Yoke for universal joint

A technology for universal joints and fastening parts, applied to rigid shaft couplings, elastic couplings, mechanical equipment, etc., can solve the problem of inability to completely prevent the bending of bolts 109, the complex shape of fastening parts 107, and fatigue resistance. (Decrease in durability and other issues, achieve the effect of reducing manufacturing cost, preventing bolt bending, and suppressing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

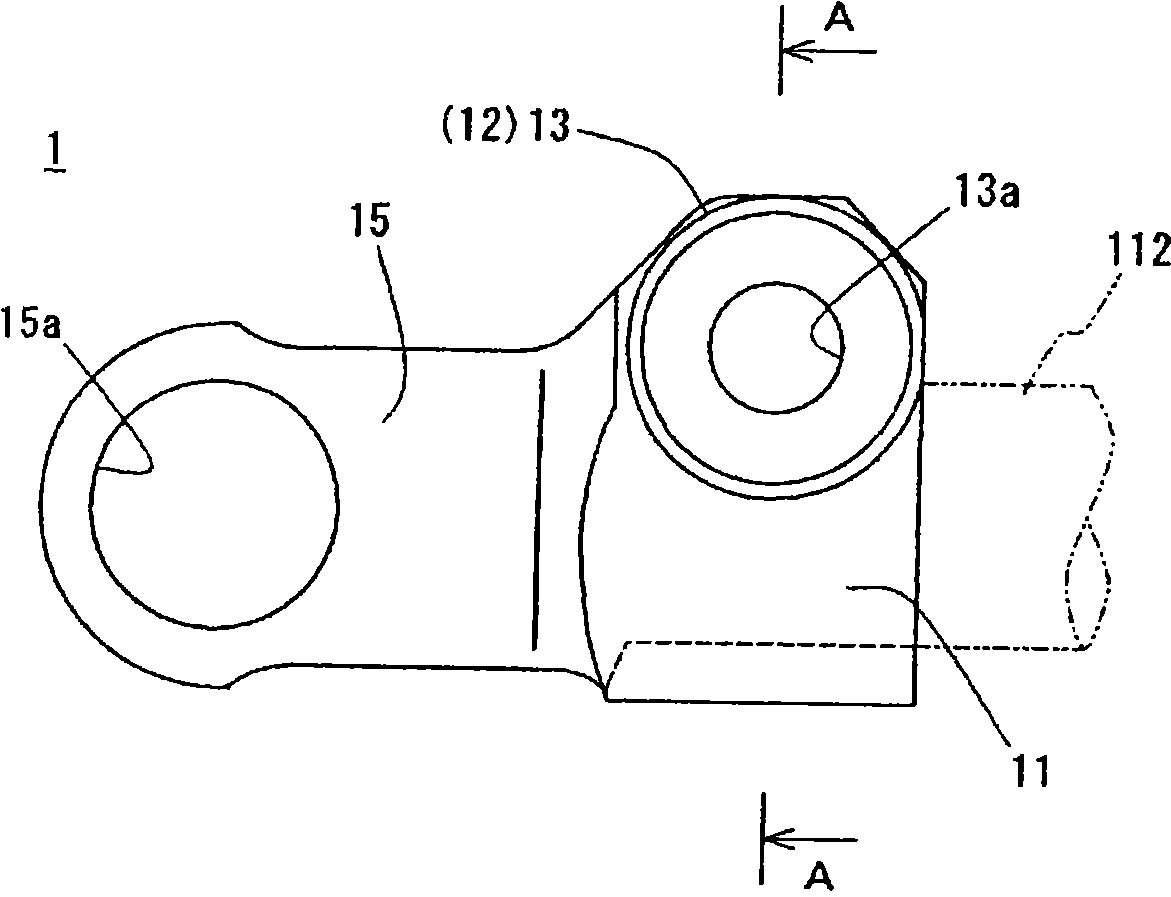

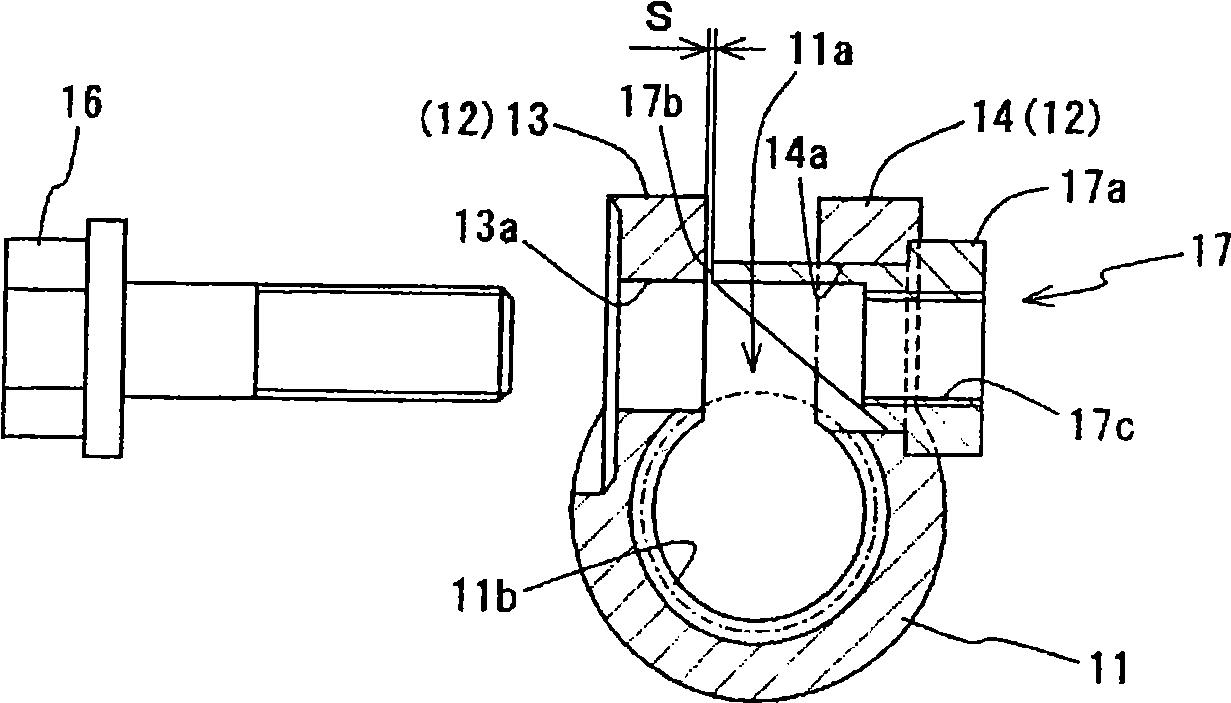

[0050] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings. in, figure 1 It is a front view showing a schematic structure of a yoke for a universal joint according to an embodiment of the present invention, figure 2 It is a rear view showing a schematic structure of a yoke for a universal joint according to this embodiment, image 3 for along figure 1 A cross-sectional view in the direction of arrow A-A, Figure 4 It is a side view showing the schematic structure of the nut in this embodiment. Also, in the following description, Figure 1 ~ Figure 4 The universal joint shown in this example uses yoke 1 that replaces Figure 9 ~ Figure 11 In the case of the second yoke 105 shown, descriptions other than the yoke 1 will be given the same reference numerals as those described above, and detailed description will be omitted.

[0051] Such as Figure 1 ~ Figure 4 As shown, the yoke (second yoke) 1 for a universal joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com