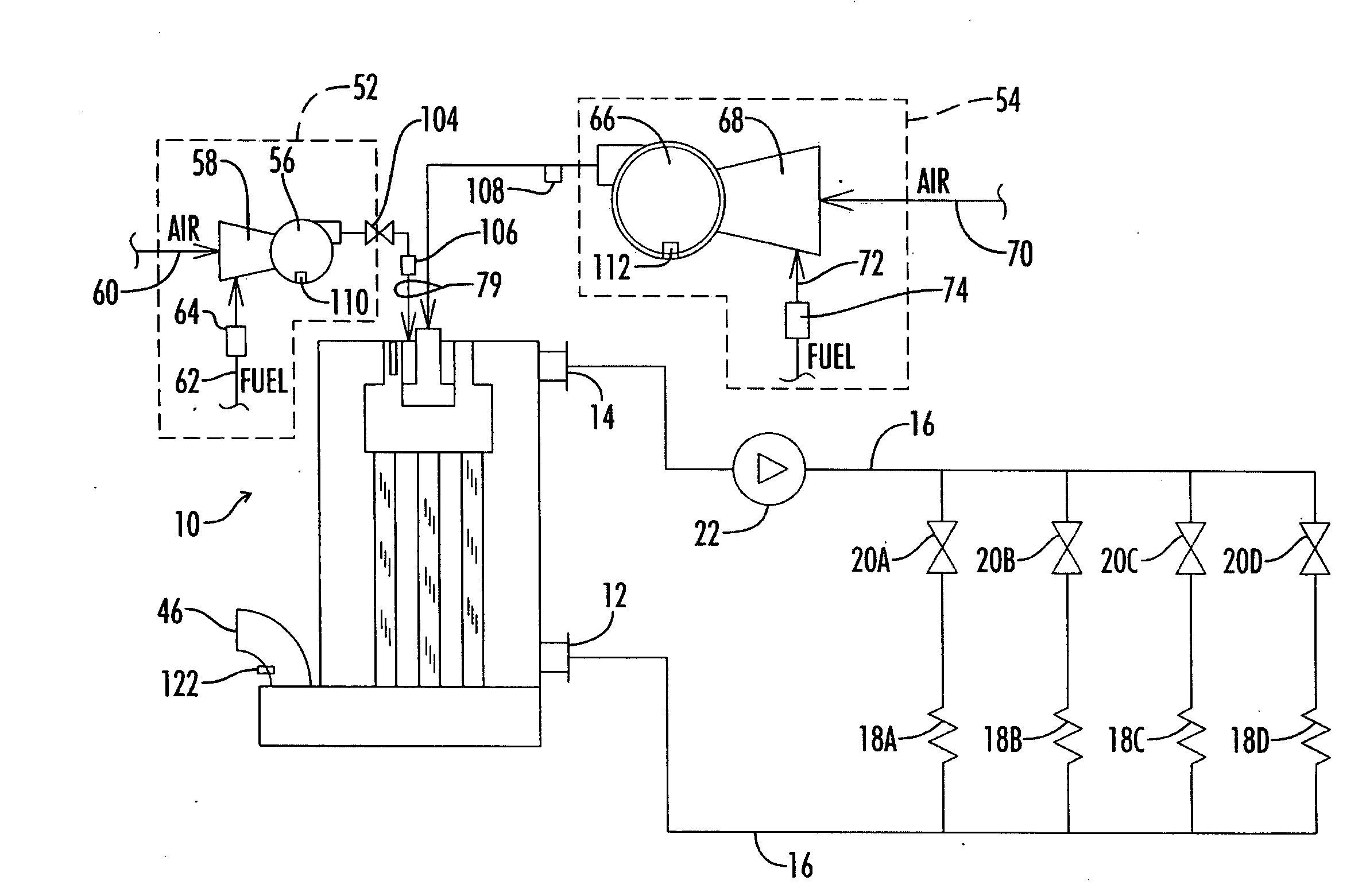

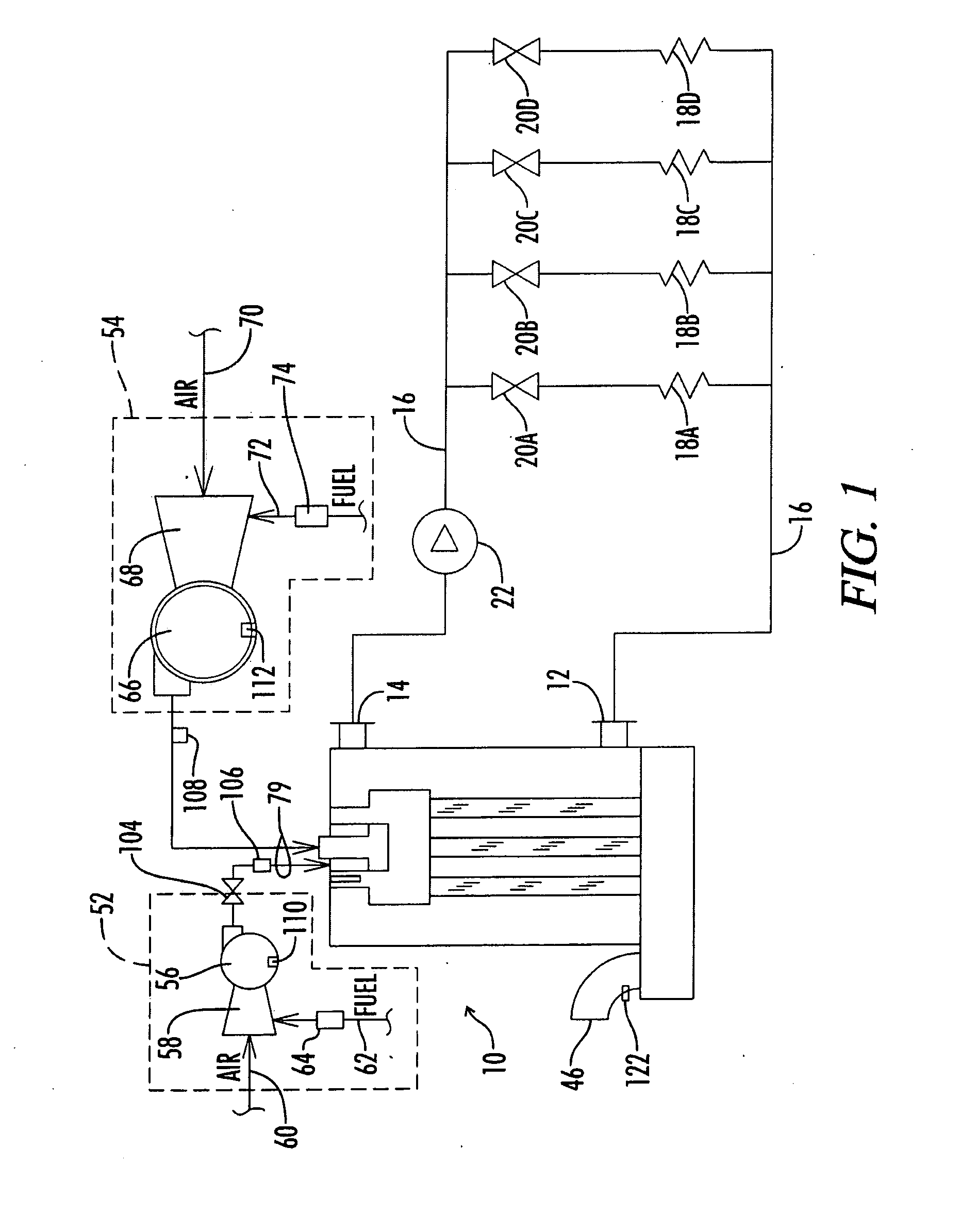

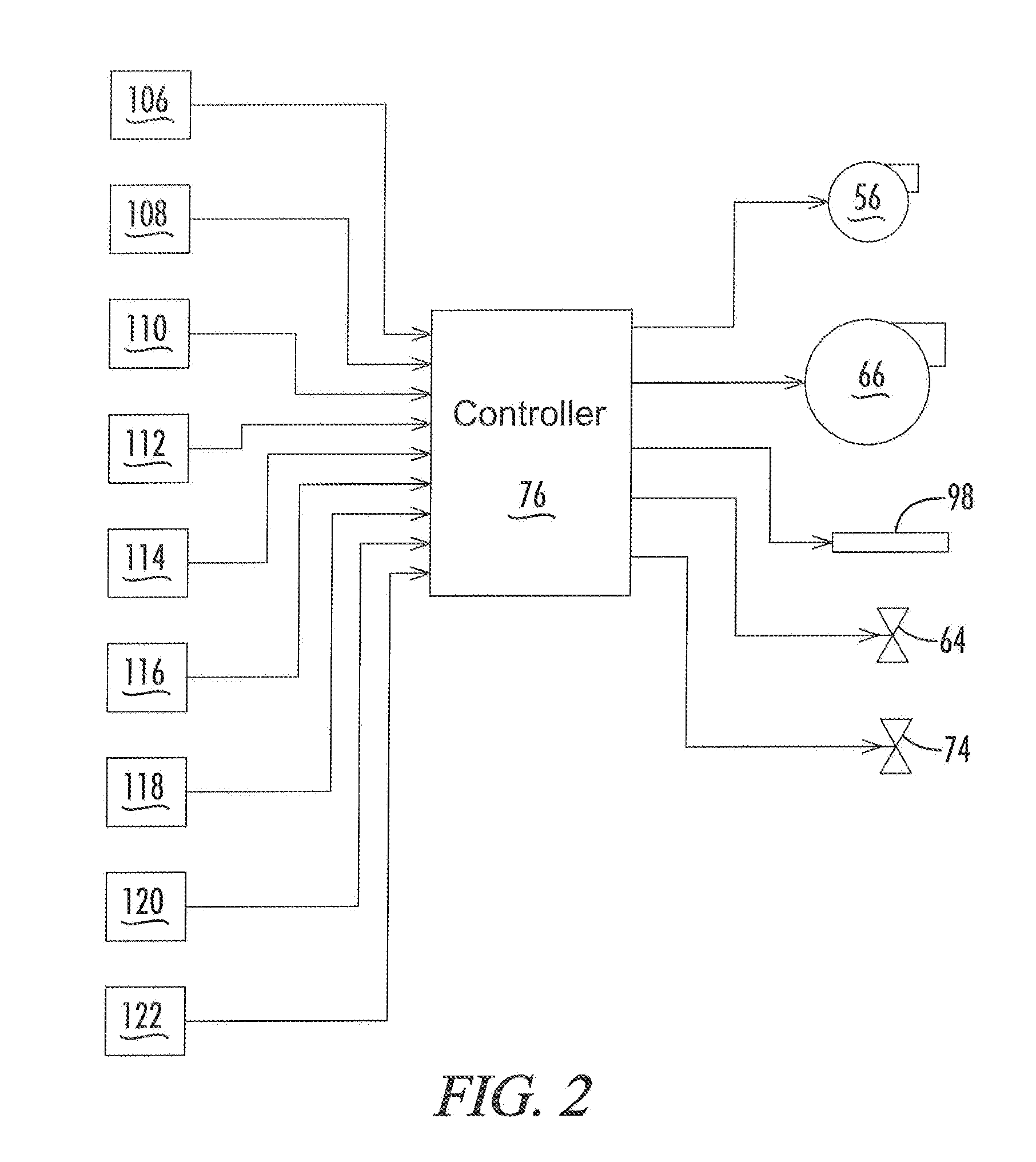

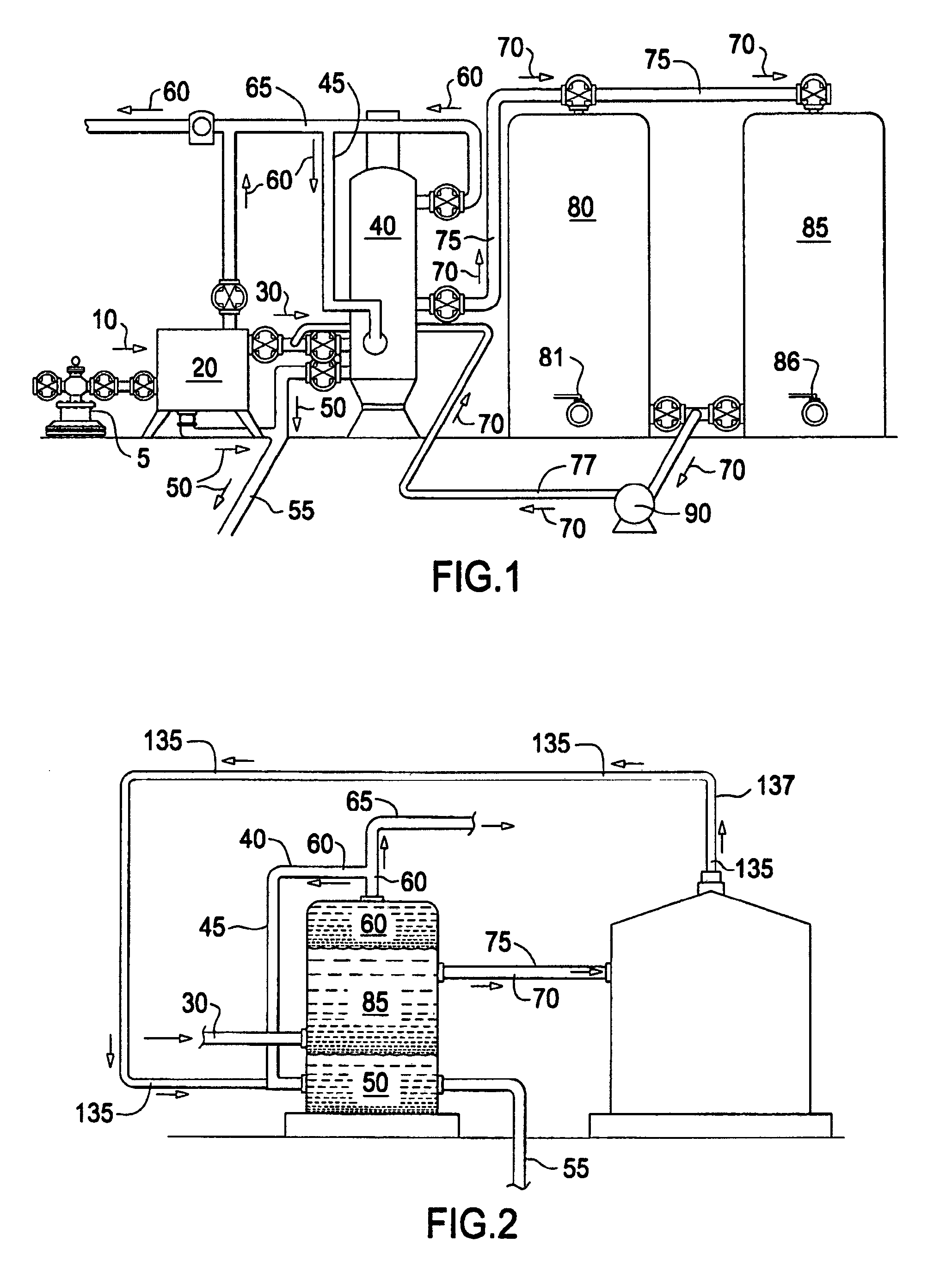

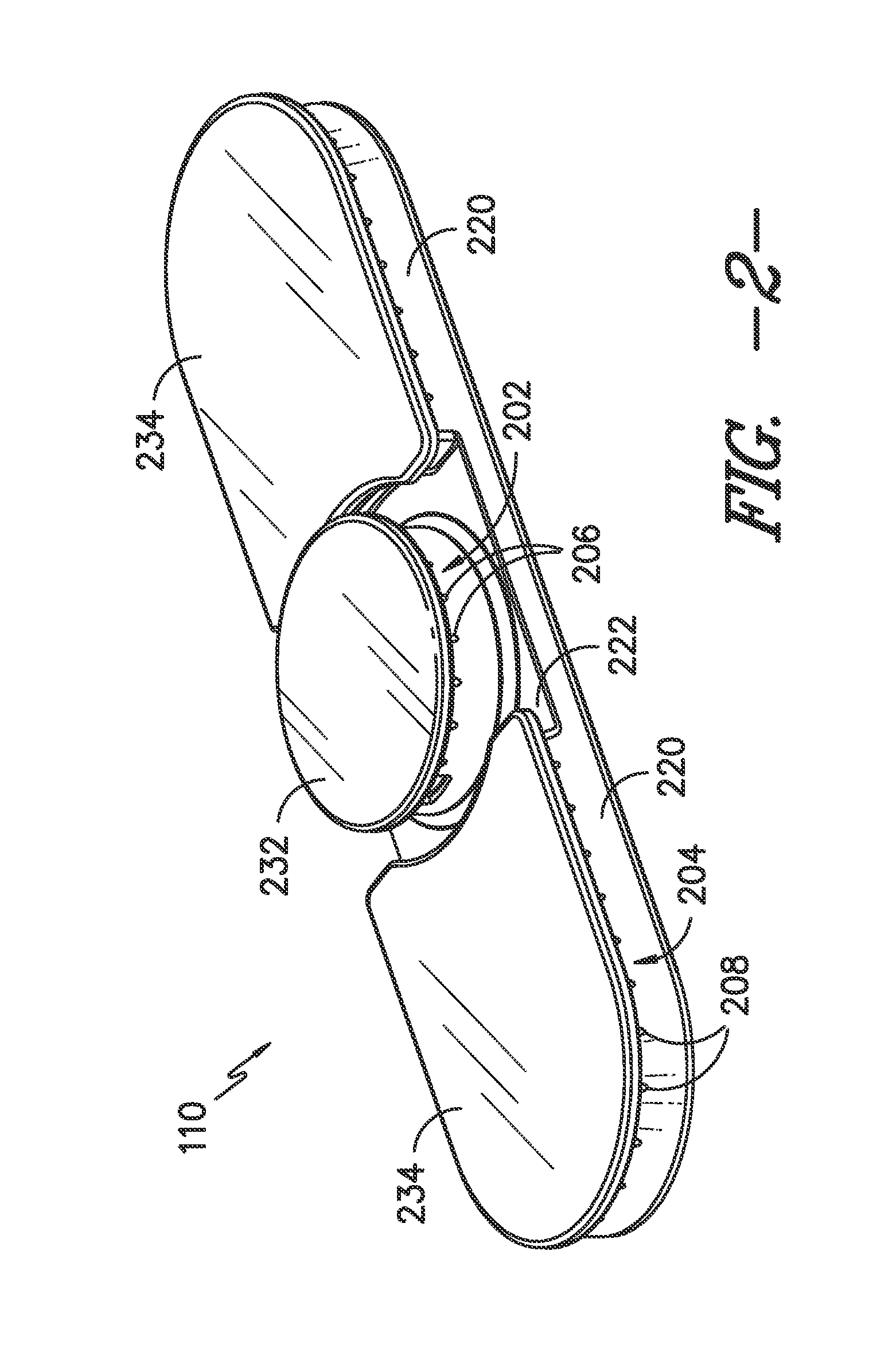

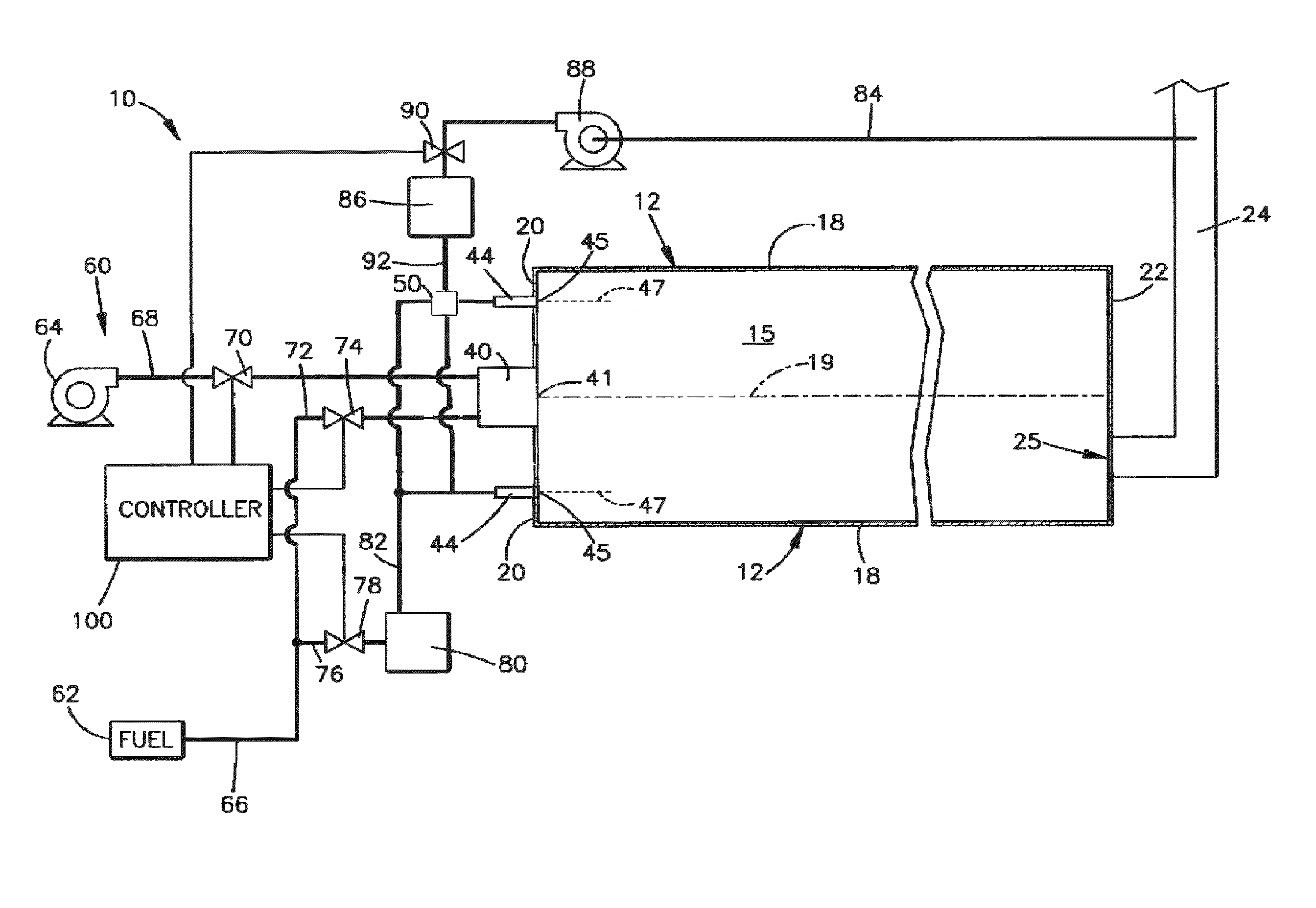

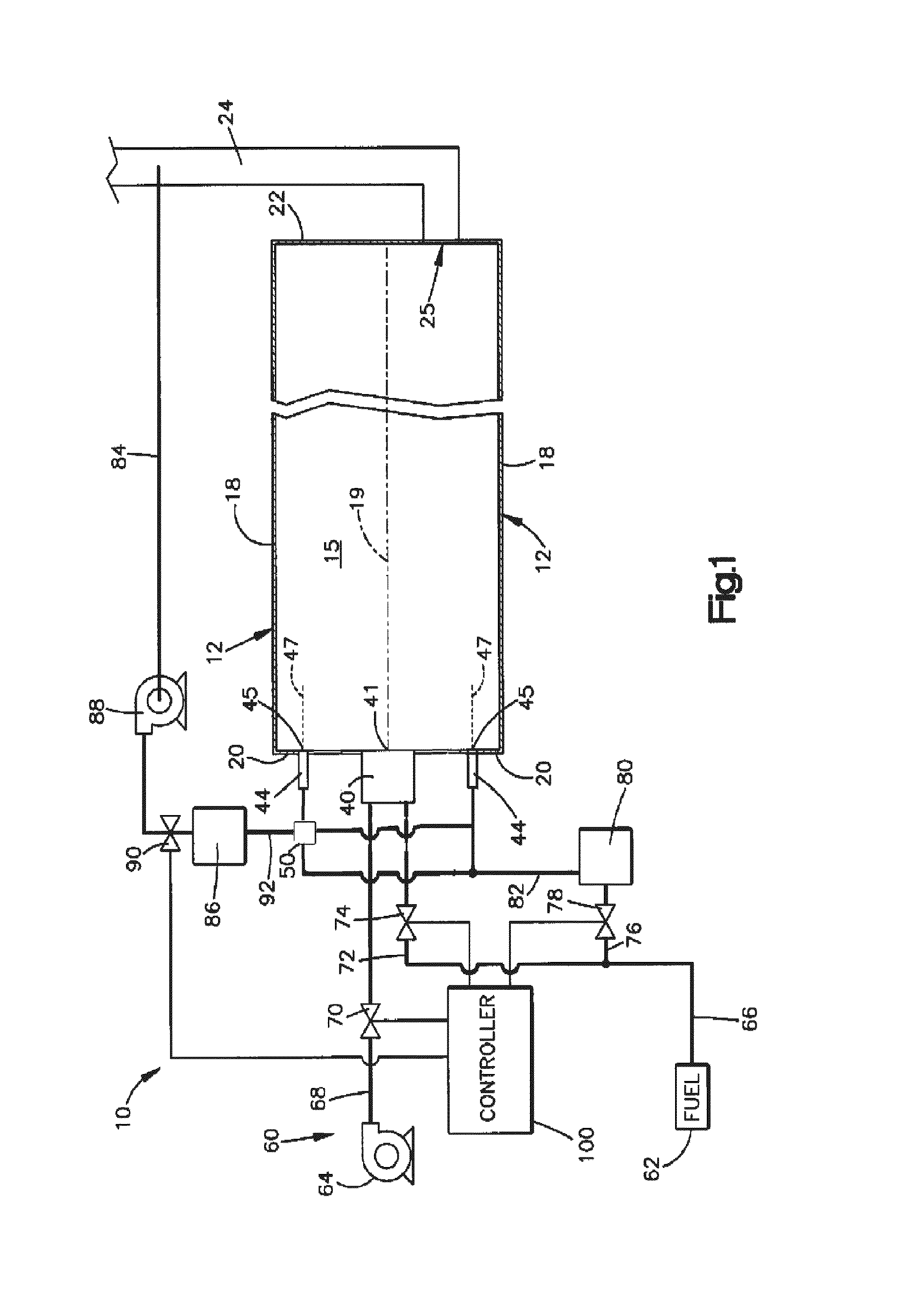

Gas fired modulating water heating appliance with dual combustion air premix blowers

ActiveUS8286594B2Avoid condensationIncrease the turndown ratioWater circulationEnergy efficient heating/coolingCombustorEngineering

A water heating apparatus uses a low range blower assembly and a high range blower assembly, each providing a variable flow of premixed fuel and air to a burner assembly. Appropriate choice of the operating ranges of the blower assemblies can provide a high turndown ratio approximately equal to the product of the turndown ratios of each of the individual blower assemblies. Turndown ratios as high as 25:1 are achievable.

