Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Jet stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

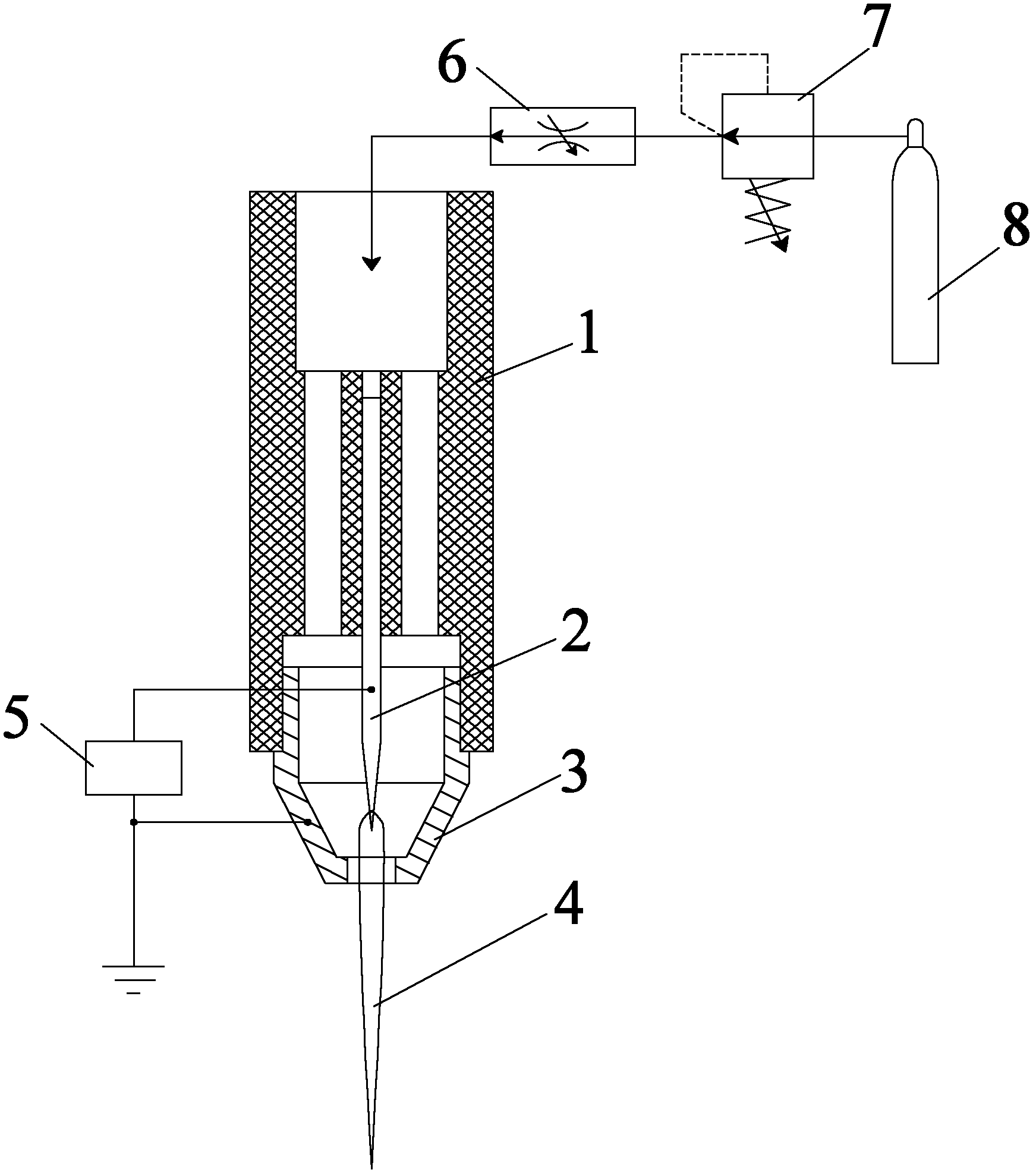

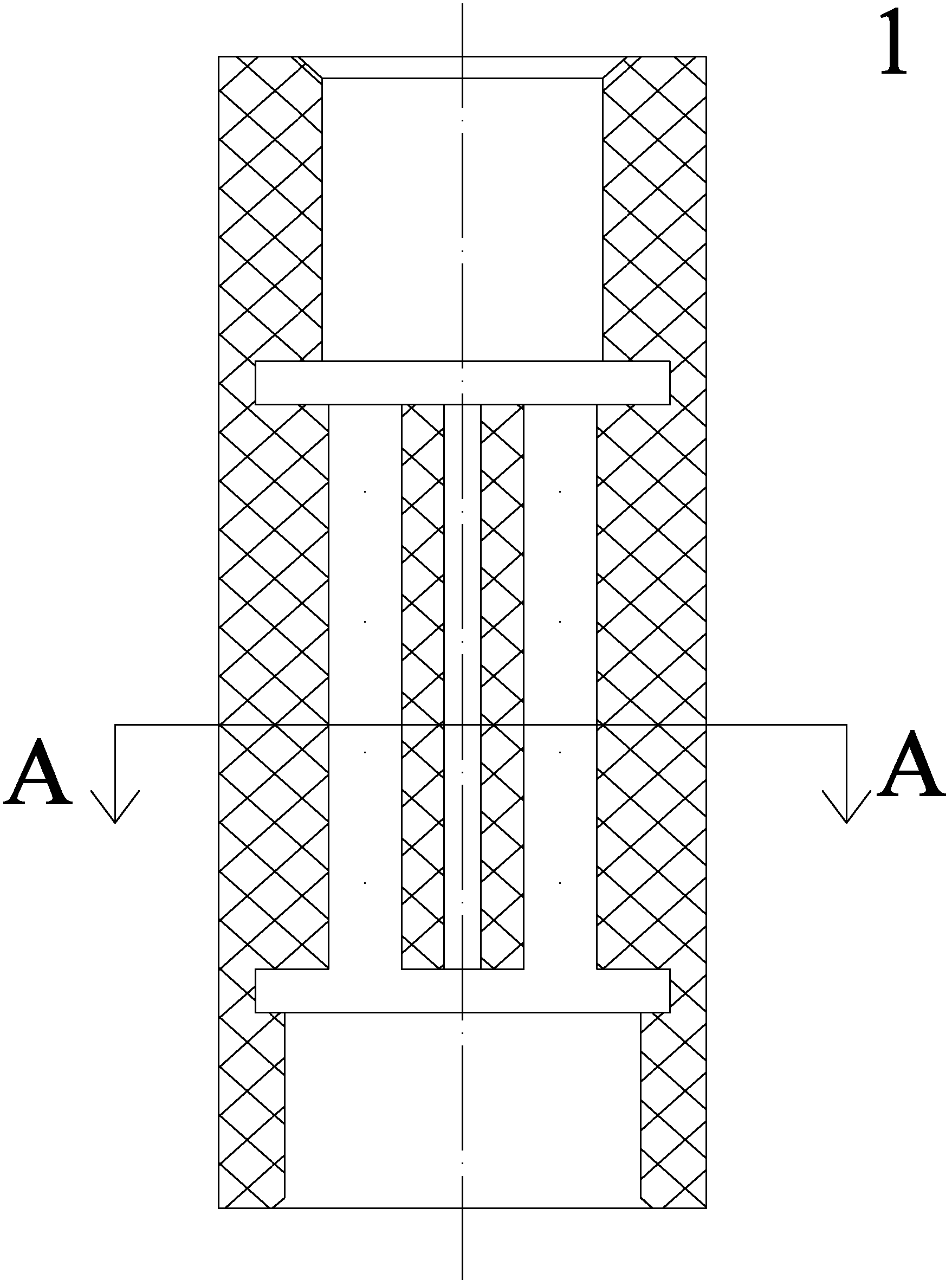

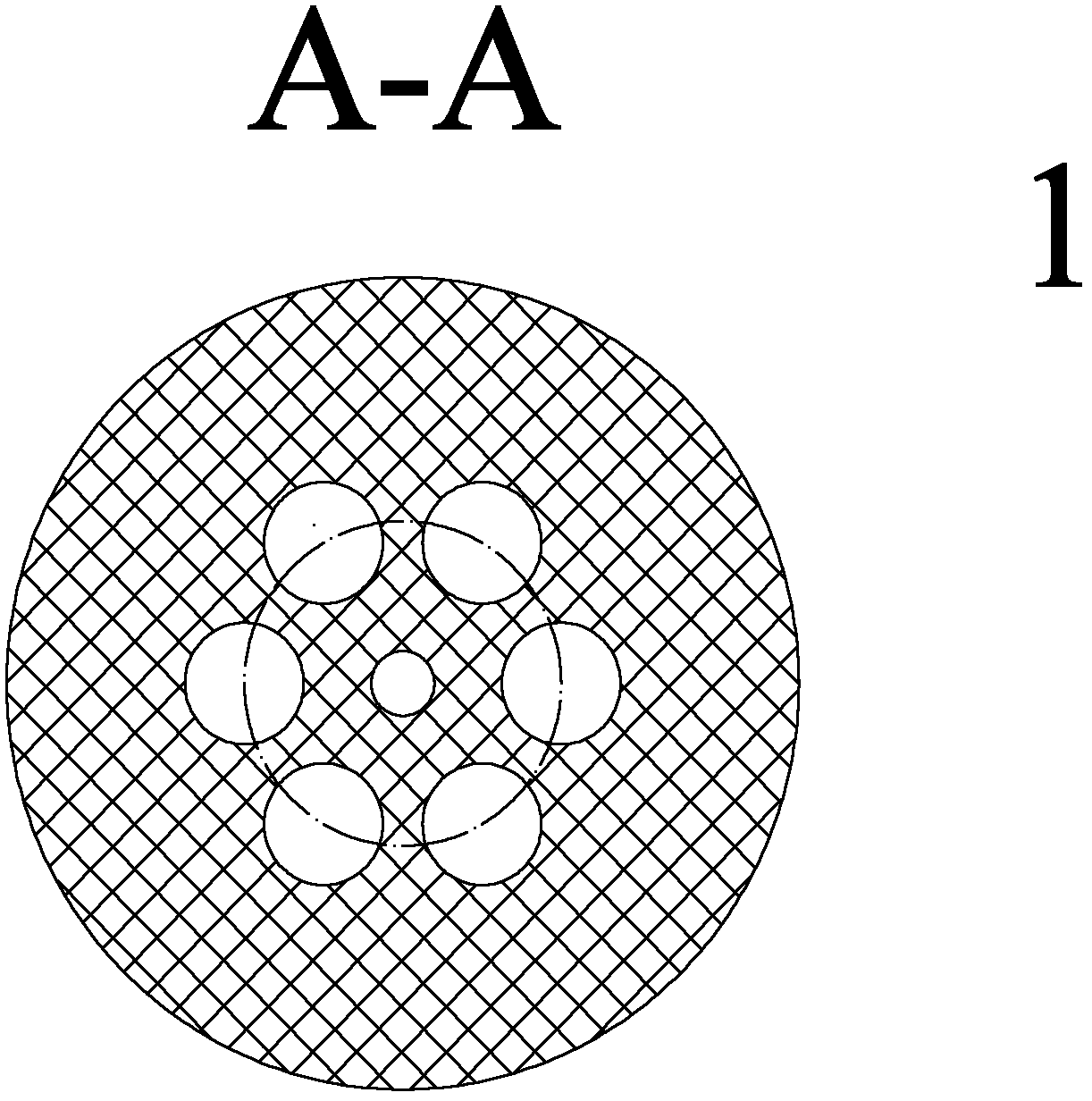

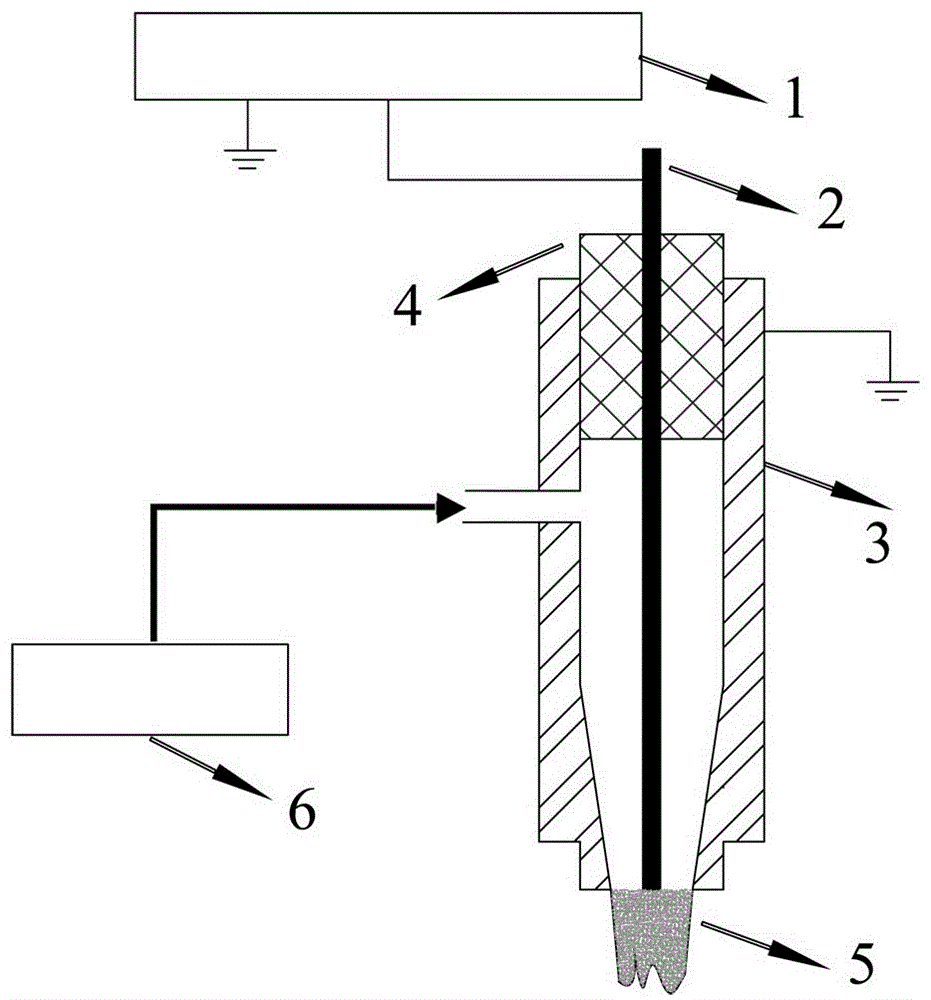

Generating device for atmospheric bare electrode cold plasma jet

The invention provides a generating device for an atmospheric bare electrode cold plasma jet. The generating device comprises a working gas source, a pressure reducing valve, an adjustable flow meter, a high-voltage power supply, a cylindrical shell, a nozzle electrode and a pin electrode, wherein the tail part of the cylindrical shell made of insulating material is connected with a gas supply system; the front end of the cylindrical shell is connected with the nozzle electrode through a thread; the pin electrode is fixedly arranged in a central hole of the cylindrical shell; a certain discharging clearance is kept between the tip of the pin electrode and the nozzle electrode; a plurality of through holes parallel to the central hole of the cylindrical shell are distributed around the central hole; the through holes are used for conveying the working gas to a discharging area in the nozzle electrode; a high-voltage output end of the high-voltage power supply is connected with the pin electrode; and a low-voltage output end of the high-voltage power supply is connected with the nozzle electrode and is grounded. Cold plasma is generated at the tip of the pin electrode by adjusting the high-voltage power supply and the flow of the working gas, and the cold plasma is jetted from an outlet of the nozzle electrode so as to form the cold plasma jet. According to the generating device provided by the invention, uniform and stable cold plasma jet can be obtained under an atmospheric open air environment.

