Block copolymer of aromatic hydrocarbon, conjugated diene and epoxide and preparation method thereof

A technology of block copolymer and conjugated diene, which is applied in the field of polymer block copolymer modified materials, can solve the problems such as the decrease of HMPSA adhesion, achieve controllable peeling force, complete monomer conversion, and efficient method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

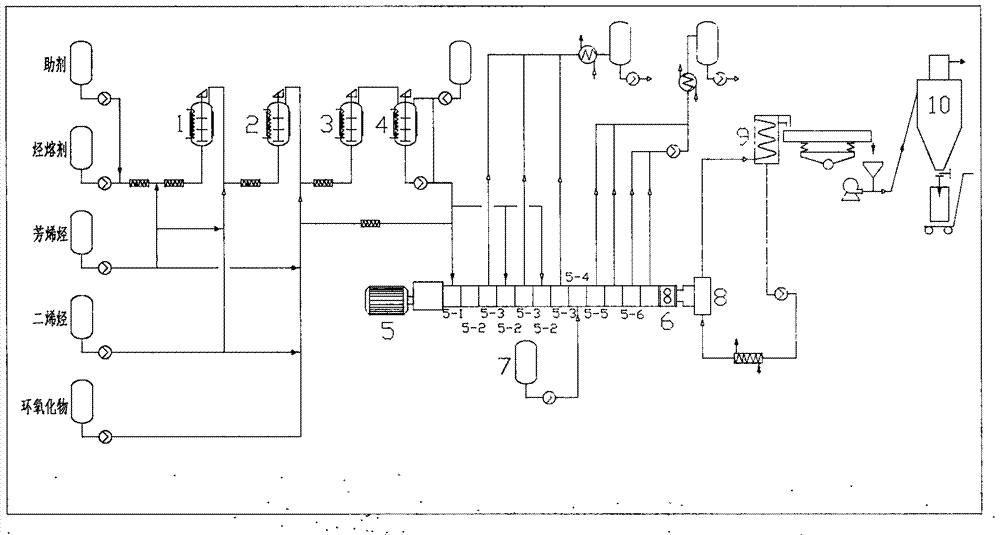

[0026] In the system of two 10-liter reactors connected in series, heat the heat medium of the reactor jacket and replace it with high-purity nitrogen to make the oxygen and water content reach 3PPM, and then add 4000 grams of cyclohexane and 100 grams of styrene, start stirring to make the temperature of the kettle reach 60-70 °C, add 17 mmol of butyllithium, and carry out active negative ion polymerization reaction, then add 350 grams of isoprene, 100 grams of styrene, isoprene 350 grams, 100 grams of styrene, the five-step reaction process controls the maximum temperature not to exceed 100 ° C, and finally stops for 60 minutes to end the reaction.

[0027] Transfer all the reactants to the second reaction kettle, start stirring and adjust the temperature to 50-60°C, and add 58 grams of toluene solution of alkylaluminum to reduce the reactivity of the system and slow down the chain growth rate. The reaction materials are transferred to the feeder of the twin-screw extrusion ...

Embodiment 2

[0029] On the same experimental device as in Example 1, add 4200 grams of cyclohexane and hexane mixture (9 / 1) and 100 grams of styrene to the first reaction kettle, heat the kettle to 60° C., start stirring, add 0.019 mmol of butyllithium, After 60 minutes, add 350 grams of isoprene, 60 grams of styrene, 350 grams of isoprene, 100 grams of styrene, 350 grams of isoprene, 60 grams of styrene and divinylbenzene mixture (which contains divinylbenzene 5 g). Reaction time of each stage: 60 minutes after adding styrene, 40 minutes after adding isoprene. Enter the second reactor after the reaction is over, adjust the temperature to 60°C under stirring, and after adding 43 grams of butylmagnesium toluene solution, transfer it to the feeder of the twin-screw extrusion reactor, and continuously add to the reactor of Example 1 at a rate of 2800g / h. The twin-screw extrusion reaction unit (5) of φ25, L / D=64 used in the process is added to the reaction materials. A total of 86g / h (8.5:1....

Embodiment 3

[0031] A 20-liter sealed system of 3 polymerizers in series, each reactor has a jacket and internal cooling auxiliary temperature control, the residual water and oxygen in the system are less than 5ppm, the first reactor is maintained at 80 ° C, and the stirring is started to carry out continuous reaction production , Add solvent cyclohexane and 1500 g / h of 20wt% styrene solution from the bottom at a speed of 9000 g / h, and add 48.6 mmol / h of butyllithium solution. After 40 minutes, add 4500 g / h solution containing 33.3wt% isoprene to the middle part of the first reaction kettle, add 1000 g / h solution containing 20% styrene to the bottom of the second reaction kettle after 30 minutes, and then add the solution in the second reaction kettle after 30 minutes. Add a 4500 g / h solution containing 33.3 wt% isoprene to the middle of the kettle, add 1500 g / h of a 20 wt% solution containing styrene to the bottom of the third kettle after 30 minutes, and add 33.3 wt% isoprene from the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com