Owner:LOCHINVAR

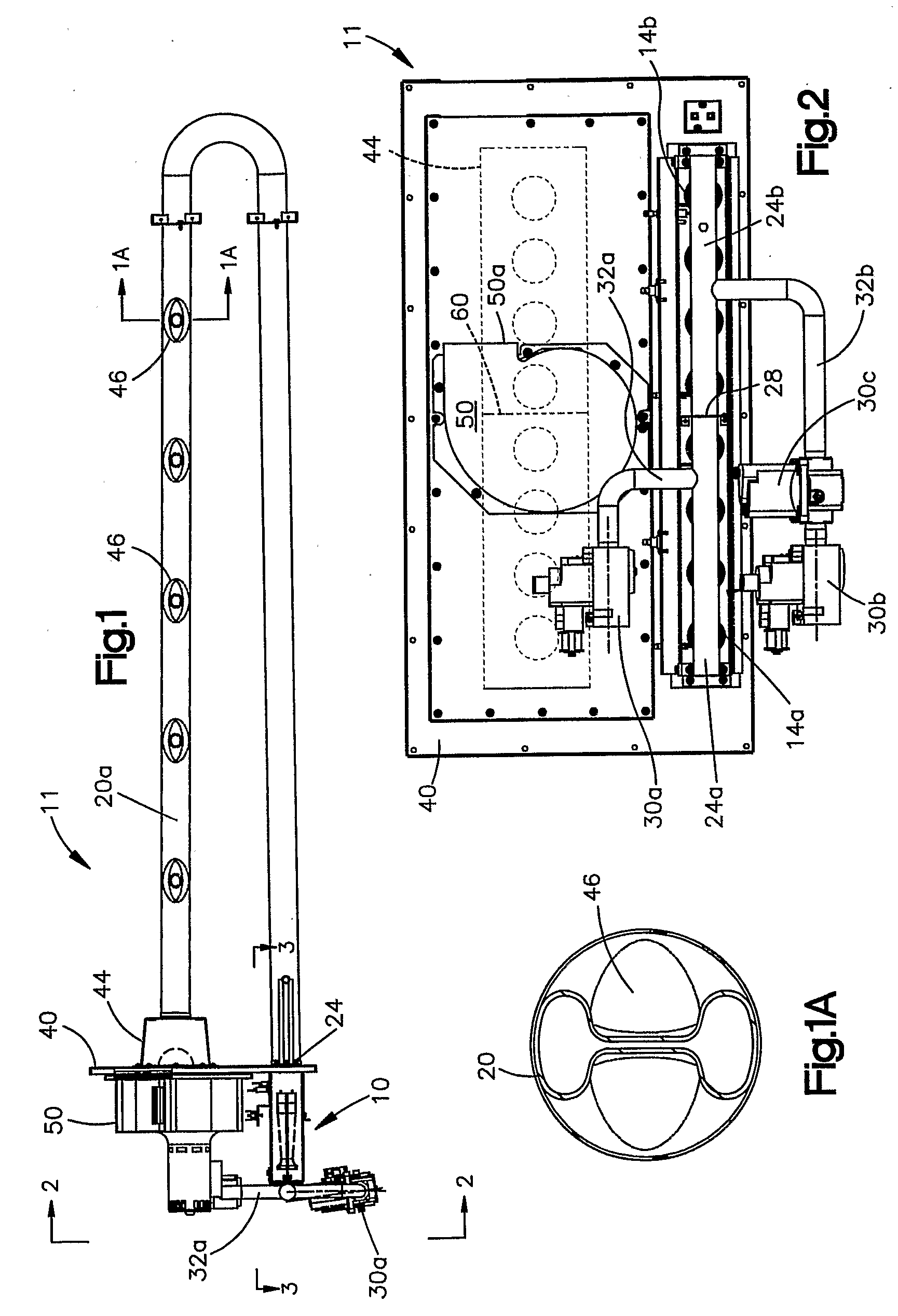

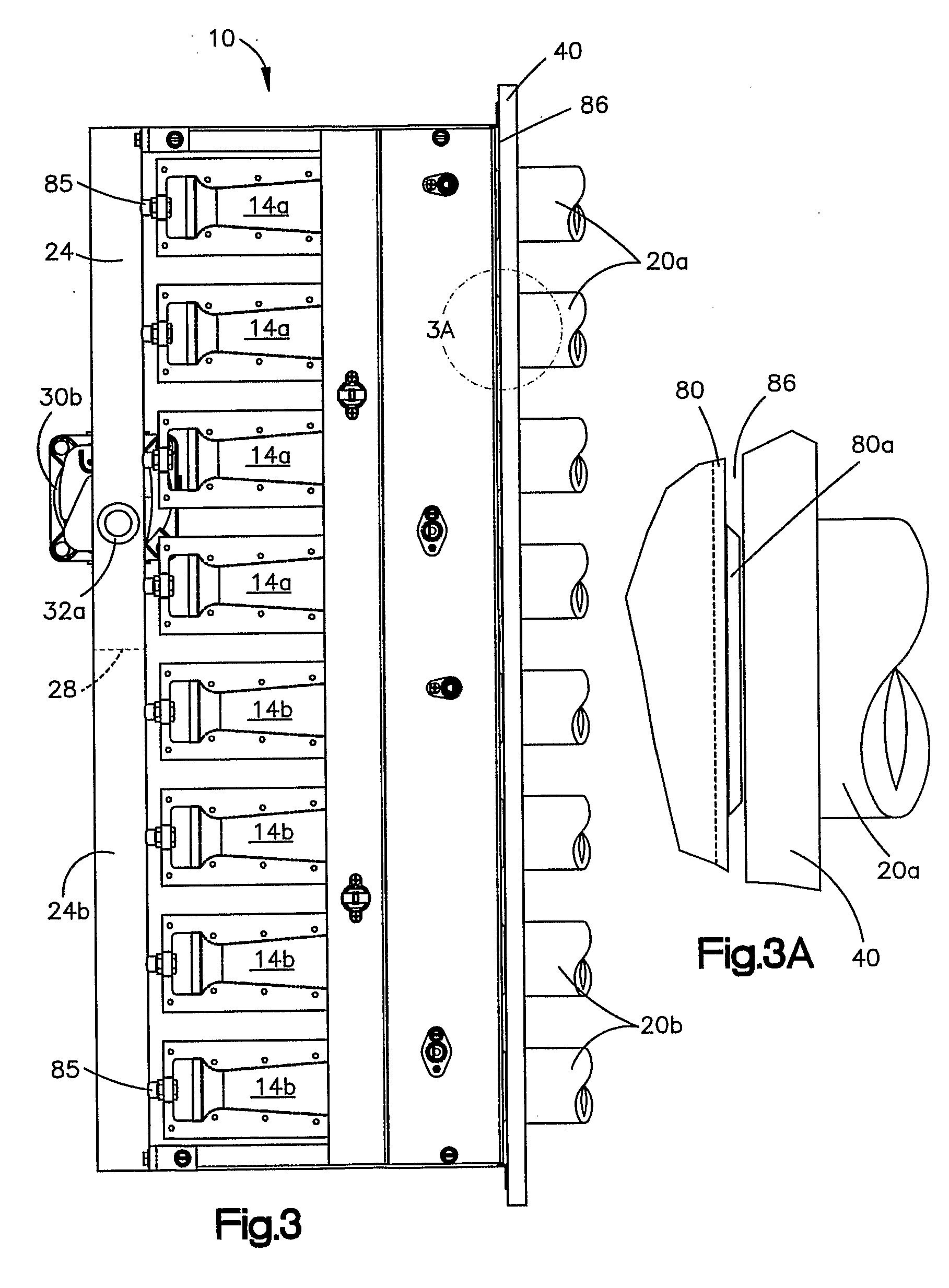

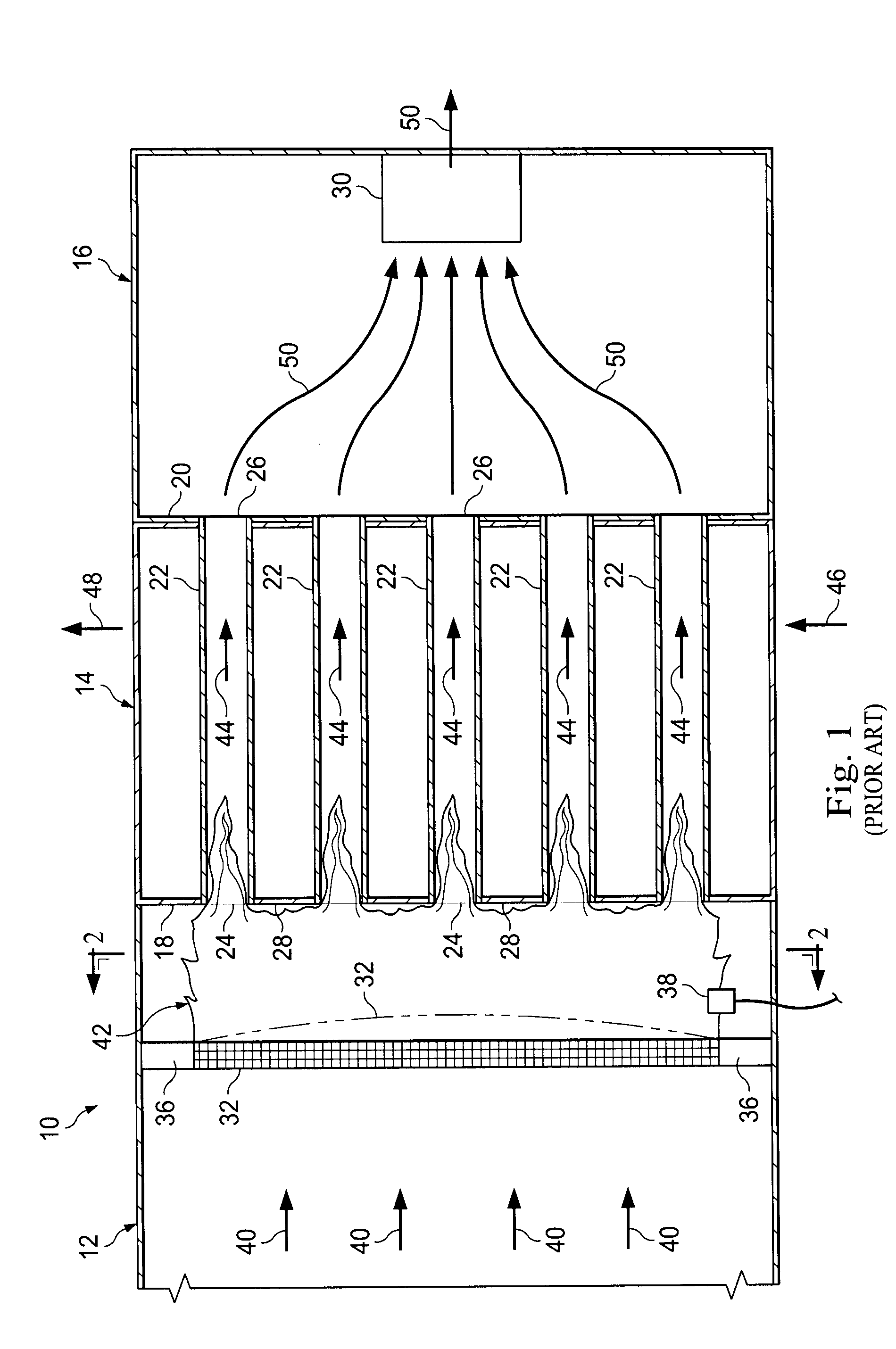

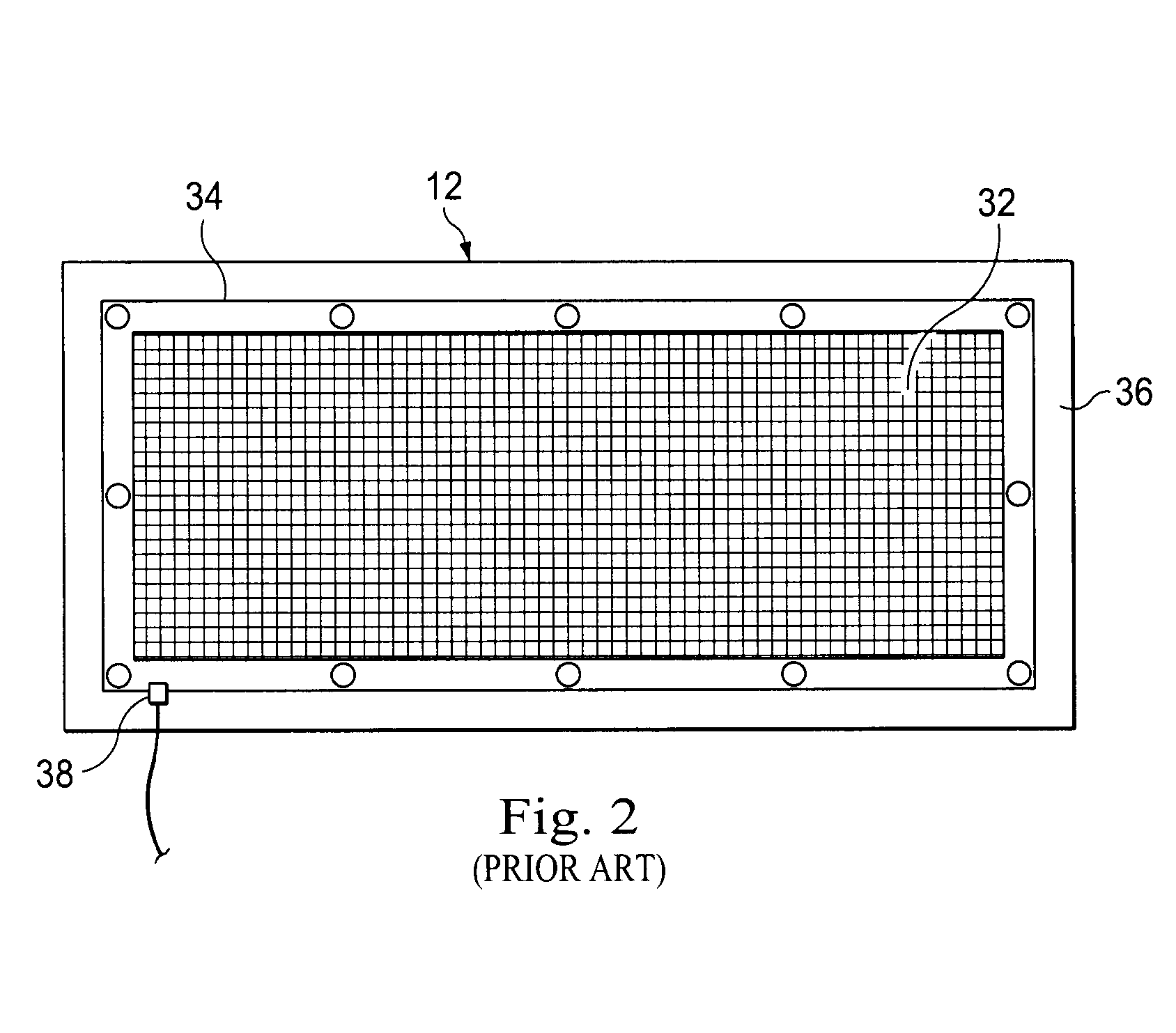

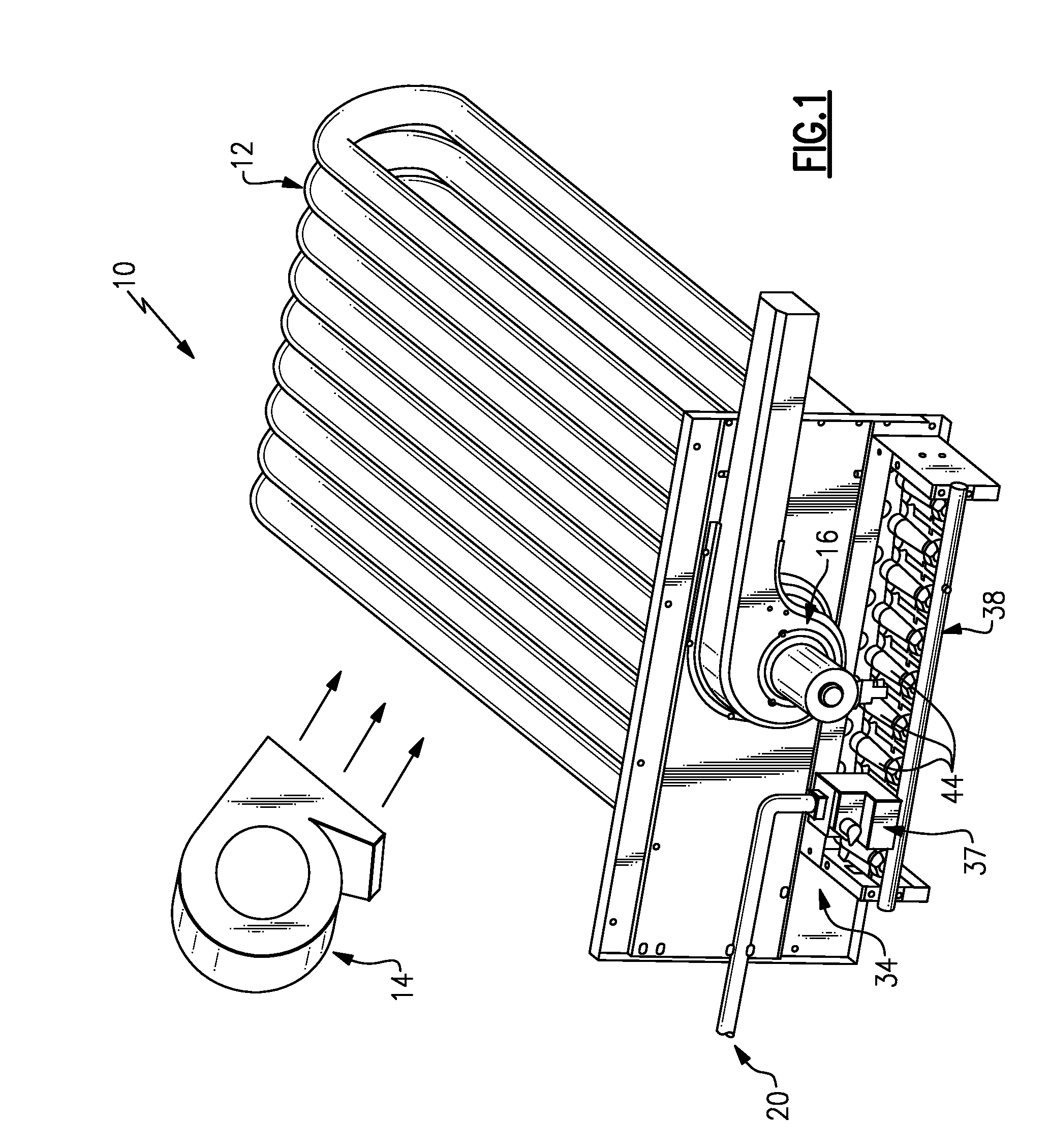

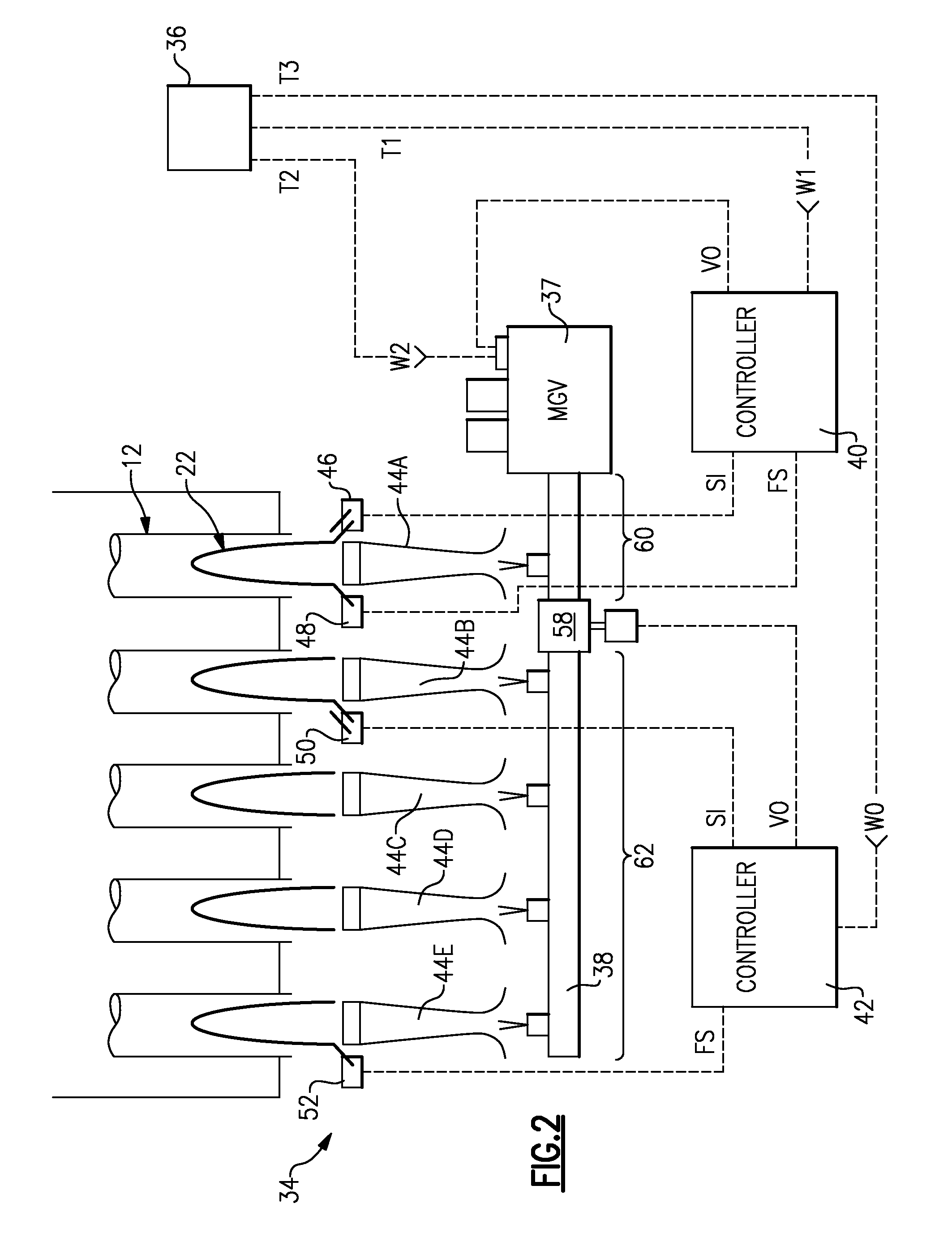

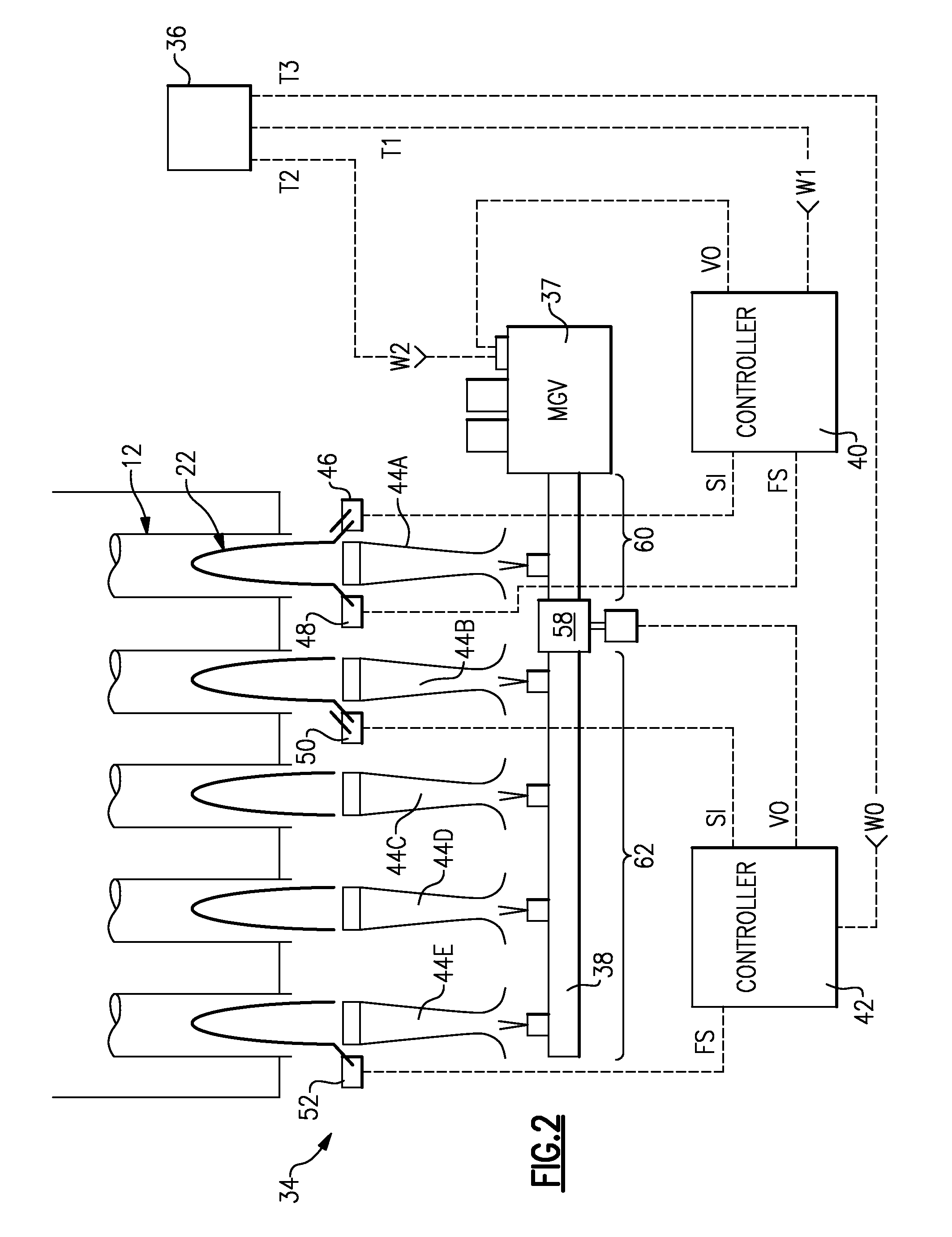

Furnace

ActiveUS20070272228A1Difference in densityImprove flame stabilityAir-treatment apparatus arrangementsAir heatersCombustorControl signal

A gas fired furnace capable of operating with a 16:1 turndown ratio or greater. The furnace includes a plurality of burners (10) grouped into at least (14a) first and second (14b) groups, each group connected to a source of combustible gas through a control valve (30a, 30b, 30c). The control valve (30c) controlling at least one group of burners is of a modulating type having an output proportional to a control signal applied to the valve. The burners fire into associated heat exchange tubes (20a), each tube having an inlet (24) and an outlet. The tube outlets are connected to a collector chamber (44) that includes a baffle plate (60) that divides the collector into two sections, one of the sections communicating with the outlets of the tubes associated with the first group of burners, the other section communicating with the outlets of the heat exchanger tubes associated with the other group of burners.

