Nonyl phenol poly-oxypropylene ether amine

A nonylphenol polyoxypropylene ether amine and amino technology, which is applied in the field of petrochemical industry, can solve the problems of complex production process and high production cost, and achieve the effects of good application effect, low production cost and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

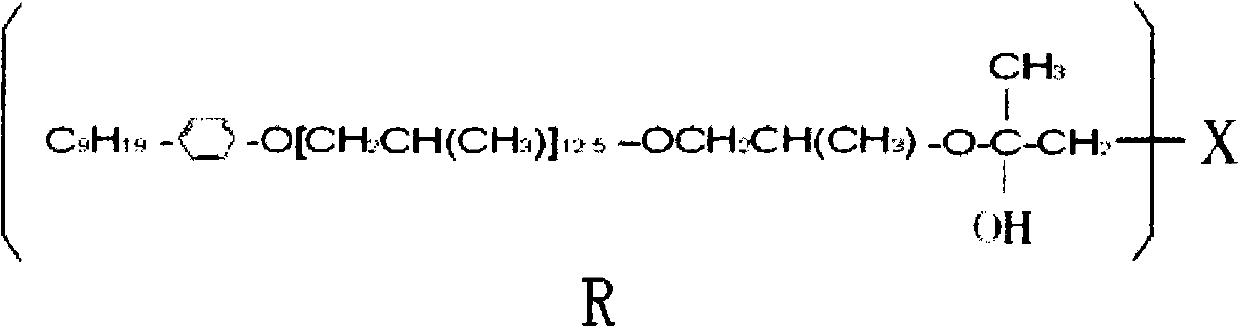

[0020] The structural formula of a kind of nonylphenol polyoxypropylene ether amine is:

[0021]

[0022] The number-average molecular weight of the product R group is Mn=880, and the molecular distribution Mw / Mn is 1.

Embodiment 2

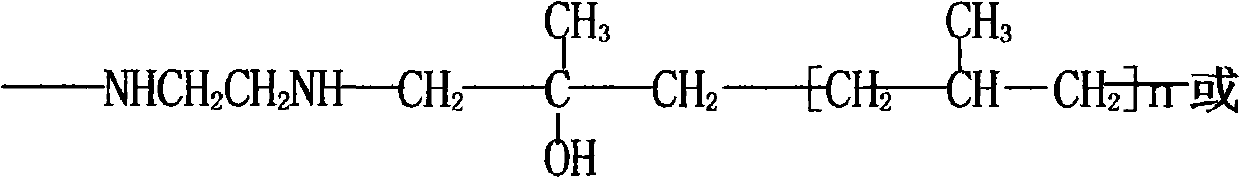

[0024] The structural formula of a kind of nonylphenol polyoxypropylene ether amine is:

[0025]

[0026] The number-average molecular weight of the product R group is Mn=1000, and the molecular distribution Mw / Mn is 1.4.

Embodiment 3

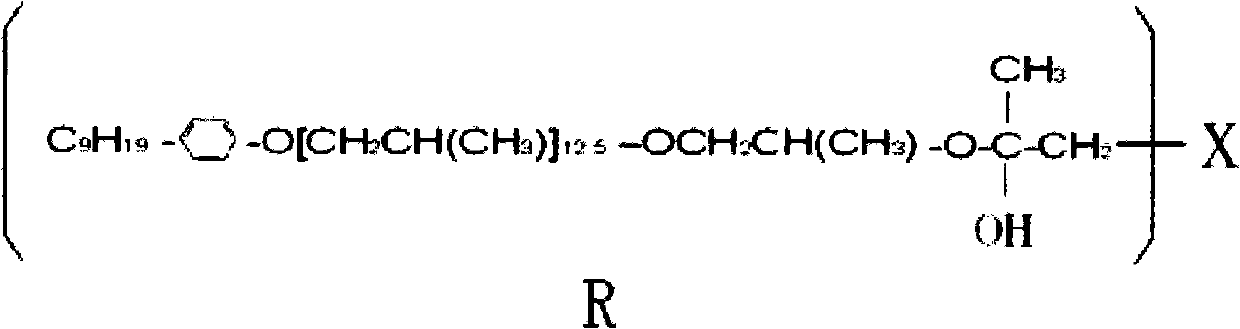

[0028] The structural formula of a kind of nonylphenol polyoxypropylene ether amine is:

[0029]

[0030] The number average molecular weight of the R group of this product is Mn=1200, and the molecular distribution Mw / Mn is 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com