Anthracite-combusted single fire ball four-corner direct current burner

A burner and anthracite technology, which is applied in the direction of burning powder fuel, burning with multiple fuels, burners, etc., can solve the problems of complexity, difficulty in design and layout of the design institute, and large occupation of land, so as to ensure timely ignition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

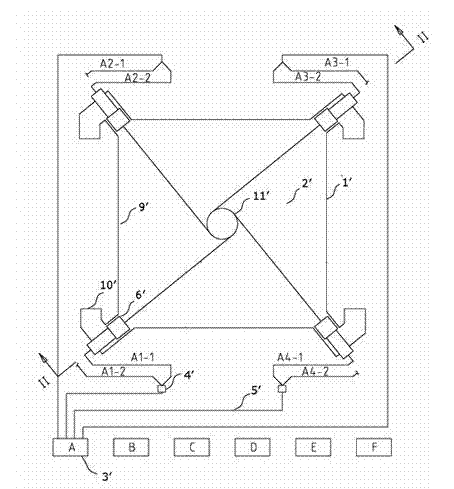

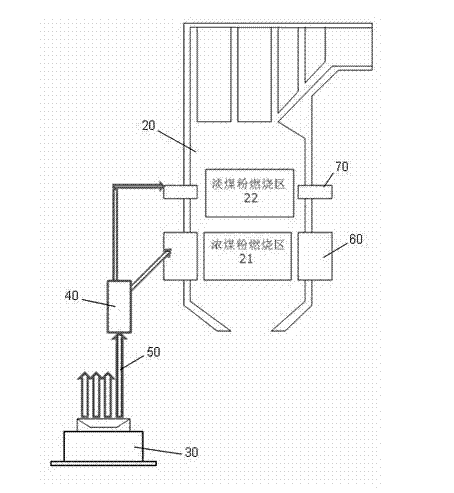

[0038] see image 3 As shown, the single-fireball four-corner direct-flow burner for burning anthracite in the present invention adopts "a medium-speed mill with a pulverized coal concentration separation device or a double-inlet and double-outlet direct-blown pulverization system". On each pulverized coal pipeline 50 at the outlet of the coal machine 30, add a pulverized coal concentration separation device 40 to separate the primary air / powdered coal into a "concentrated" pulverized coal flow with 80% pulverized coal and 50% primary air. , and the remaining 20% pulverized coal and the "light" pulverized coal airflow of 50% primary air, these two pulverized coal airflows pass through the "primary air / coal powder" nozzle 60 and the "primary air / light coal" nozzle 60 of the burner respectively. powder "nozzle 70, into the corresponding rich combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com