Owner:BECKETT GAS

Gas Fired Modulating Water Heating Appliance With Dual Combustion Air Premix Blowers

ActiveUS20100095905A1Avoid condensationPrevent backflowFuel supply regulationEnergy efficient heating/coolingCombustorEngineering

A water heating apparatus uses a low range blower assembly and a high range blower assembly, each providing a variable flow of premixed fuel and air to a burner assembly. Appropriate choice of the operating ranges of the blower assemblies can provide a high turndown ratio approximately equal to the product of the turndown ratios of each of the individual blower assemblies. Turndown ratios as high as 25:1 are achievable.

Owner:LOCHINVAR

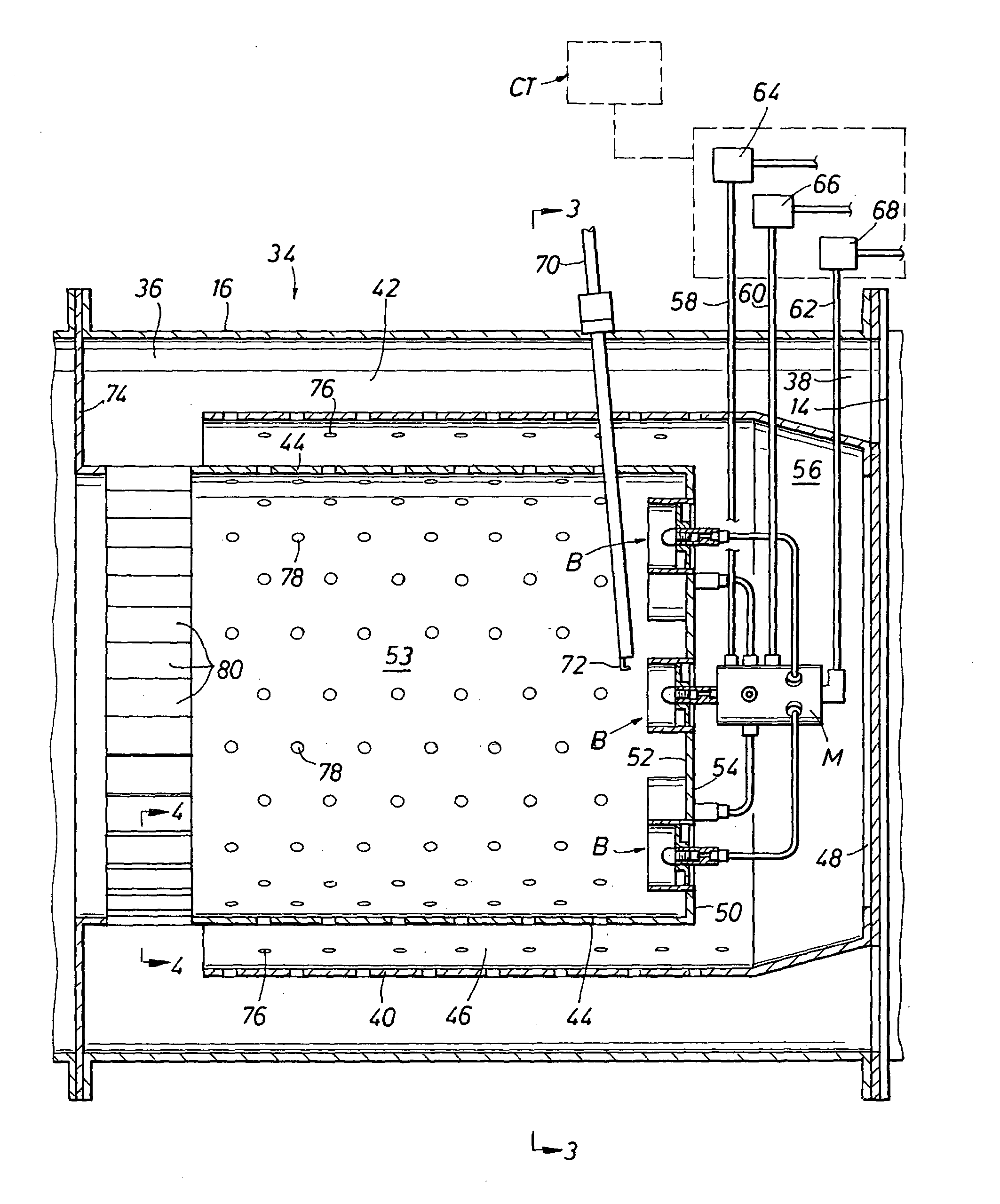

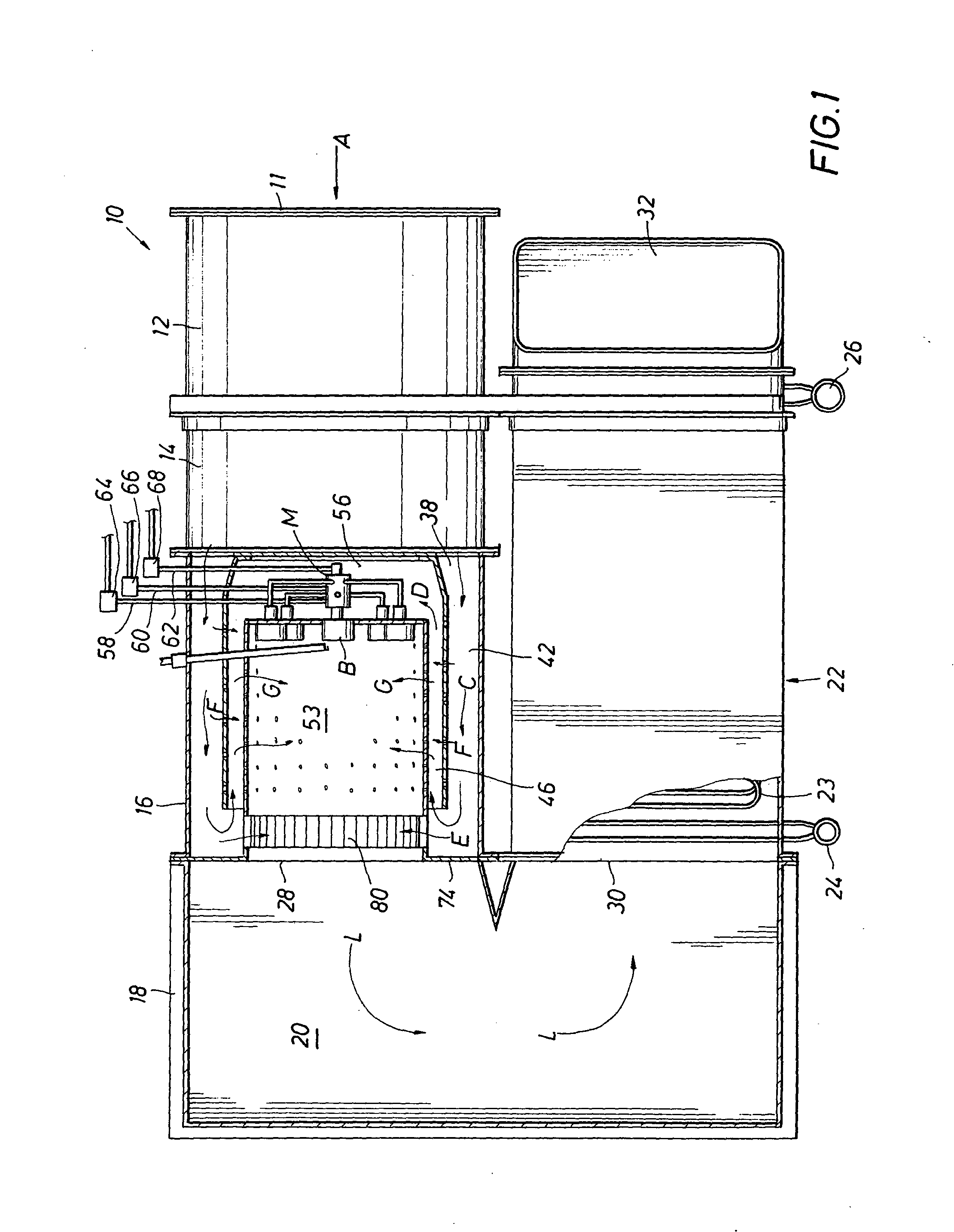

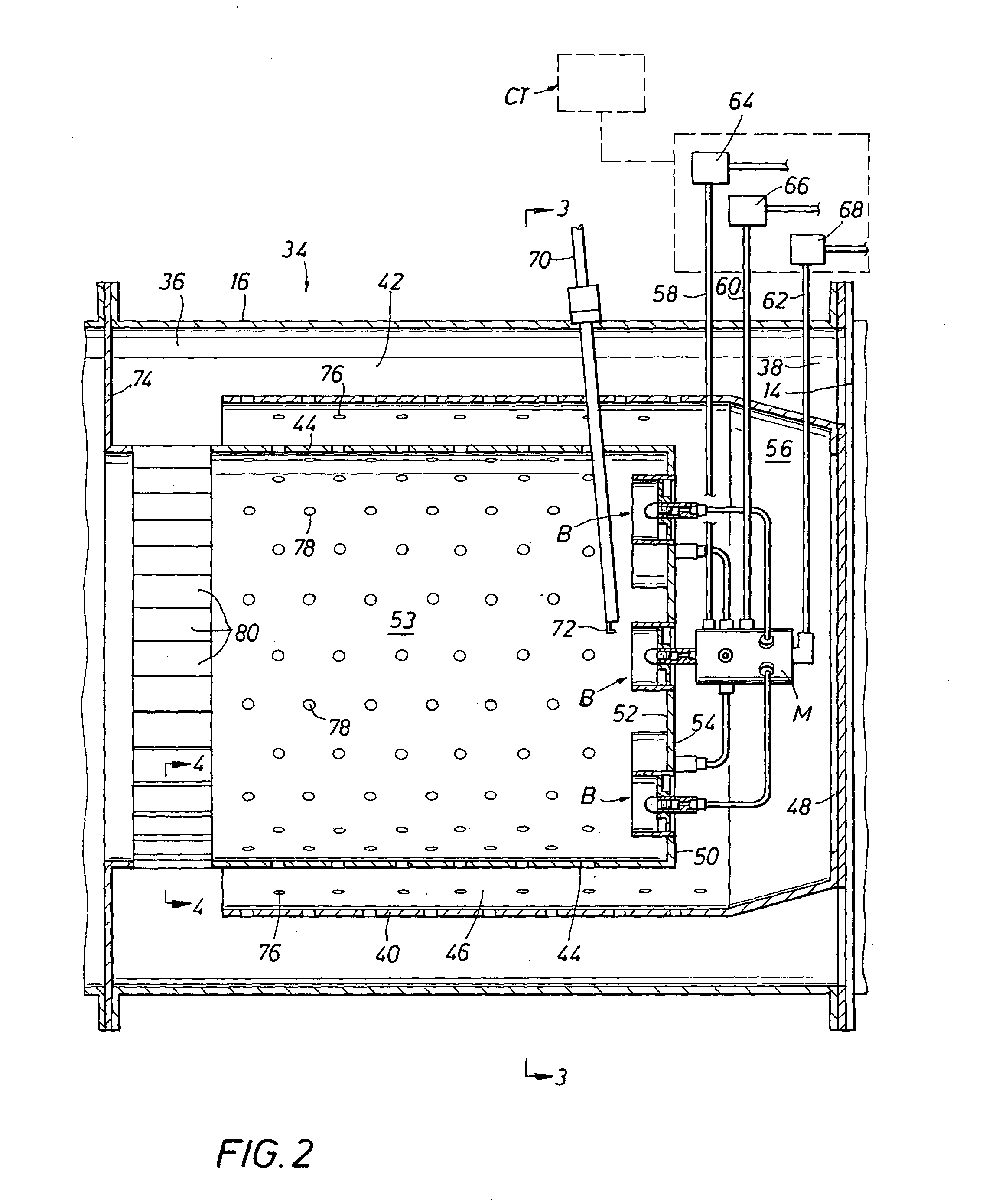

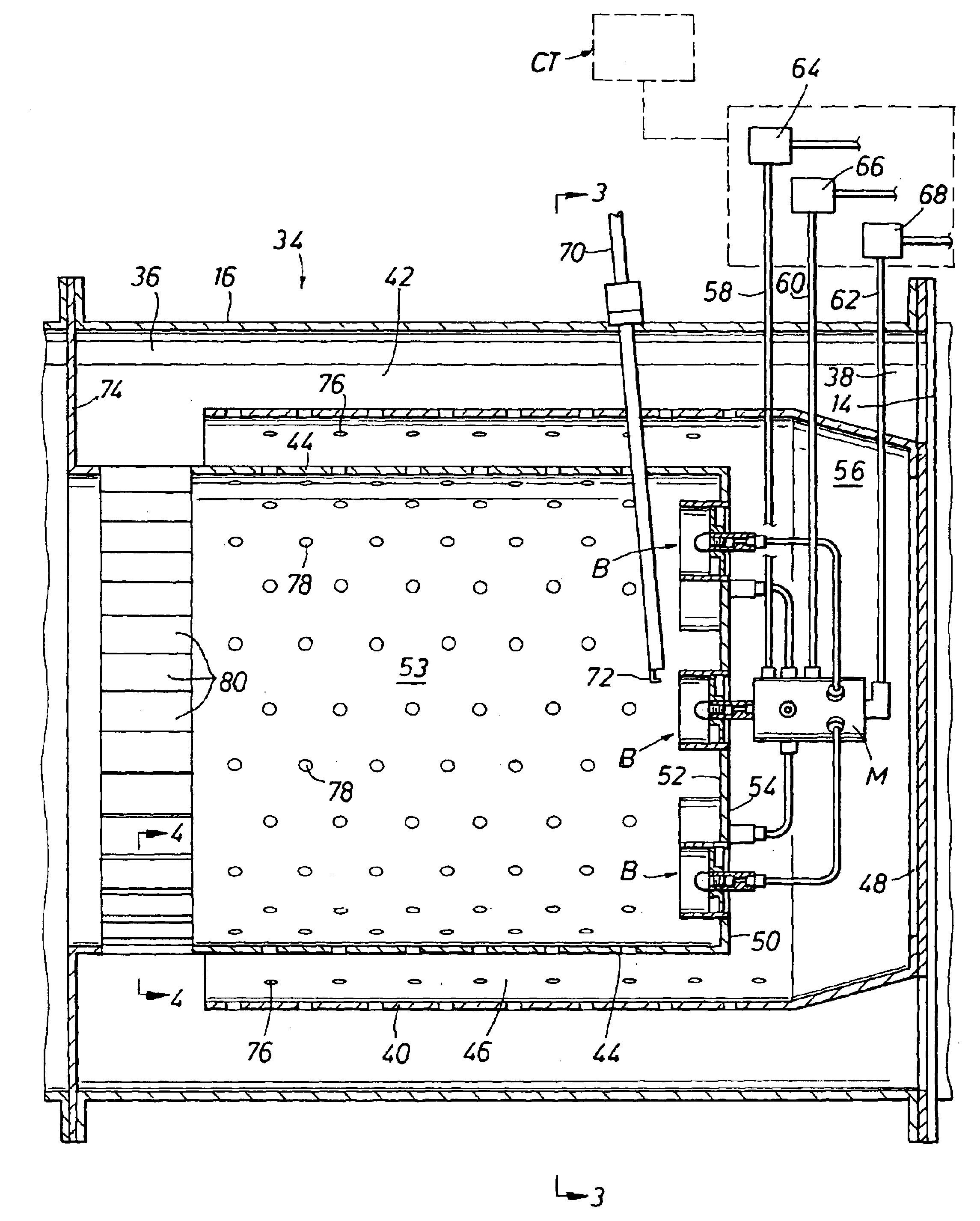

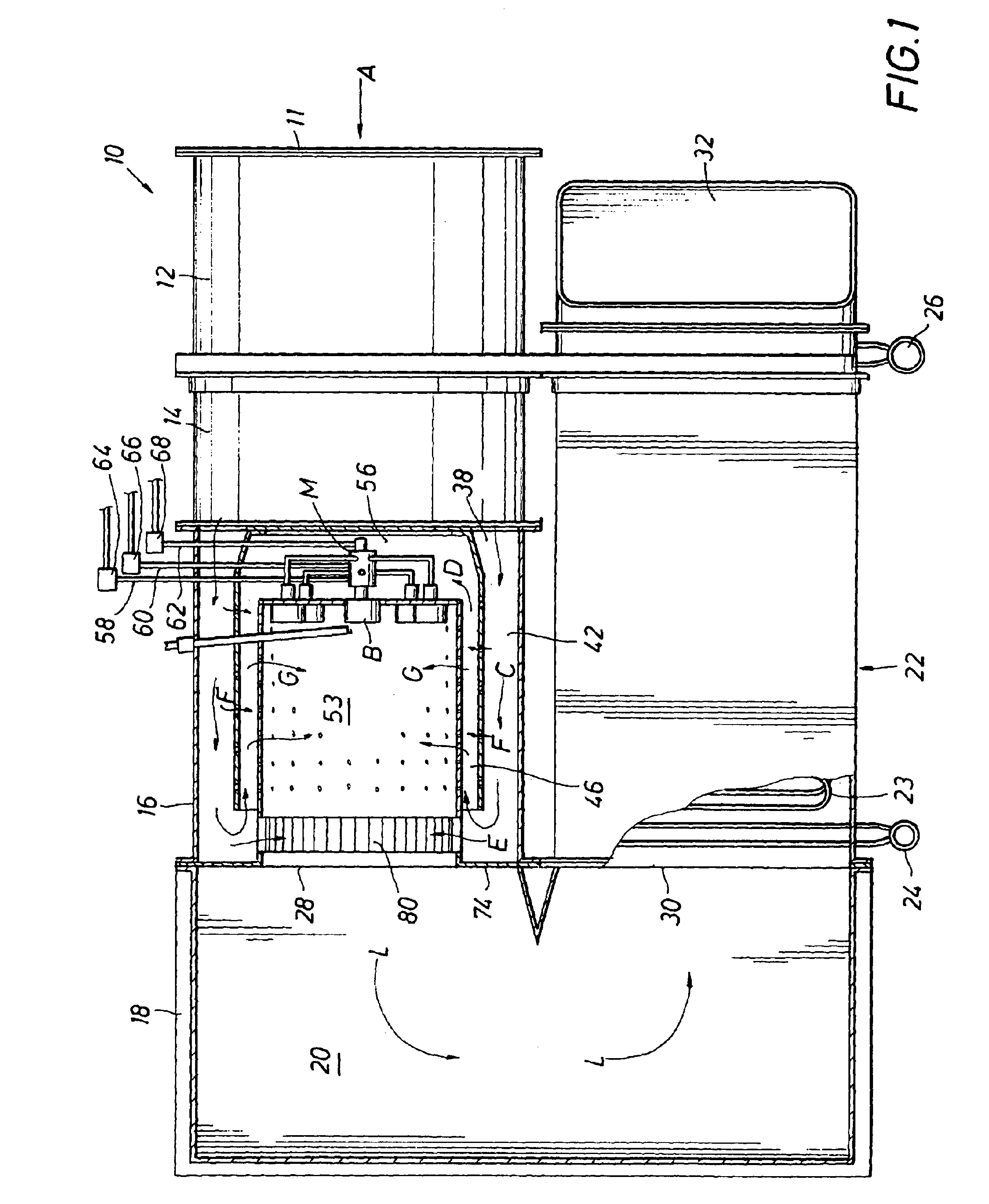

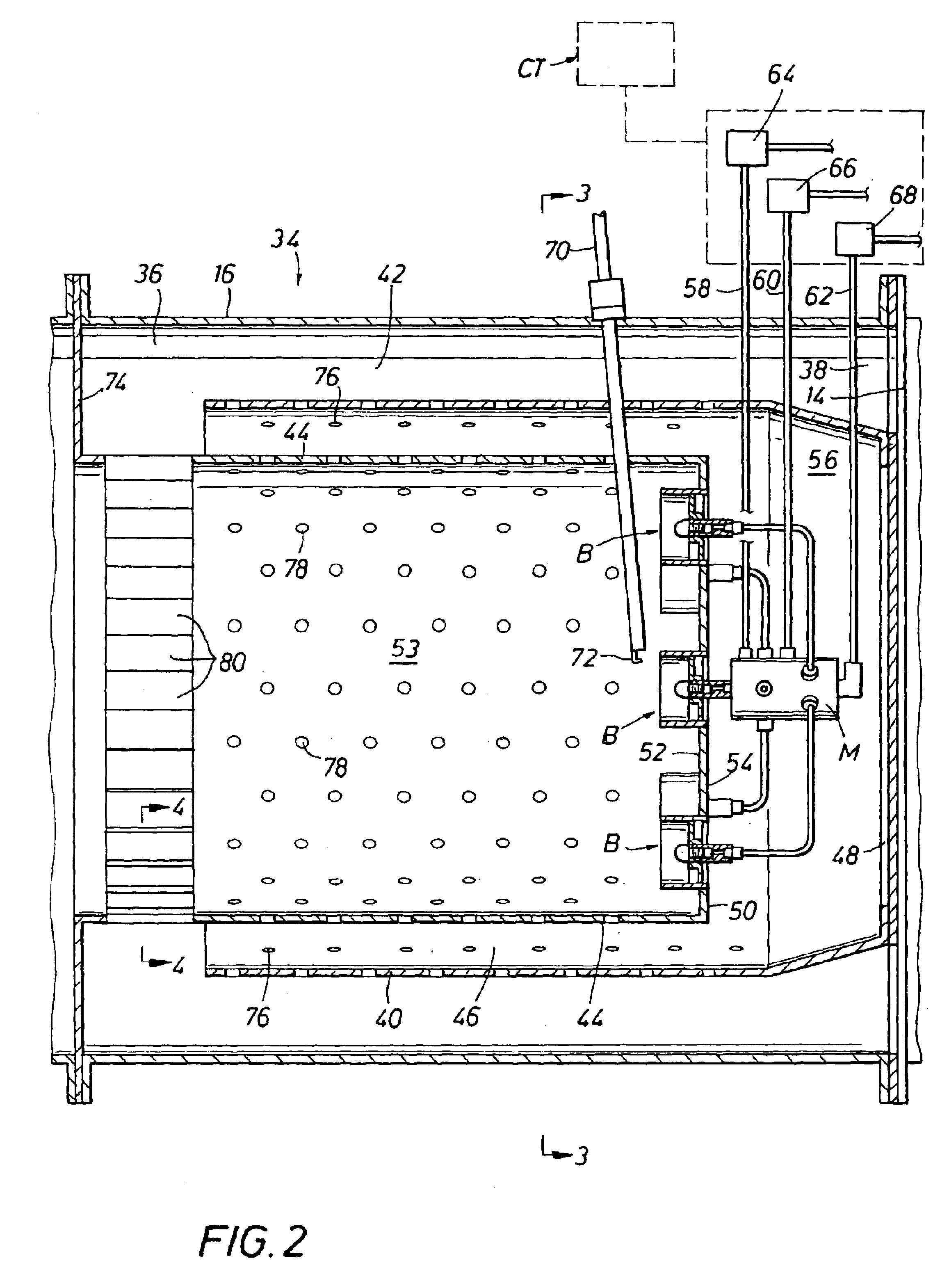

Burner apparatus

InactiveUS20050048430A1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

A burner apparatus comprising housing defining a chamber and having an air inlet, a peripherally extending baffle disposed in the housing, a first peripherally extending flow passage being formed between the housing and the baffle, the first flow passage being in open communication with the air inlet, a peripherally extending combustion liner disposed inwardly of the baffle, a second peripherally extending flow passage being formed between the liner and the baffle, the second flow passage being in open communication with the first passage, a reversing diverter disposed in the chamber and positioned to direct air flowing from the first flow passage into the second flow passage, a burner assembly mounting plate disposed in the liner and having a first side and a second side, the mounting plate and the liner at least partially defining a burner barrel on the first side of the mounting plate, at least one burner assembly mounted on the burner mounting plate and a plenum on the second side of the mounting plate that is in open communication with the second flow passage.