Owner:DALIAN UNIV OF TECH

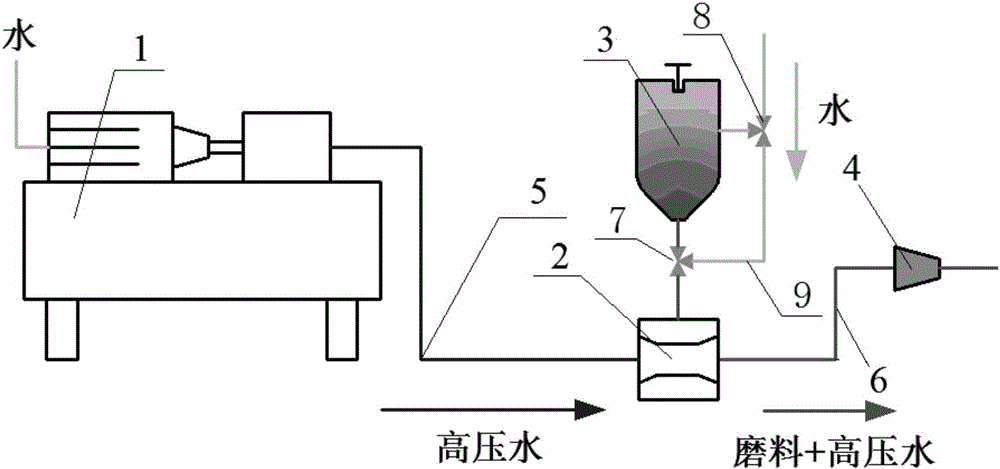

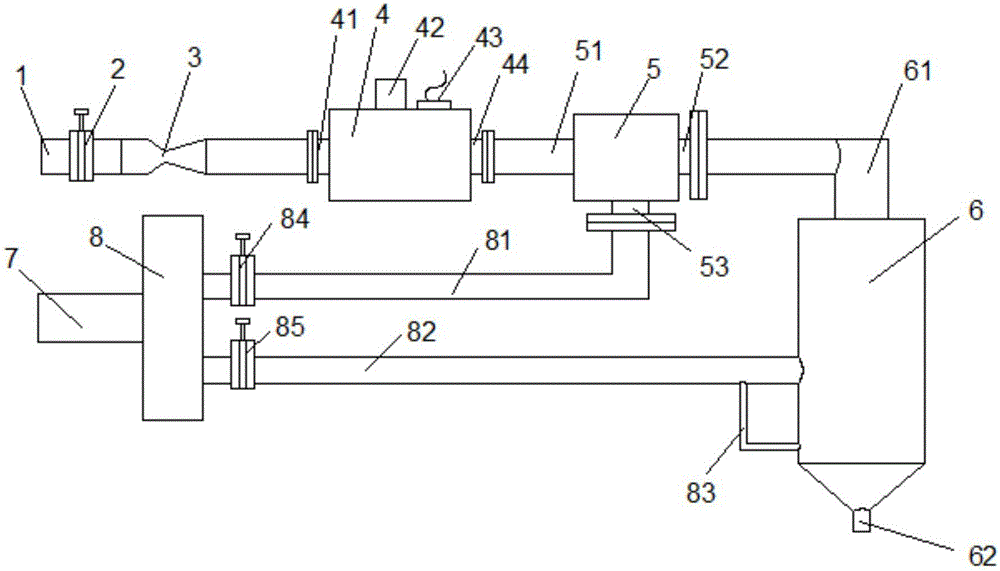

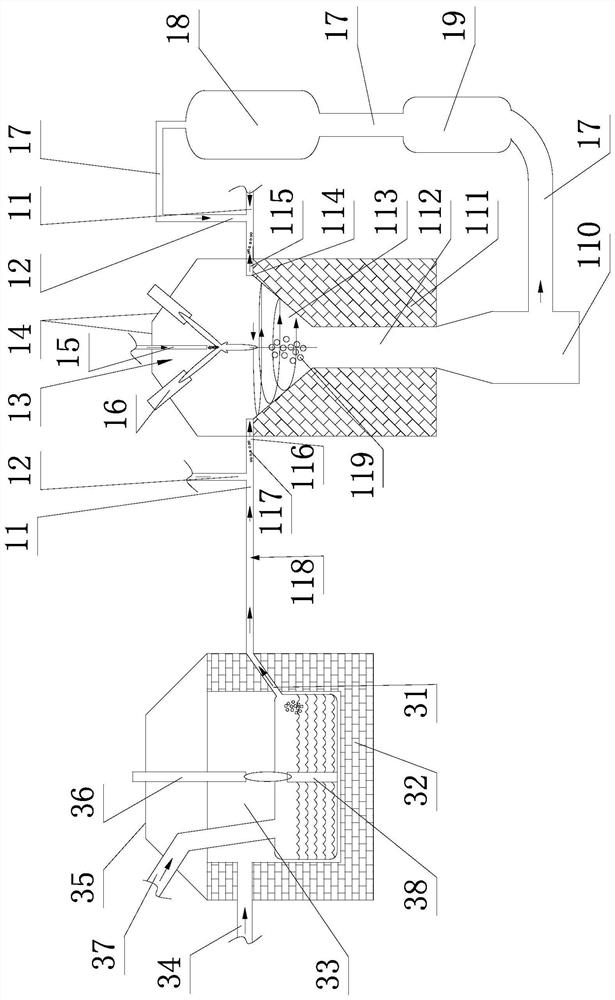

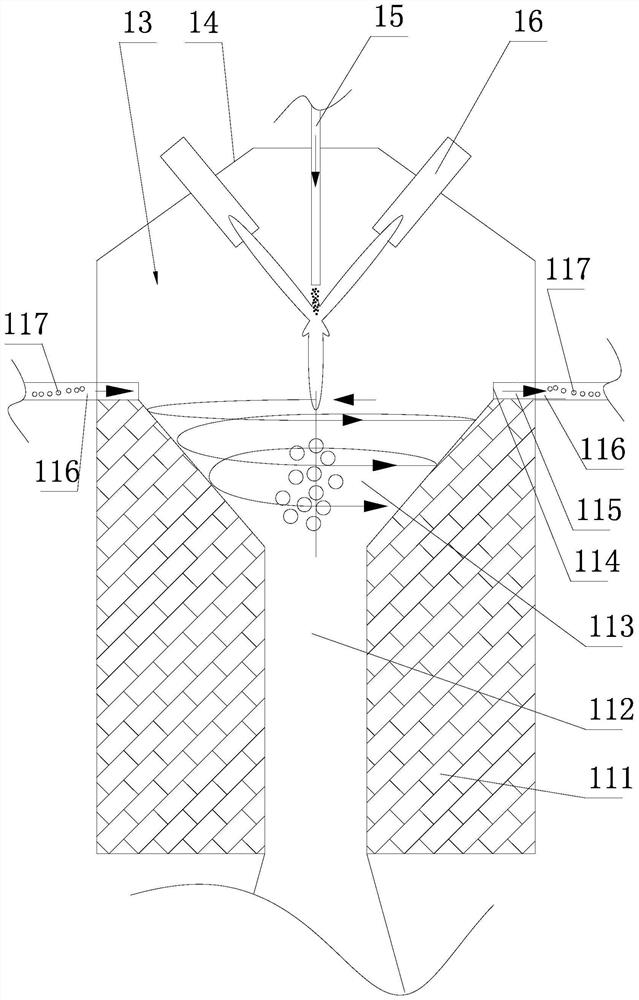

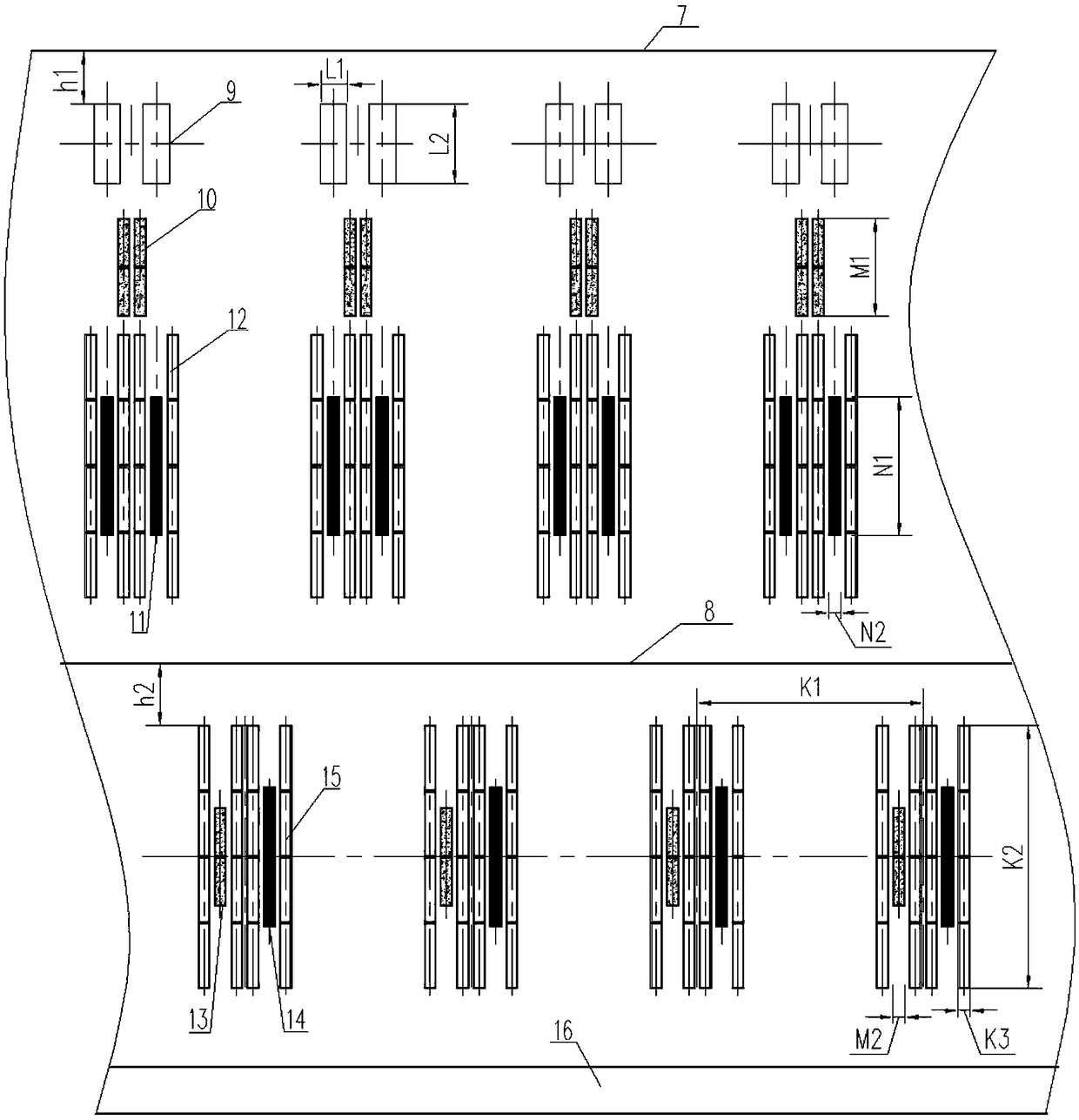

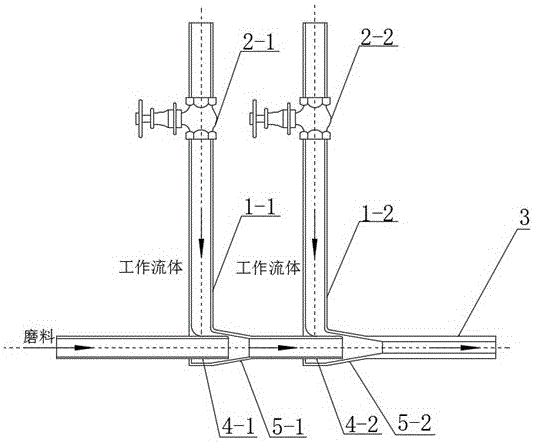

Pre-mixed abrasive water jet type continuous working system and method

ActiveCN106112821AJet stabilizationUninterrupted jetJet pumpsAbrasive feedersSpray nozzleHigh pressure water

The invention provides a pre-mixed abrasive water jet type continuous working system. The system comprises a jet pump, and a high pressure pump device for outputting high-pressure water, wherein the high pressure pump device is connected with the input end of the jet pump through a high-pressure water pipeline; an abrasive tank is connected to a material sucking port of the jet pump; the output end of the jet pump is connected with an abrasive jet nozzle through an abrasive water jet pipeline. The invention also provides a pre-mixed abrasive water jet type continuous working method. According to the system and the method, the abrasive can be quickly pumped and sucked under the entrapment effect of the jet pump as well as the weight effect of the abrasive; after being mixed with water, the abrasive is pressurized and accelerated through the abrasive jet nozzle, and then a pre-mixed abrasive water jet can be sprayed out; and the stable pre-mixed abrasive water jet can be formed on the premise that the abrasive in the abrasive tank for supplying the abrasive is continuously supplied. Therefore, the problem that the abrasive cannot be continuously supplied in the prior art can be solved.

Owner:CHONGQING UNIV

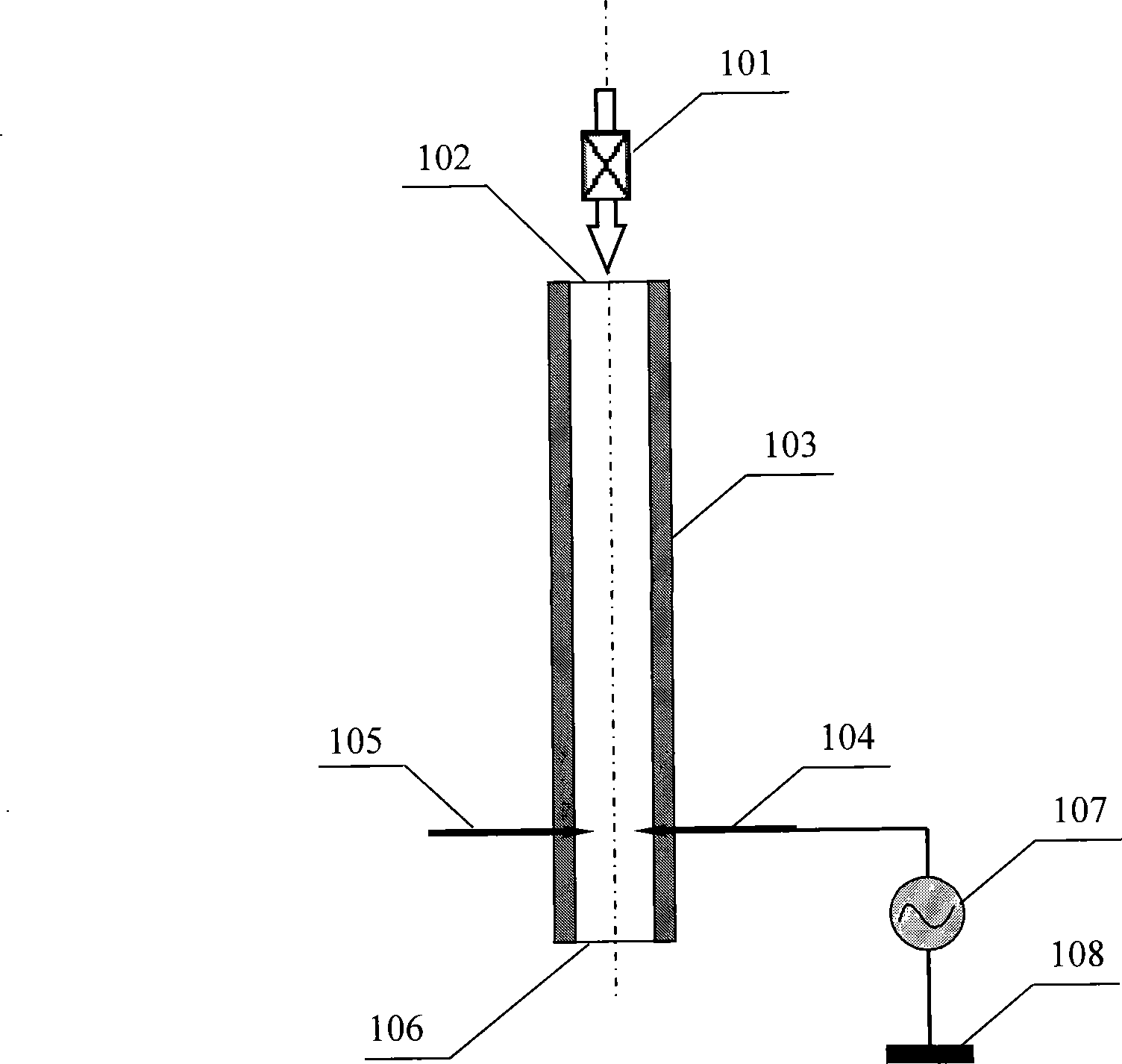

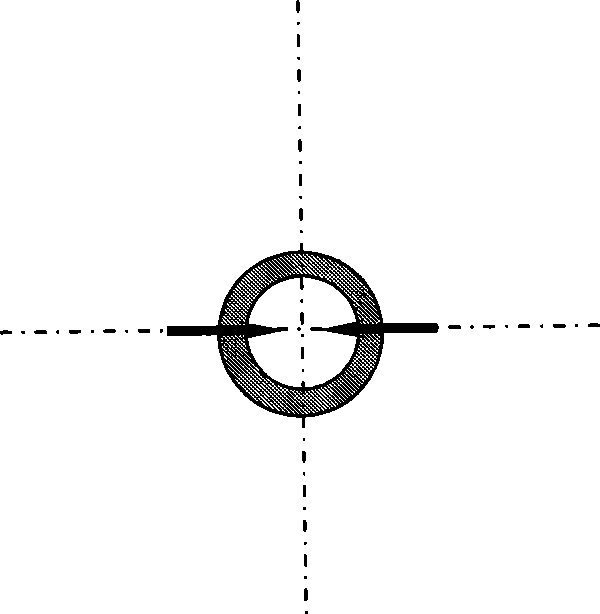

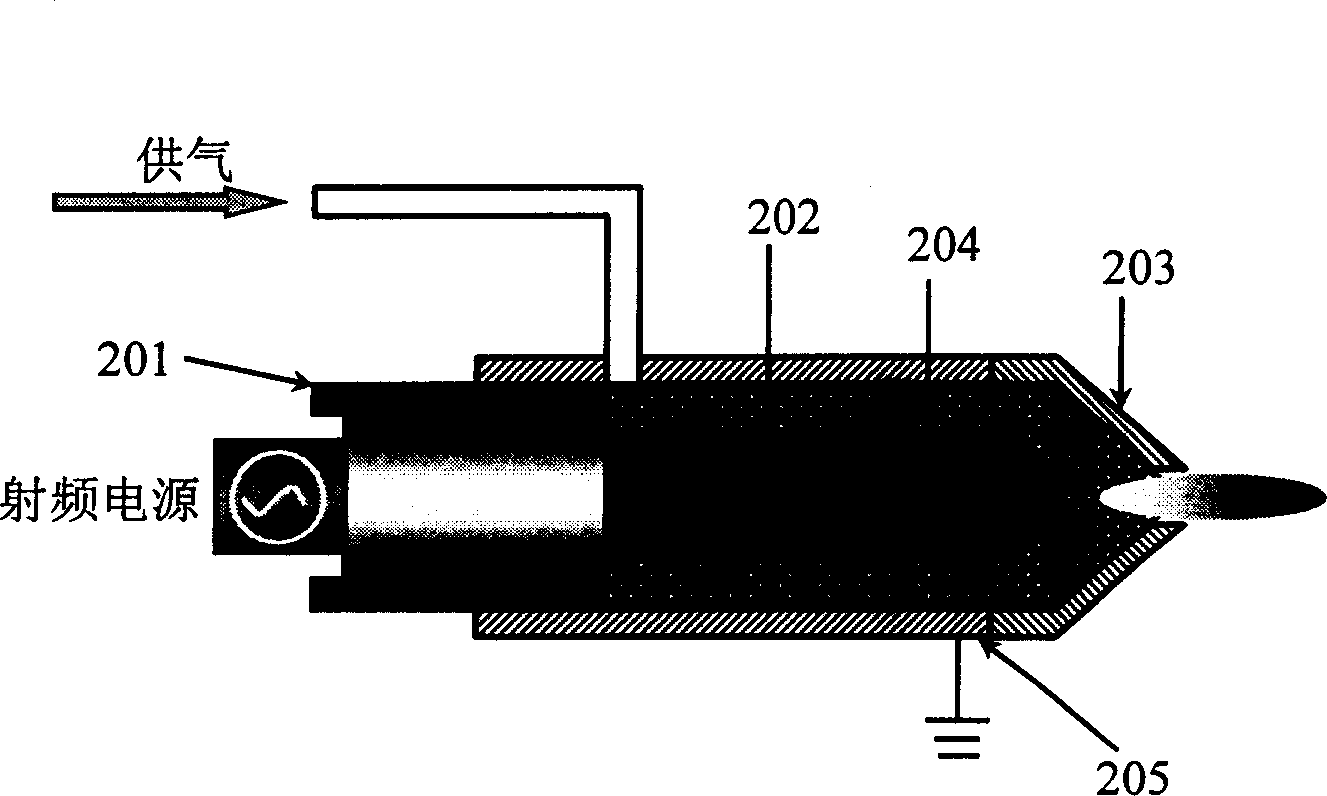

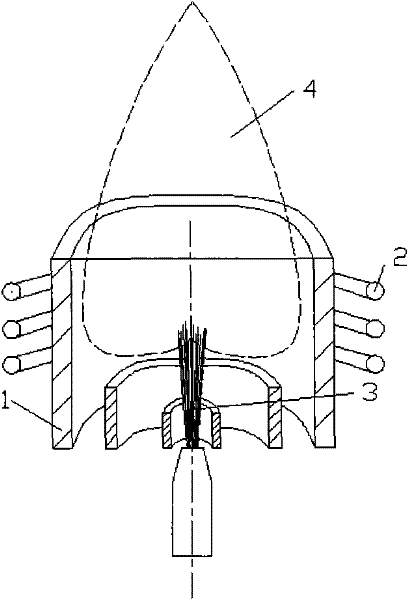

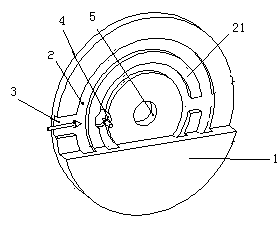

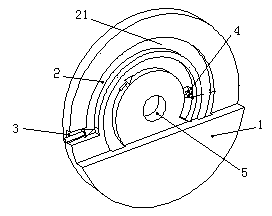

Simple atmosphere pressure suspending electrode cold plasma fluid generator

InactiveCN101252805AImprove jet propertiesJet stabilizationElectric discharge tubesPlasma techniquePlasma jetJet flow

The invention relates to a simple cold plasma jet flow generating device for the barometric suspended electrode, which belongs to the technical field of the plasma discharging reactor. The cold plasma jet flow generating device is characterized in that a main body of the device is a millimeter magnitude quartz tube, a gas inlet opening is arranged at one end connected with a gas supplying source, and a jet flow outlet opening is arranged at the other end; a pair of needle electrodes are embedded into the quartz tube above the jet flow outlet opening, both the electrodes are symmetrical in the radial direction, the needle electrode at one side connected with an alternating current power supply is adopted as a power electrode, and the other electrode at the other side is suspended in the air and adopted as the suspended electrode; through applying voltage, the electrodes discharge to generate plasmas which are sprayed out of the tube to form the jet flow through the action of flowing air. The jet flow generating device has the advantages that the needle electrode structure can reduce the generation of the jet flow and maintain the voltage; the suspended electrode is favorable not only for enhancing the utilization factor of the energy, but also for effectively controlling the discharging intensity and maintaining the stable discharging; the non-pressure plasma jet flow is characterized in low temperature, large length, low produced and maintained voltage, long continuous working time and simple structure.

