Method for incinerating low-viscosity organic mixed waste liquid

A low-viscosity, waste-liquid technology, applied in combustion methods, incinerators, combustion types, etc., can solve the problems of capital waste, backlog of organic mixed waste liquid, illegal discharge, etc., and achieve the effect of stable incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

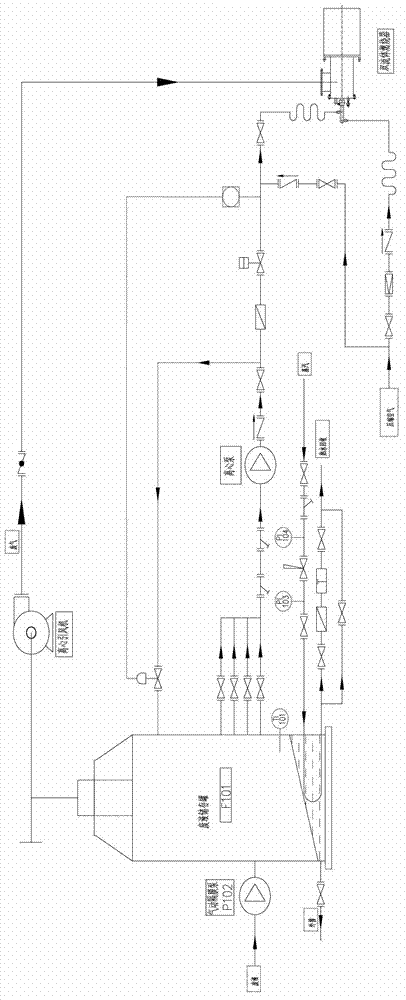

[0017] Refer to the following figure 1 Examples of the present invention will be described.

[0018] With reference to the accompanying drawings, the detailed steps of the incineration method of the low-viscosity organic mixed waste liquid of the present invention are as follows:

[0019] A method for incinerating low-viscosity organic mixed waste liquid, comprising the following steps:

[0020] A) The external low-viscosity organic mixed waste liquid is injected into the waste liquid storage tank with a pneumatic diaphragm pump, and the external steam heat source is used to control the temperature of the waste liquid in the waste liquid storage tank to 30-40°C to ensure that the waste liquid is in a flowable state ; The temperature of the waste liquid in the waste liquid storage tank and the flow rate of the external steam heat source are controlled in chain to ensure the accuracy of the control.

[0021] B) The waste liquid in the waste liquid storage tank is transported t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com