Owner:L & S CRYOGENICS

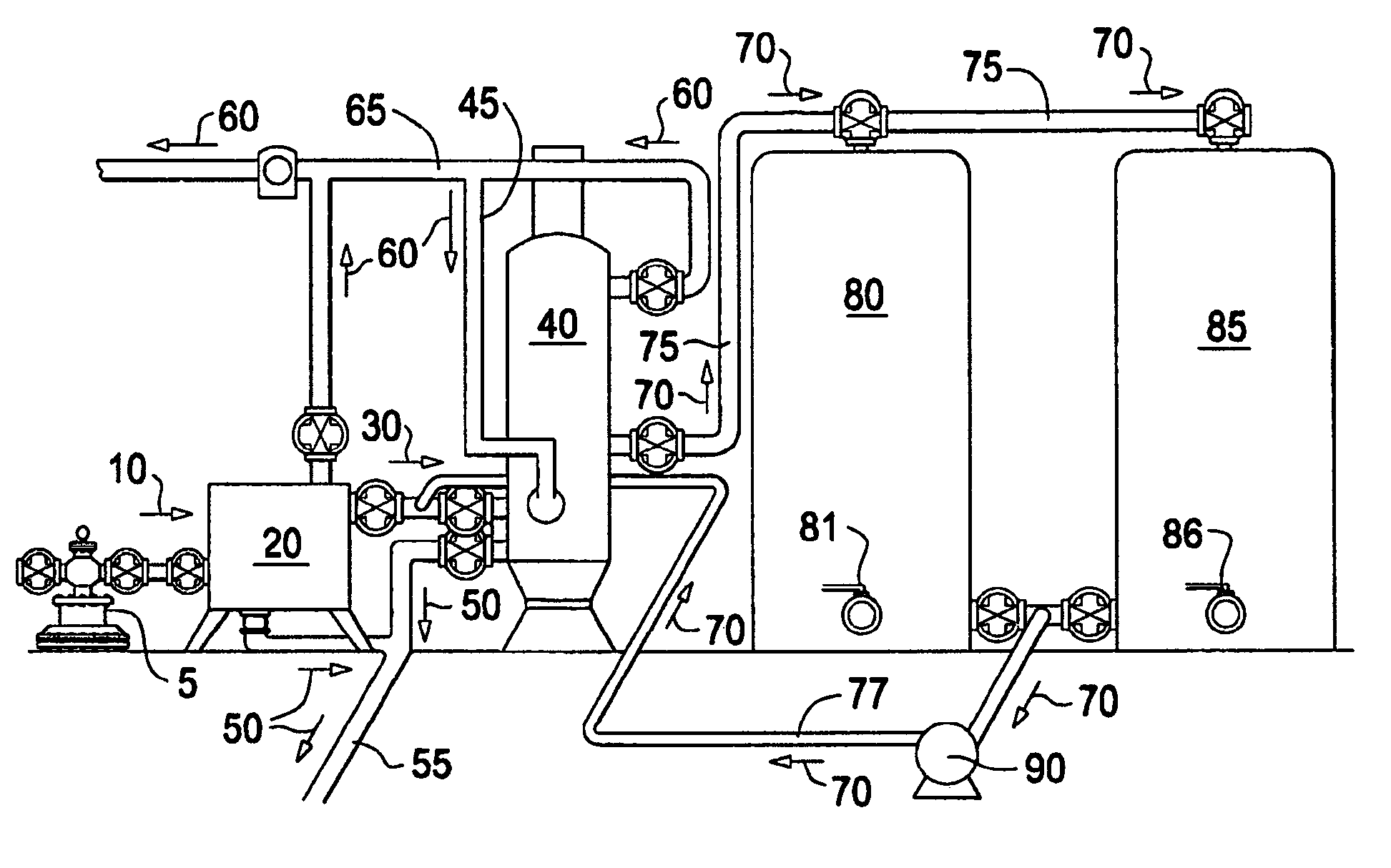

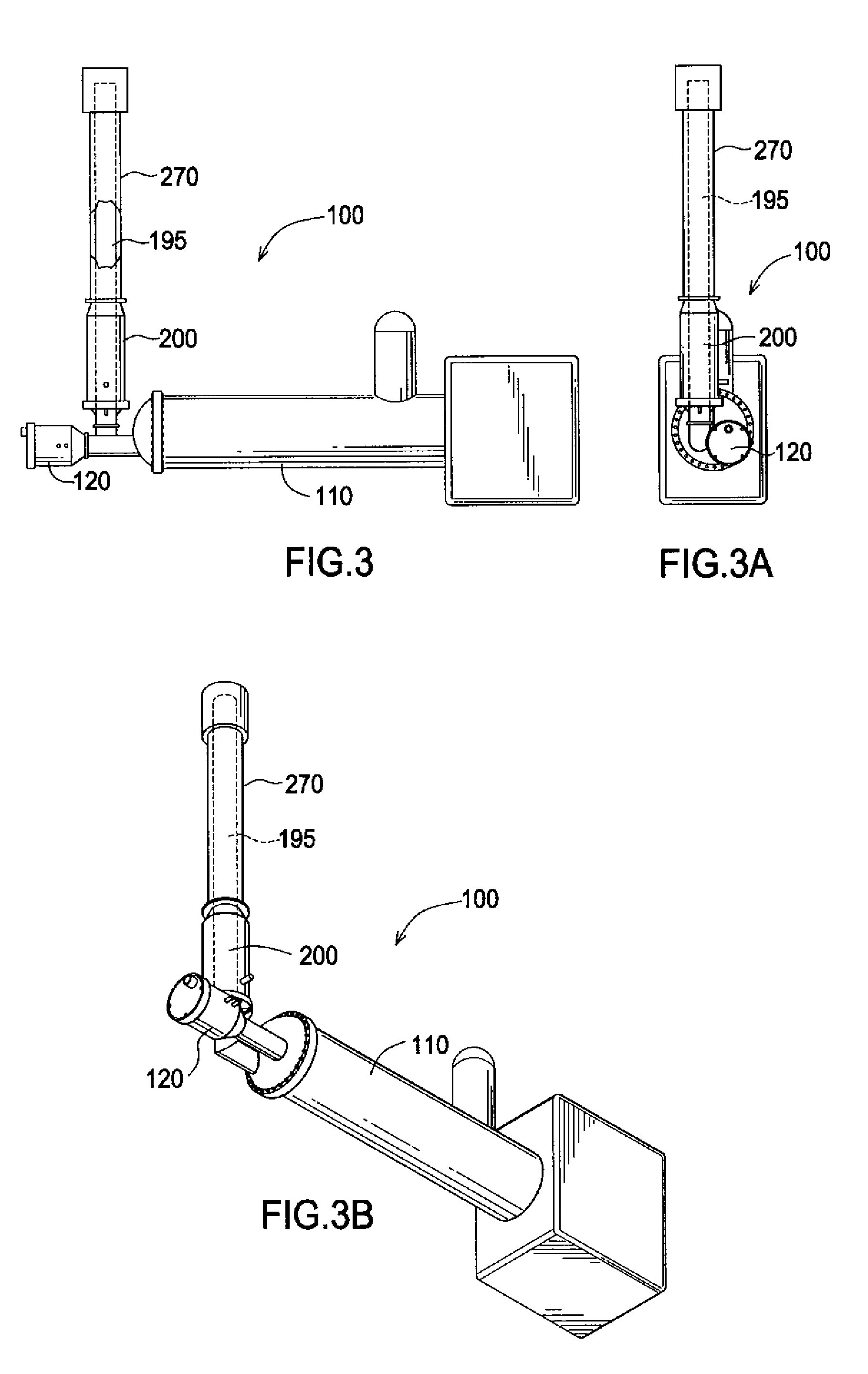

Method and apparatus to reduce a venting of raw natural gas emissions

InactiveUS7520743B1Facilitate phase separationEfficient separationFluid removalWater/sewage treatment by heatingCombustorExhaust fumes

With the disclosed device, some or all of the available oil tank vent gas in a production system can be utilized to augment the primary fuel gas needed by a heater treater unit to separate the gas, oil, and water fractions from raw natural gas extracted at the wellhead. Augmenting the primary fuel gas with vent gas reduces the demand for primary fuel gas, which thereby increases the amount of gas traversing a meter. The disclosed device also provides for an auxiliary burner unit that can directly address any available oil tank vent gas that is not utilized to augment fuel gas as waste gas. A method and apparatus for reducing the venting of raw natural gas emissions from an oil storage tank is described.

Owner:CHEM APPL & ENG

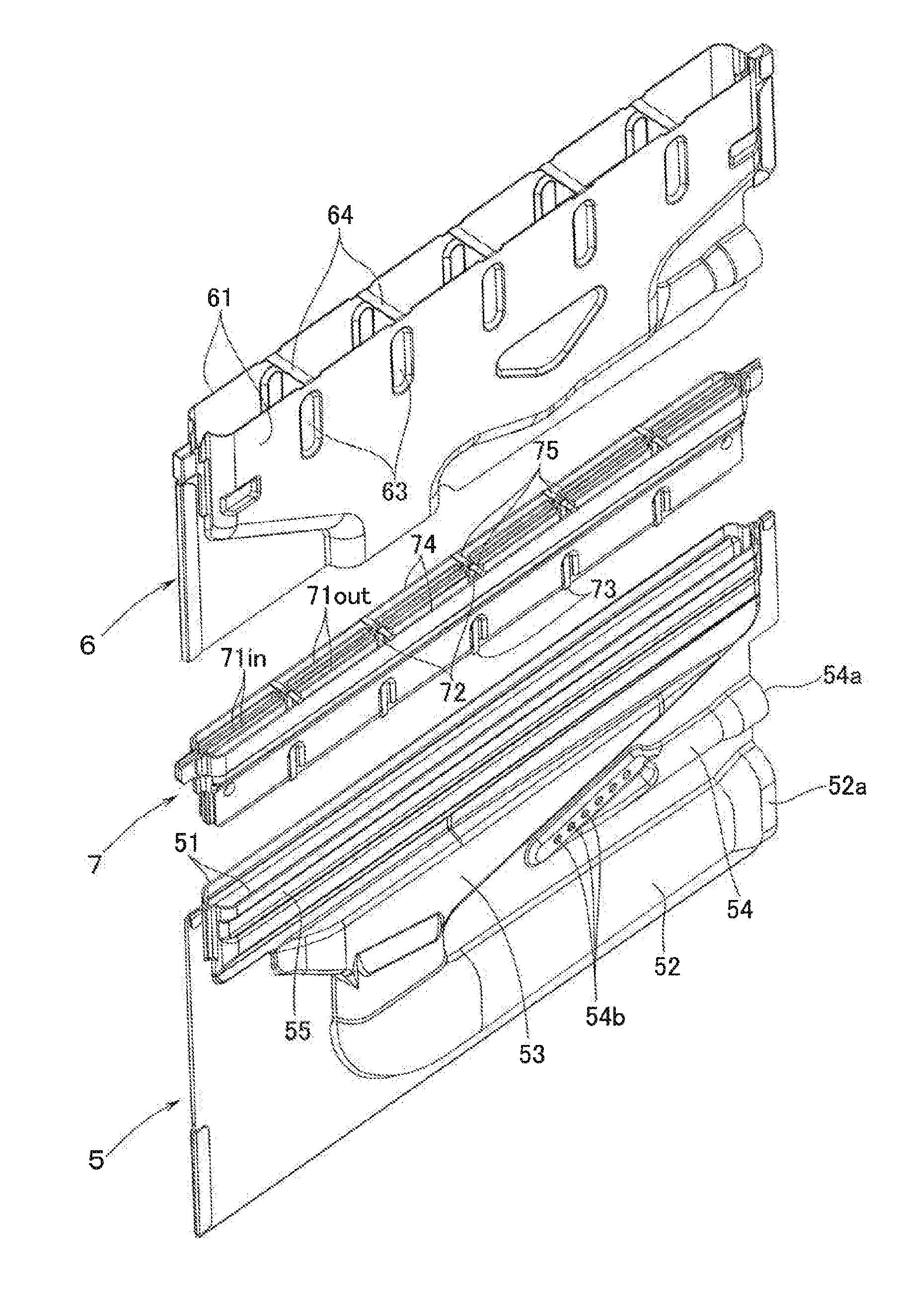

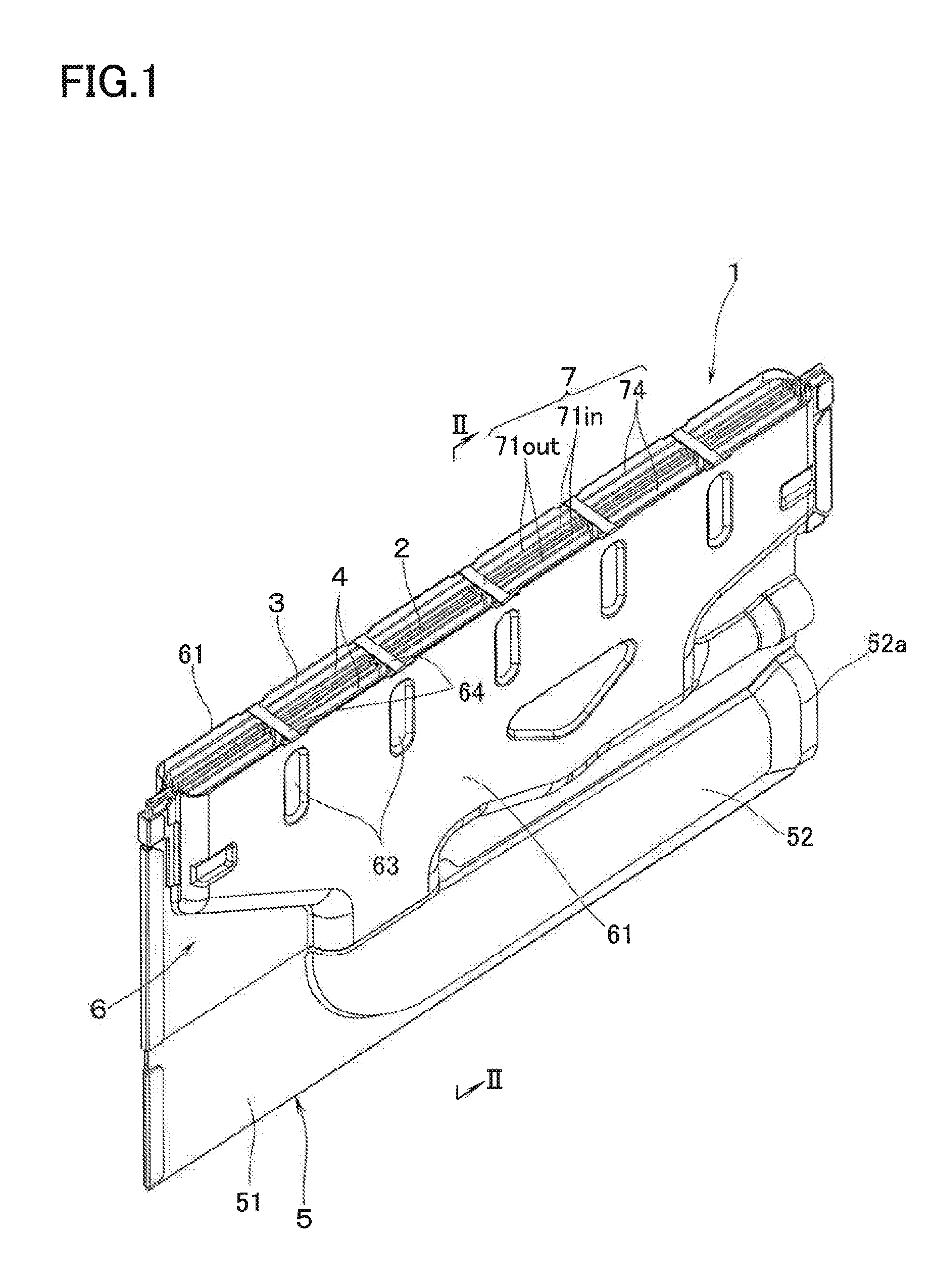

Rich-Lean Burner

InactiveUS20150184849A1Prevented deterioration in combustibilityReduce thermal effectsPilot flame ignitersGaseous fuel burnerCombustorMechanical engineering

A rich-lean burner with a lean flame port, a blind clearance, and a rich flame port has: a burner main body with a pair of burner-main-body side plates on both lateral sides thereof; a burner cap with a burner-cap side plate covering the burner main body from at least one lateral outside thereof; and a straightening member with straightening plates to divide the lean flame port into laterally disposed zones. Upper ends of the burner-main-body side plates are below upper ends of the burner-cap side plate and of the straightening plates. The straightening member has a partition plate which is located laterally outside an outer straightening plate contiguous to the blind clearance and which extends upward beyond the burner-main-body side plates. The blind clearance is defined between the partition plate and the outer straightening plate, and the rich flame port is defined between the partition plate and the burner-cap side plate.