Owner:DALIAN UNIV OF TECH

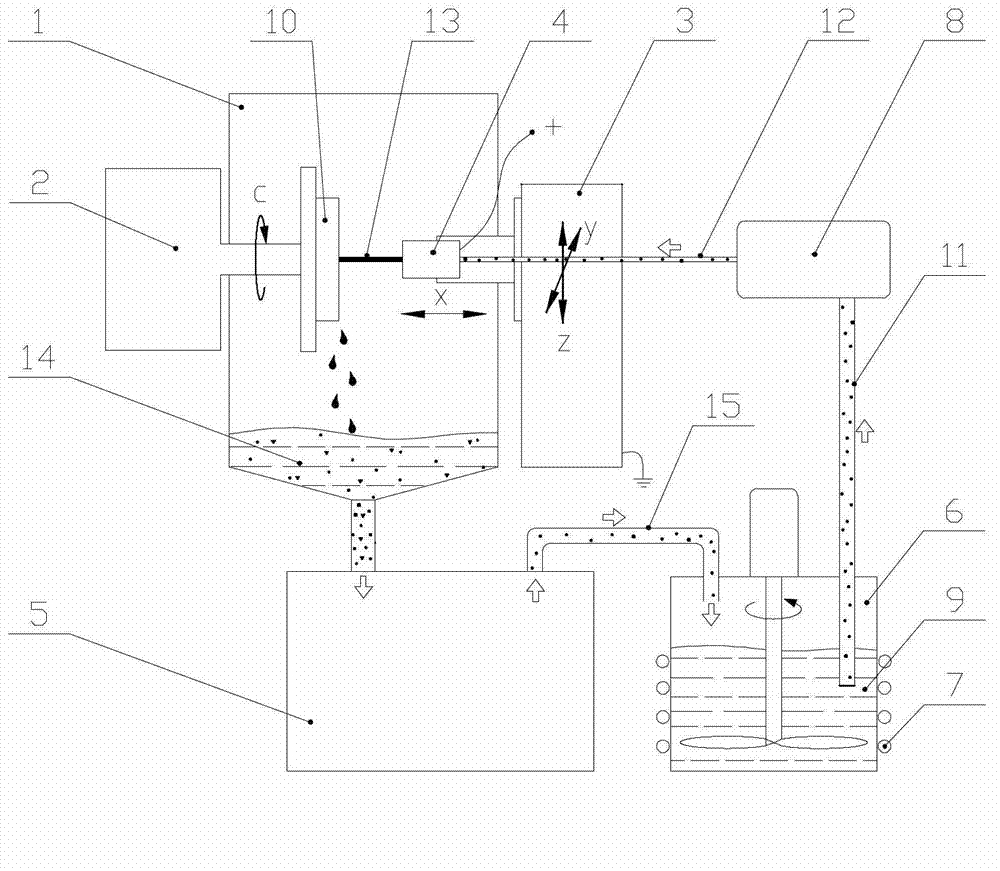

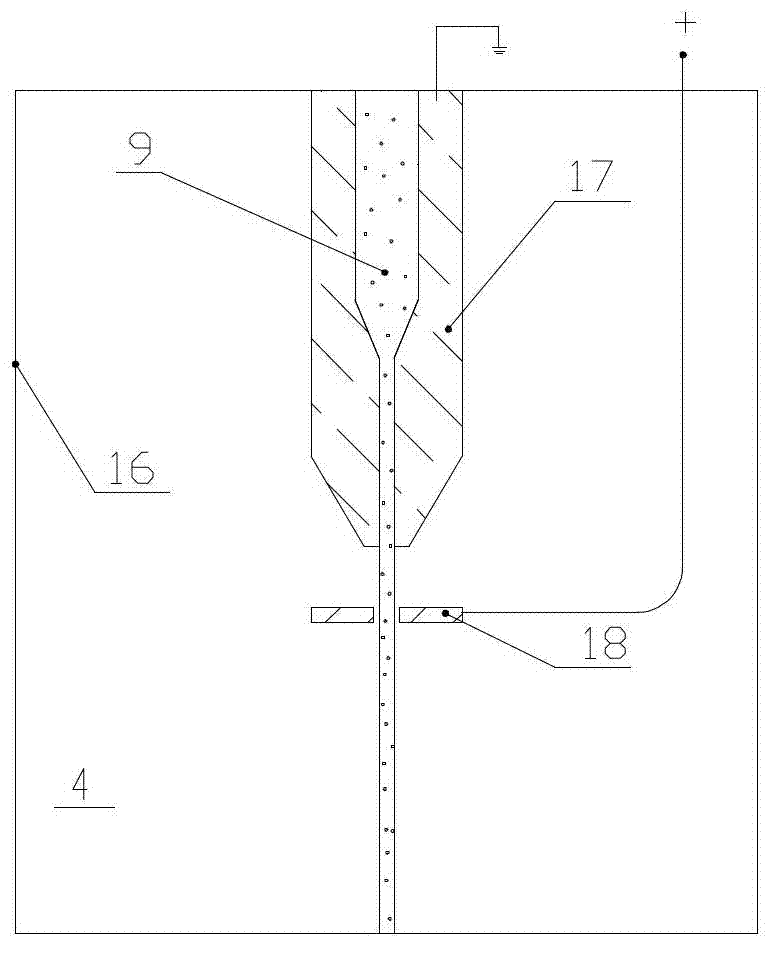

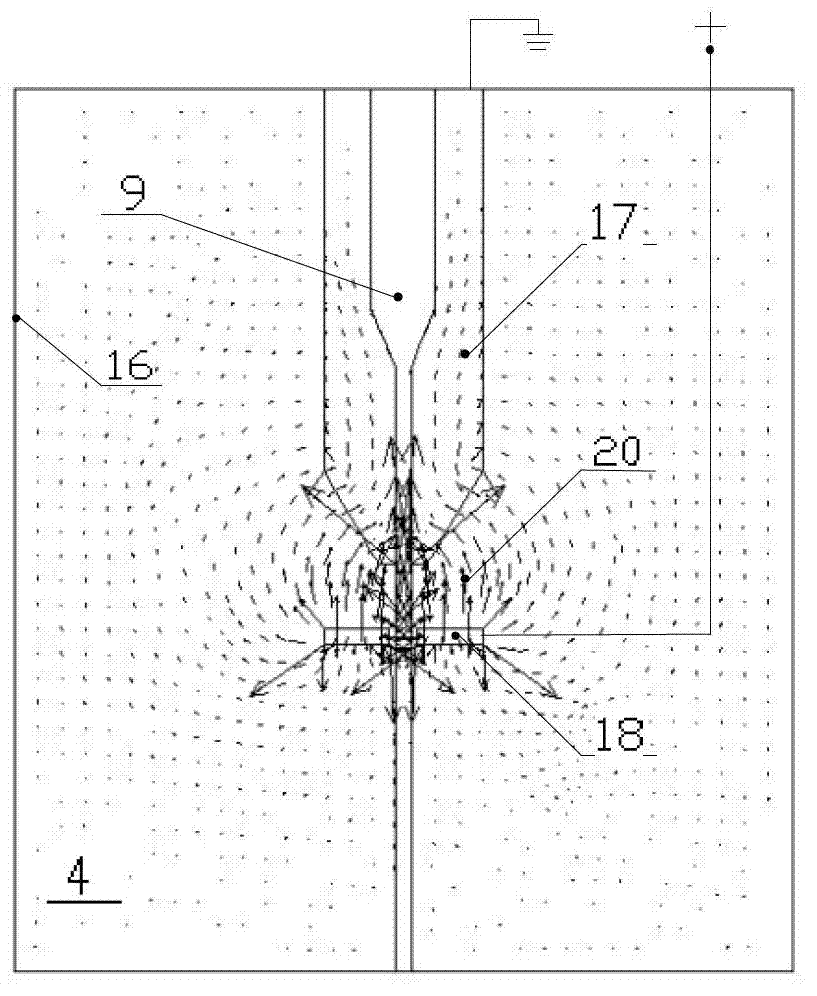

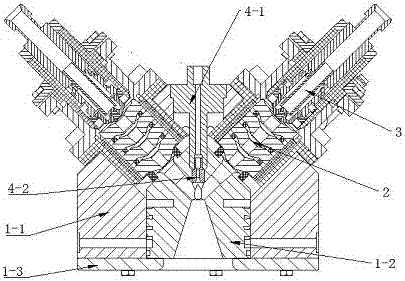

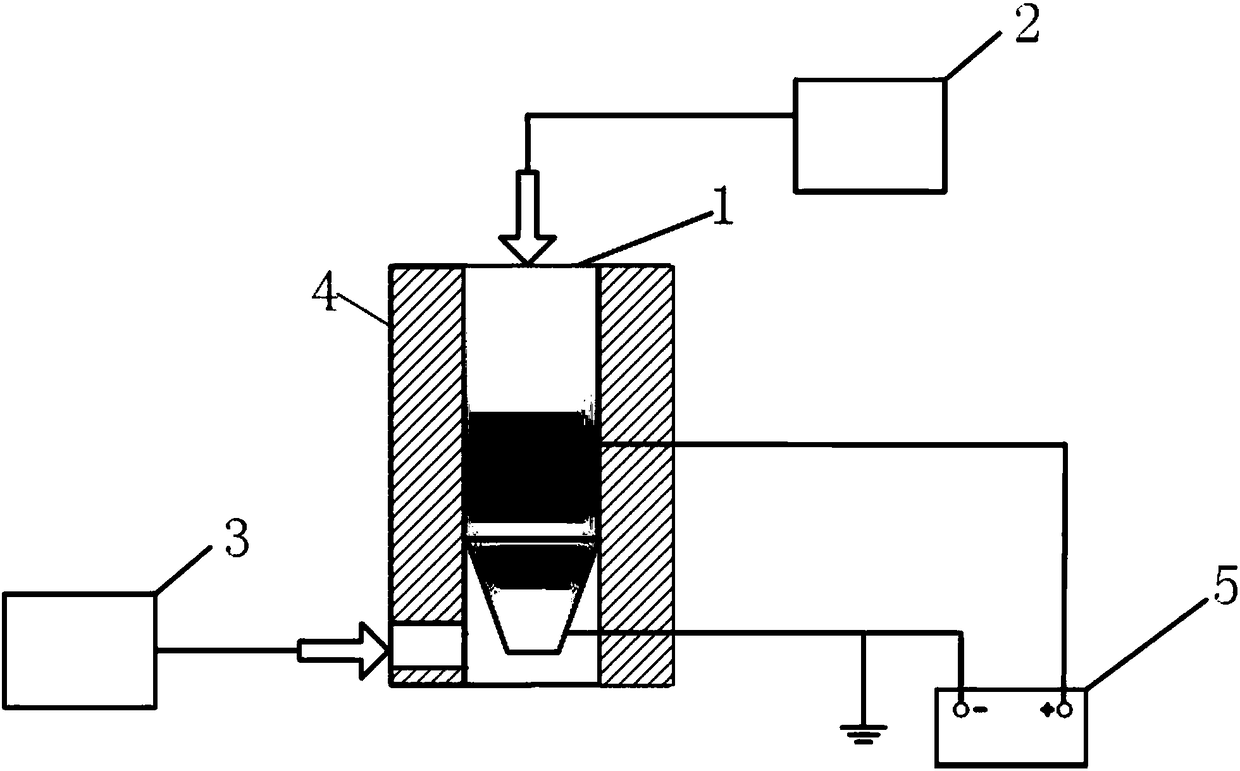

Electric field electrorheological jet polishing device

InactiveCN102962776AWide range of changesImprove stabilityBlast gunsAbrasive machine appurtenancesAfter treatmentPower flow

The invention discloses an electric field electrorheological jet polishing device. The electrorheological jet polishing device comprises a work chamber, a rotary table, a machine tool, a jetting device, a filter, a stirring tank, a cooling device, a boosting device, flow guide pipes and an electrorheological polishing liquid. The machine tool does three-dimensional linear movement; the jetting device is fixed on a horizontal moving shaft driving device and faces the object carrying tabletop of the rotary table; the jetting device and the object carrying table of the rotary table are sealed by the work chamber; the filter is arranged between the work chamber and the stirring tank; the cooling device is arranged on the outer wall of the stirring tank; a boosting system is arranged between the jetting device and the stirring tank; and all parts of a system are connected through the flow guide pipes to form a liquid loop. When the electrorheological jet polishing device is in work, the electrorheological polishing liquid is boosted by the boosting device, input into the electrified jetting device, shaped by the jetting device and subjected to an electrorheological effect to form stable standard straight jets for polishing a workpiece; and waste liquid can be recycled for use after treatment. The electric field electrorheological jet polishing device combines an electrorheological polishing technology and a jet polishing technology and belongs to the domain of optical fine machining.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Firework fuel gas driven high speed sprinkling device

InactiveCN1701858AIncrease gas productionFast gas productionLiquid spraying apparatusLiquid jetEngineering

The present invention provides a liquid high speed spraying device, which uses solid propellant, gunpowder or gas propellant as power source and fuel gas with high pressure from the burn of agents spray from the nozzle to form high speed liquid jet with some spraying angle. The spraying device comprises gas generator, copper seal membrane, piston, liquid storage room and nozzle. All the agents has the characters of large gas product, quick speed, stable burn and easy to store for long term, to make liquid form moment stable jet, and benefit to device miniaturization for liquid spraying bomb with small volume. The jet from this device has the advantages of quick speed, good distribution, well direction and easy control cloud shape.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

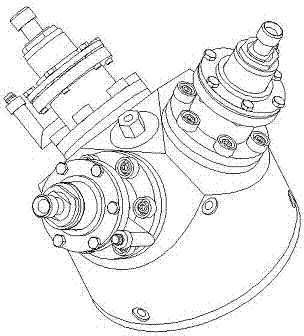

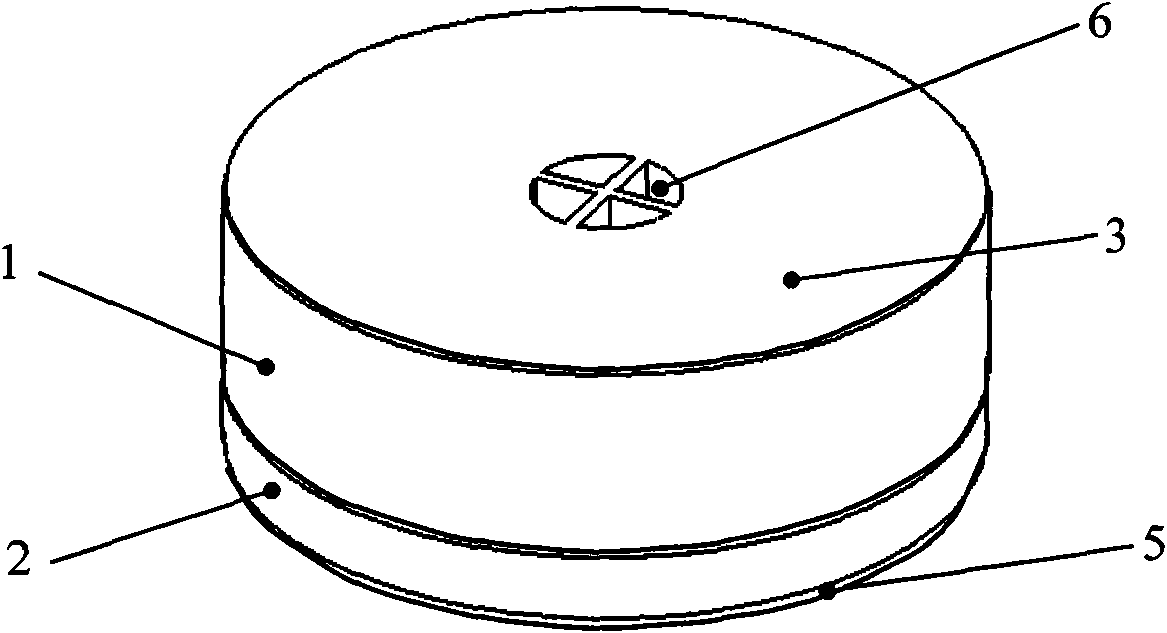

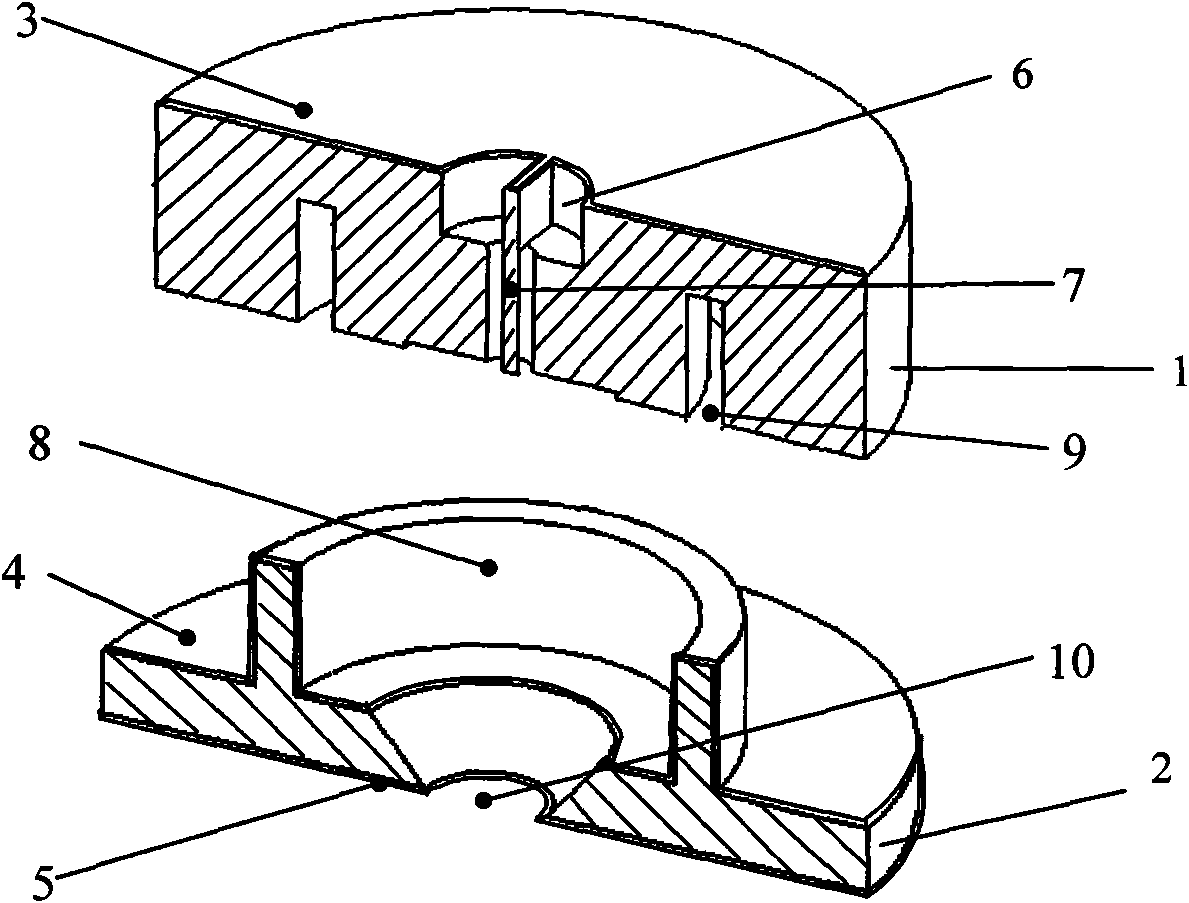

Multi-cathode laminar flow plasma powder spheroidization device

PendingCN107124814AReduce volatilityReduce ablationTransportation and packagingMetal-working apparatusJet flowControllability

The invention provides a multi-cathode laminar flow plasma powder spheroidization device, which consists of an anode part, an interpole part, a cathode part, a power feeding part and an accessory, wherein the anode electrode part consists of an anode casing, an anode, a compression cover and the like. Each part is compressed and connected through screw bolts; the interpole part consists of an arcing ring, an insulation ring, an interpole, an interpole inner sleeve, an interpole outer sleeve and the like; the cathode part and the anode part are simultaneously compressed; the cathode part consists of a cathode case, a cathode sleeve, a cathode and a cathode fastening ring; each part is sequentially connected; the cathode compression ring is in contact with the cathode sleeve and is fixedly connected with the cathode case; the powder feeding part consists of a power feeding pipe and a powder feeding spray nozzle which are sequentially and fixedly connected. The excellent characteristics of good jet flow controllability, high enthalpy value, long jet flow length and the like of the laminar plasma are utilized for realizing the spheroidization on powder; the treated powder has the advantages of high spheroidization rate, high uniformity and the like.

