Planar optical waveguide type parallel optical assembly and optical module

A planar optical waveguide and optical component technology, applied in the field of optical communication, can solve the problems of increasing the electrical parasitic effect of optical components, limiting the transmission rate of the system, and high manufacturing cost, and achieving the effects of reducing electrical parasitic effect, simple coupling structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

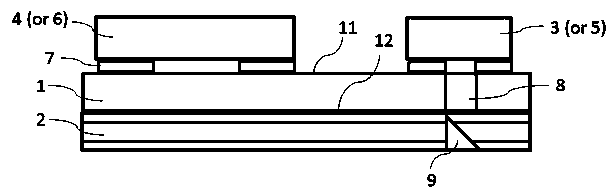

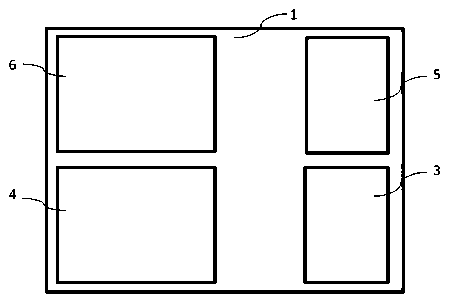

[0032] Such as figure 1 and figure 2 As shown, the planar optical waveguide type parallel optical component of this embodiment includes a circuit board 1 , an optical waveguide 2 , a laser array 3 , a driver 4 , an optical detector array 5 and a transconductance amplifier 6 . Both the laser array 3 and the photodetector array 5 are four parallel arrays. The laser in this embodiment is a vertical cavity surface emitting laser (VCSEL).

[0033] An electrode array 7 is arranged on the first side 11 of the circuit board 1, and the VCSEL array 3, the driver 4, the photodetector array 5 and the transconductance amplifier 6 are mounted on the first side of the circuit board 1 in a flip-chip bonding manner. side 11 and is electrically connected to the electrode array 7 . The arrangement of the VCSEL array 3, driver 4, photodetector array 5 and transconductance amplifier 6 on the circuit board 1 is as follows: figure 2 shown.

[0034] Such as figure 1 As shown, the light-transm...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the light-transmitting device provided on the circuit board 1 is realized by using a transparent substrate, such as Figure 4 shown. In this embodiment, the transparent substrate is a polyimide film. The polyimide film is selected as the transparent substrate of the circuit board, and its transmittance to the 850nm near-infrared light emitted by the VCSEL can reach more than 85%. The thickness of the polyimide film in this embodiment is 30 microns. The circuit board 1 itself has a multilayer circuit. Using transparent polyimide film as the substrate of the circuit board can save the drilling procedure, thereby reducing the cost.

[0040] Such as figure 2 and Figure 4 As shown, the planar optical waveguide type parallel optical component of this embodiment includes a circuit board 1 , an optical waveguide 2 , a laser array 3 , a driver 4 , an optical detector array 5 and a transconductance amplifier 6...

Embodiment 3

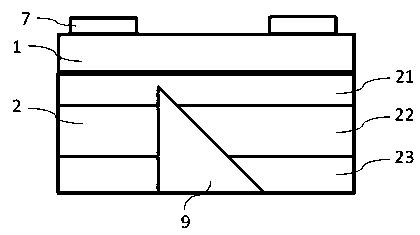

[0046] The difference between this embodiment and Embodiment 1 is that the polymer film of the optical waveguide 2 is hot-pressed on the circuit layer by layer with the first cladding layer 11, the core layer 2, and the second cladding layer 13 by dry film lamination. plate 1. Firstly, the first cladding layer 11 is made on the circuit board 1, and the dry film of the core layer 12 is hot-pressed, and the core layer 12 is exposed and developed according to the preset optical path pattern to form the wiring of the optical signal channel, Then press the second cladding layer 13 , that is, the upper cover layer of the waveguide to fill the gaps in the wiring. The polymer film in this embodiment is formed by mixing oligomers and polymer resins. Preferably, an ultraviolet curable oligomer can be used.

[0047] The polymer film formed by mixing oligomer and polymer resin has a small bending radius, which can be about 3 mm. After repeated bending and folding, the optical loss incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com