Owner:RINNAI CORP

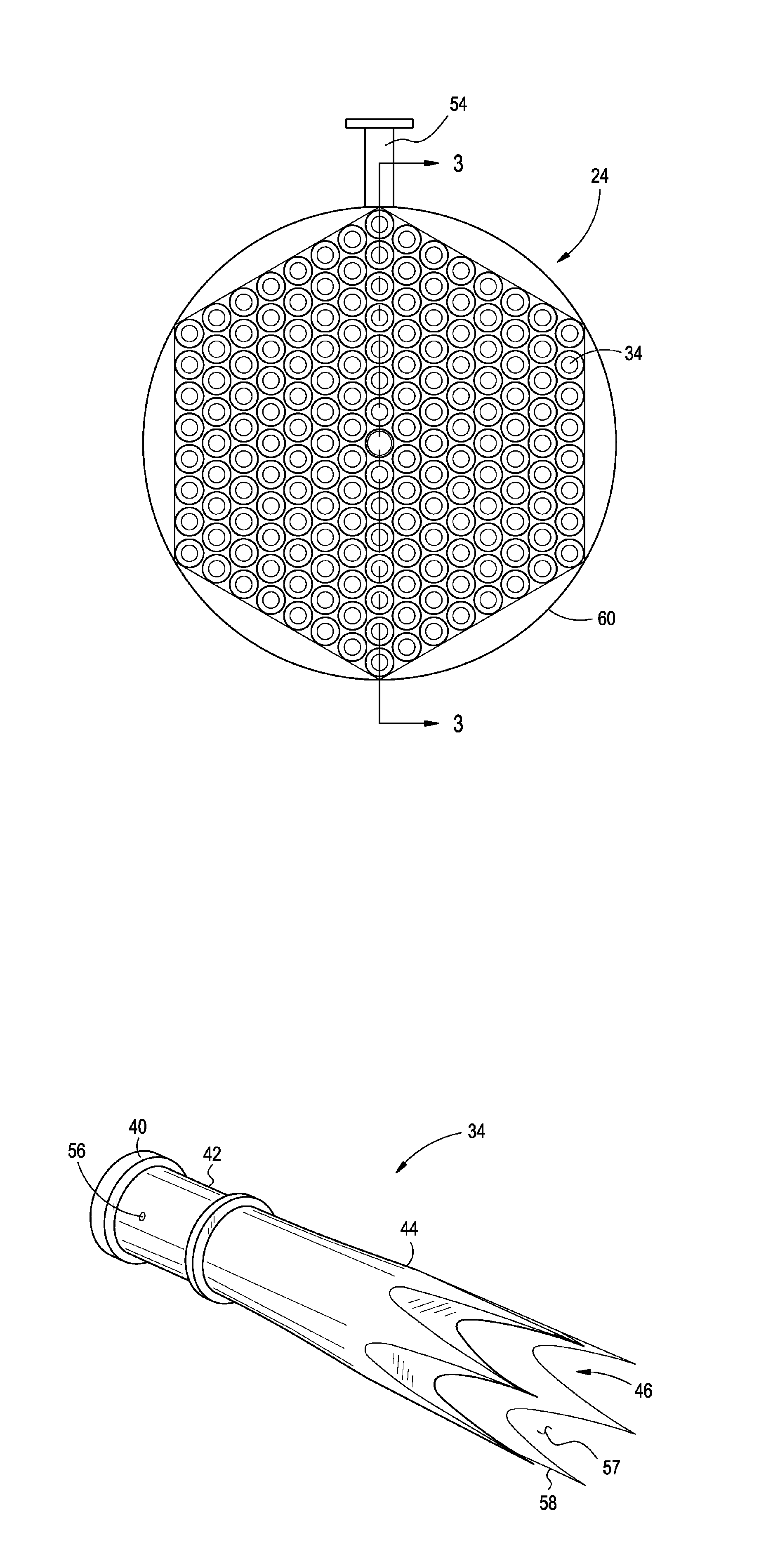

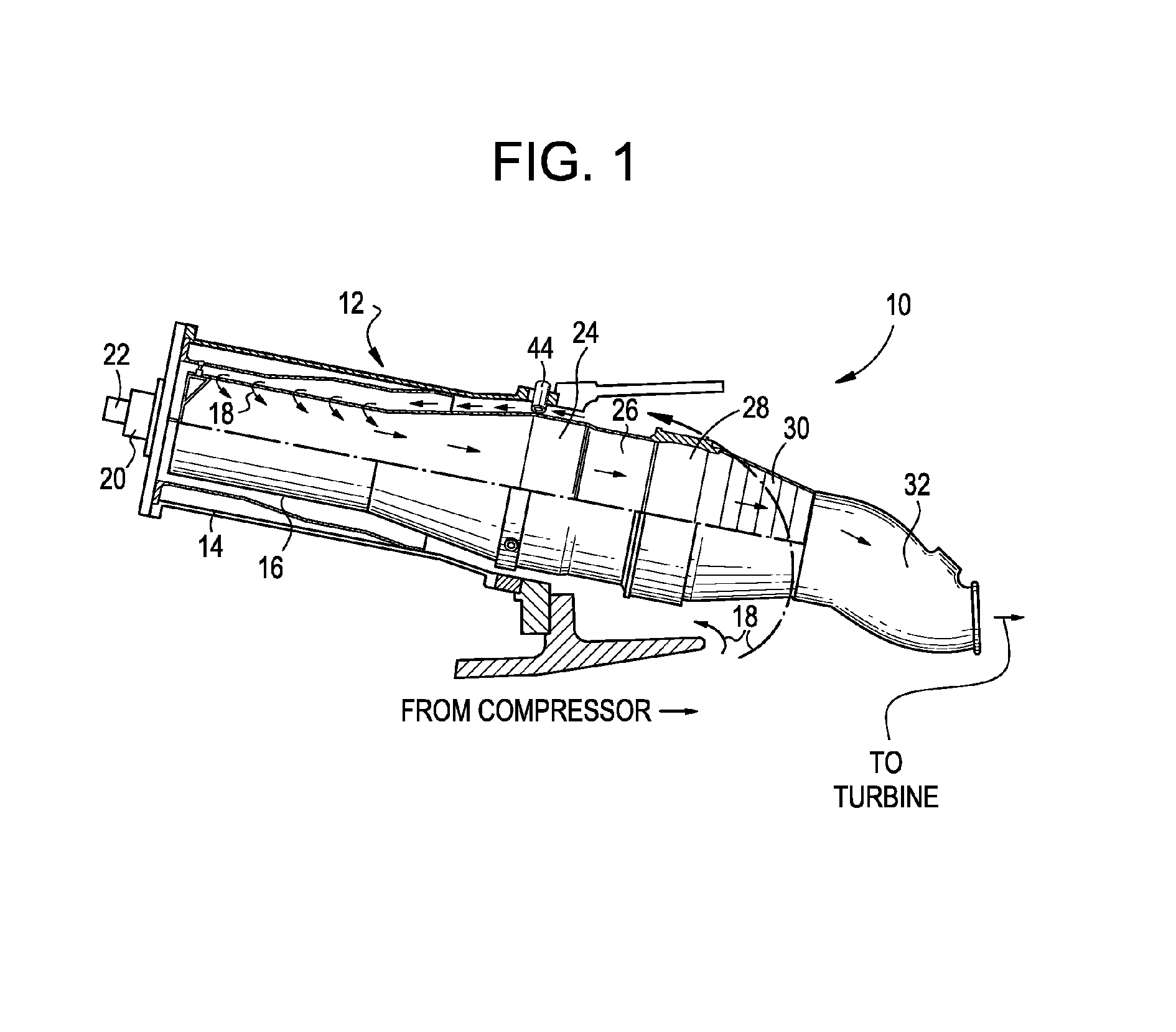

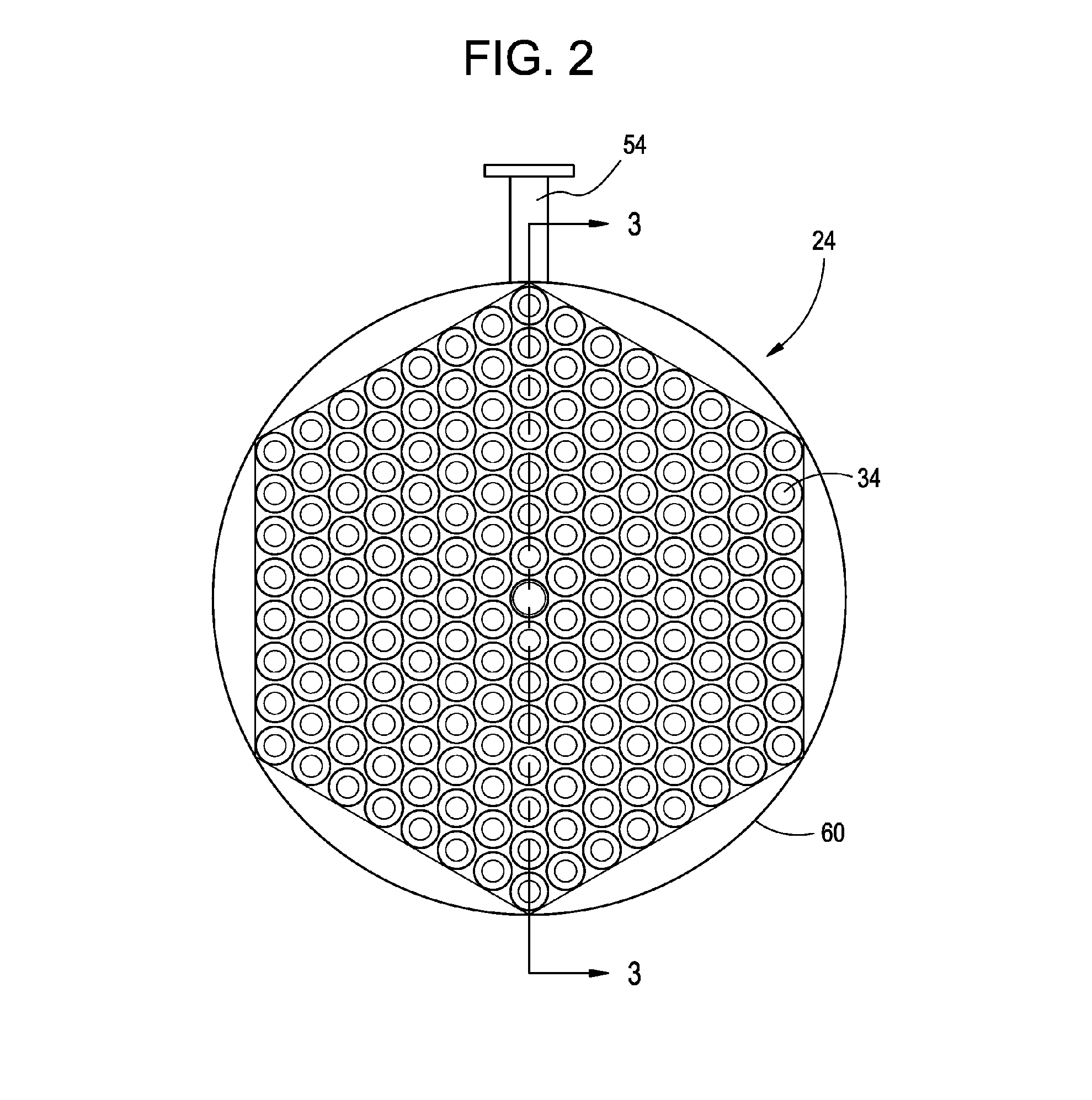

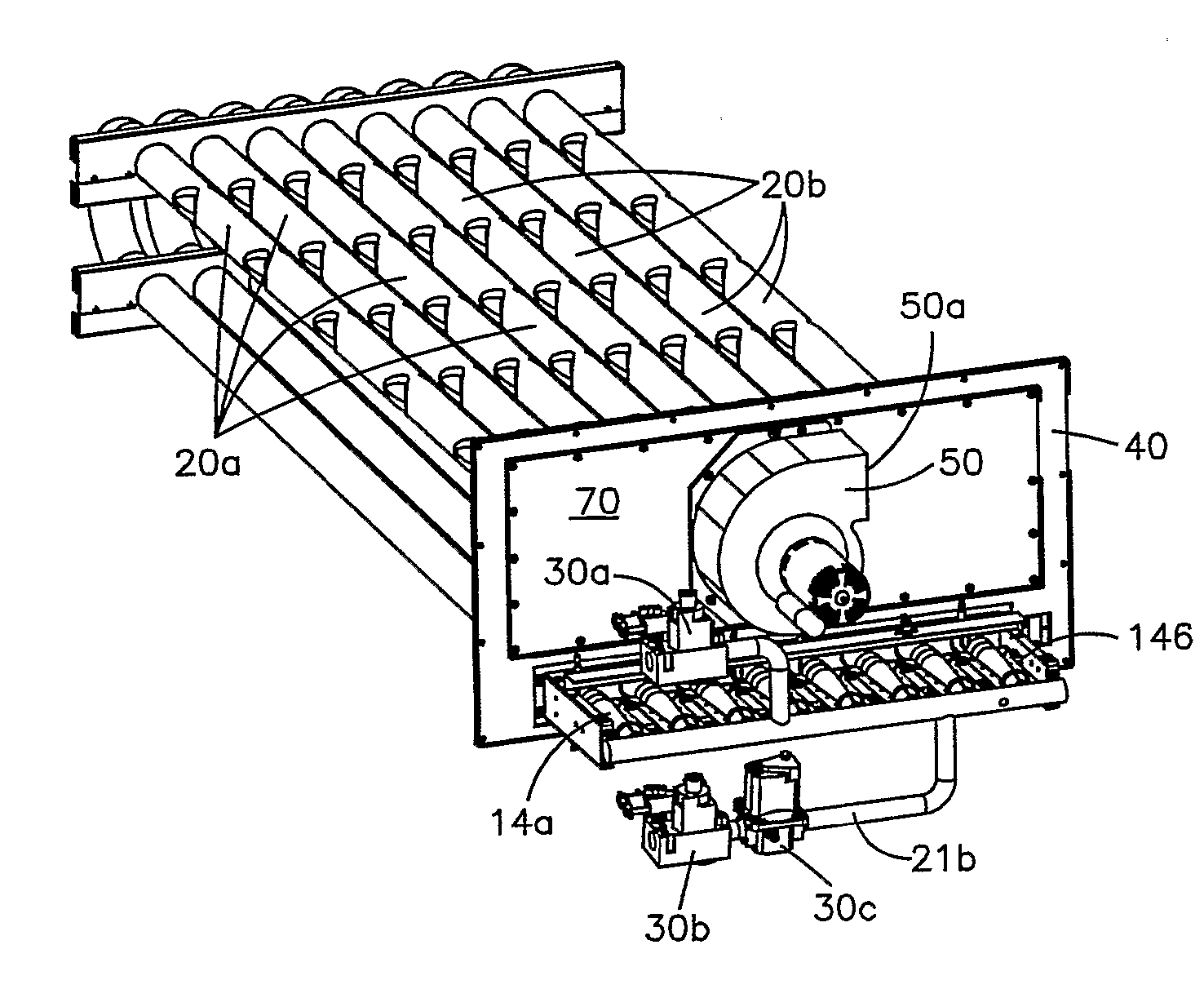

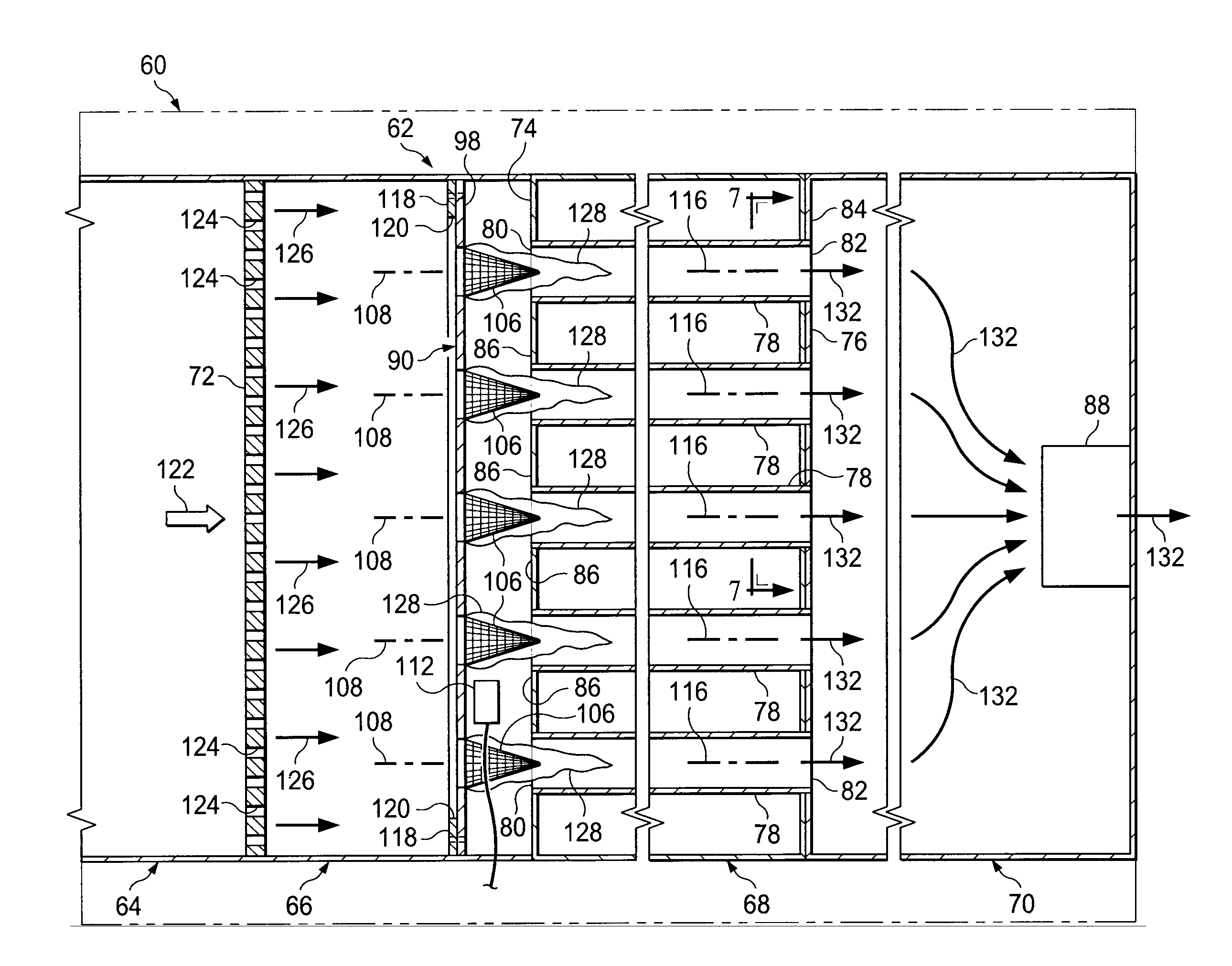

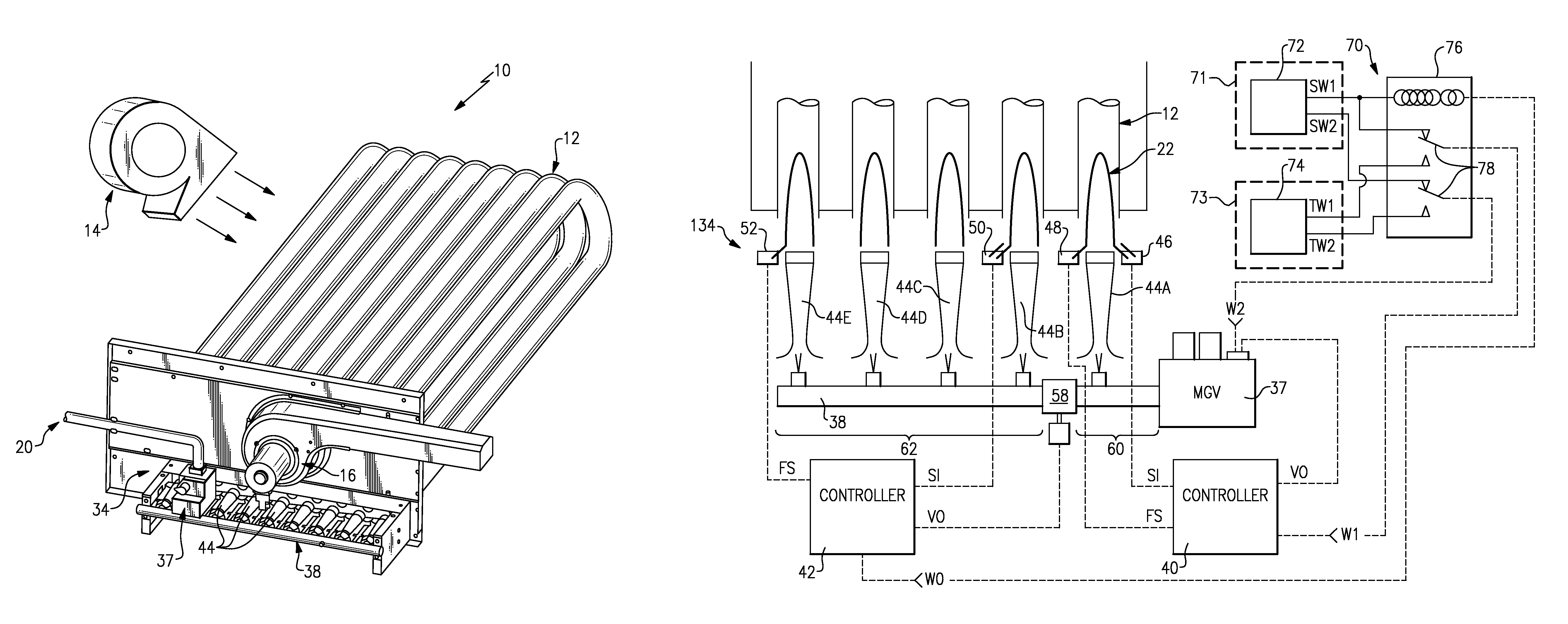

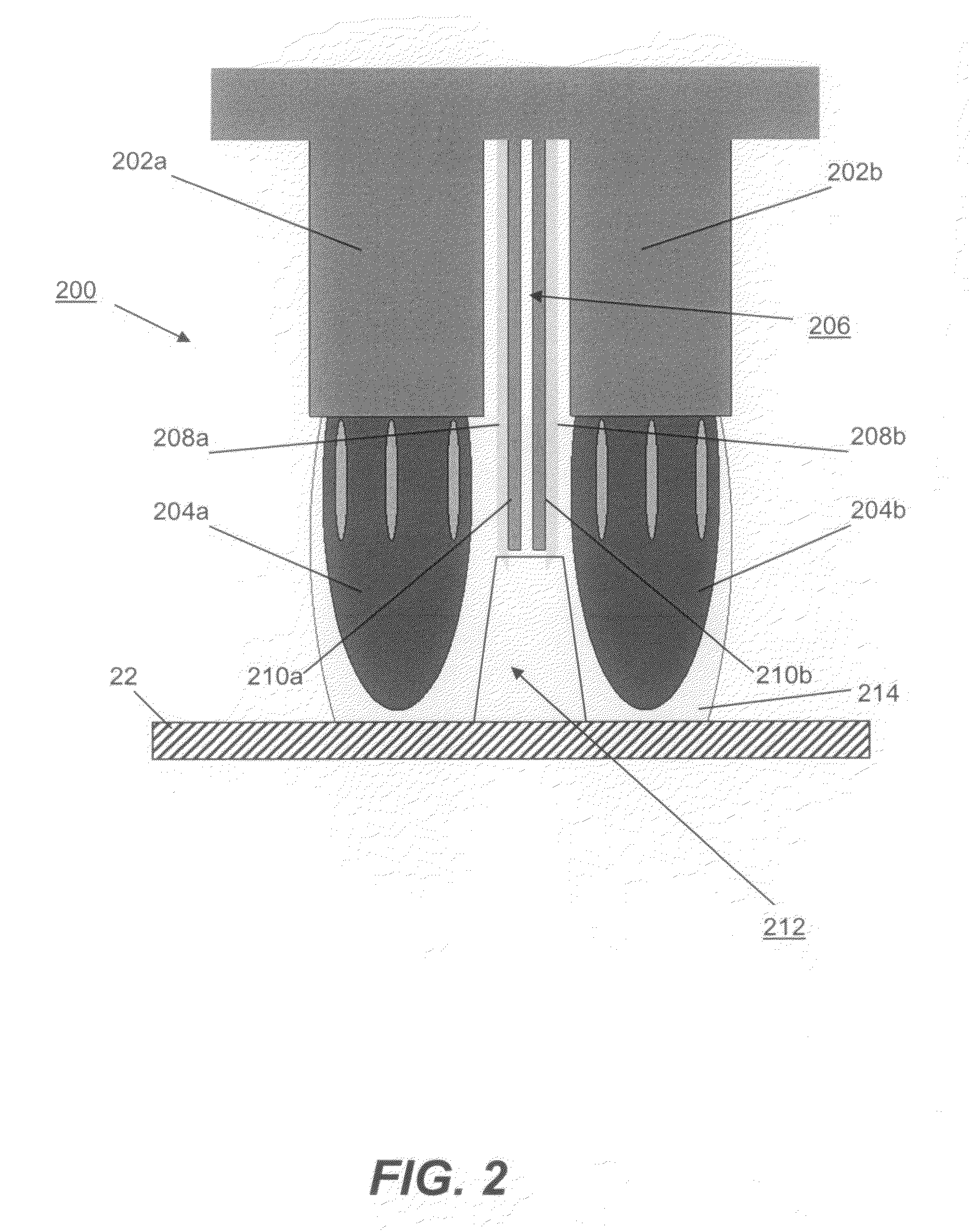

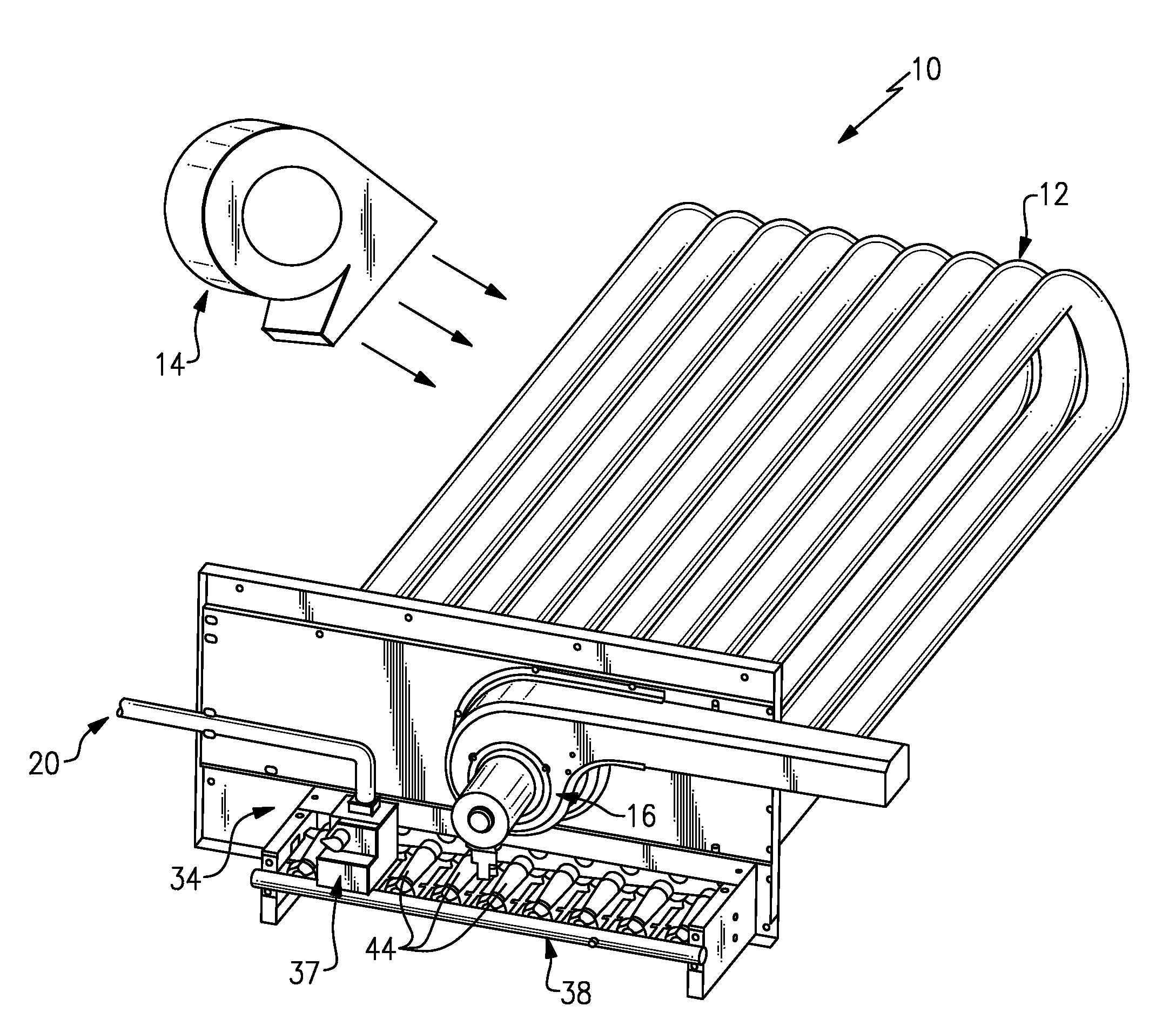

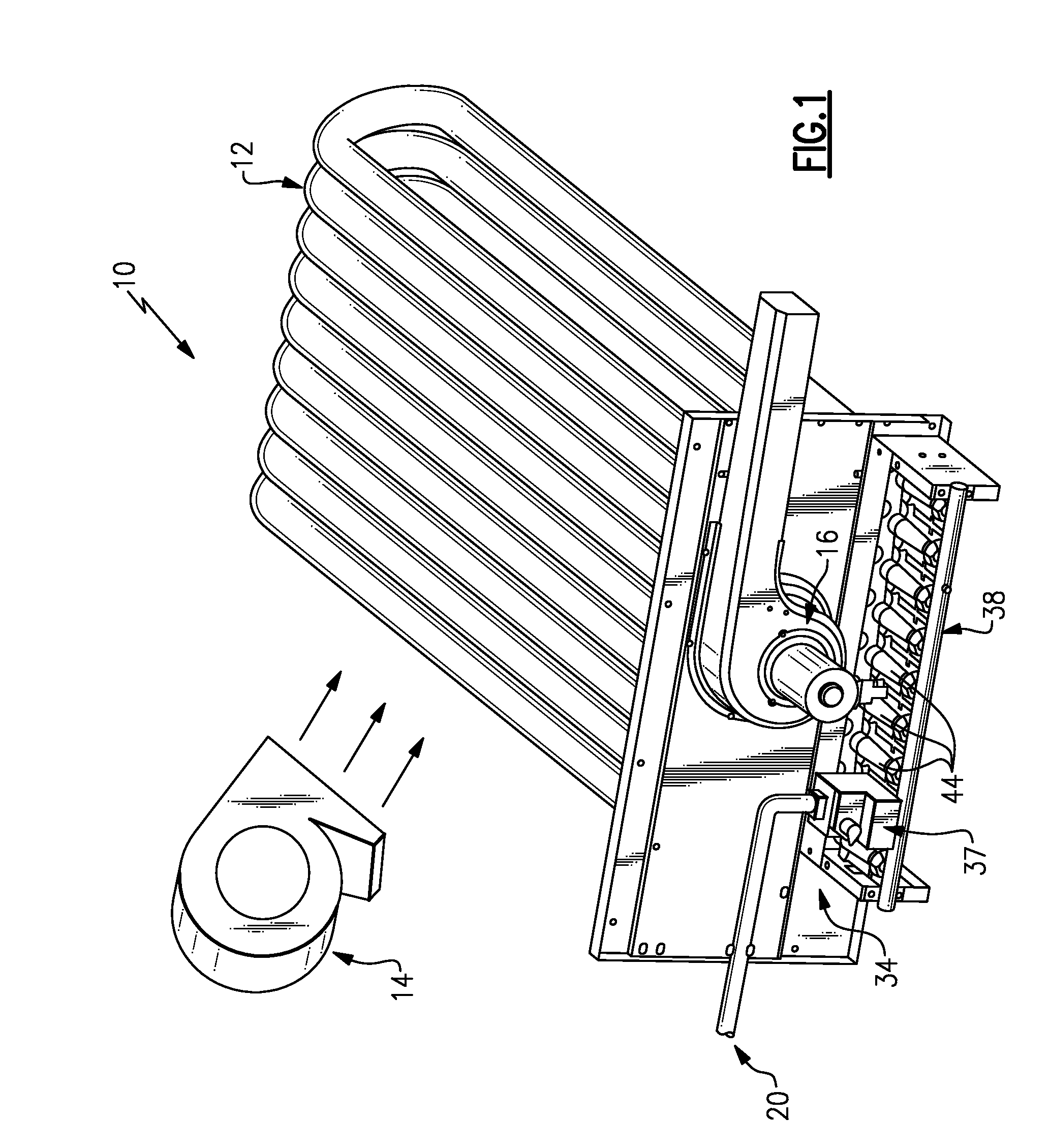

Multi-Cone Fuel Burner Apparatus For Multi-Tube Heat Exchanger

InactiveUS20150192291A1Hot-air central heatingAir-treatment apparatus arrangementsMixed flowCombustor

Installed in a fuel-fired heating appliance is a specially designed burner assembly operative to receive and combust a pre-mixed flow of fuel and air to create therefrom a spaced apart plurality of flames which are aligned with and flow directly into the inlets of a corresponding spaced plurality of heat exchanger tubes. The flames create within the tubes hot combustion gases that transfer combustion heat to a supply fluid flowed externally across the tubes. The burners are of a hollow perforate metal construction, are mounted on and forwardly project from a support structure toward the tube inlets, and have rearwardly facing open inlet ends that receive the pre-mixed flow of fuel and air. In one illustrated embodiment thereof, the burners have conical configurations, and in another illustrated embodiment have generally dome-shaped configurations. Via a flame carryover structure, a single igniter is utilized to ignite all of the burners.