Owner:SICHUAN UNIV

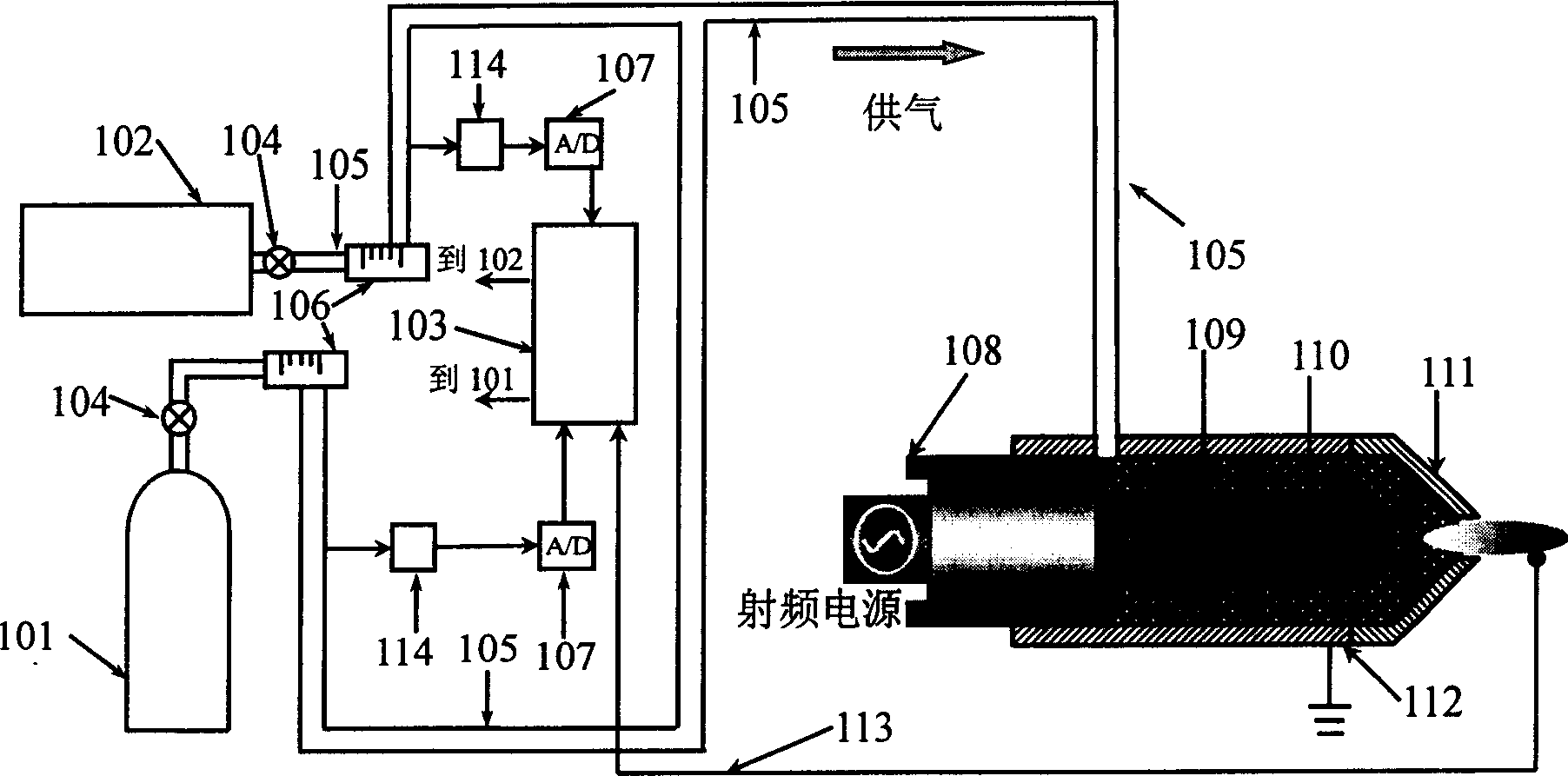

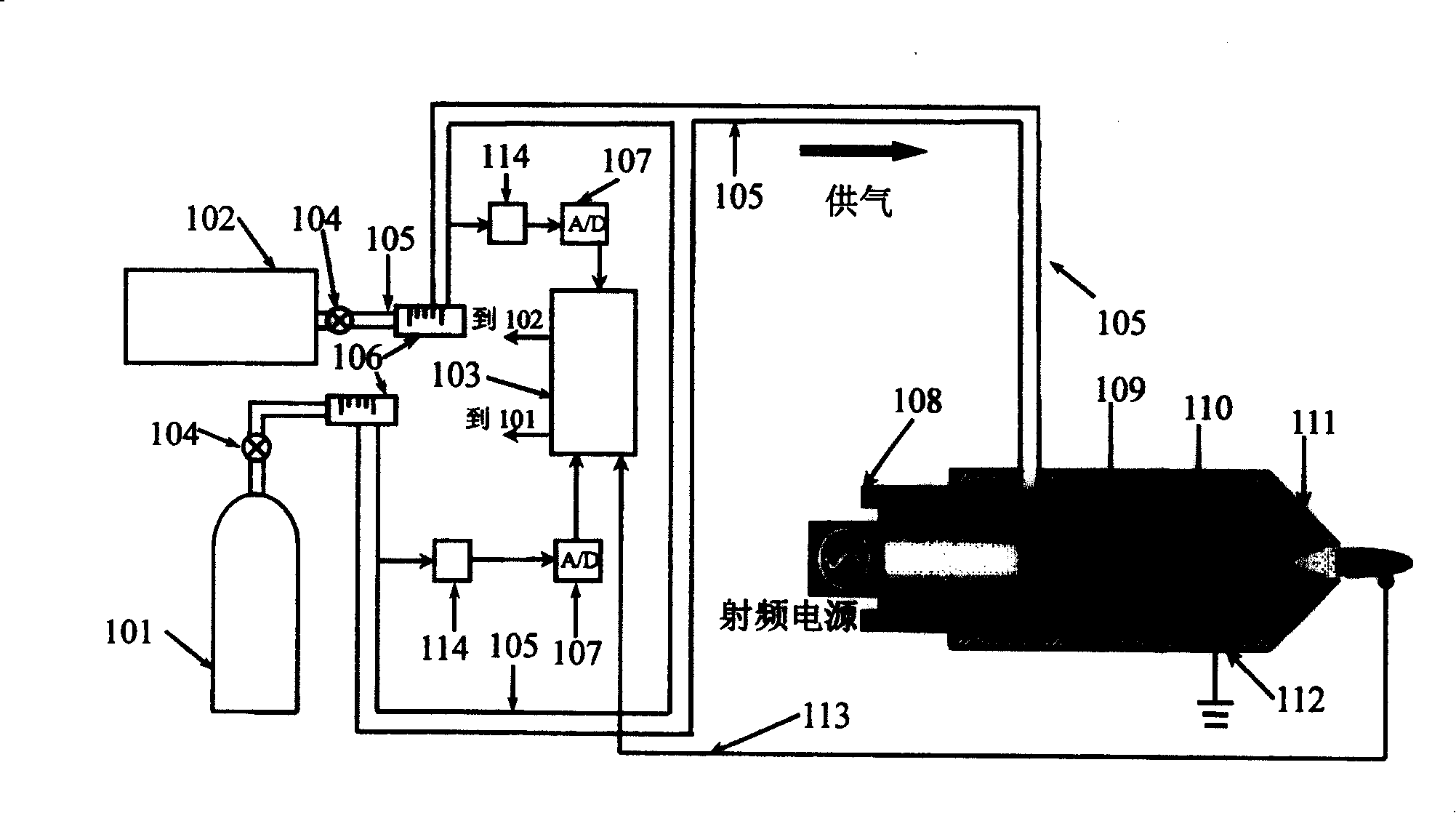

Atmospheric pressure discharge cold plasma generator based on double gas source

The present invention belongs to atmospheric pressure discharge cold plasma generator technology field. It features said generator gas supply system adopting double gas source gas supply system and uncover electrode structure, thereby constituting flat plate type or circle type or elliptic type atmospheric pressure discharge cold plasma generator. Said double gas source gas supply system can realize stabilizing gaseous discharge unable realized in inducing air or other atmospheric pressure, uncover electrode structure capable of avoiding electrode surface dielectric medium damage in current media blocking discharge.

Owner:TSINGHUA UNIV

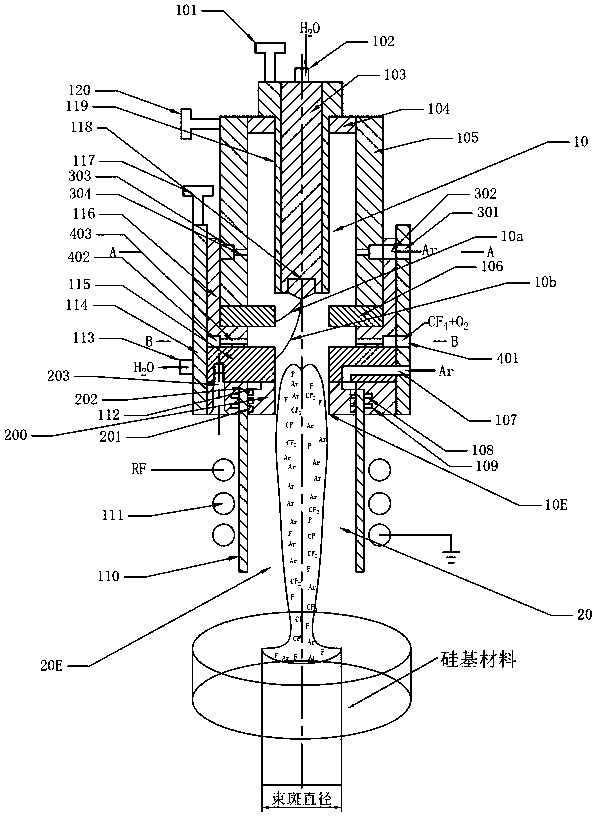

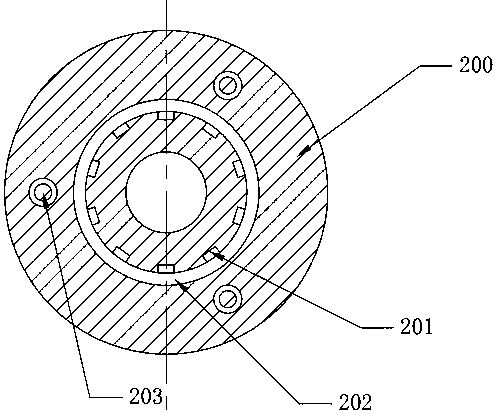

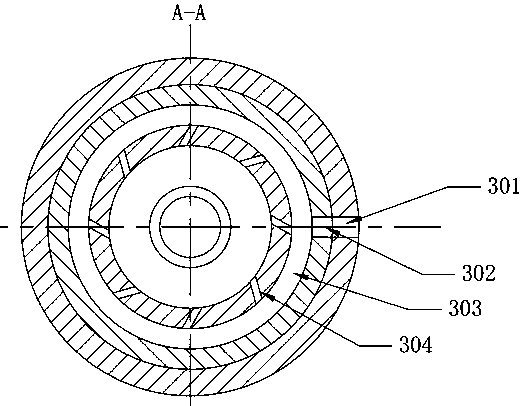

Hybrid plasma generator for processing silicon-based material

A hybrid plasma generator for processing a silicon-based material comprises a DC plasma generator and a radio frequency induction coupling plasma generator. Compared with a conventional radio frequency coupling plasma generator for processing the silicon-based material, the hybrid plasma generator has the following remarkable advantages that 1, the processing efficiency is high, arc plasma jet issimulated secondarily under an effect of an induction coil magnetic field, more energy is obtained within unit time to simulate working gas, so that the number of reaction active particles in unit volume is increased; 2, the ignition process is optimized, ignition is completed through an electric spark generated by a negative electrode part and a positive electrode part, and the problem that a quartz glass tube is easy to damage during the ignition process of a traditional radio frequency induction coupling plasma generator is solved; and 3, the surface quality of the silicon-based material after being processed is improved, the plasma jet with constant beam spot diameter is maintained for a long time under the condition that a setting parameter is not changed, and the certainty processingof a material surface is achieved.

Owner:SICHUAN UNIV

Gliding arc discharge plasma jet generation device and method thereof

The invention discloses a gliding arc discharge plasma jet generation device and a method thereof. The device comprises a plasma generator, an external power supply and an external gas source, wherein the plasma generator comprises a tubular external electrode with a tapered outlet, a central electrode and a hollow insulated supporting column. The device is mainly characterized in that the tubular external electrode has a forming and processing design which integrates a cavity body, a tapered nozzle, a gas inlet and a grounding electrode as a whole, and due to the tapered nozzle structure, arc striking is controlled to only happen at the outlet, and a beam current role is played; the external gas source is air or oxygen, and the air can be provided by an air compressor in the field. Under effects of high voltage, the plasma generator performs discharge and arc striking at the narrowest distance place between two electrodes and jetting out of the cavity under driving of a certain velocity of air or oxygen is carried out to form plasma jet. Different working parameters can be provided in view of different processing objects and application fields.

Owner:GANNAN NORMAL UNIV

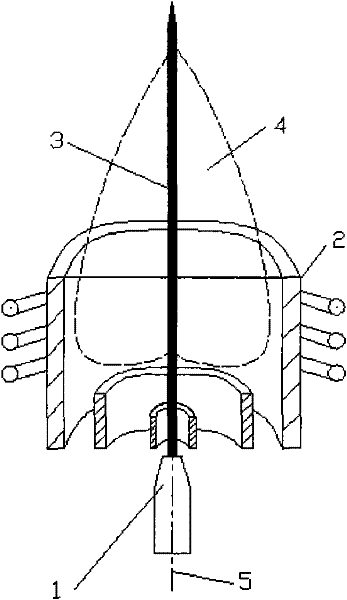

Ammonia-hydrogen fusion type hybrid power system and engine

ActiveCN114412668AStable combustionBurn quicklyInternal combustion piston enginesFuel supply apparatusCombustion chamberThermodynamics

The invention relates to the technical field of ammonia fuel engines, and provides an ammonia-hydrogen fusion type hybrid power system and an engine. The ammonia-hydrogen fusion type hybrid engine includes: a fuel tank for storing liquid ammonia, the fuel tank including a discharge port; the ammonia catalysis hydrogen production device is used for catalyzing ammonia gas to form hydrogen and comprises an ammonia inlet and a hydrogen outlet, and the ammonia inlet is connected with the discharge port; the ammonia fuel engine comprises a main combustion chamber, a jet ignition cavity and an ignition device, the main combustion chamber is connected with the discharge port, the hydrogen discharge port is connected with the jet ignition cavity, the ignition device is arranged in the jet ignition cavity, and the jet ignition cavity is communicated with the main combustion chamber. Combustion hydrogen can form jet flames and enter the main combustion chamber, and ammonia mixed gas is stably ignited. The hydrogen flame jet flow has multiple ignition sites and can form free radicals such as OH <-> with high concentration in the main combustion chamber, the combustion speed of ammonia mixed gas can be increased, and therefore stable ignition and rapid combustion of ammonia gas are achieved.

Owner:TSINGHUA UNIV

Composite bionic surface jet nozzle

A composite bionic surface jet nozzle is mainly composed of a truncated-cone-shaped contraction section and a circular-tube-shaped outlet section, the inner wall of the truncated-cone-shaped contraction section is a composite bionic surface composed of bionic sharkskin resistance reduction surfaces and bionic super-hydrophobic surfaces, the sharkskin resistance reduction surfaces are rectangular protrusions, long edges of the multiple identical rectangular protrusions are adjacent, in addition, the rectangular protrusions are distributed in the circumferential direction of the inner surface ofthe jet nozzle, and discontinuous bionic sharkskin resistance reduction convex rings are formed; the bionic super-hydrophobic surfaces are circular protrusions which are the same as the bionic sharkskin resistance reduction protrusions in height, the multiple circular protrusions which are the same as the bionic sharkskin resistance reduction convex rings in quantity are also distributed in the circumferential direction of the inner surface of the jet nozzle, discontinuous bionic super-hydrophobic convex rings are formed, and the bionic sharkskin resistance reduction convex rings and the bionic super-hydrophobic convex rings are sequentially arranged on the inner surface of the truncated-cone-shaped contraction section of the jet nozzle at intervals. According to the composite bionic surface jet nozzle, liquid resistance during jetting can be effectively reduced, thus, stable liquid jetting is achieved, the jetting distance is increased, and the energy saving effect is achieved.

