Supersonic plasma spray gun

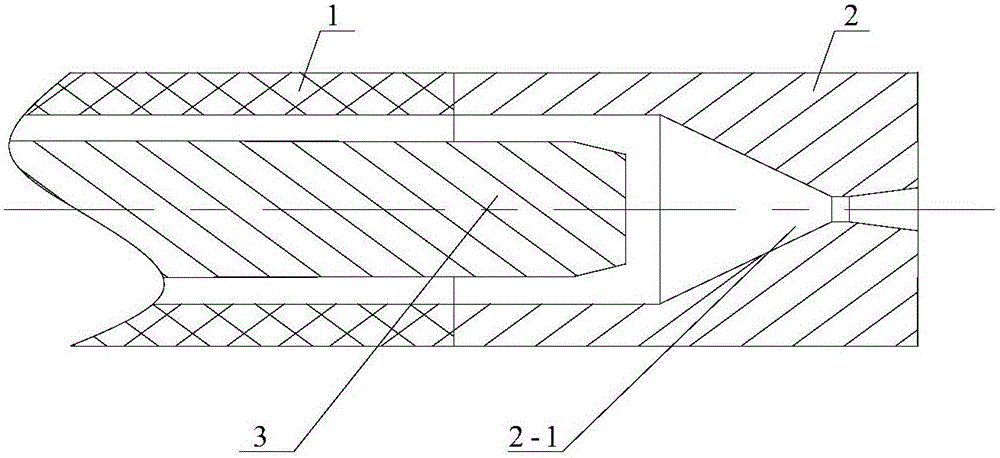

A supersonic plasma and spray gun technology, applied in the direction of plasma, electrical components, etc., can solve the problems of short electrode life, unstable spray gun arc voltage, low jet energy density and speed, etc., to achieve low cost, long service life, jet flow stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

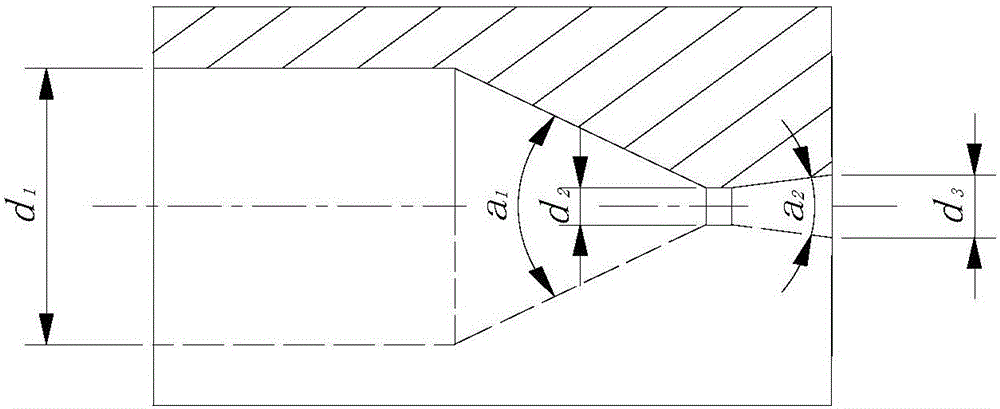

[0022] When the anode inlet diameter d 1 15mm, throat diameter d 2 2.0mm, outlet diameter d 3 When the anode compression angle is 80, the Mach number Ma reaches 2.41 at the outlet of the nozzle, which meets the requirements of supersonic plasma jet.

Embodiment 2

[0024] When the anode inlet diameter d 1 15mm, throat diameter d 2 3.0mm, outlet diameter d 3 When the anode compression angle is 60, the Mach number Ma reaches 2.37 at the outlet of the nozzle, which meets the requirements of supersonic plasma jet.

Embodiment 3

[0026] When the anode inlet diameter d 1 15mm, throat diameter d 2 4.0mm, outlet diameter d 3 When the anode compression angle is 90, the Mach number Ma reaches 2.38 at the outlet of the nozzle, which meets the requirements of supersonic plasma jet.

[0027] Moreover, the outlet pressures of the above three embodiments all reach the ambient pressure, the jet is in the best expansion state, and there is no shock wave.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com