Owner:RHEEM MFG CO

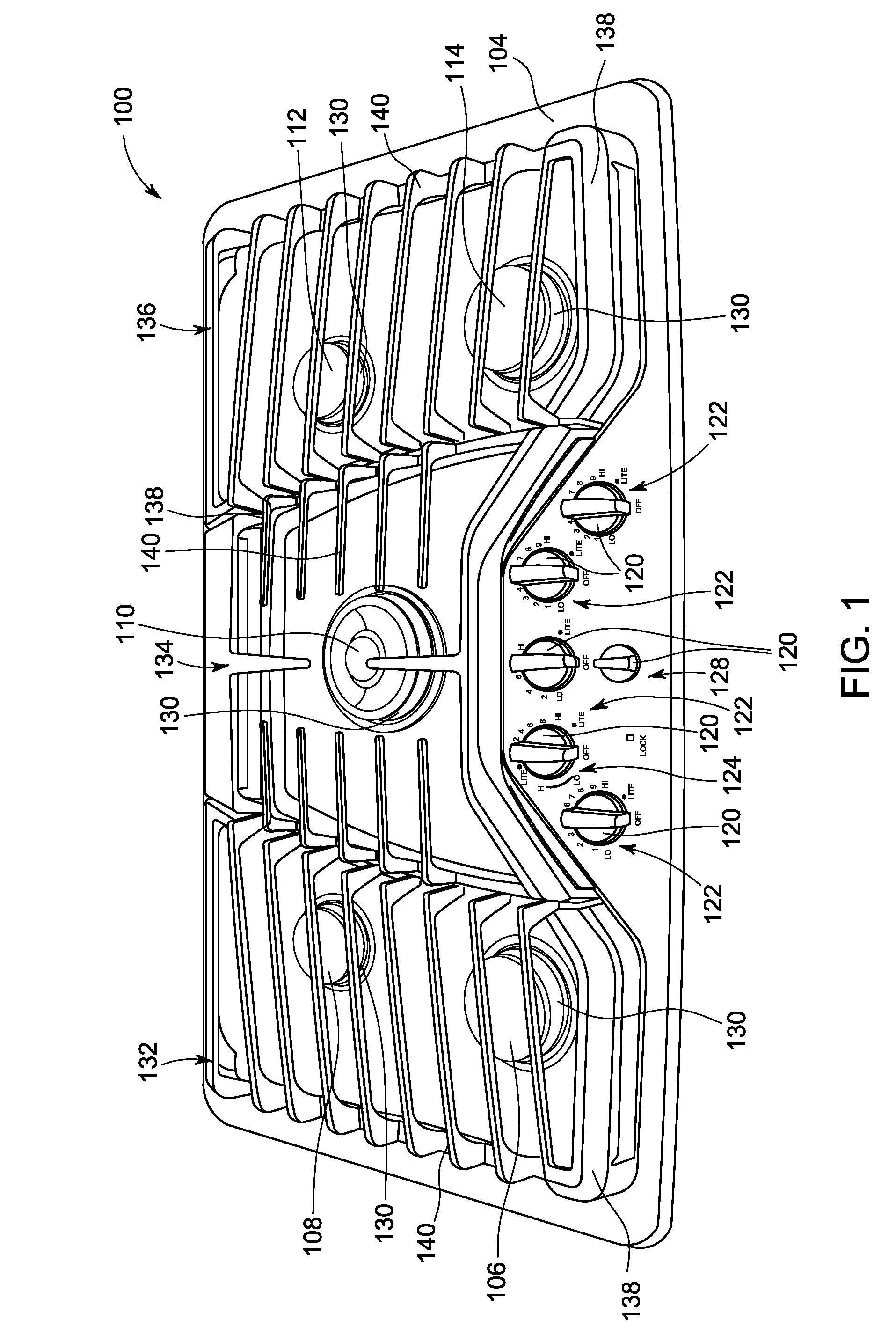

Burner assembly for cooktop appliance and method for operating same

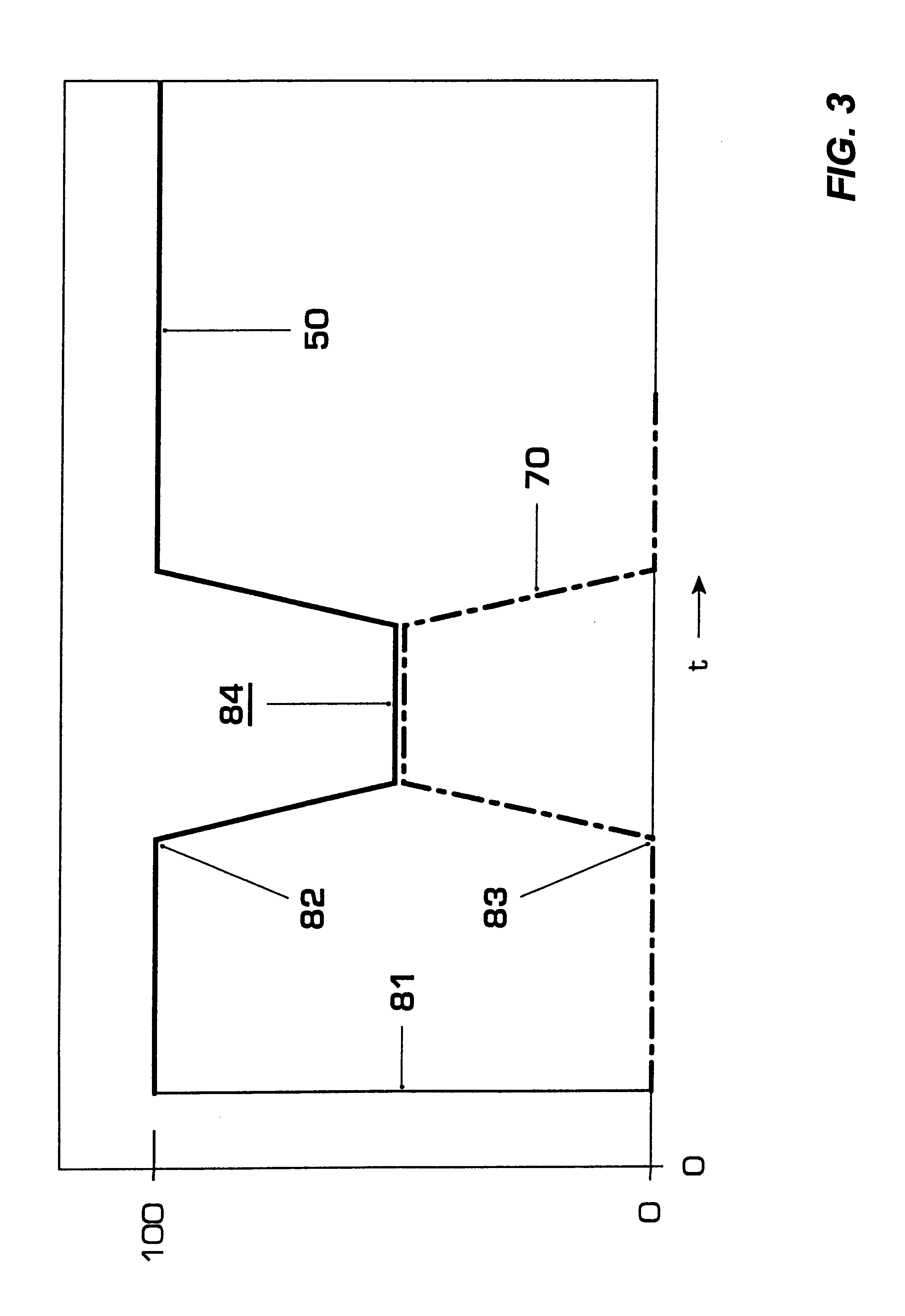

Burner assemblies and methods for operating burner assemblies are provided. A method includes outputting a maximum gaseous fuel supply to a first burner and no gaseous fuel supply to a second burner when a burner assembly knob is in a first position, outputting a minimum gaseous fuel supply to the first burner and no gaseous fuel supply to the second burner when the knob is in a second position, outputting a minimum gaseous fuel supply to the first burner and a maximum gaseous fuel supply to the second burner when the knob is in a third position, and outputting a minimum gaseous fuel supply to the first burner and a minimum gaseous fuel supply to the second burner when the knob is in a fourth position.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Multistage gas furnace having split manifold

A heating apparatus for a heat exchanger system includes a manifold having a plurality of burners, a shutoff valve, a first controller and a second controller. The shutoff valve divides the manifold into a first manifold portion and a second manifold portion. The first controller selectively controls the communication of a fluid within the manifold. The second controller selectively actuates the shutoff valve between a first position and a second position to control a firing rate of the plurality of burners.

Owner:CARRIER CORP

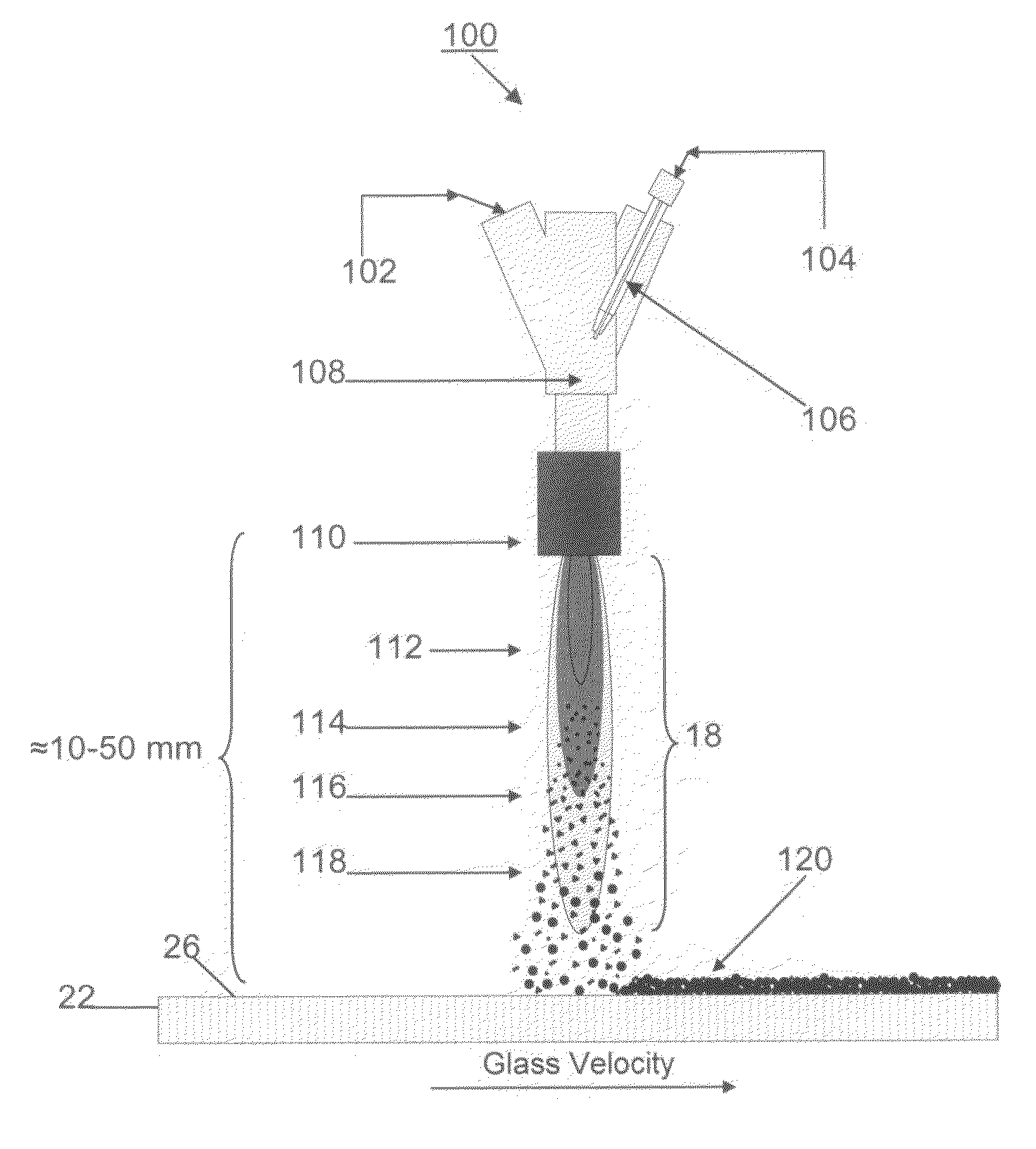

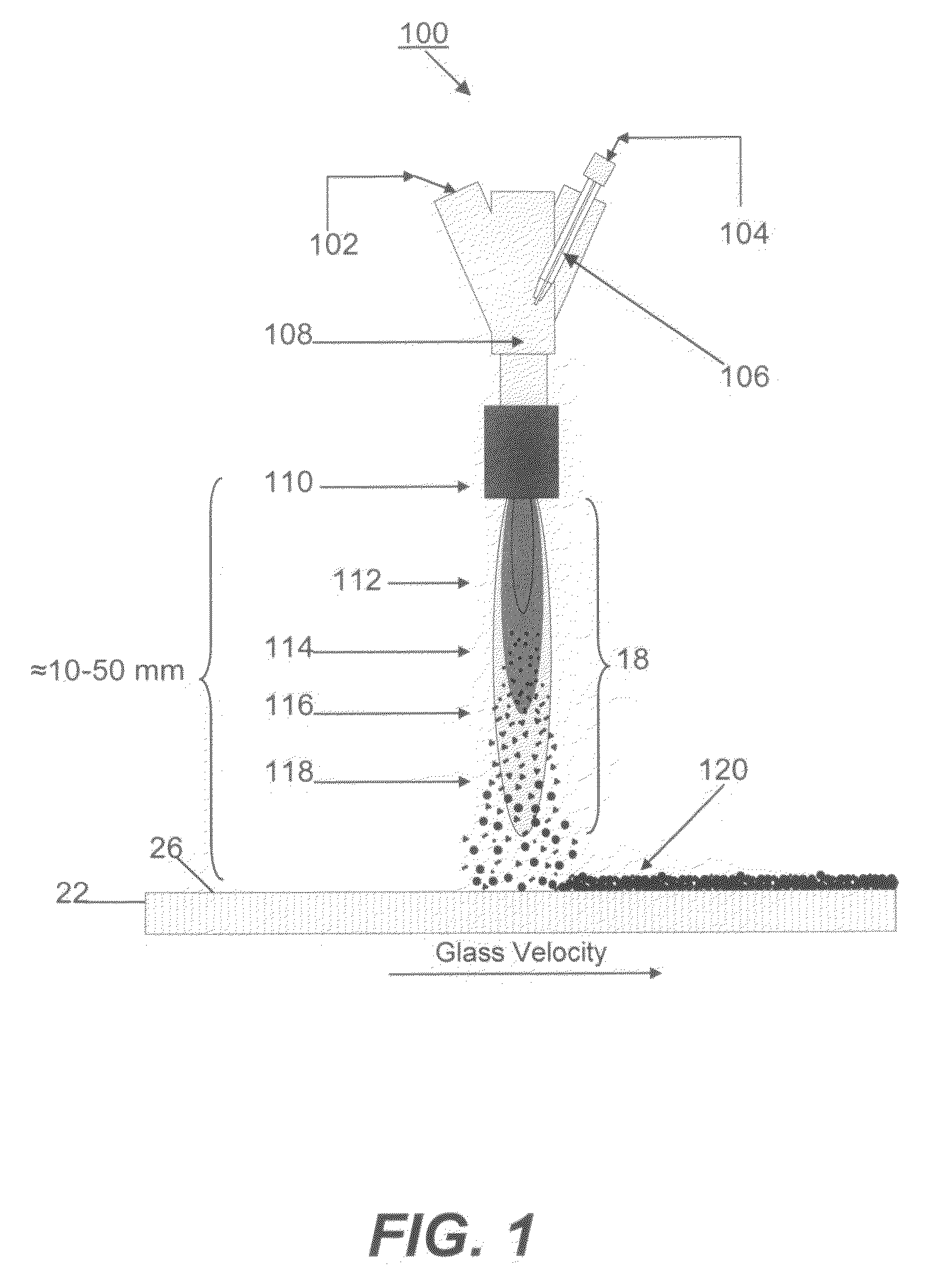

Combustion deposition burner and/or related methods

InactiveUS20090304941A1Reduce generationNarrow distributionLiquid surface applicatorsMolten spray coatingCombustorReaction zone

Certain example embodiments relate to a burner for use in combustion deposition depositing a coating on a substrate. First and second spaced-apart combustion gas manifolds are configured to respectively produce first and second flames (which may effectively combine to form a single flame front beyond the outer face of the burner in certain example embodiments). The first and second combustion gas manifolds form a precursor reaction zone therebetween. An adjustable precursor delivery manifold located between the first and second combustion gas manifolds is configured to receive a precursor used in forming the coating. The precursor delivery manifold is positioned so as to substantially directly provide the precursor to a desired or predetermined portion of the precursor reaction zone. The precursor delivery manifold includes first and second cooled walls arranged to reduce the occurrence of precursor pre-reactions upstream of the precursor reaction zone. The burners of certain example embodiments may be used to combustion deposition deposit metal oxide coatings onto glass substrates.

Owner:GUARDIAN GLASS LLC

Burner assembly for cooktop appliance and method for operating same

Burner assemblies and methods for operating burner assemblies are provided. A method includes outputting a maximum gaseous fuel supply to a first burner and no gaseous fuel supply to a second burner when a burner assembly knob is in a first position, outputting a minimum gaseous fuel supply to the first burner and no gaseous fuel supply to the second burner when the knob is in a second position, outputting a minimum gaseous fuel supply to the first burner and a maximum gaseous fuel supply to the second burner when the knob is in a third position, and outputting a minimum gaseous fuel supply to the first burner and a minimum gaseous fuel supply to the second burner when the knob is in a fourth position.

