Four-arch W flame two-stage dense and thin combustion device

A thick-thin combustion and flame technology, which is applied in the direction of using a variety of fuel combustion, combustion methods, combustion types, etc., can solve the problem that the degree of reduction is not particularly obvious, and achieve the effects of uniform heat load distribution, improved fuel reburning efficiency, and large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

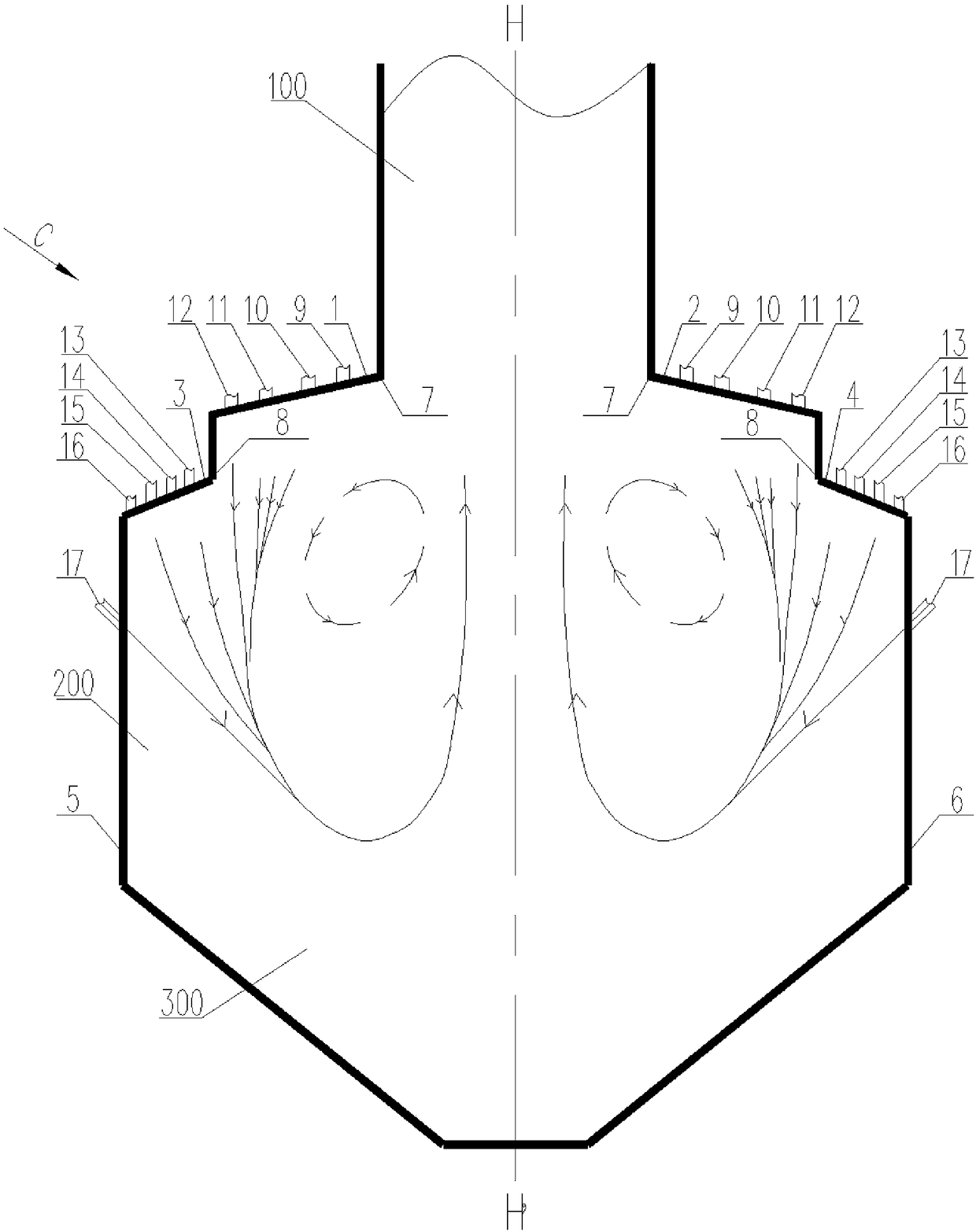

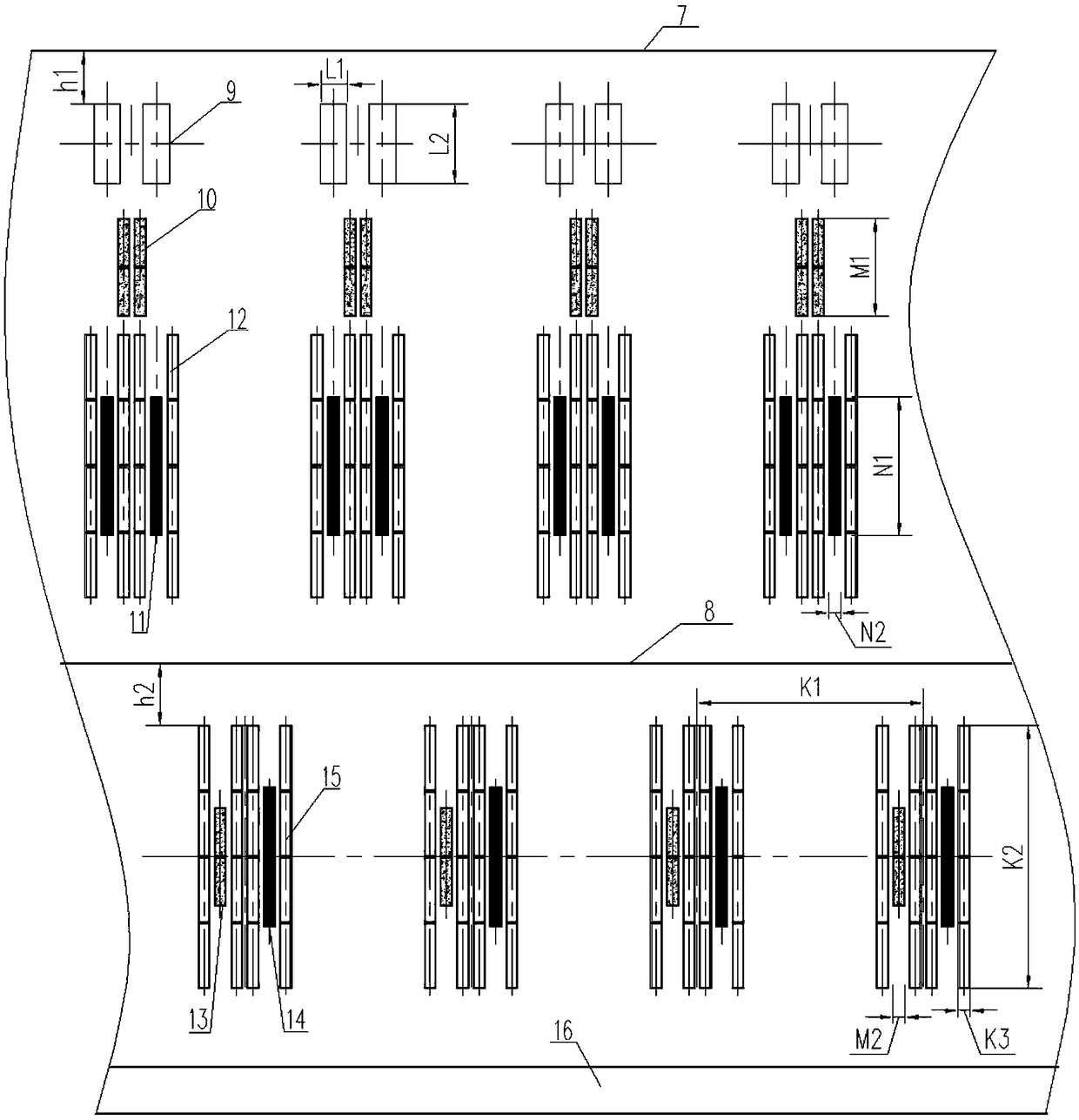

[0036] Such as Figure 1 ~ Figure 2 A four-arch W flame two-stage thick-lean combustion device shown, wherein figure 1 It is a cross-sectional flow field schematic diagram of the present invention, in which the flow field distribution takes the hearth center line HH' as a plane of symmetry, and the velocity direction of each stream injected into the furnace is marked by arrows in the figure. The hearth of the device includes an upper furnace body 100, a lower furnace body 200 and a cold ash hopper 300, wherein the lower furnace body 200 consists of a front upper furnace arch 1, a rear upper furnace arch 2, a front lower furnace arch 3, and a rear lower furnace arch. Arch 4, front wall 5 and rear wall 6 surround and form;

[0037] A circle of upper throat connection line 7 is formed horizontally on the furnace arch at the junction of the upper furnace body 100 and the lower furnace body 200, the front upper furnace arch 1, the rear upper furnace arch 2, the front lower furnace...

Embodiment 2

[0044] A four-arch W flame two-stage thick-lean combustion device, the rest are the same as embodiment 1, such as Figure 1 ~ Figure 2 As shown, each of the first tuyere groups includes the above-mentioned two rectangular overburned air nozzles 9, two primary exhaust gas nozzles 10, two primary dense coal powder nozzles 11 and four inner secondary air nozzles 12;