Owner:YANSHAN UNIV

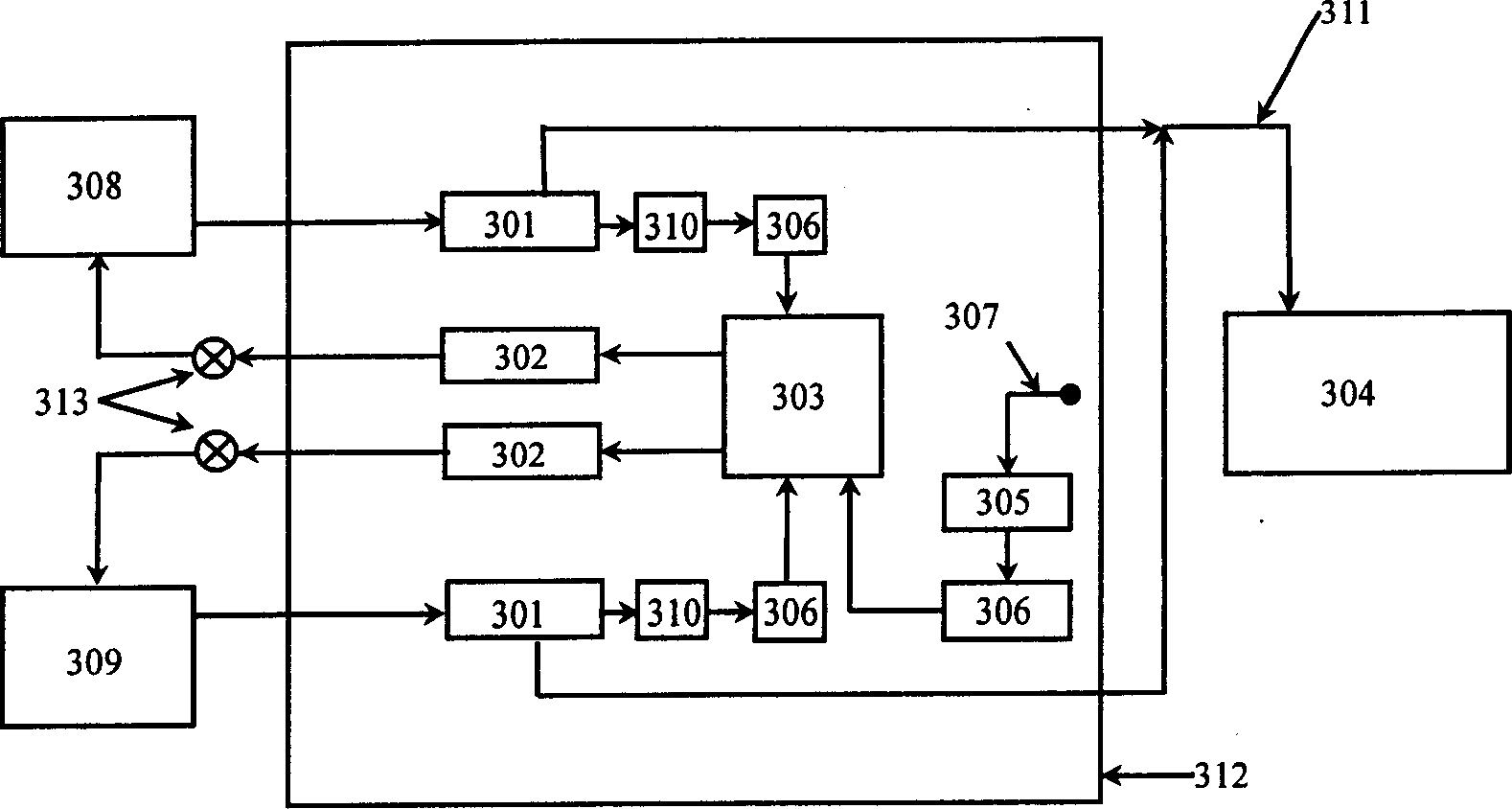

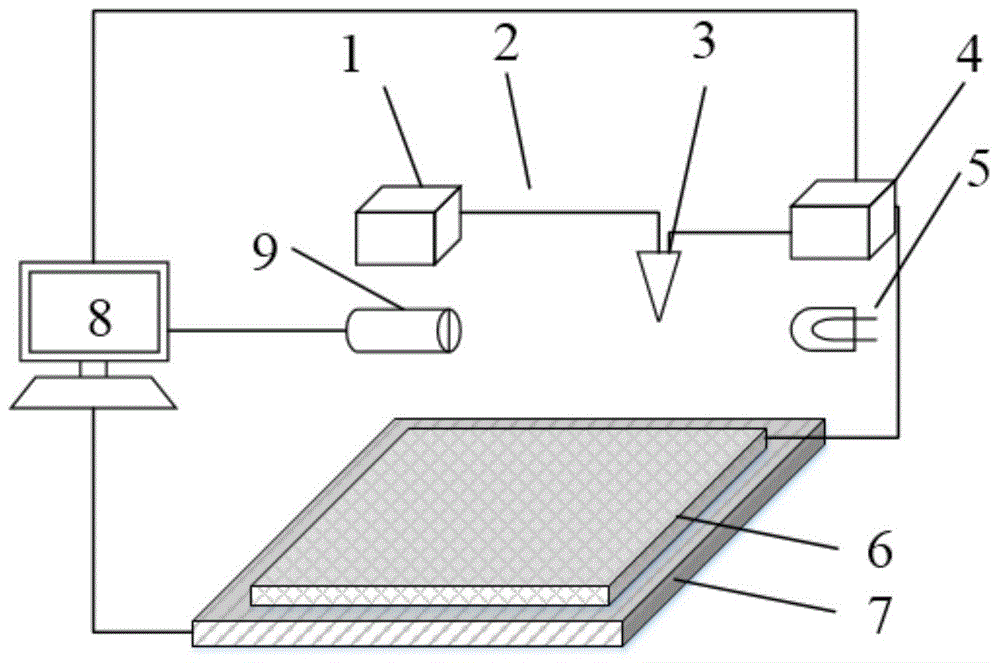

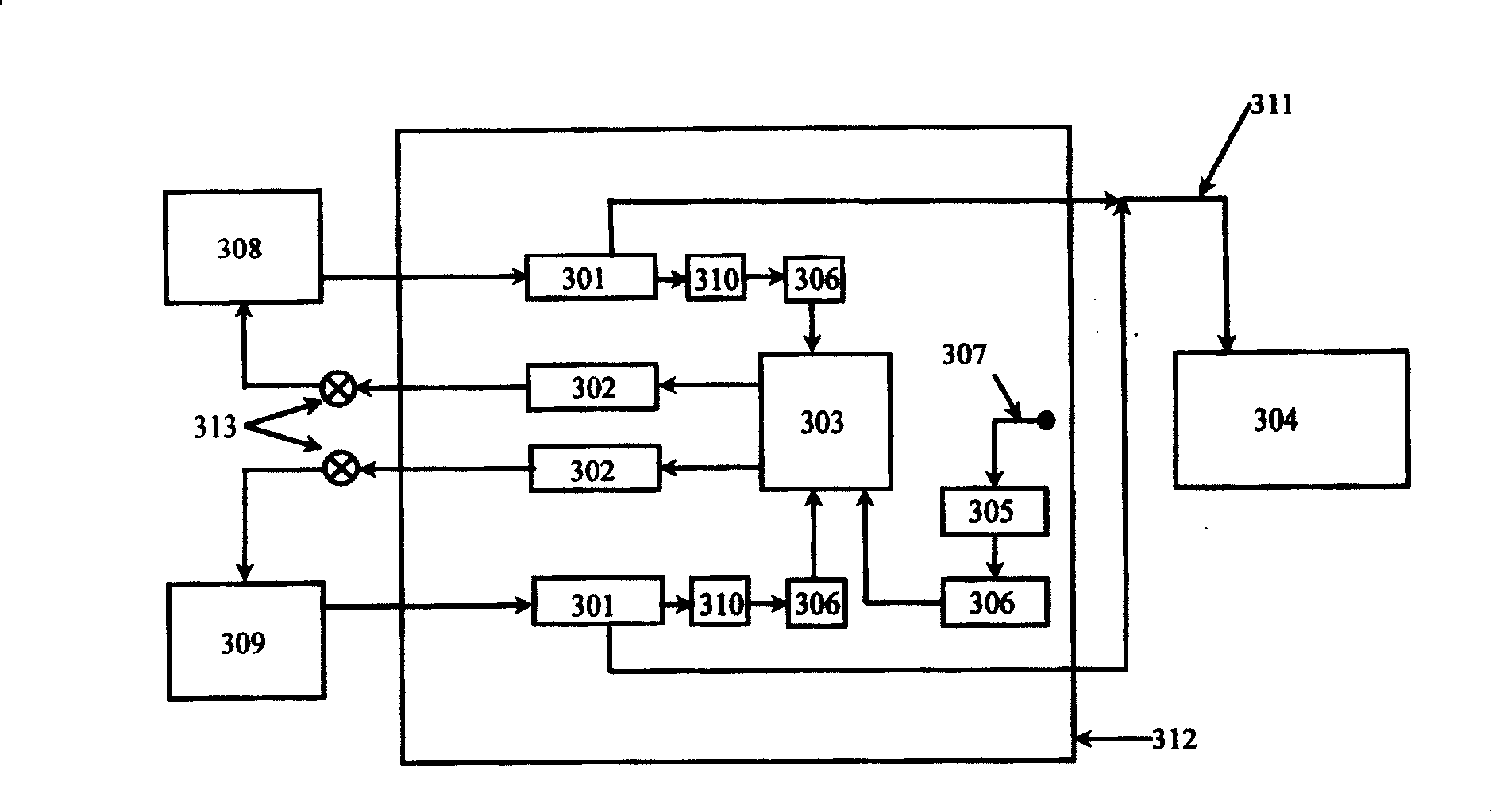

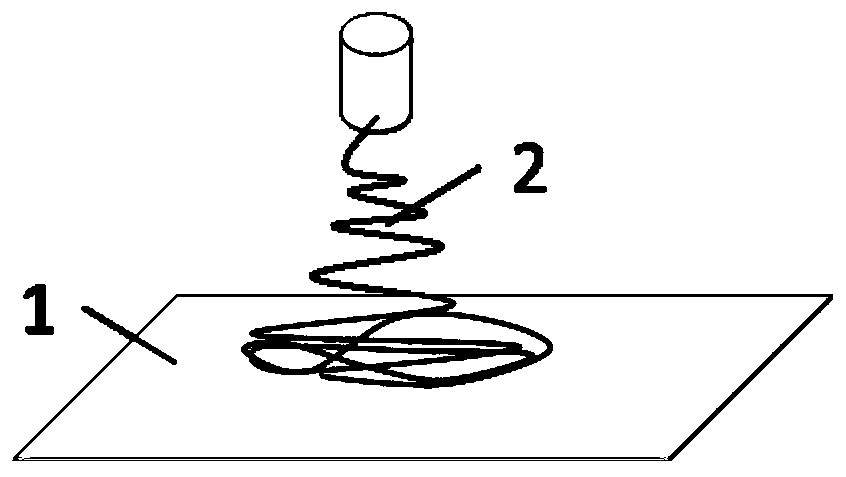

Closed-loop control method for electrospining direct writing technology

InactiveCN104309338AEffective removal of interferenceEliminate distractionsSpinning head liquid feederFilament manufactureFiberLoop control

The invention discloses a closed-loop control method for electrospining direct writing technology, according to the fluid change at actual spraying time, the liquid at the nozzle is divided into taylor cone and jet flow for control, the high speed camera is used for detecting the form, the end information is directly fed back to the controller for adjusting and controlling the substrate movement speed and spraying voltage impacting the jet flow and taylor cone, having closed-loop control to the electrospining direct writing technology, controlling the fiber morphology and diameter and preparing high precision array pattern.

Owner:HUAZHONG UNIV OF SCI & TECH

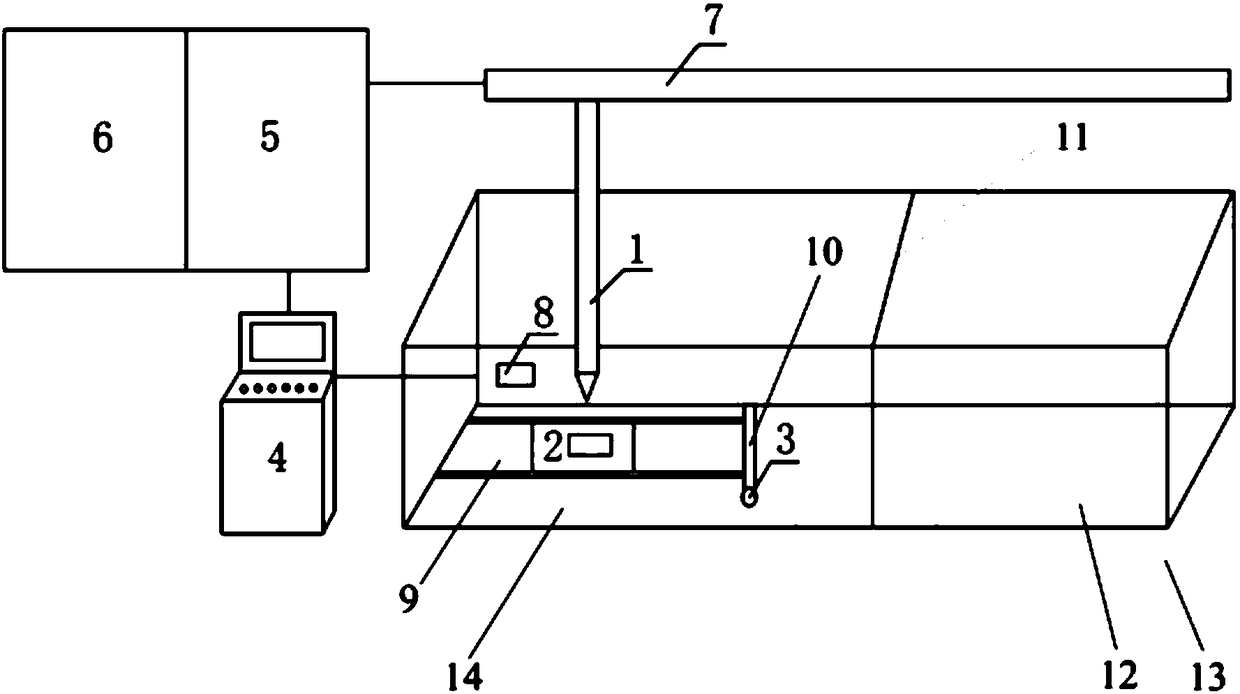

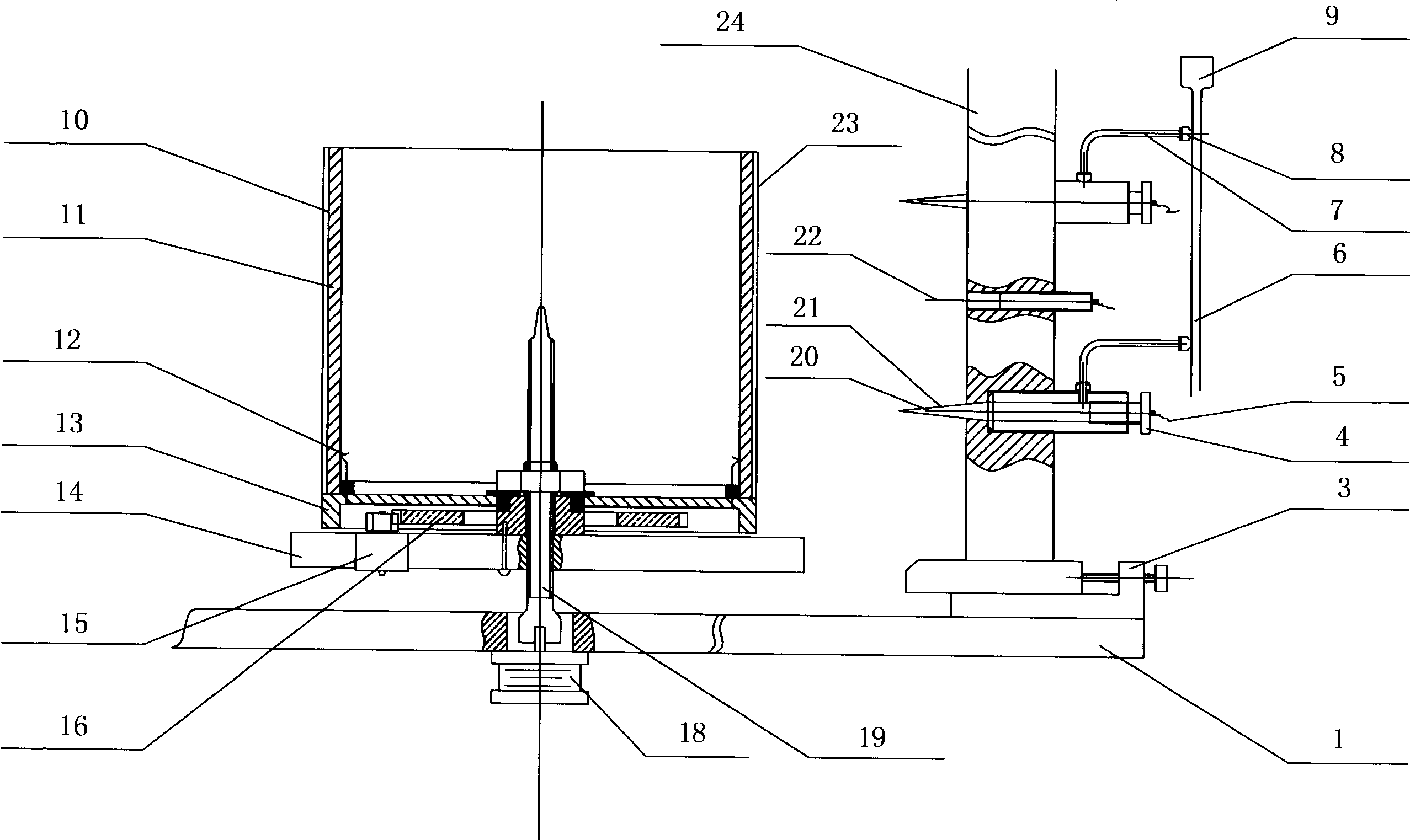

Cavitation water jet impact strengthening device

ActiveCN108330265AFlexible adjustment of different water volumesSmooth and controllable rotationWater jetEngineering

The invention provides a cavitation water jet impact strengthening device. The cavitation water jet impact strengthening device comprises a water tank (13), a spray gun (1), a high-pressure device (5)and a low-pressure device (6). The spray gun (1) is arranged to be immersed into water in the water tank (13) so as to spray a sample (2) to be treated, the high-pressure device (5) and the low-pressure device (6) supply pressure water to the spray gun (1), and the low-pressure device (6) is provided with a cavitation gain increasing equipment. According to the cavitation water jet impact strengthening device, surface treatment can be carried out on the material, and observation and the treatment process control are facilitated.

Owner:STATE POWER INVESTMENT CORP RES INST

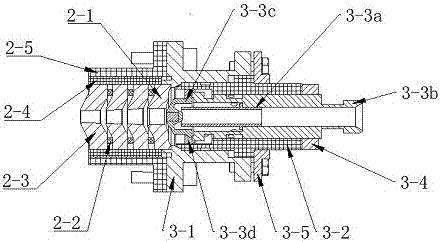

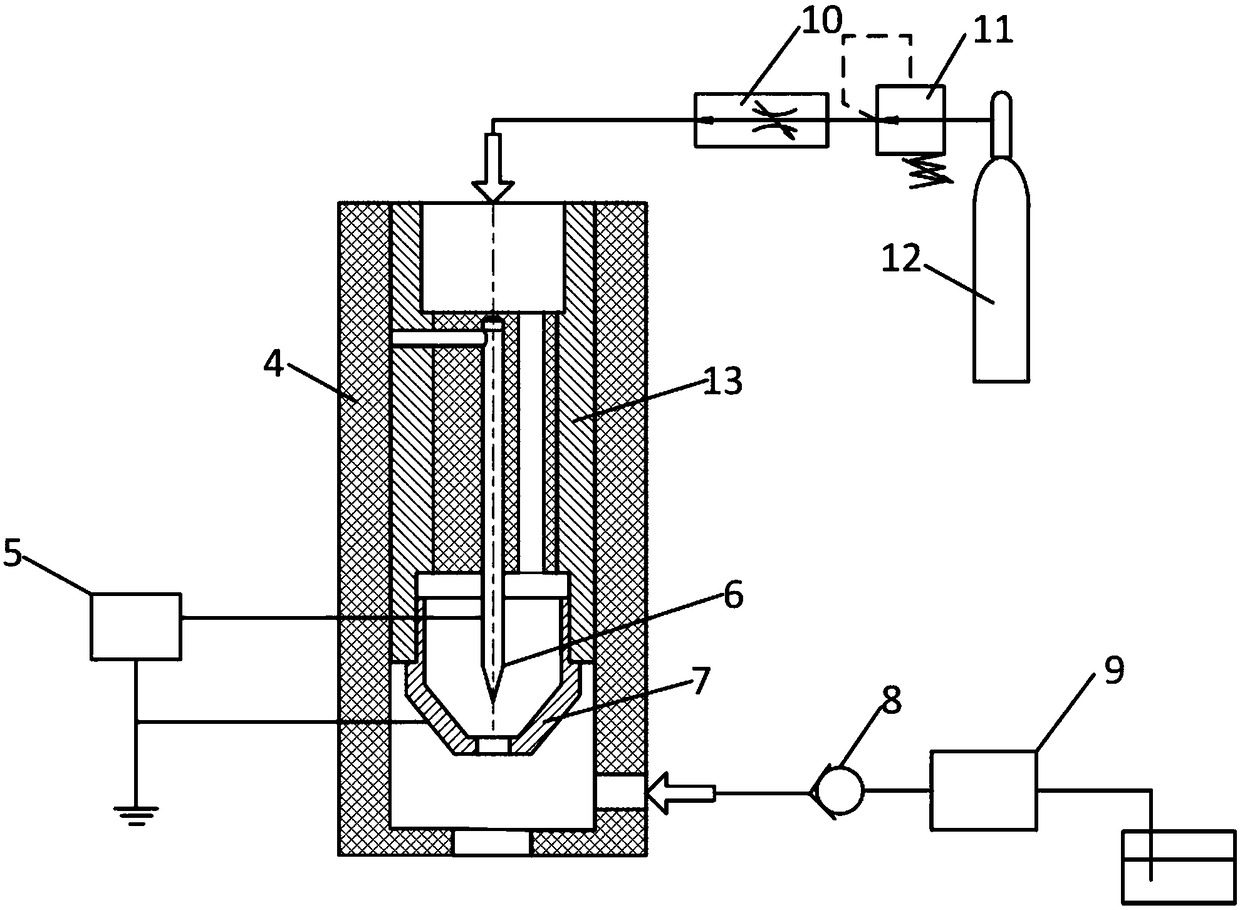

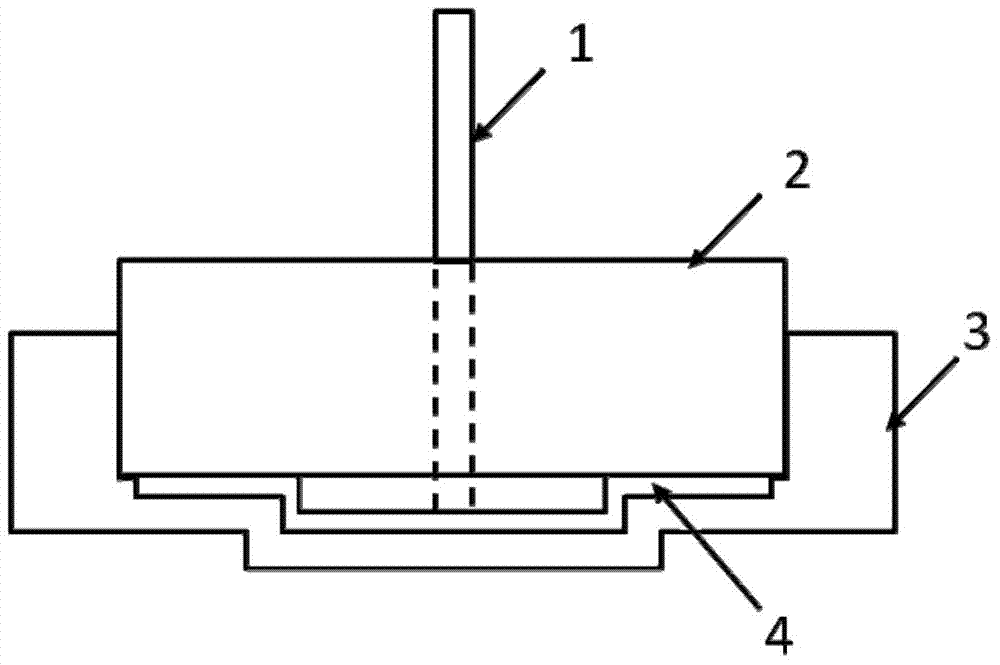

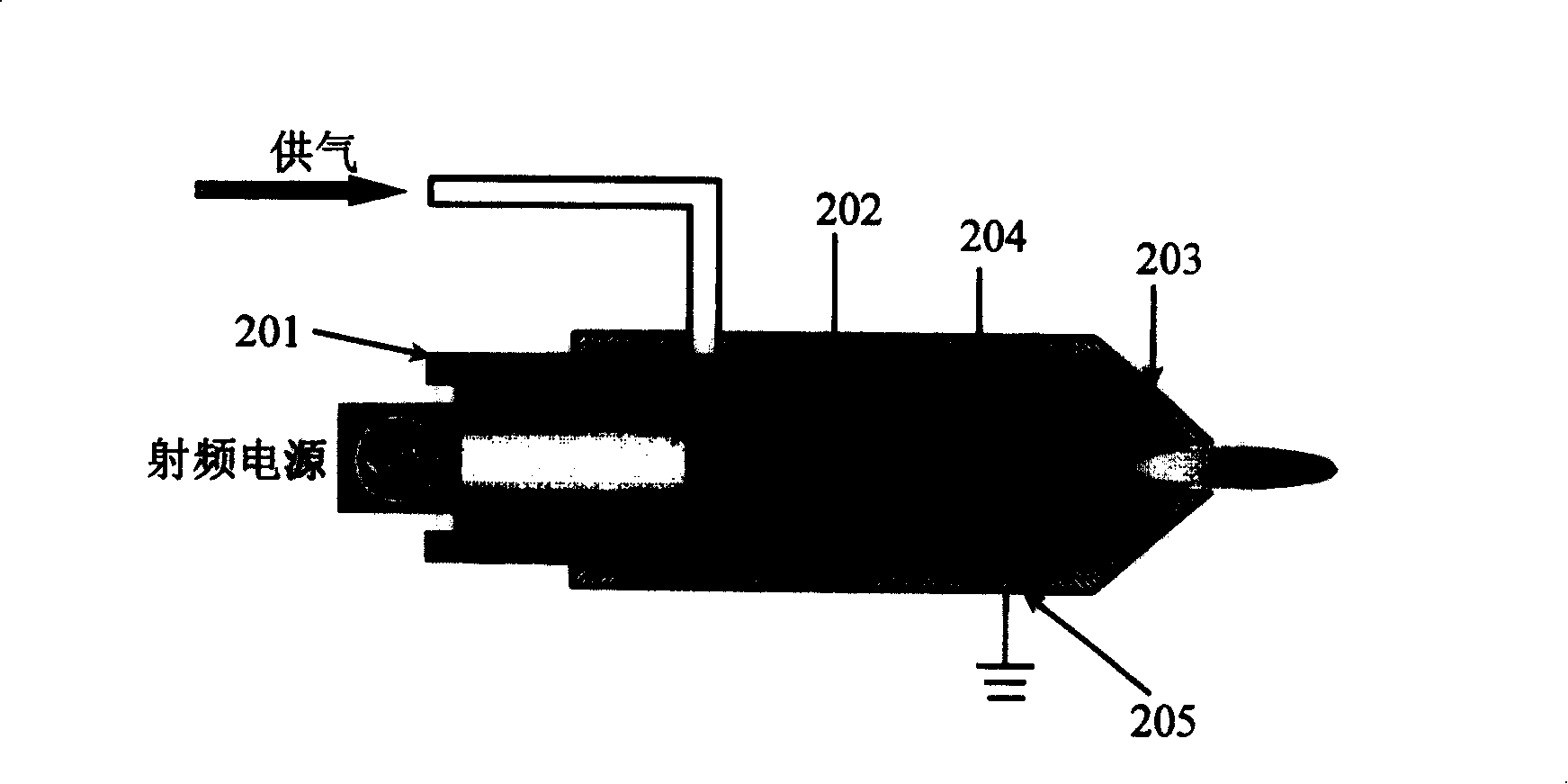

Atomizing cold plasma jet generation device

The invention discloses an atomizing cold plasma jet generation device, which comprises a gas supply system, an atomizing system, a high-voltage power supply, a cold plasma jet generation device and acylindrical outer shell, wherein the cold plasma jet generation device is mounted in the cylindrical outer shell, and the cold plasma jet generation device and the cylindrical outer shell are coaxial; the gas supply system inputs working gas into the cold plasma jet generation device from the tail part; the high-voltage and low-voltage output ends of the high-voltage power supply are connected with electrodes of the cold plasma jet generation device; the atomizing device inputs atomized liquid into the interior of the cylindrical shell; when the cold plasma jet generated by the cold plasma jet generation device is ejected, negative pressure is generated inside the cylindrical outer shell, the atomized liquid is introduced into the cylindrical outer shell and is mixed with the cold plasmajet to form the atomized cold plasma jet, and the atomized cold plasma jet is ejected at an outlet of the cylindrical outer shell. Uniform and stable atomized cold plasma jet is obtained by the atomizing cold plasma jet generation device, and the hydrophilic modification effect of the plasma on the solid surface and the cooling and lubricating effects of the cutting contact area in the cutting process are favorably improved.