Owner:HAIER US APPLIANCE SOLUTIONS INC

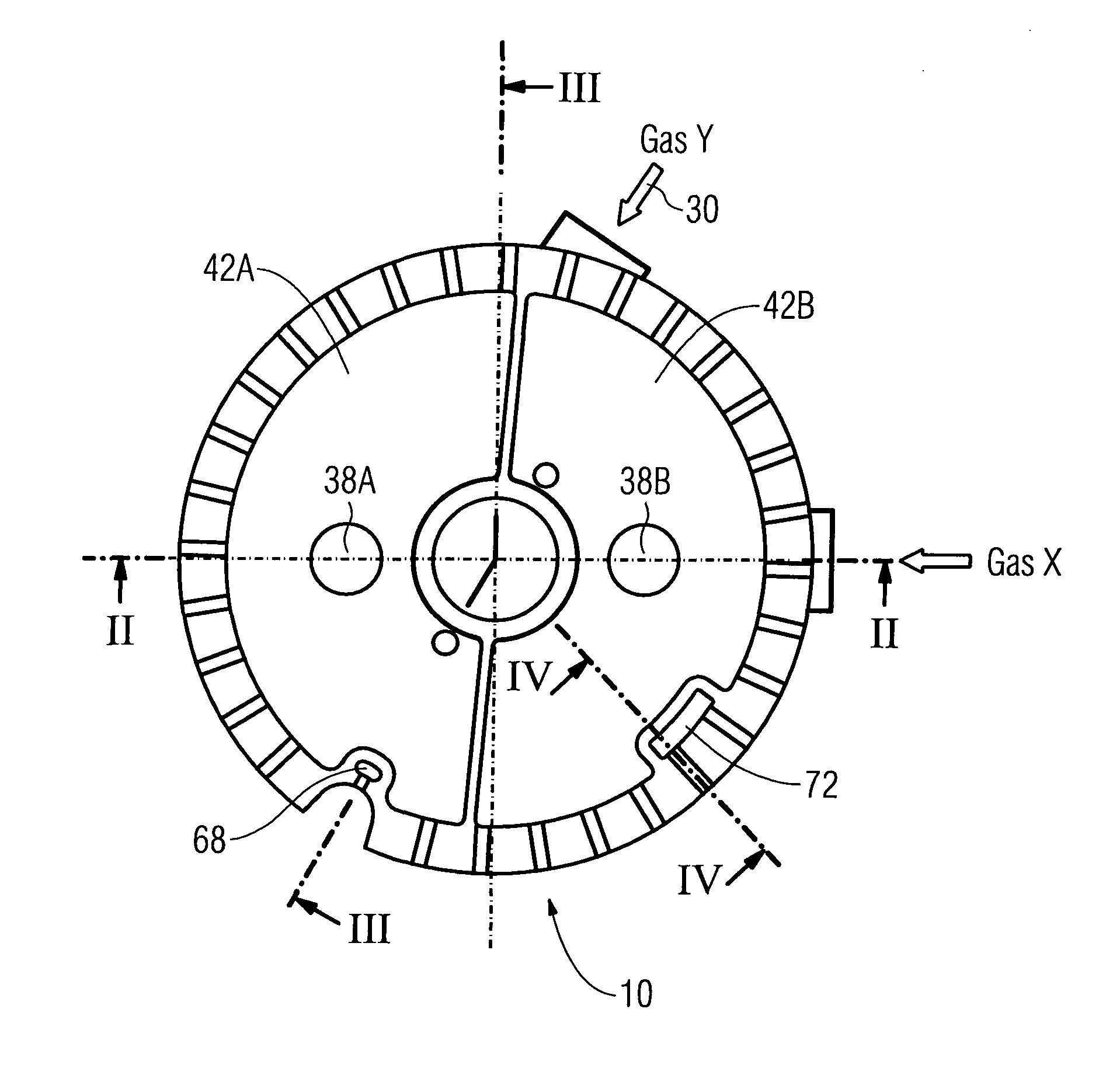

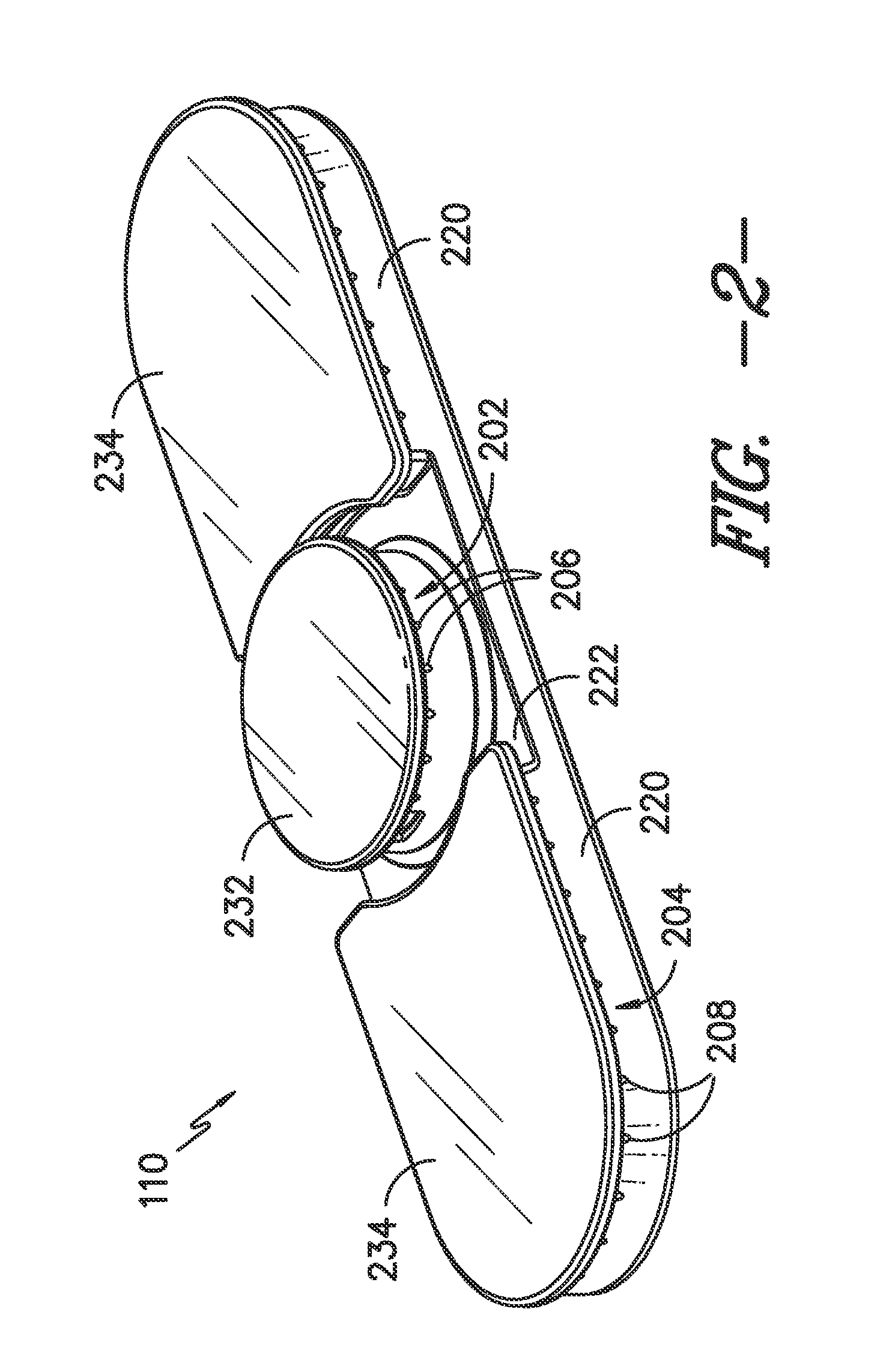

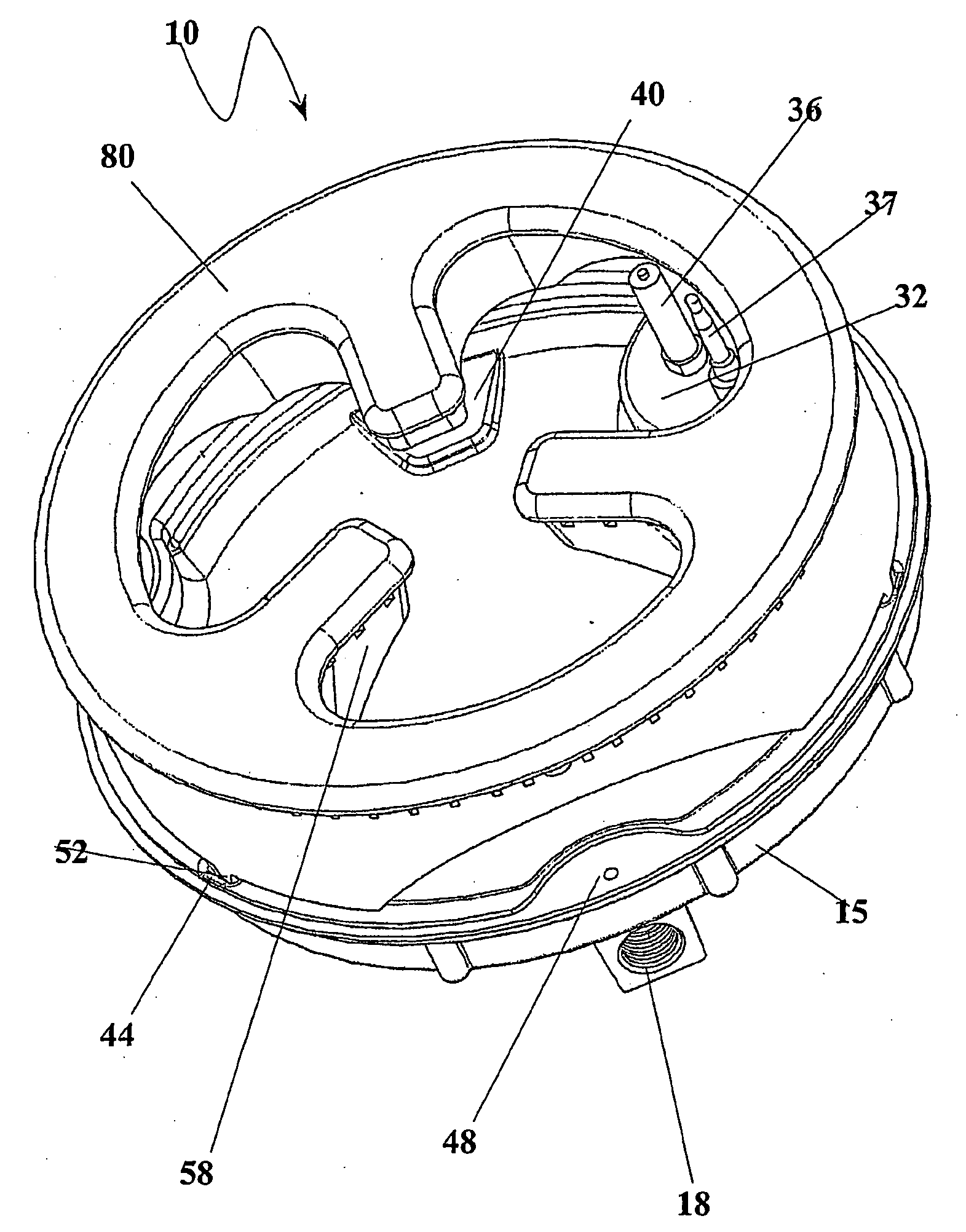

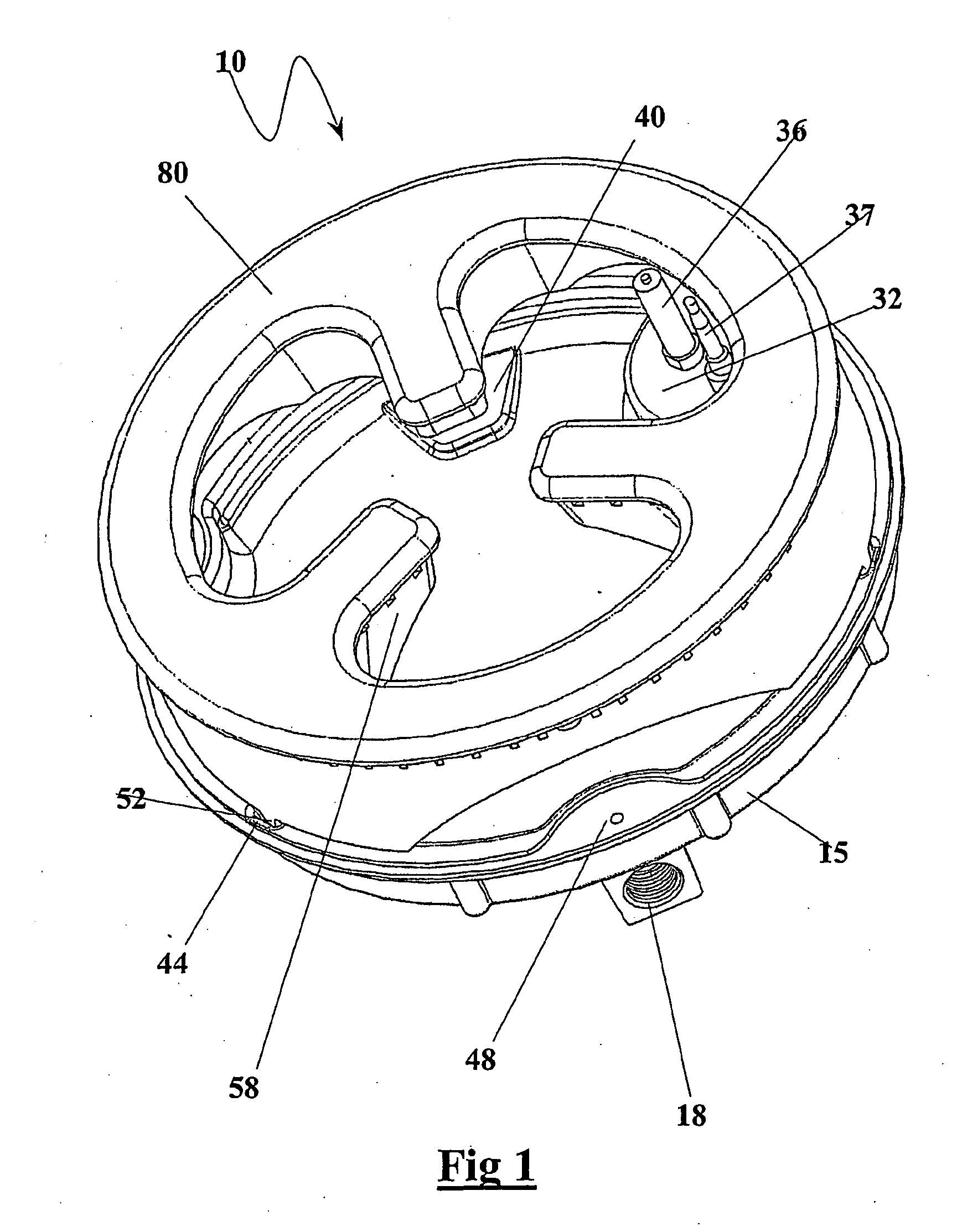

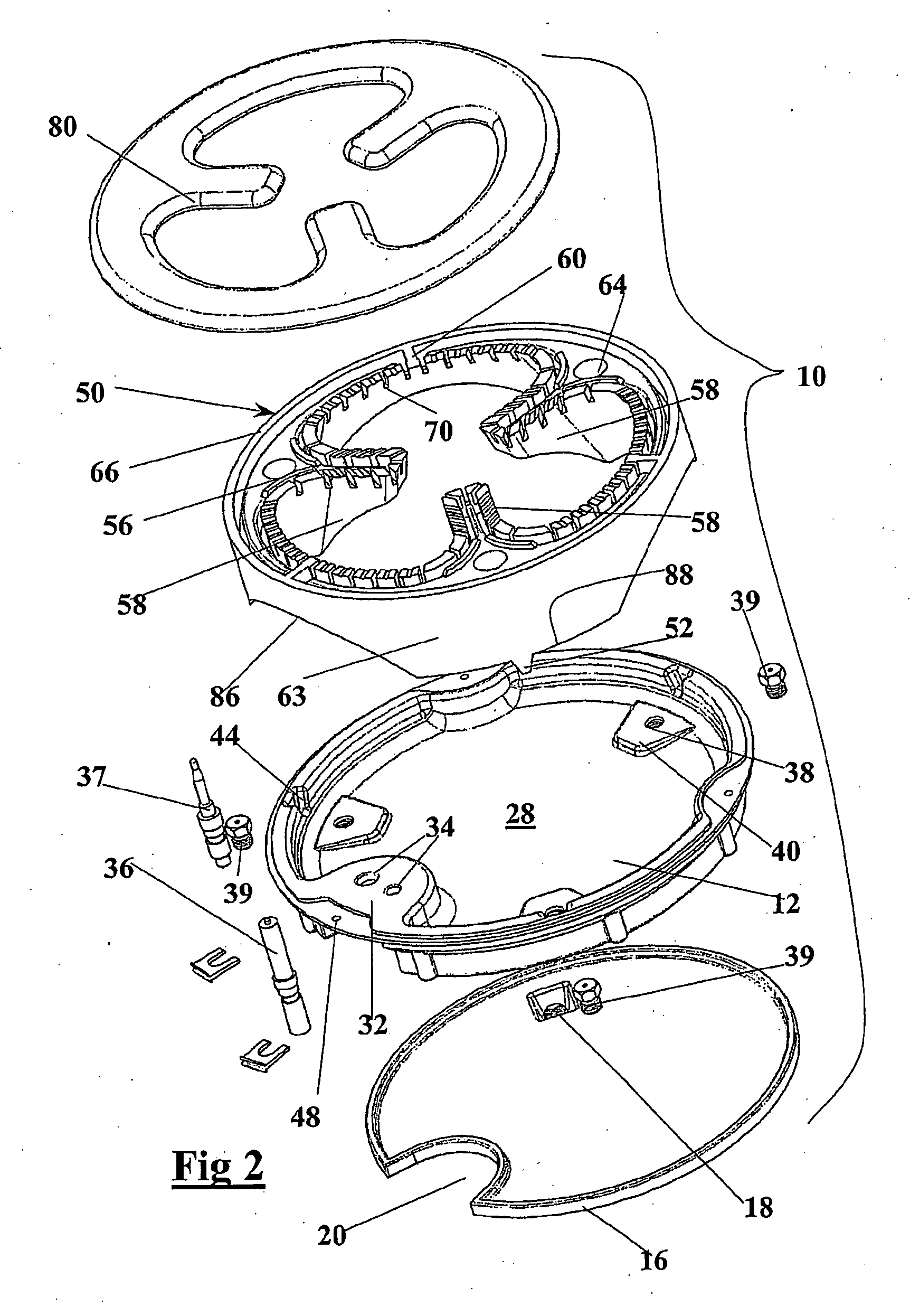

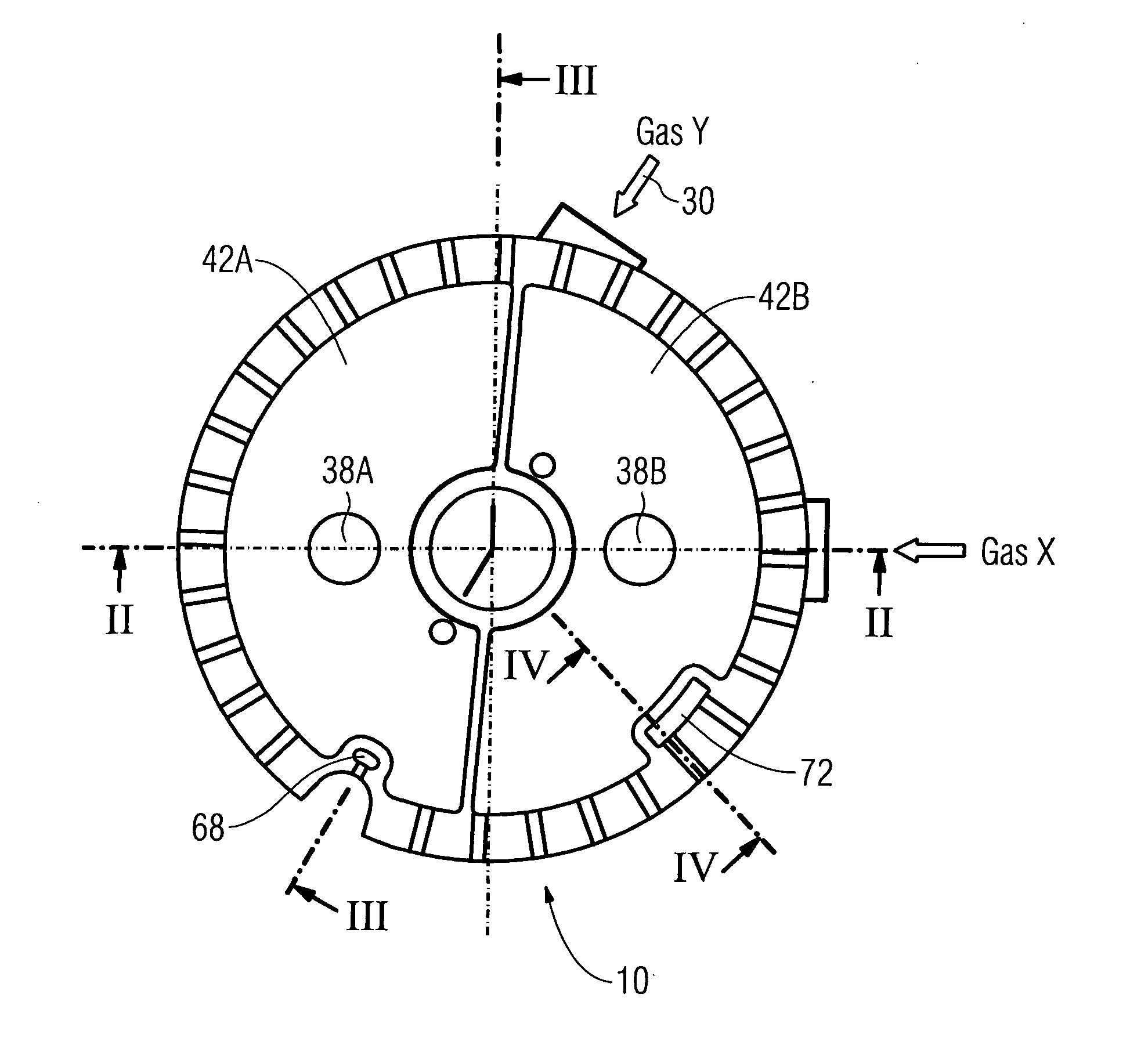

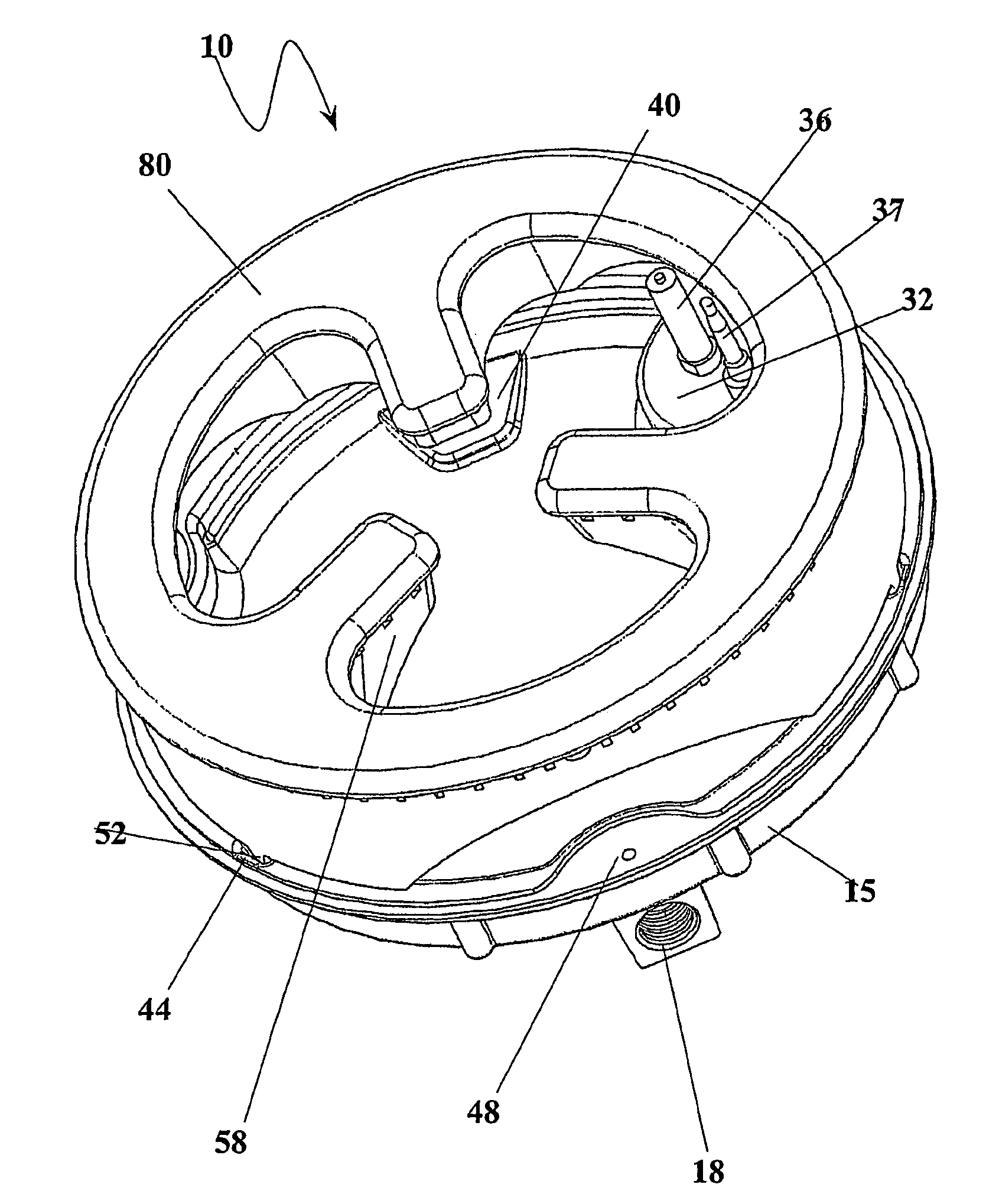

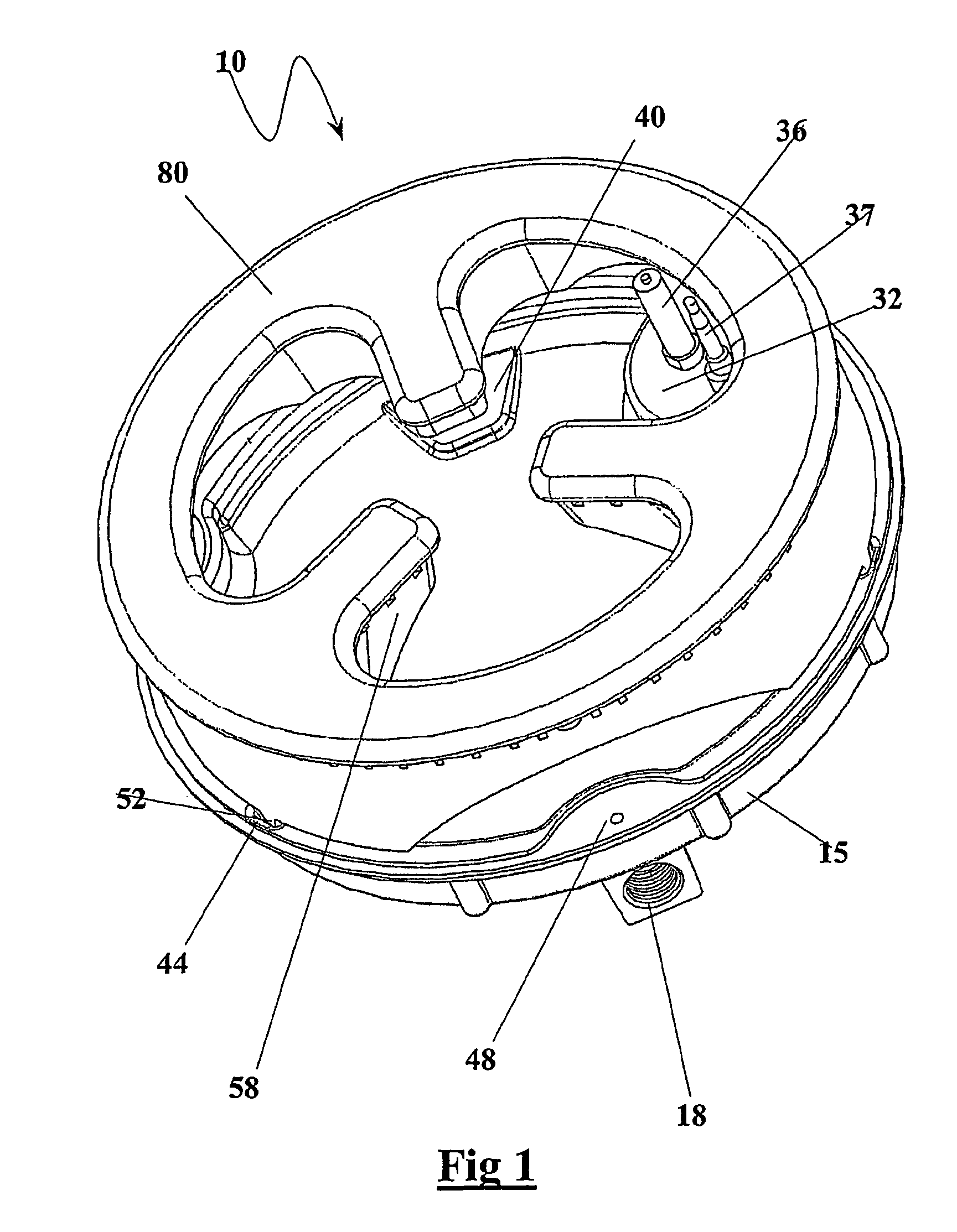

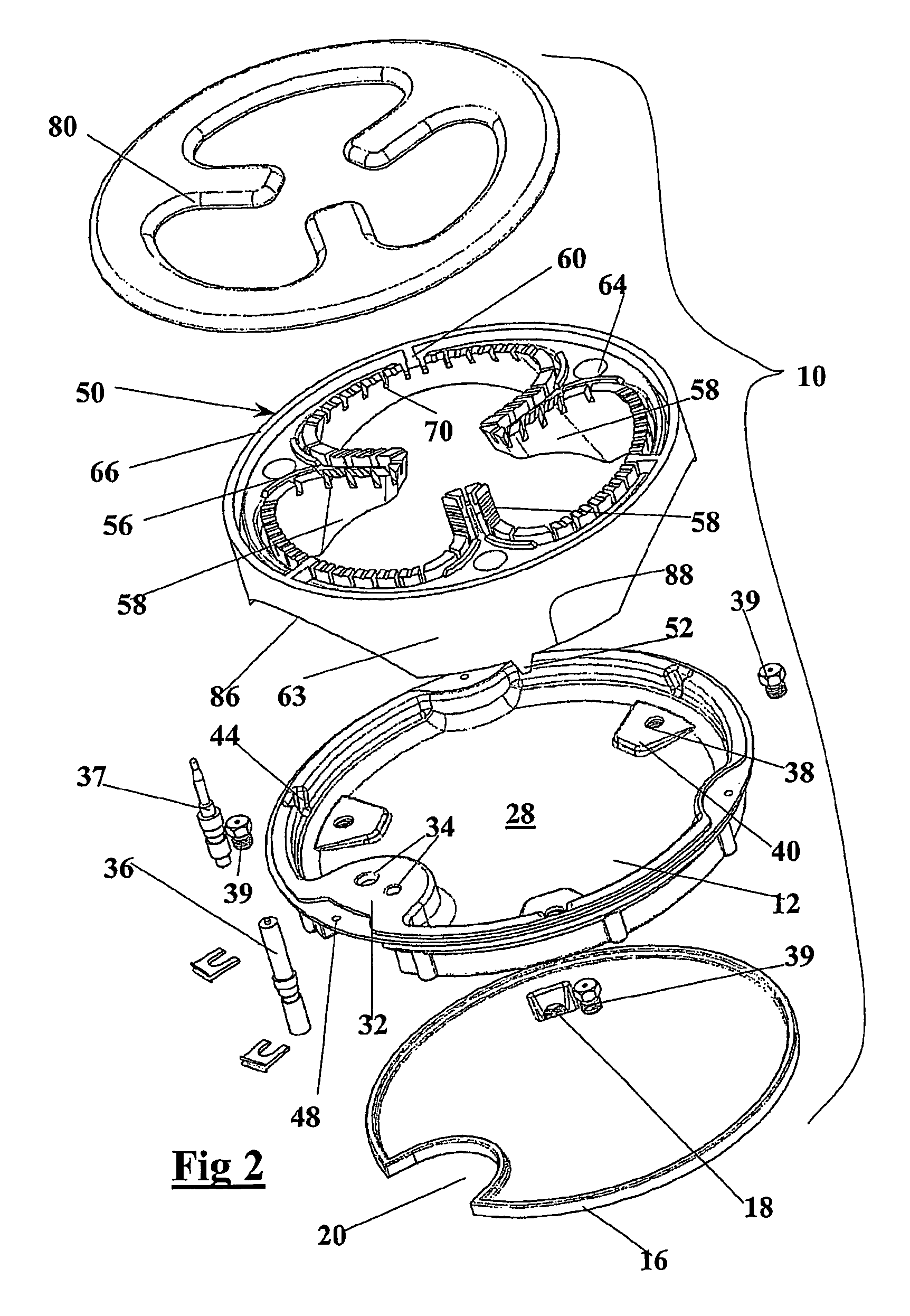

Gas Burner

InactiveUS20080241777A1Avoid interactionDomestic stoves or rangesSpray nozzlesEngineeringDistributor

The present invention provides a gas burner (10) including: a distributor means (50) having at least one distribution chamber to distribute an air gas mixture around said distributor (50), said burner (10) including a plurality of flame ports (70) through which said gas mixture can pass and be ignited; at least one injector (39) associated with said distributor (50), said at least one injector (39) being positioned to inject gas into said at least distribution chamber via a venture formed of a vertically directed passage and transition port (64) and at least one venturi extension extending away from said transition port (64). The present invention also provides manifold for a gas burner (10), said manifold having an upper wall (12) and a lower wall (16) held in spaced apart relationship by a peripheral wall to define a cavity there between, said manifold including means (38) to mount at least one injector (39) so as to deliver an air gas supply to a distribution means (50) and an inlet port (18) to allow connection to a supply of gas, which can pressurise said cavity, said upper (12) and said lower (16) wall being formed from relatively thin sections.