[0045] The arrangement order of the two primary dense coal powder nozzles 11 and the four internal secondary air nozzles 12 is, from left to right, an internal secondary air nozzle 12, a primary dense coal powder nozzle 11, and two internal secondary air nozzles. Nozzle 12, a primary dense coal powder nozzle 11 and an inner secondary air nozzle 12;

[0046] Each of the second tuyere groups includes the above-mentioned secondary exhaust gas nozzle 13, a secondary concentrated pulverized coal nozzle 14 and four outer secondary air nozzles 15, and the arrangement order of these nozzles is one from left to right. Outer...

Embodiment 3

[0048] A four-arch W flame two-stage thick-lean combustion device, the rest are the same as embodiment 2, such as Figure 1 ~ Figure 2 As shown, the aspect ratio of the rectangular overburning air nozzle 9 is (2.5-3):1.

[0049] The number of rectangular overburning air nozzles (9) provided on the device is 24 each, and the overburning air rate is 20%. The distance between the rectangular overburning air nozzle 9 and the plane where the upper throat connection line 7 is located is h1 (h1=0.9m).

[0050] The ratio of the primary exhaust gas to the secondary exhaust gas in the device is 3:1, the ratio of the primary concentrated coal powder to the secondary concentrated coal powder is 1.67:1, and the ratio of the internal secondary air to the external secondary air is 5: 2.

[0051] to combine figure 1 with figure 2 , the front lower furnace arch and the rear lower furnace arch are respectively symmetrically distributed with 11 groups of secondary exhaust gas nozzles 13, ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com