Preparation method of precursor fibers for wet-process spinning PAN-based carbon fibers

A carbon fiber, wet spinning technology, applied in wet spinning, fiber chemical characteristics, stretch spinning, etc., can solve the problems of loss of competitive advantage in price, difficulty in capital recovery, low market share, etc., and achieve solvent residue in the original silk. The effect of small volume, high transparency and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

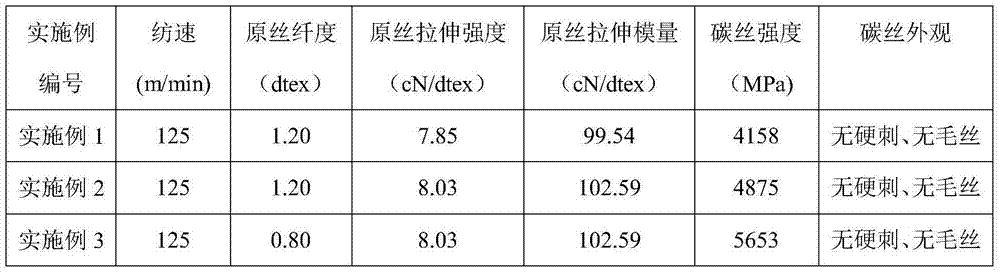

Examples

Embodiment 1

[0023] The preparation method of the raw silk for the wet spinning PAN-based carbon fiber comprises the following steps:

[0024] (1) Preparation of polyacrylonitrile stock solution:

[0025] (A) raw materials for dissolution: acrylonitrile (AN) accounting for 98% of the total weight of the polymer, itaconic acid accounting for 1.0% of the total weight of the polymer, and methyl acrylate accounting for 1.0% of the total weight of the polymer are dissolved in In 80% dimethyl sulfoxide (DMSO) of the total weight of the polymerization solution, stirring for 1 h;

[0026] (B) Polymerization reaction: The azo initiator accounting for 0.05% of the total weight of the polymer is fully dissolved by the solvent and then added to the 3-stage series polymerization kettle at room temperature for polymerization. The polymerization kettle has a jacket and an external circulation device for the kettle. Before entering the polymerization tank, the initiator and the mixed single material are ...

Embodiment 2

[0034] The preparation method of the raw silk for the wet spinning PAN-based carbon fiber comprises the following steps:

[0035] (1) Preparation of polyacrylonitrile stock solution:

[0036] (A) Dissolving raw materials: acrylonitrile (AN) accounting for 97.5% of the total weight of the polymer, itaconic acid accounting for 1.0% of the total weight of the polymer, and methyl acrylate accounting for 1.5% of the total weight of the polymer are dissolved in In 80% dimethyl sulfoxide (DMSO) of the total weight of the polymerization solution, stirring for 1 h;

[0037] (B) Polymerization reaction: The azo initiator accounting for 0.05% of the total weight of the polymer is fully dissolved by the solvent and then added to the 3-stage series polymerization kettle at room temperature for polymerization. The polymerization kettle has a jacket and an external circulation device for the kettle. Before entering the polymerization tank, the initiator and the mixed single material are ful...

Embodiment 3

[0045] The preparation method of the raw silk for the wet spinning PAN-based carbon fiber comprises the following steps:

[0046] (1) Preparation of polyacrylonitrile stock solution:

[0047] (A) Dissolving raw materials: acrylonitrile (AN) accounting for 97.5% of the total weight of the polymer, itaconic acid accounting for 1.0% of the total weight of the polymer, and methyl acrylate accounting for 1.5% of the total weight of the polymer are dissolved in In 80% dimethyl sulfoxide (DMSO) of the total weight of the polymerization solution, stirring for 1 h;

[0048] (B) Polymerization reaction: The azo initiator accounting for 0.05% of the total weight of the polymer is fully dissolved by the solvent and then added to the 3-stage series polymerization kettle at room temperature for polymerization. The polymerization kettle has a jacket and an external circulation device for the kettle. Before entering the polymerization tank, the initiator and the mixed single material are ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com