Owner:AB ELECTROLUX

Gas burner

ActiveUS20120152230A1Stable combustionDomestic stoves or rangesBurner control devicesEngineeringFuel gas

Owner:ELECTROLUX HOME PROD CORP NV

Gas water heater

PendingCN109708299ASimple structureCompact structureWater heatersGaseous fuel burnerPlate heat exchangerCombustion chamber

The invention discloses a gas water heater provided with a cold water inlet pipe and a hot water outlet pipe. The gas water heater comprises a shell, a catalysis combustor, a preheating combustor anda heat exchanger. A combustion chamber is formed in the shell. The catalysis combustor is arranged in the combustion chamber. The preheating combustor is arranged in the combustion chamber and is adjacent to the catalysis combustor. When the preheating combustor conducts combustion, the preheating combustor acts on the catalysis combustor, and the catalysis combustor is heated. One end of the heatexchanger communicates with the cold water inlet pipe, and the other end of the heat exchanger communicates with the hot water outlet pipe. The heat exchanger is used for absorbing heat generated dueto combustion of the preheating combustor and combustion of the catalysis combustor and conducting heat exchange on the absorbed heat and water in the heat exchanger. The gas water heater is simple and compact in structure, the energy utilization rate can be sufficiently improved, and harmful substance emission is reduced.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD +1

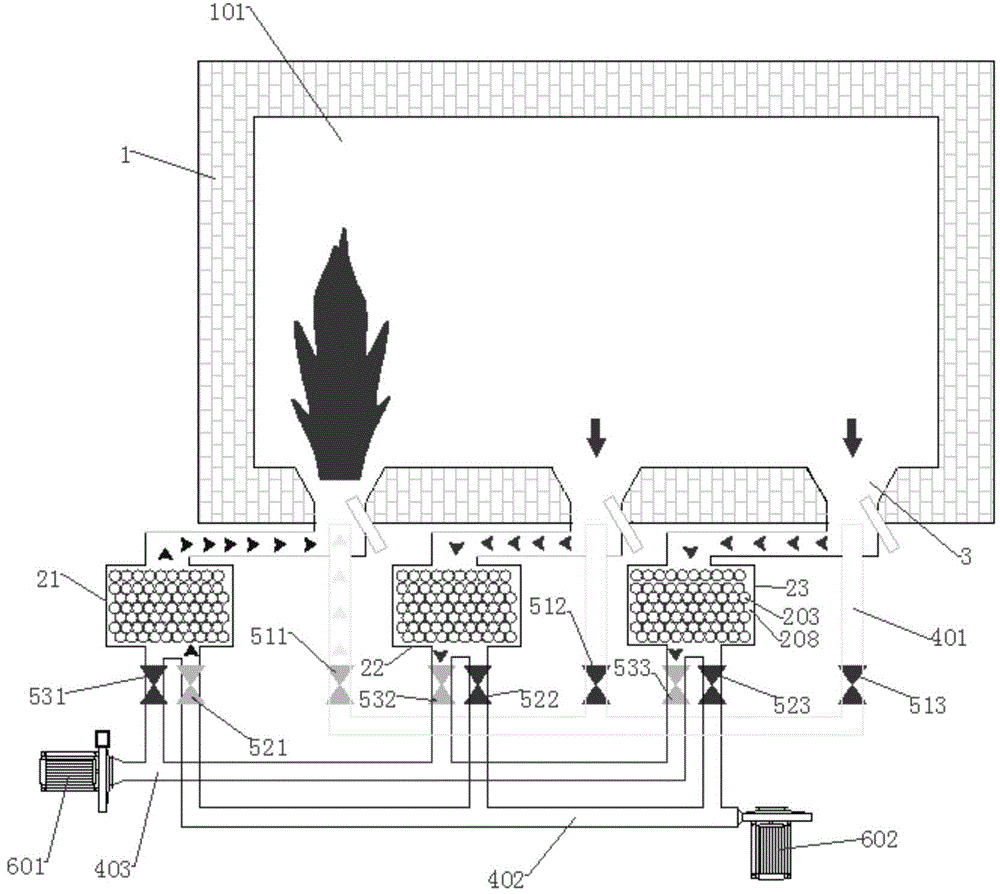

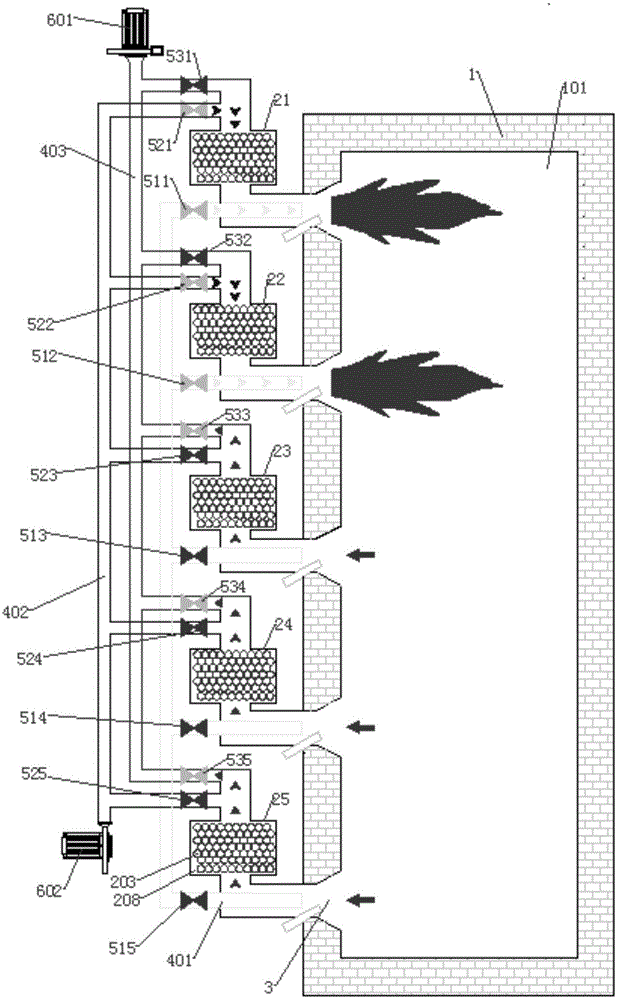

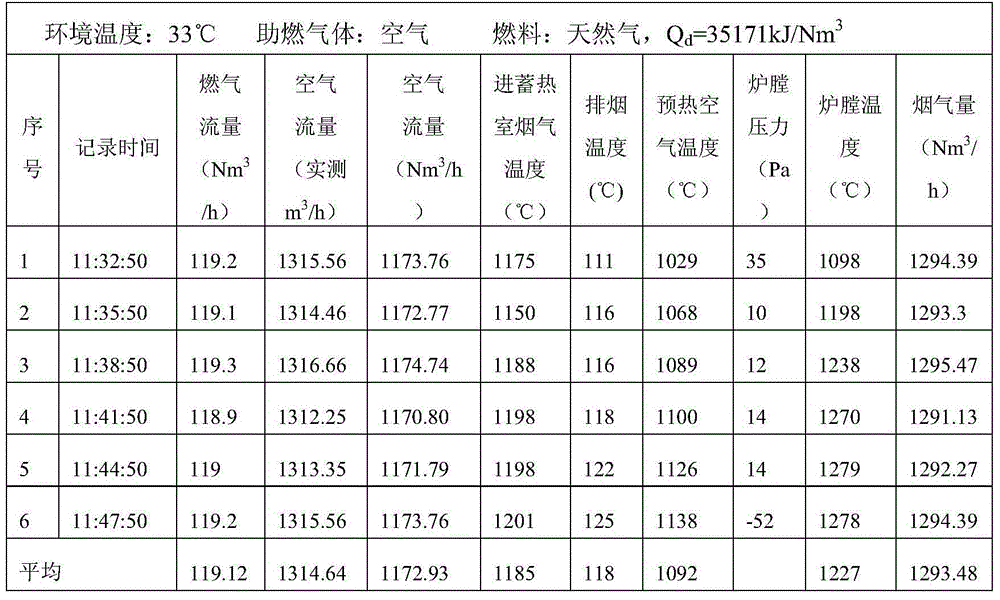

Regenerative combustion device

InactiveCN104457302ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCombustorLow nitrogen

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

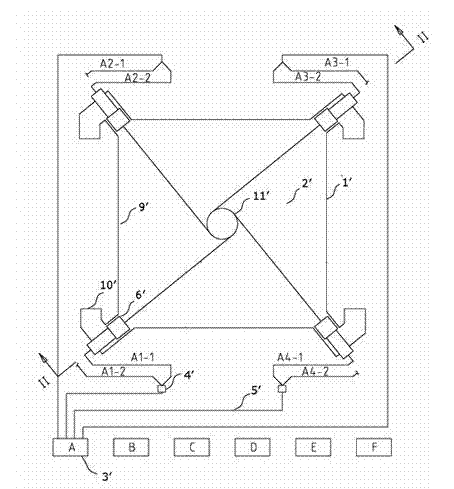

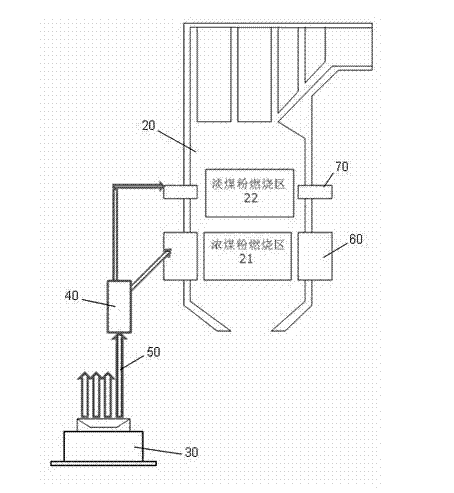

Anthracite-combusted single fire ball four-corner direct current burner

ActiveCN102494333AFire stableIncrease concentrationFuel feeding arrangementsSolid fuel pretreatmentLow loadHearth

An anthracite-combusted single fire ball four-corner direct current burner includes four burner groups placed at the four corners at a hearth and at least one coal pulverizer, wherein the pulverized coal airflow sprayed by the burner groups forms an imaginary tangent circle at the center of the hearth; two groups of burners are vertically arranged at each burner group at intervals; four pulverized coal pipelines are arranged at the outlet of each coal pulverizer and are connected to four concentrated / thin pulverized coal separators correspondingly; the separated four ways of concentrated pulverized coal airflow is transferred to four primary air / concentrated pulverized coal nozzles on the same horizontal plane and at the lower parts of the four corners of the hearth; and the separated four ways of thin pulverized coal airflow is transferred to four primary air / thin pulverized coal nozzles on the same horizontal plane and at the upper parts of the four corners of the hearth. Under the premise of meeting the heat power of the entire boiler, the anthracite-combusted single fire ball four-corner direct current burner increases the pulverized coal concentration at the concentrated pulverized coal area, and enables the wall thermal load qHr at the lower part of the burner to be higher, thereby enabling the combustion temperature at the lower part of the burner to meet the requirement of inflammation and stable combustion for the anthracite, and guaranteeing the anthracite pulverized coal airflow to be combusted timely and the low-load stable combustion of the oilless boiler.

Owner:SHANGHAI BOILER WORKS

Burner apparatus

InactiveUS6916172B2Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

A burner apparatus comprising housing defining a chamber and having an air inlet, a peripherally extending baffle disposed in the housing, a first peripherally extending flow passage being formed between the housing and the baffle, the first flow passage being in open communication with the air inlet, a peripherally extending combustion liner disposed inwardly of the baffle, a second peripherally extending flow passage being formed between the liner and the baffle, the second flow passage being in open communication with the first passage, a reversing diverter disposed in the chamber and positioned to direct air flowing from the first flow passage into the second flow passage, a burner assembly mounting plate disposed in the liner and having a first side and a second side, the mounting plate and the liner at least partially defining a burner barrel on the first side of the mounting plate, at least one burner assembly mounted on the burner mounting plate and a plenum on the second side of the mounting plate that is in open communication with the second flow passage.

Owner:L & S CRYOGENICS

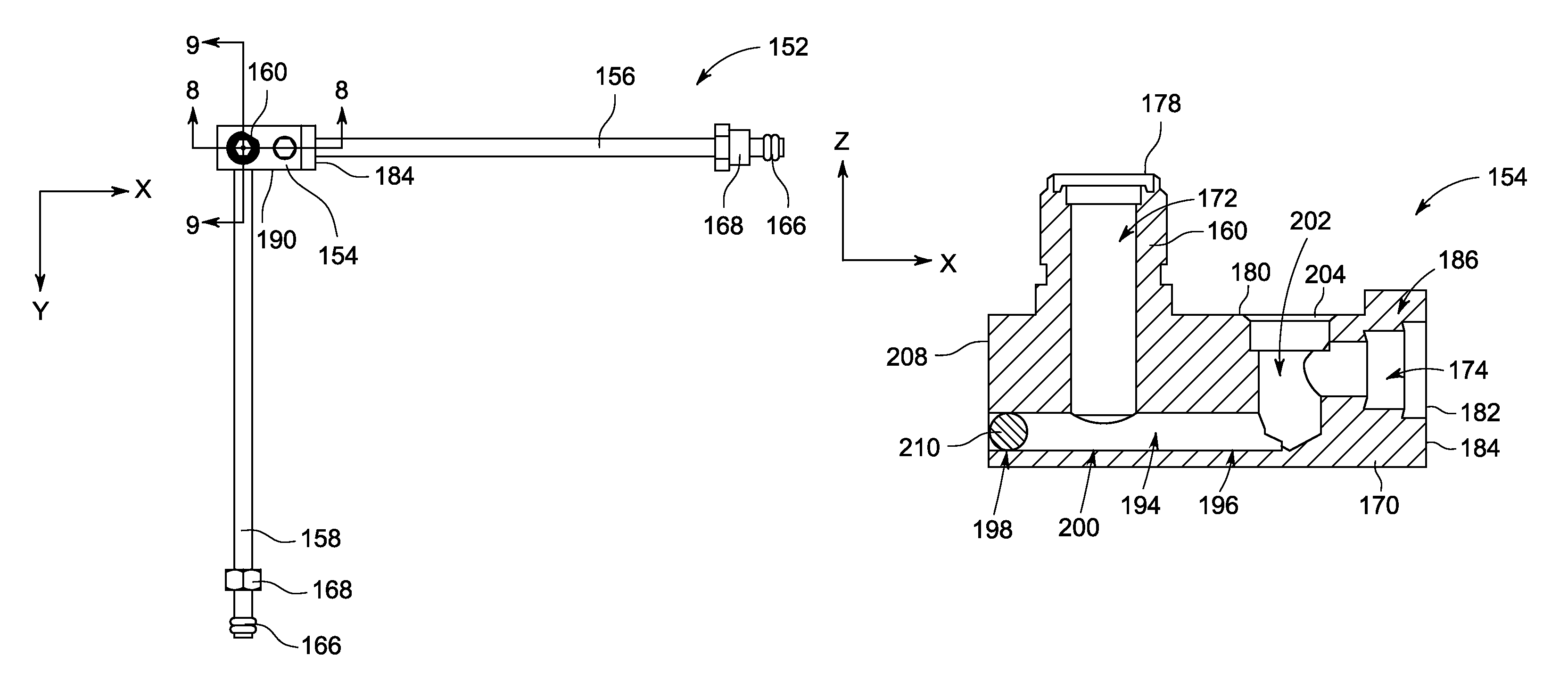

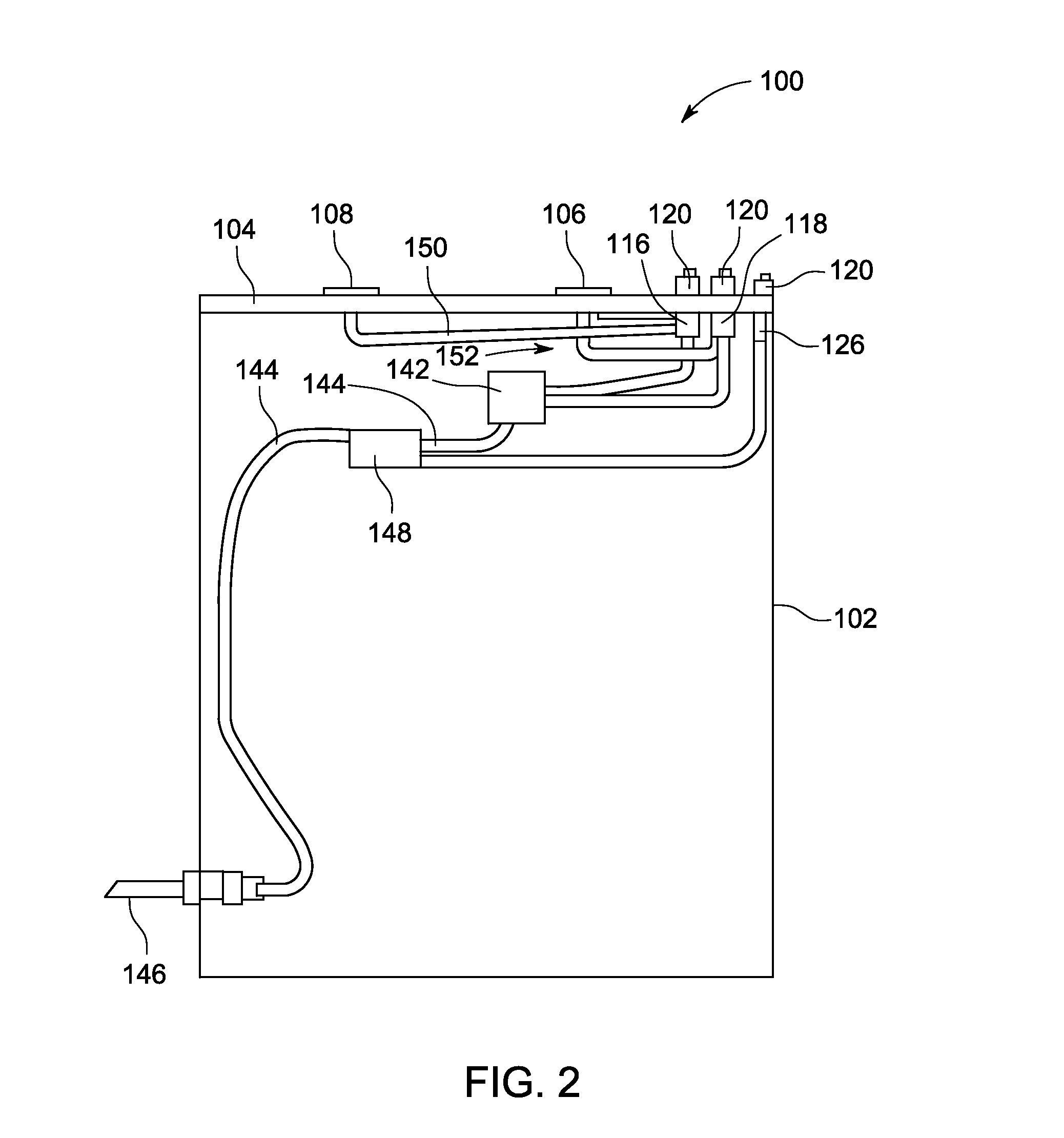

Orifice holder and tube assembly for use with a gas-fueled appliance

Owner:HAIER US APPLIANCE SOLUTIONS INC

Orifice holder and tube assembly for use with a gas-fueled appliance

ActiveUS20130014744A1Domestic stoves or rangesSpecial fuel supply arrangementsEngineeringMechanical engineering

Owner:HAIER US APPLIANCE SOLUTIONS INC

Gas burner

The present invention provides a gas burner (10) including: a distributor means (50) having at least one distribution chamber to distribute an air gas mixture around said distributor (50), said burner (10) including a plurality of flame ports (70) through which said gas mixture can pass and be ignited; at least one injector (39) associated with said distributor (50), said at least one injector (39) being positioned to inject gas into said at least distribution chamber via a venture formed of a vertically directed passage and transition port (64) and at least one venturi extension extending away from said transition port (64). The present invention also provides manifold for a gas burner (10), said manifold having an upper wall (12) and a lower wall (16) held in spaced apart relationship by a peripheral wall to define a cavity there between, said manifold including means (38) to mount at least one injector (39) so as to deliver an air gas supply to a distribution means (50) and an inlet port (18) to allow connection to a supply of gas, which can pressurize said cavity, said upper (12) and said lower (16) wall being formed from relatively thin sections.

Owner:AB ELECTROLUX

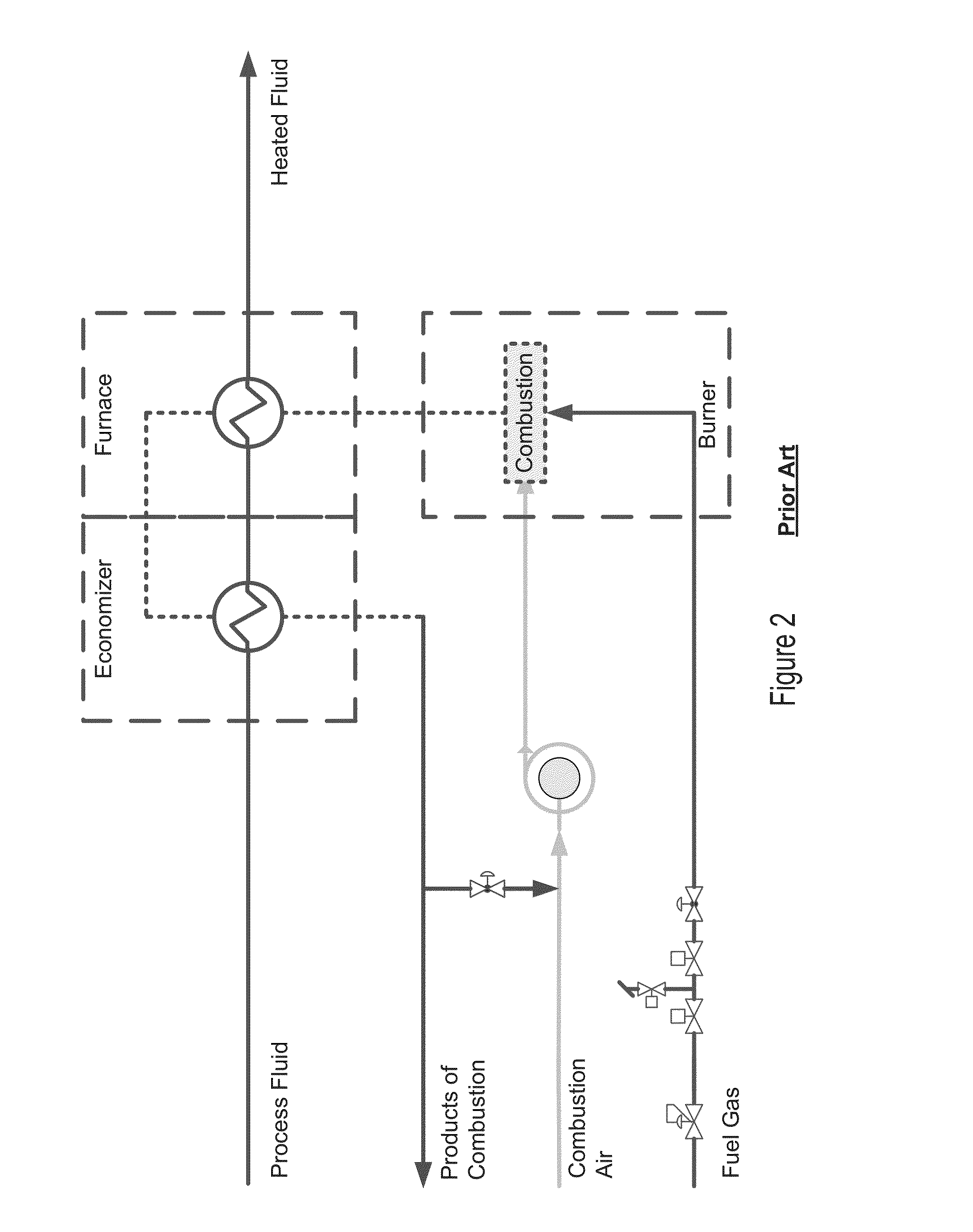

LOW NOx COMBUSTION METHOD AND APPARATUS

ActiveUS20160018102A1Reduce nitrogen oxide emissionsCombustion using gaseous and pulverulent fuelLiquid fuel feeder/distributionCombustorFlue gas

A steam generator system employing a fired burner with a flue gas recirculation system with low NOx emission is disclosed. A method to retrofit fired burners for low NOx emission is also disclosed. In the system, the flue gas recirculation system is configured to include a pre-mixer, and the recirculated flue gas (RFG) is routed to the stage of the pre-mixer for mixing with a portion of the fuel stream, forming a secondary RFG fuel mixture. The secondary RFG fuel mixture is routed to the secondary stage of the burner via a plurality of injector ports. The injection of the second RFG fuel mixture results in a reduction of temperature for the NOx emission to be less than 5 ppm at 3% O2, dry basis.

Owner:CHEVROU USA INC

Multistage gas furnace having split manifold

A heating apparatus for a heat exchanger system includes a manifold having a plurality of burners, a shutoff valve, a first controller and a second controller. The shutoff valve divides the manifold into a first manifold portion and a second manifold portion. The first controller selectively controls the communication of a fluid within the manifold. The second controller selectively actuates the shutoff valve between a first position and a second position to control a firing rate of the plurality of burners.

Owner:CARRIER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com