Owner:DALIAN UNIV OF TECH

Liquid-magnetization-based high-concentration gas-liquid two-phase mixed atomizer

InactiveCN106694268AReduce usageImprove solubilityLiquid spraying apparatusHigh concentrationMagnetization

The invention discloses a liquid-magnetization-based high-concentration gas-liquid two-phase mixed atomizer. The liquid-magnetization-based high-concentration gas-liquid two-phase mixed atomizer comprises a liquid inlet pipe, a liquid speed adjusting valve, a laval pipe, a magnetization mixer, a primary atomizer, an atomization nozzle, a compressed air pipe and a gas distribution valve. The liquid inlet pipe communicates with the liquid speed adjusting valve, the laval pipe, the magnetization mixer, the primary atomizer and the atomization spray head sequentially. The novel structure is reasonable in design and convenient to use, dissolution of ozone in water can be increased in a magnetized water mode, and thus the concentration of ozone water is increased so as to ensure the disinfection effect. The atomization effect is ensured in a secondary atomization mode, meanwhile, due to arrangement of a rotational flow channel, jet flow at a nozzle is stable, speed fluctuation is not generated, and the equipment cost is reduced.

Owner:合肥九州龙腾科技成果转化有限公司

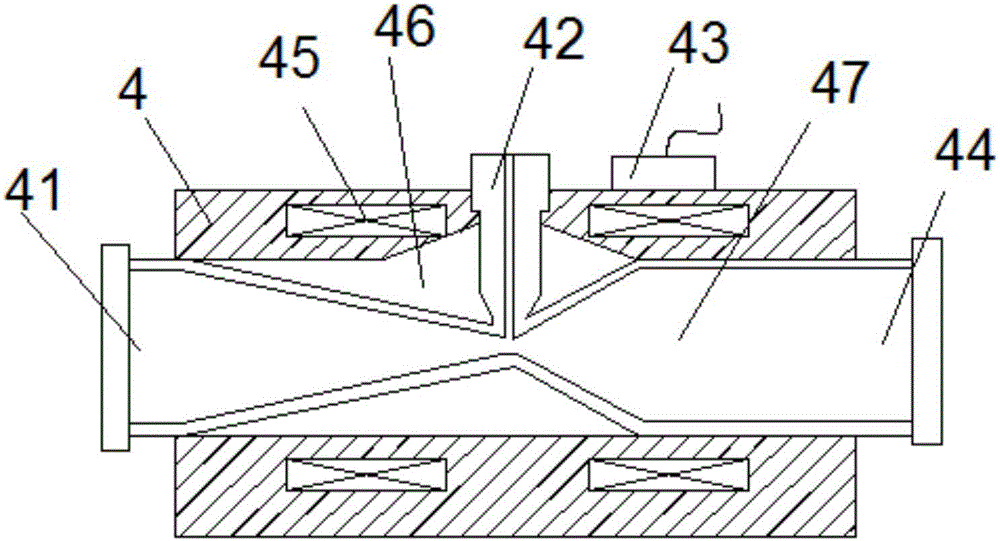

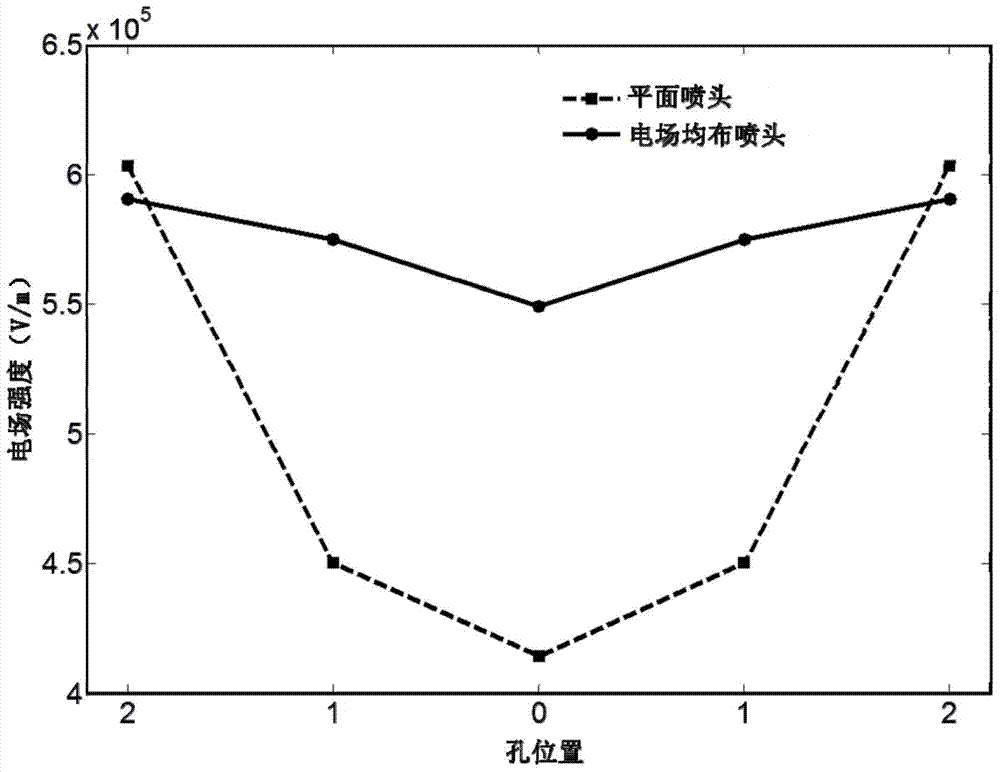

Multi-jet-flow electrostatic spinning sprayer with uniformly distributed electric fields

InactiveCN103668482AEliminate electric field repulsionGood for collectionSpinnerette packsElectric fieldMultiple stages

The invention relates to a multi-jet-flow electrostatic spinning sprayer with uniformly distributed electric fields. The multi-jet-flow electrostatic spinning sprayer with the uniformly distributed electric fields comprises a solution injection tube, a spinneret plate and an electrode. The spinneret plate is a step-shaped spinneret plate formed by overlaying small circular truncated cones on multiple stages of hollow circular truncated cones, and the upper bottom surface of each stage of circular truncated cone is provided with spinneret orifices. The electrode is consistent with a hollow cavity of the spinneret plate in shape, and a gap is reserved between the electrode and the hollow cavity of the spinneret plate to form a solution cavity. The spinneret plate is made of hydrophobic insulation materials. According to the multi-jet-flow electrostatic spinning sprayer with the uniformly distributed electric fields, holes are formed in the hydrophobic insulation materials so that traditional metal needles can be replaced, electric field rejection between the needles is avoided, the rejection effect of jet flow sprayed out from the spinneret plate is weakened, and therefore nanofibers can be collected conveniently; in addition, the electric fields at the position of a center hole are effectively increased by the utilization of the step-shaped electrode and the spinneret plate matched with the step-shaped electrode, therefore, stable jet flow can be formed at the position of the center hole, and the nanofibers with even fineness can be obtained.

Owner:DONGHUA UNIV

Atmospheric pressure discharge cold plasma generator based on double gas source

The present invention belongs to atmospheric pressure discharge cold plasma generator technology field. It features said generator gas supply system adopting double gas source gas supply system and uncover electrode structure, thereby constituting flat plate type or circle type or elliptic type atmospheric pressure discharge cold plasma generator. Said double gas source gas supply system can realize stabilizing gaseous discharge unable realized in inducing air or other atmospheric pressure, uncover electrode structure capable of avoiding electrode surface dielectric medium damage in current media blocking discharge.

Owner:TSINGHUA UNIV

Ultrasonic plasma gun feeding powder internally

The invention discloses an ultrasonic plasma gun feeding powder internally, which is designed by adopting a parameterized structure design method in combination with a numerical simulation technique. The ultrasonic plasma gun mainly comprises a cathode, an anode, a powder feeding air flow channel, and a main air flow channel formed by matching the cathode with the anode. The mechanical compression effect of a nozzle is adjusted by changing the parameter of each pore canal in the internal compression segment and expanding segment of an anode nozzle, so that plasma jet flow in the gun is high in energy density and speed, the thermal efficiency of the gun is increased, and meanwhile the stability of arc voltage is ensured. The internal powder feeding angle is changed to an optimal position, so that heating and acceleration of sprayed powder materials are facilitated, and the problem of blocking of the gun nozzle is solved. The size of the gun is selected on the basis of an advanced computer simulation technology, so that the development period of the gun is shortened greatly, and the design cost is lowered. As proved by results, the novel gun has higher flow field characteristic than an original structure.

Owner:XI AN JIAOTONG UNIV

Machine for spinning nano-fiber for production of non-woven cloth

InactiveCN1837436AGuaranteed uniformityEasy to adjustFilament/thread formingNon-woven fabricsNanofiberLiquid tank

This invention discloses a nonwovens spinning machine of nanometer fibre, which mainly includes the high pressure power set, the liquid tank of spinning fluid, receiving device, and at least one group of spinning components. Said liquid tank of spinning fluid is connected with spinning pipe of spinning components by pumps, wherein receiving device including a cylinder vertically disposited on movement devices and metal receiving netting disposited on the cylinder excircle in circle, the movement device having rolling degree of freedom that revolution axis is paralleled with z axis and translation degree of freedom; each group of spinning components including spinning component shelf and at least two spinning pipes fixed on the shelf, the pipe having electric electrode in it, the distance between the spout of the pipe and metal receiving netting is 5-25 centimeters; mounting an isolated electrode between adjacent spinning pipes. The invention comprises the following merits: assuring uniformity of product obtained, avoiding the disturbance of electric field of adjacent spinning pipes, preventing unsteadiness in spinning and inhomogeneity of fibre dispersion.

Owner:SUZHOU UNIV +1

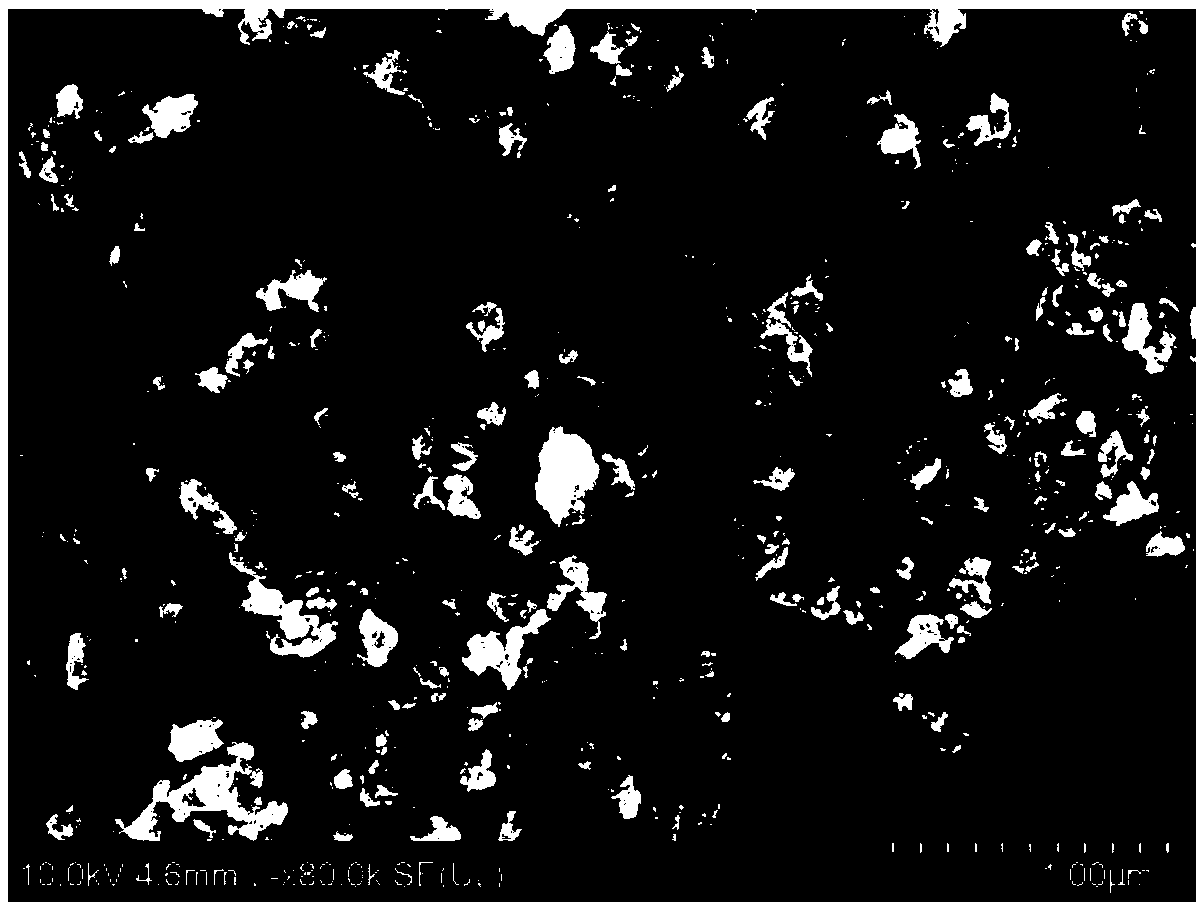

Ultrahigh-temperature thermal barrier coating hollow-structured powder, preparation and application methods thereof and ultrahigh-temperature thermal barrier coating

The invention relates to an ultrahigh-temperature thermal barrier coating hollow-structured powder, preparation and application methods thereof and an ultrahigh-temperature thermal barrier coating andbelongs to the field of materials. The preparation method of the ultrahigh-temperature thermal barrier coating hollow-structured powder comprises mixing gadolinium zirconate materials, dispersant andbonder and performing spray pelletizing to obtain micron-sized agglomerated powder. The preparation method of the ultrahigh-temperature thermal barrier coating hollow-structured powder is rapid in drying process, high in production efficiency, capable of directly drying powder, simple in technological parameter adjustment, large in productivity and high in product quality. The prepared ultrahigh-temperature thermal barrier coating hollow-structured powder is uniform in granularity, controllable in granularity distribution range, good in fluidity, easy to enter the center of plasma flames to form stable jet flows and accordingly excellent in coating applicability. When the ultrahigh-temperature thermal barrier coating hollow-structured powder is applied to producing thermal barrier coatings of engine parts, the engine parts can better adapt to severe working environments with high temperature, high pressure and strong corrosion. The ultrahigh-temperature thermal barrier coating containing the ultrahigh-temperature thermal barrier coating hollow-structured powder is high in bonding strength, uniform in pore distribution and long in thermal resistance cycle life.

Owner:GUANGDONG INST OF NEW MATERIALS

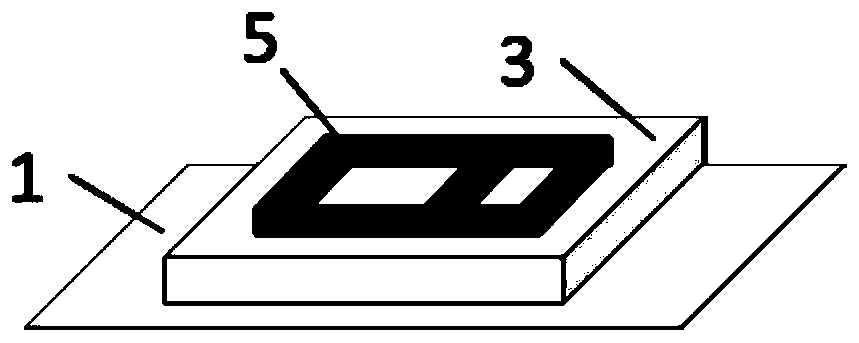

A thermal plasma arc flame generator

InactiveCN102271452AGood induction arc guidanceSimplify ignition stepsPlasma techniqueHeat flowElectric arc

The invention belongs to the technical field of high-frequency induction thermal plasma. Aiming at the problems existing in current high-frequency induction thermal plasma generation devices, such as difficulty in ignition, poor working stability, high arc maintenance power, and low efficiency, the invention provides a thermal plasma arc flame generator. The present invention includes a laminar arc thermal plasma generator [1] and a high-frequency induction thermal plasma generator [2], which is characterized in that it is injected along the central axis [5] of the high-frequency induction thermal plasma generator [2] The laminar arc thermal plasma jet [3] plays the role of arc guidance, arc maintenance and induction enhancement of the high-frequency induction thermal plasma flame [4]. The laminar arc thermal plasma jet [3] has the advantages of long jet length, small fluctuation of flow field parameters, almost no entrainment of ambient gas, long length of high temperature zone, and small axial gradient of parameters such as temperature. Adopting the technical scheme of the present invention can solve the problems of difficult ignition and easy arc breaking of the high-frequency induction thermal plasma generator, reduce the operating frequency and arc maintenance power of the high-frequency induction thermal plasma generator, and increase the Efficiency facilitates the development of higher power high-frequency induction thermal plasma generators.

Owner:四川金虹等离子技术有限公司

Preparation method of nano-metal coating powder

ActiveCN113290239ANo reunionAvoid reunionTransportation and packagingMetal-working apparatusMetal coatingCore Particle

The invention discloses a preparation method of nano-metal coating powder. The preparation method comprises the following steps that preparation of nano-core particles and preparation of the nano-metal coating powder are performed continuously, specifically, core raw materials are heated and evaporated by adopting a core particle preparation device; core raw material steam is cooled into solid nano-core particles through airflow of a working medium gas circulation system, the solid nano-core particles are conveyed to a coating device, and the nano-core particles are in a dispersed state in a nano-core particle conveying pipeline; and metal steam of a metal coating material and the nano-core particles meet in a hollow circular truncated cone-shaped coating tank with a large upper part and a small lower part, and the surfaces of the nano-core particles are uniformly and completely deposited to form a metal coating layer in the spiral descending and shrinking process, and after the metal coating layer enters a solidification tank along with air flow to be solidified, a compact metal coating layer is formed on the surfaces of the nano-core particles. In the conveying and coating process, the core particles are good in dispersity, and uniform deposition and complete coating of the coating powder on the nano-core particles can be achieved.

Owner:宁波广新纳米材料有限公司

Supersonic plasma spray gun

The invention discloses a supersonic plasma spray gun. The supersonic plasma spray gun comprises an insulating gun body, an anode nozzle which is coaxially and fixedly connected with the insulating gun body, and a cathode which is arranged in the insulating gun body and the anode nozzle, wherein the front end of the cathode is a round table; a nozzle air current channel of the anode nozzle consists of a straight channel segment which is in size fitting with a gun body air current channel of the insulating gun body, and a Laval nozzle channel segment; the front end of the cathode is positioned in the straight channel segment of the anode nozzle; and the contraction segment of the Laval nozzle channel segment is matched with the round table shape of the front end of the cathode. Both the anode nozzle and the cathode adopt special structural designs, so that an ultrasonic plasma jet speed (Ma is greater than 2.2) can be obtained at the power of less than 30KW. The nozzle and electrodes of the spray gun have long service lives; the jet flow is stable; and the cost is low.

