Hybrid plasma generator for processing silicon-based material

A technology of plasma and silicon-based materials, applied in the direction of plasma, electrical components, etc., can solve the problems that the quality of the machined surface cannot reach the ideal target, the shape of the plasma jet is unstable, and the diameter of the beam spot cannot be obtained, so as to overcome the easy damage. Quartz glass tube, optimized ignition process, morphologically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better explain the present invention, the specific implementation of the present invention will now be described in detail in conjunction with the accompanying drawings.

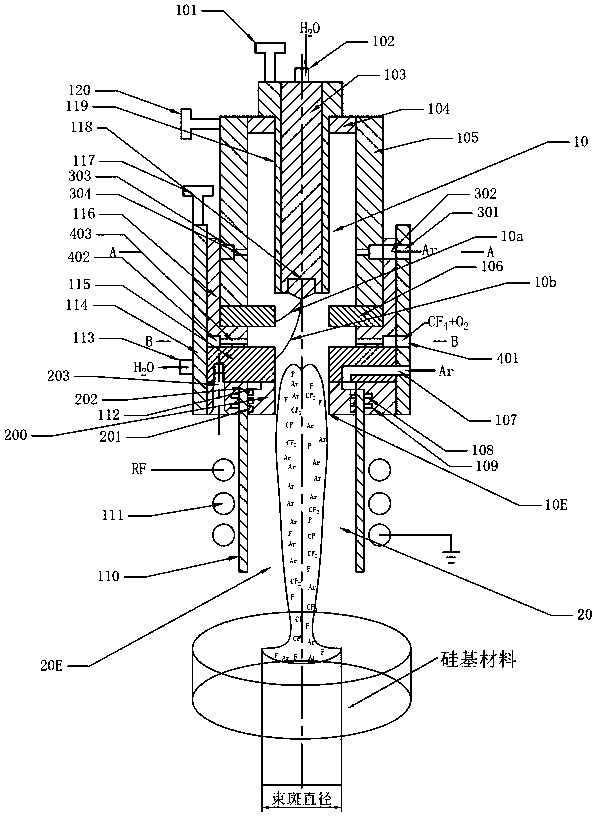

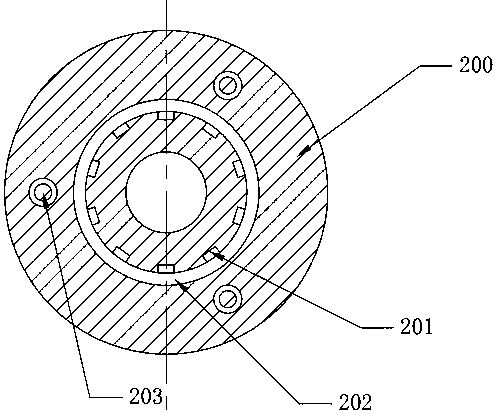

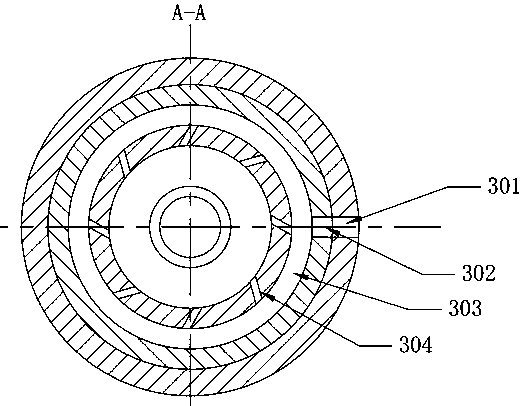

[0027]A hybrid plasma generator for etching processing of silicon-based materials disclosed by the invention is composed of a DC plasma generator (10) and a radio frequency inductively coupled plasma generator (20). Among them, the DC plasma generator is mainly composed of the cathode part, the arc starting casing, the first anode body, the anode casing, the second anode part, the first insulating sleeve, and the second insulating sleeve; the RF inductively coupled plasma generator is mainly composed of quartz glass Tube, composed of induction coils. The cathode part is assembled by the cathode head (118) and the cathode seat. The cooling water enters from the cooling water inlet (102), flows through the internal cooling water channel, and flows out from the cooling water outlet (113); the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com