Hazardous Waste Pretreatment System

A hazardous waste and pretreatment technology, applied in the field of hazardous waste treatment systems, can solve the problems of low burnout rate, pollution, unstable incineration effect, etc., and achieve the effect of full combustion and stable efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

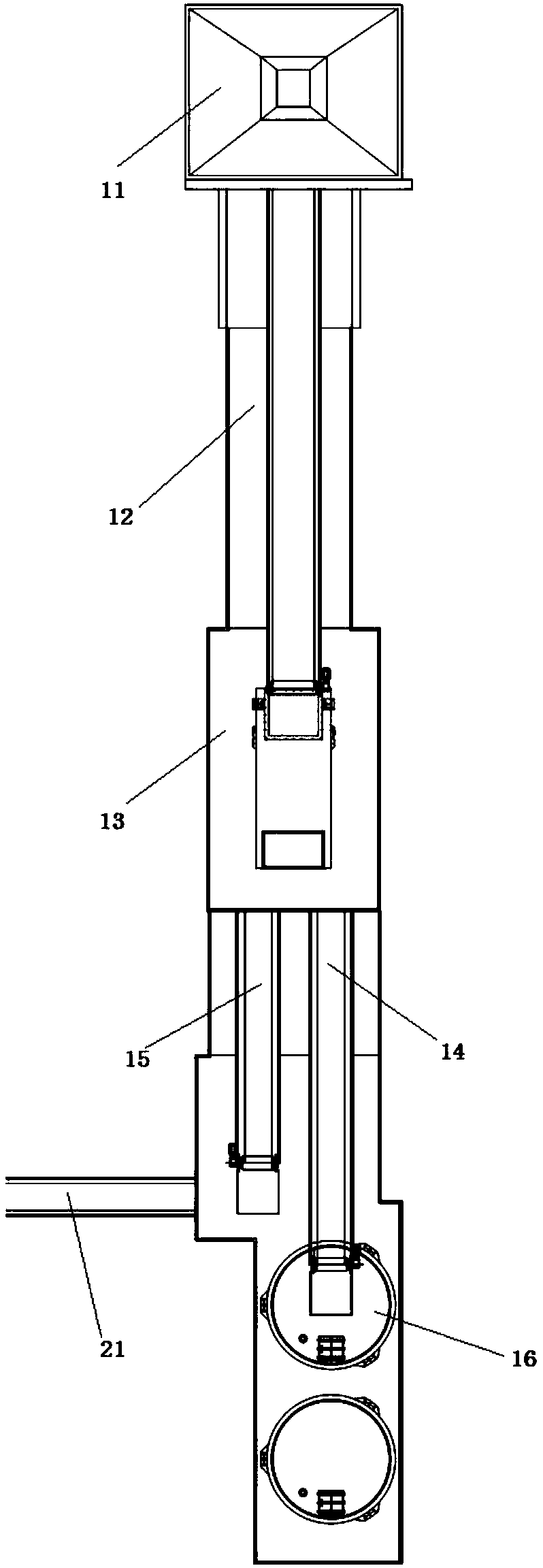

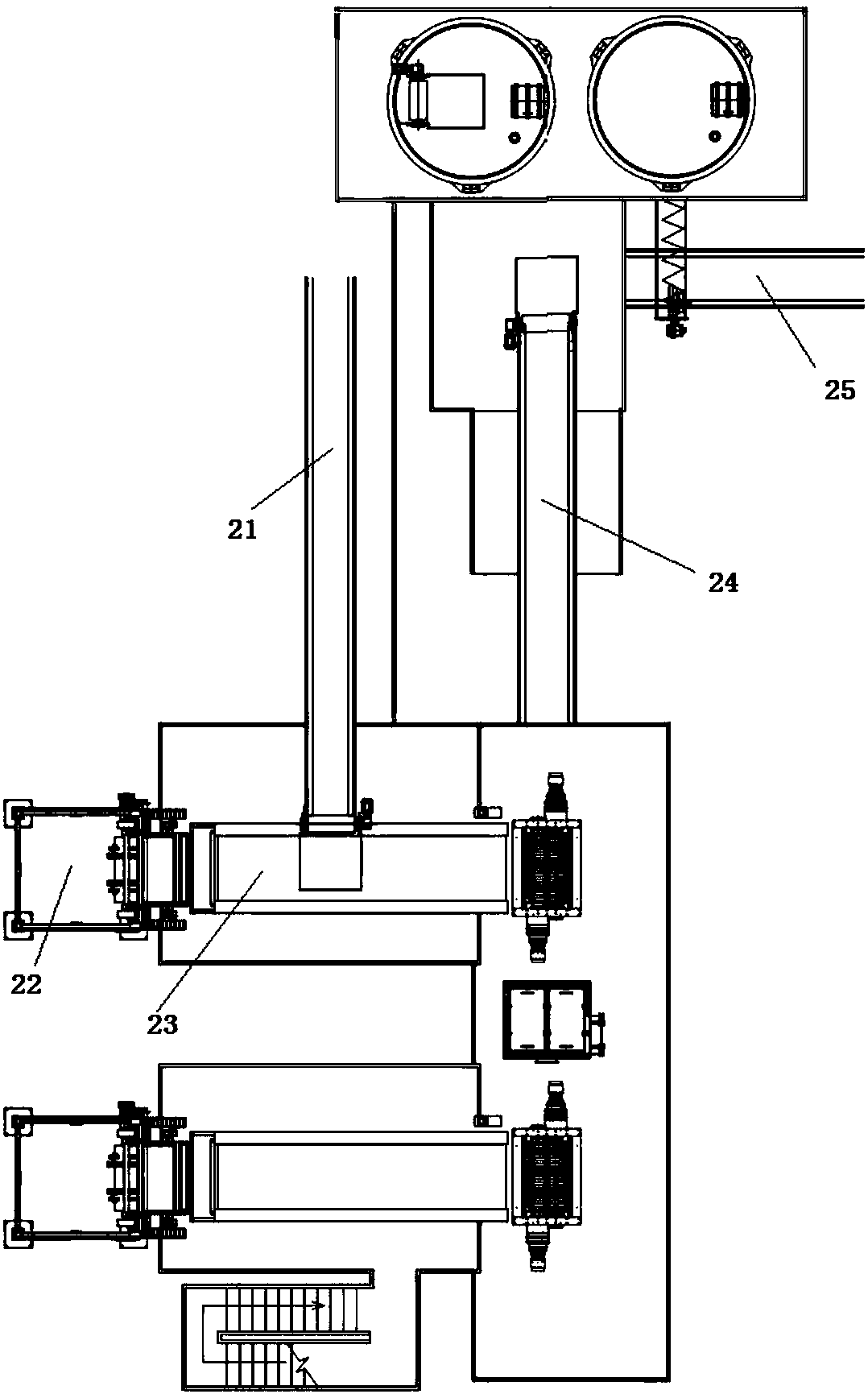

[0028] The present invention will be further described in conjunction with accompanying drawing and embodiment now. The drawings illustrate only the basic structure of the invention in a schematic way, and therefore only show configurations that are relevant to the invention.

[0029] figure 1 It generally shows a schematic diagram of a hazardous waste pretreatment system according to the present invention, which mainly includes a coarse powder hazardous waste pretreatment unit 1, a solid hazardous waste pretreatment unit 2, a special hazardous waste pretreatment unit 3 and The liquid hazardous waste pretreatment unit 4 is respectively used for preprocessing coarse powder hazardous waste, solid hazardous waste, special hazardous waste and liquid hazardous waste.

[0030] In this article, coarse powder hazardous waste refers to the size of most of the materials it contains is less than or equal to 50×50×80mm, such as granular or powder hazardous waste; solid hazardous waste ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com