Owner:NANJING UNIV OF SCI & TECH

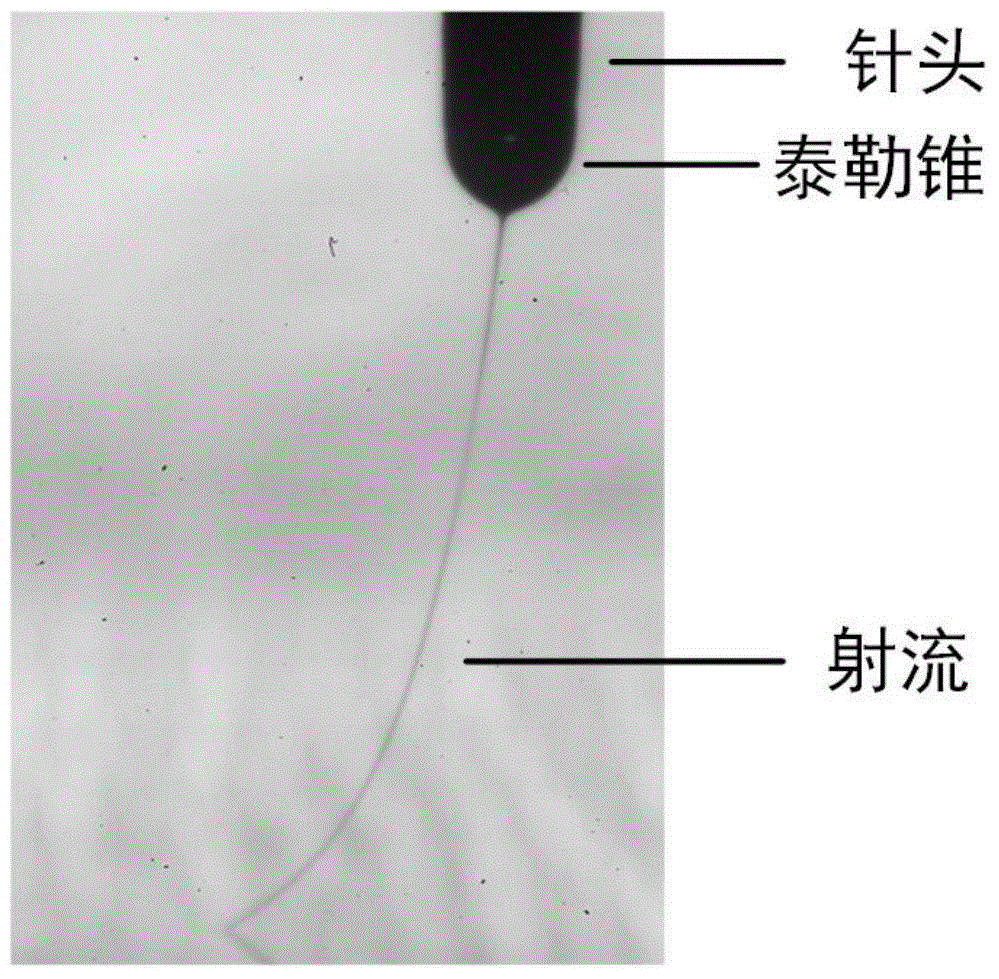

Electronic pen, printing equipment and printing method

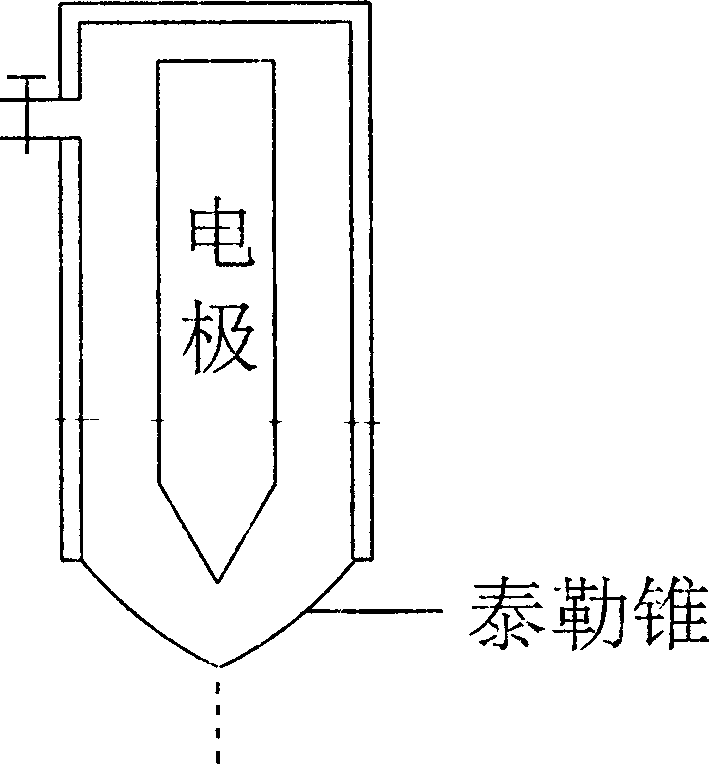

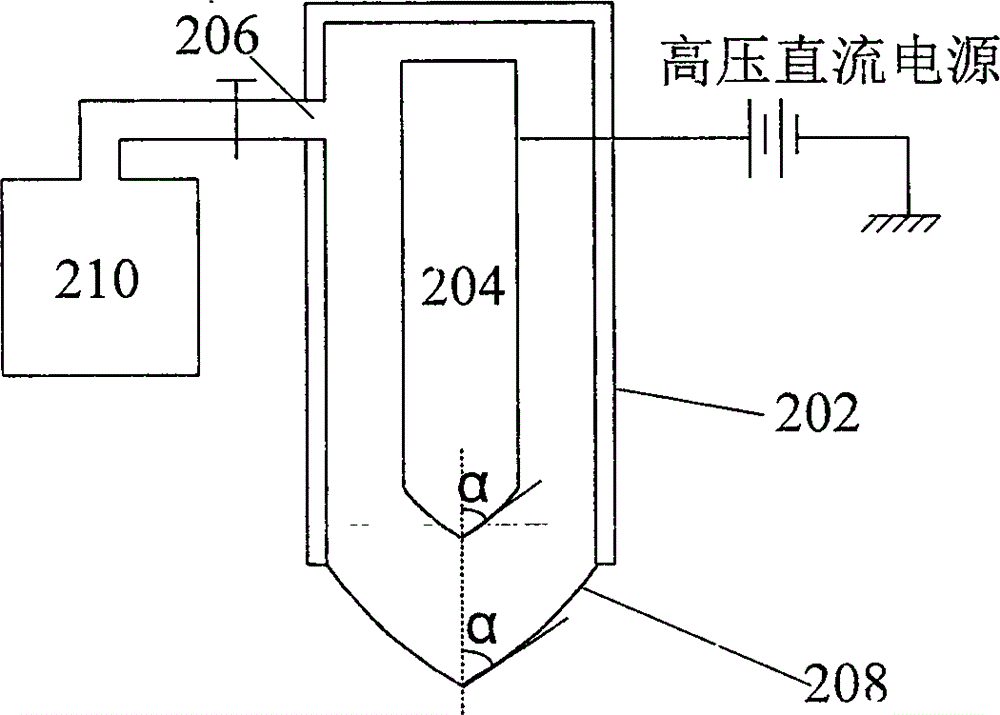

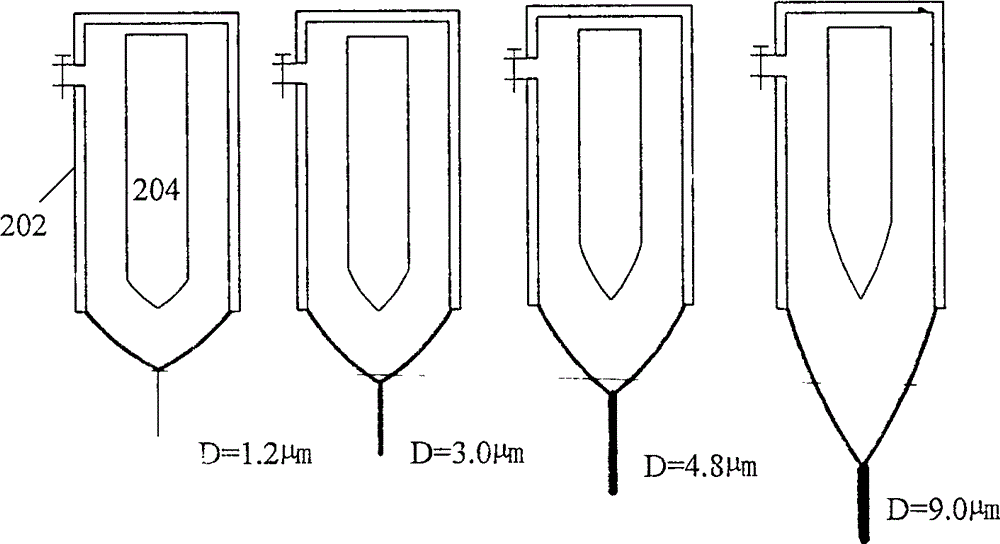

ActiveCN105291585AJet stabilizationResistance to external disturbancesTypewritersEngineeringTaylor cone

The invention provides an electronic pen, printing equipment and a printing method. The electronic pen comprises a shell body and an electrode. The shell body contains liquid and a discharging hole where the liquid is discharged is formed in the bottom end of the shell body. The electrode is located in the shell body. The end, close to the discharging hole, of the electrode is the free end. The shape of the free end of the electrode is formed to be matched with an expected Taylor cone formed in the position of the discharging hole of the liquid. A liquid thin bundle with a specific diameter can be steadily obtained through the electronic pen, and stable jet flow of the required thin bundle can be obtained when the liquid is continuously output through the discharging hole.

Owner:深圳市比欧特光电有限公司

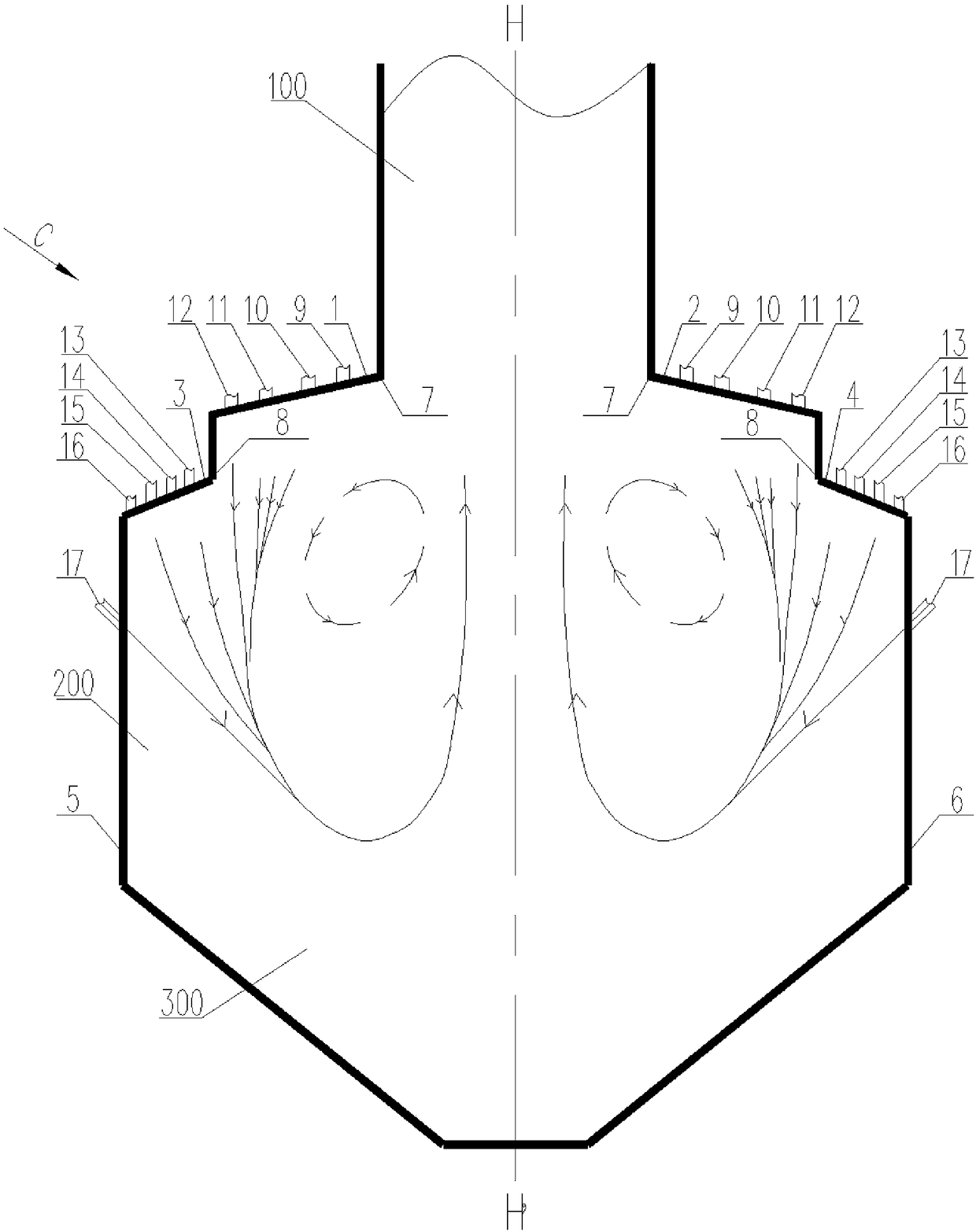

Four-arch W flame two-stage dense and thin combustion device

PendingCN108758613APromote refluxWay of increaseCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorFlue gas

The invention relates to the technical field of W flame staged combustion, in particular to a four-arch W flame two-stage dense and thin combustion device. A hearth of the device comprises an upper furnace body, a lower furnace body and a cold ash bucket, wherein the lower furnace body consists of a front upper furnace arch, a rear upper furnace arch, a front lower furnace arch, a rear lower furnace arch, a front wall and a rear wall bag. The four-arch W flame two-stage dense and thin combustion device has the beneficial effects that the ignition is stable, the space between the two sides of the jet flow of the two-stage combustor becomes large, the gas supplementing condition is good, the backflow of high-temperature flue gas is facilitated, the combustion is stable, and the heat load distribution is uniform; secondary air, dense coal powder and thin coal powder are subjected to layered injection and staged combustion after entering the hearth, so that the partial-stage concentrated community in the hearth is formed, and the air flow of the pulverized coal is reduced, the two-stage "thin-dense-dense and thin mixing" layered arrangement mode of coal power airflow is achieved, the mode of the single-layer combustor is further enhanced; and the high-efficiency low-NOx double-stage combustor and the air staged combustion technology are combined, so that the fuel reburning efficiency is improved and the emission of NOx is reduced.

Owner:CHINA SINOGY ELECTRIC ENG

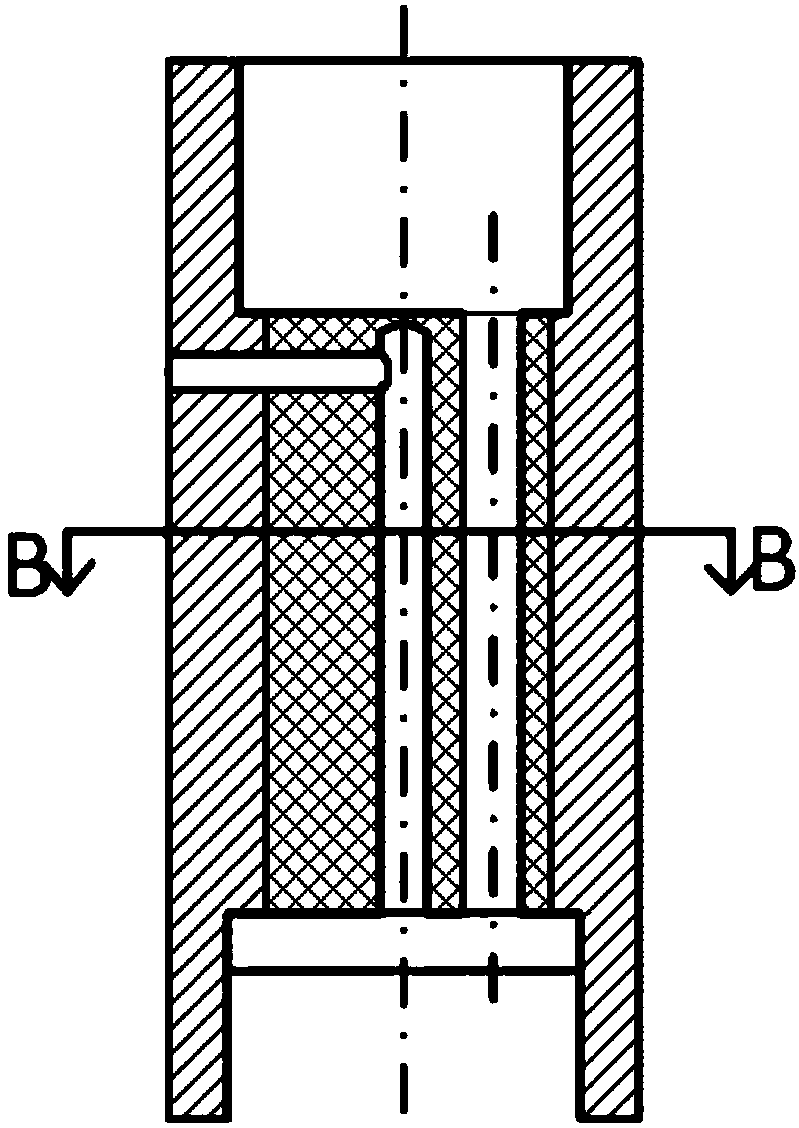

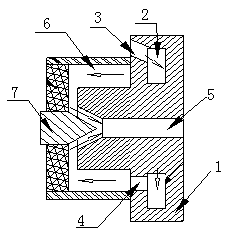

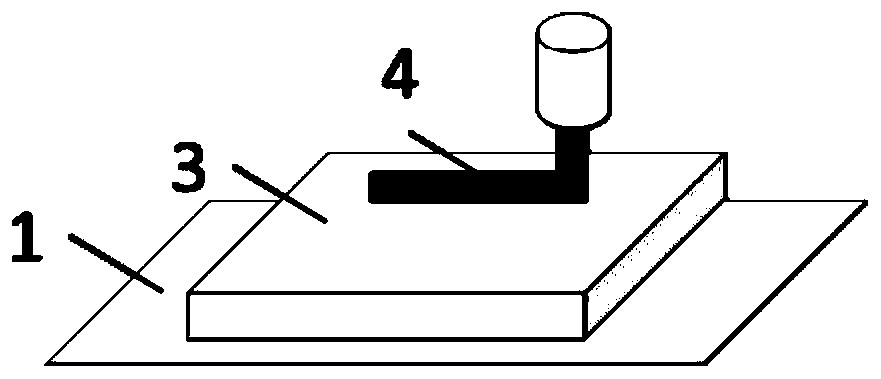

Laminar plasma jet stabilizing method

InactiveCN104602431AJet stabilizationHigh thermal efficiencyPlasma techniquePlasma jetPlasma generator

The invention discloses a laminar plasma jet stabilizing method and relates to the technical field of plasma jets. The method includes when a plasma source operates, allowing the operation gas to enter an anode member to flow into a gas channel of the plasma source and enters an arc channel finally. The method is simple, the heat released in the anode member cooling process can be utilized reasonably to heat the operation gas, the pressure of the operation gases inside and outside the arc channel can be reduced, the plasma jet can be stabilized, the self cooling of the plasma source can be implemented, the anode member energy utilization rate can be increased, energy waste can be avoided, and the heating efficiency of a high laminar plasma generator can be improved.

