Pre-mixed abrasive water jet type continuous working system and method

A pre-mixed abrasive and operating system technology, applied in the direction of abrasive jet machine tools, abrasives, abrasive feeding devices, etc., can solve the problem that abrasives cannot be fed continuously, and achieve the effects of simple structure, manpower and time saving, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

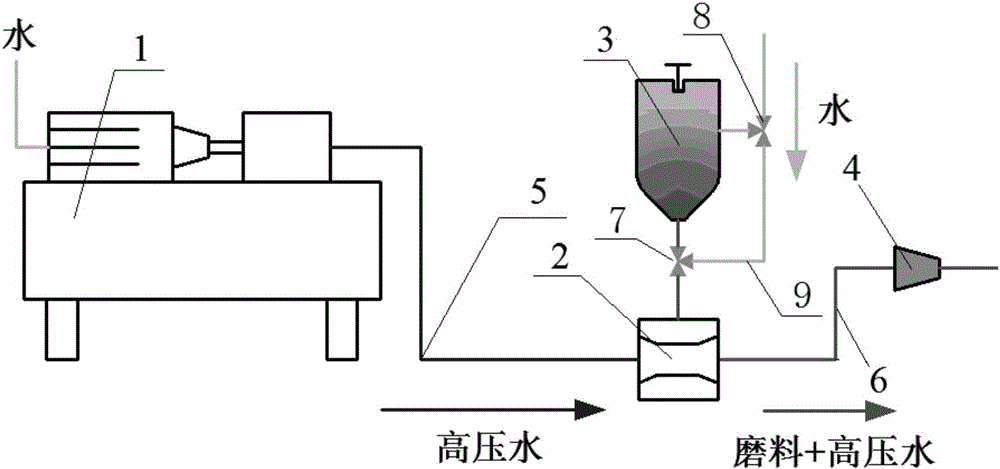

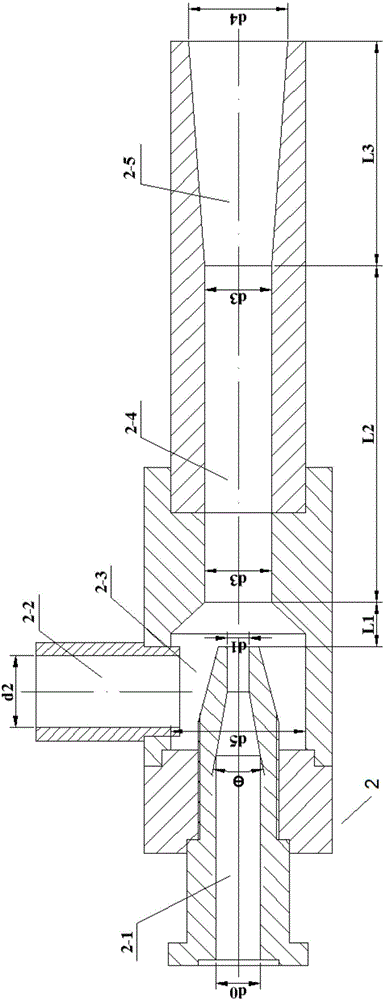

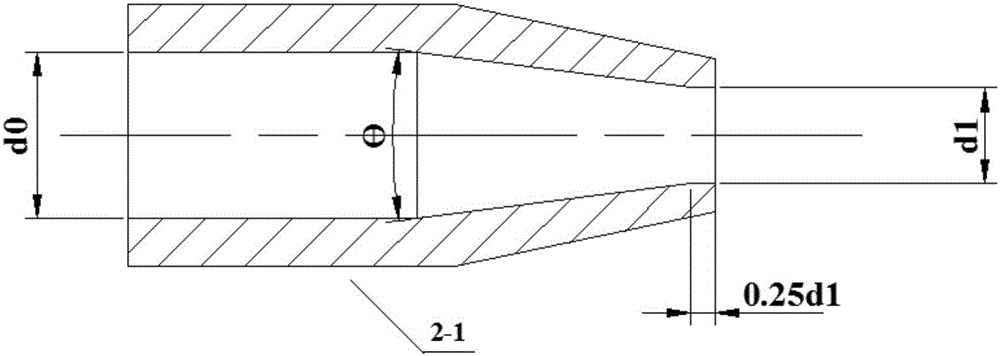

[0031] A pre-mixed abrasive water jet continuous operation system, such as figure 1 As shown, it includes a jet pump 2 and a high-pressure pump device 1 that outputs high-pressure water. The high-pressure pump device 1 is connected to the input end of the jet pump 2 through a high-pressure water pipeline 5, and the suction port 2-2 of the jet pump 2 is directly connected to Abrasive tank 3 is filled with abrasive material, and the output end of the jet pump 2 is connected to the abrasive jet nozzle 4 through the abrasive water jet pipeline 6 .

[0032]As long as the system ensures that the abrasive in the abrasive tank 3 is uninterrupted, the abrasive can be sucked quickly by using the entrainment effect of the jet pump 2 and the weight of the abrasive itself. After the abrasive is mixed with water, it will be pressurized and accelerated through the abr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com