Owner:CHENGDU PLASMAJET SCI & TECH

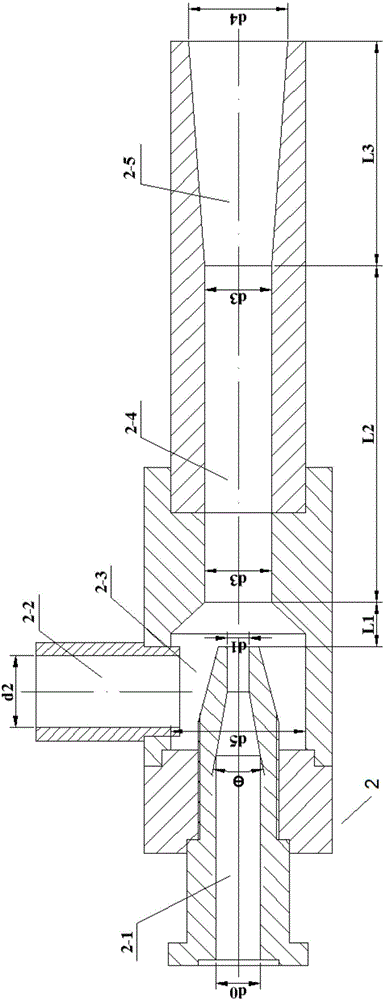

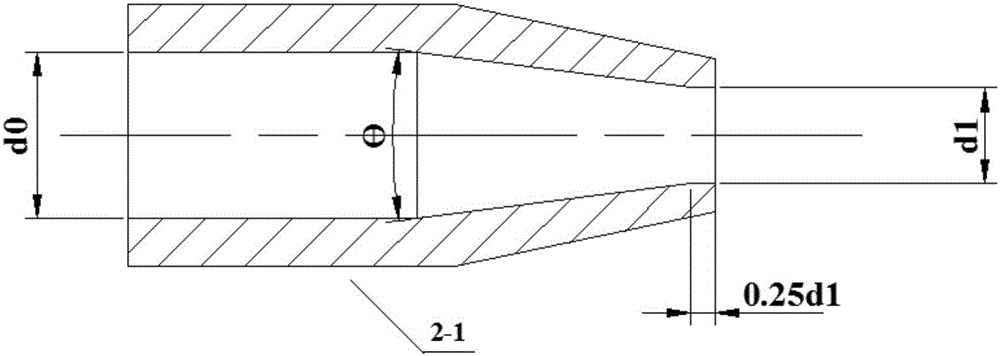

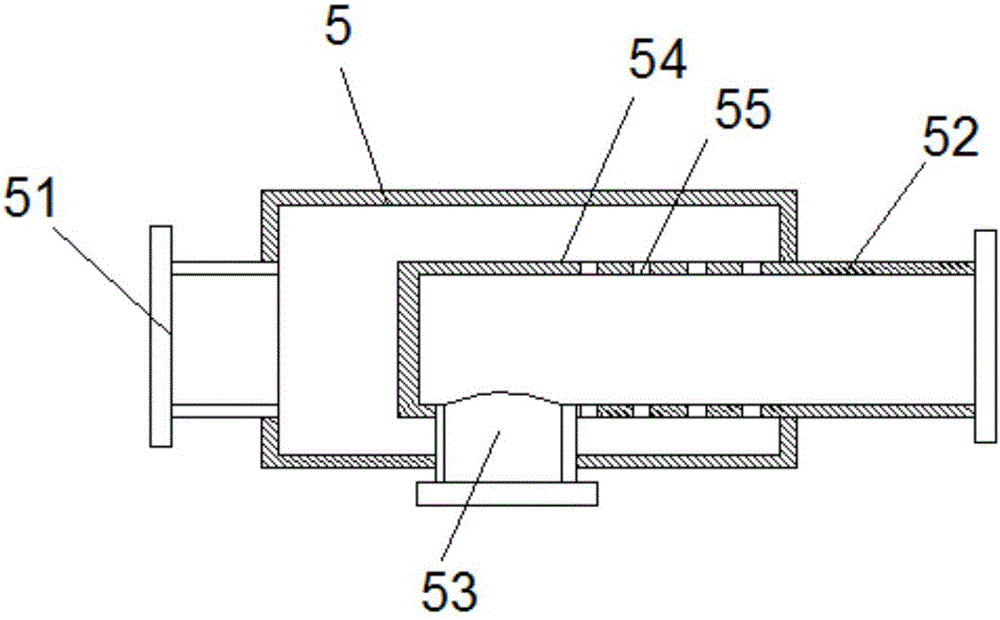

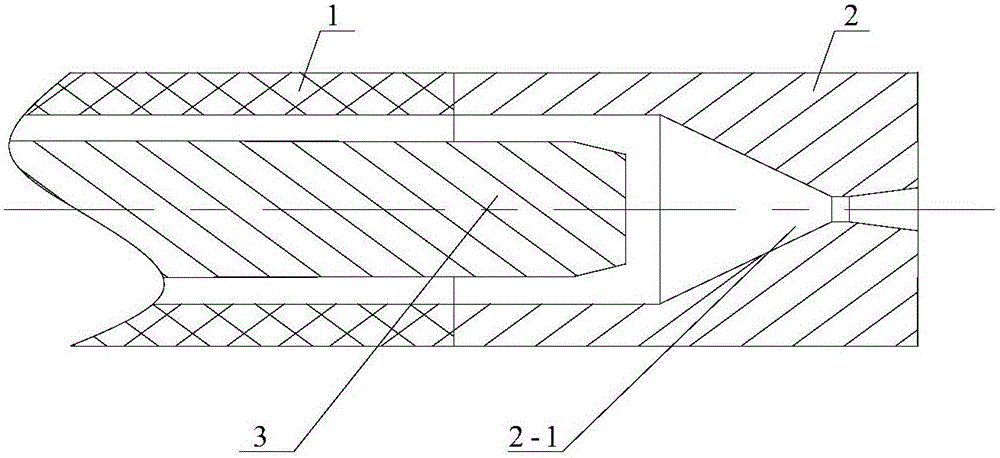

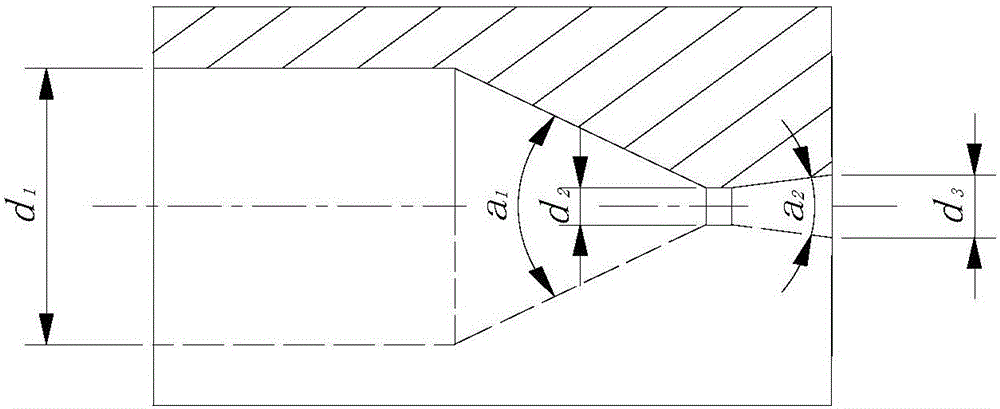

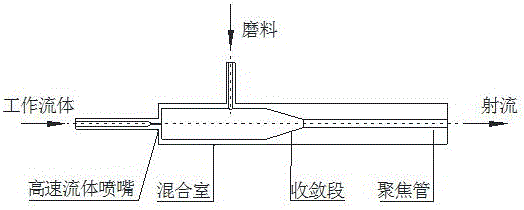

Post-mixing type abrasive water jet nozzle based on annular jet

ActiveCN106312837AReduce friction and impact wearAbrasive Waterjet StabilizationBlast gunsSpray nozzleAbrasive water jet

The invention discloses a post-mixing type abrasive water jet nozzle based on annular jet. The post-mixing type abrasive water jet nozzle comprises an annular nozzle and a secondary annular nozzle which are successively arranged from front to back, wherein a straight pipe section used for sucking abrasive is arranged at the inlet of the annular nozzle; a high-pressure water jet working fluid pipeline is arranged on the side of the annular nozzle; a convergent section and a secondary straight pipe section stretching into the inlet of the secondary annular nozzle are successively arranged at the outlet of the annular nozzle; a high-pressure water jet secondary working fluid pipeline is arranged on the side of the secondary annular nozzle; a secondary convergent section and a focusing pipe are arranged at the outlet of the secondary annular nozzle. The working fluid successively enters the annular nozzle and the secondary annular nozzle; then abrasive particles and abrasive-water mixture are sucked; the abrasive particles are mixed and accelerated; finally, the focusing pipe can form high-speed abrasive water jet. Through the post-mixing type abrasive water jet nozzle, the abrasive and the water can be efficiently and uniformly mixed; the abrasion to the focusing pipe caused by non-uniform mixing of the abrasive and the water can be reduced; the energy utilization rate can be increased; and the cutting perform of the abrasive jet can be improved.

Owner:WUHAN UNIV

Self-aligning micro spray nozzle with control grid

The invention provides a self-aligning micro spray nozzle with a control grid and relates to a spray nozzle. The self-aligning micro spray nozzle is provided with an upper layer silicon chip and a lower layer silicon chip, wherein the upper surface of the upper layer silicon chip is provided with an upper layer electrode; the upper layer silicon chip is provided with a liquid inlet; a needle tip is arranged under the liquid inlet; the inside of the upper layer silicon chip is provided with an annular positioning hole; the upper surface of the lower layer silicon chip is provided with an insulating layer and a positioning ring which is sleeve joint with the annular positioning hole in the upper layer silicon chip; the bottom of the lower layer silicon chip is provided with the control grid; and the middle part of the lower layer silicon chip is provided with a spray nozzle outlet.

Owner:XIAMEN UNIV

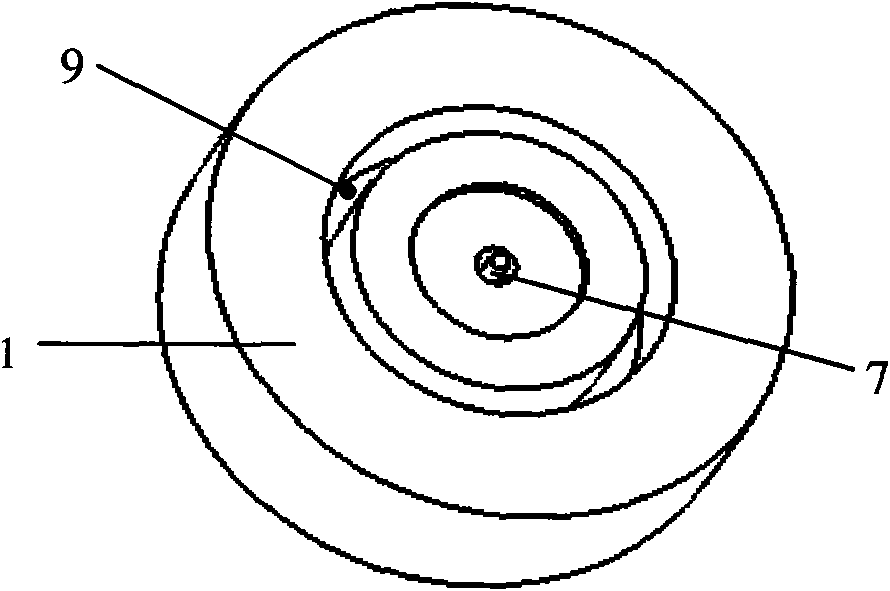

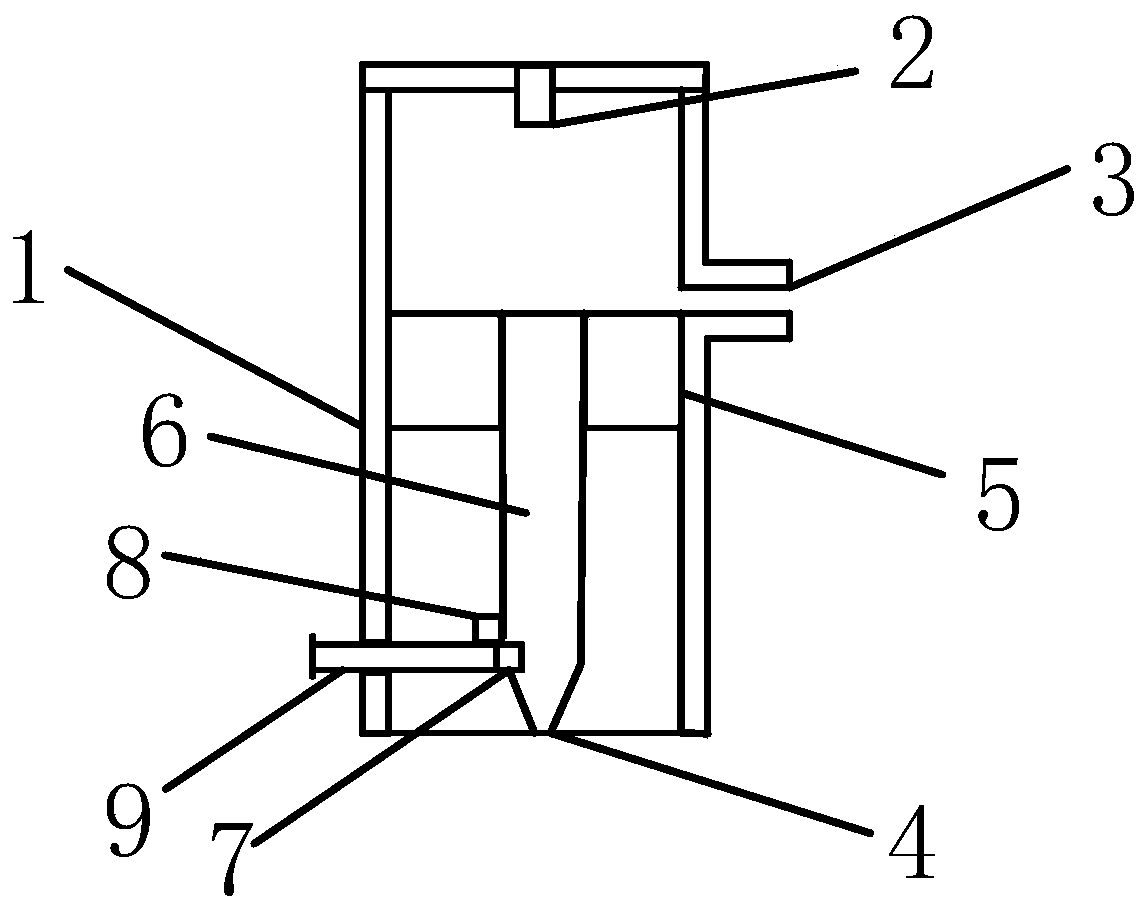

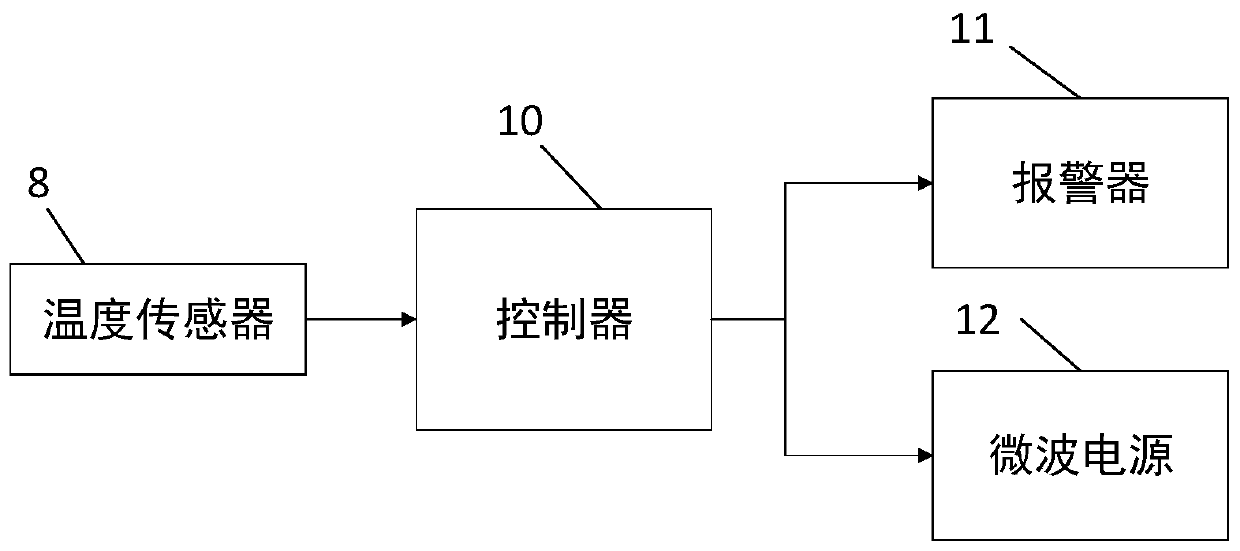

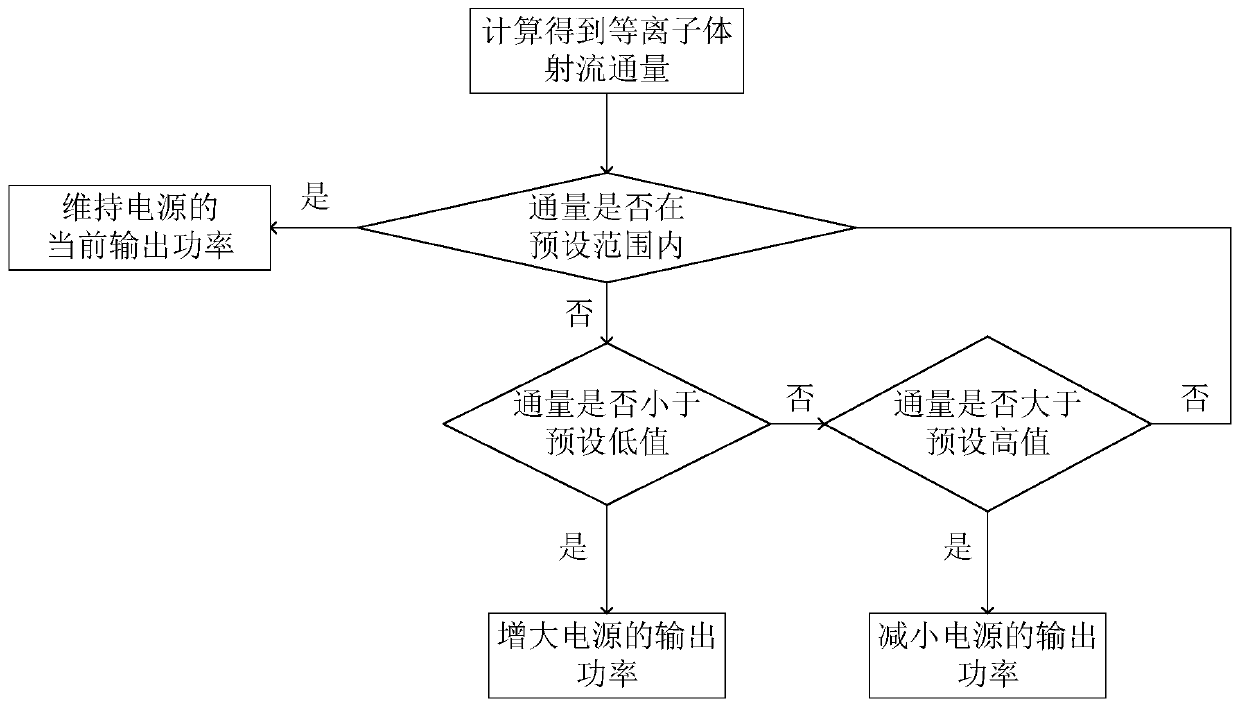

Plasma jet device

PendingCN110677969ASelf-regulating jetJet self-adjusting output stabilityVolume/mass flow by thermal effectsThermometers using electric/magnetic elementsPlasma jetEngineering

The invention relates to a plasma jet device comprising a shell. A waveguide and an inner conduit are installed in the shell. One end of the waveguide is connected with a microwave power supply. A cavity is arranged between the inner conduit and the waveguide. The cavity is provided with an air inlet which can be closed and opened. The shell is provided with a nozzle which is conducted with the inner conduit. A telescopic metal sheet is arranged at the nozzle. The metal sheet is in contact with a temperature sensor. The temperature sensor is connected with a controller. The controller is alsoconnected with the power supply and an alarm respectively. Compared with the devices in the prior art, the size of the plasma jet is positively relate to the output power of the power supply, the telescopic metal sheet, the temperature sensor and the controller are arranged and the plasma jet flux can be calculated and the output power of the power supply can be automatically adjusted so that thepurpose of autonomously adjusting the plasma jet size can be realized and the stability of the output plasma jet can be guaranteed.

Owner:SHANGHAI UNIV OF ENG SCI

Near field direct writing focusing and micro pattern separation method based on PEO electrospinning film substrate

The invention relates to the technical field of electrospinning direct writing, in particular to a near field direct writing focusing and micro pattern separating method based on a PEO electrospinningfilm substrate, according the method, the electrospinning substrate combining the PEO electrospinning film and an aluminum foil is used for realizing focusing of electrospinning direct-writing jet flows and non-destructive separation of a micro-pattern of an electrospinning material which is insoluble in water. The method comprises the following steps: firstly, spinning a layer of water-soluble PEO fiber membrane on a grounding metal substrate by an electrostatic spinning technology to prepare a composite electrospinning substrate, then using an electrospinning direct-writing technology to print the micro-pattern on the substrate, and finally, soaking the composite substrate together with the micro-pattern into a selected solution, the PEO can be dissolved, the micro-pattern cannot be dissolved, and at the moment, due to the fact that a material connected with the target fiber membrane and the substrate is dissolved, the micro-pattern is separated from the substrate. According to themethod, the self-focusing of electrospinning direct-writing and non-destructive separation of the electrospinning direct-writing micro-pattern and the metal substrate can be realized.

Owner:厦门定慧力教育科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com