Fiber-metal composite laminate, forming die therefor and forming method

A technology of fiber metal and forming molds, applied in the direction of metal layered products, other household appliances, chemical instruments and methods, etc., can solve the problems of long preparation cycle, low production efficiency, long-time curing, etc., and achieve improved forming accuracy and forming Quality, improvement of production efficiency and quality, effect of reducing forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

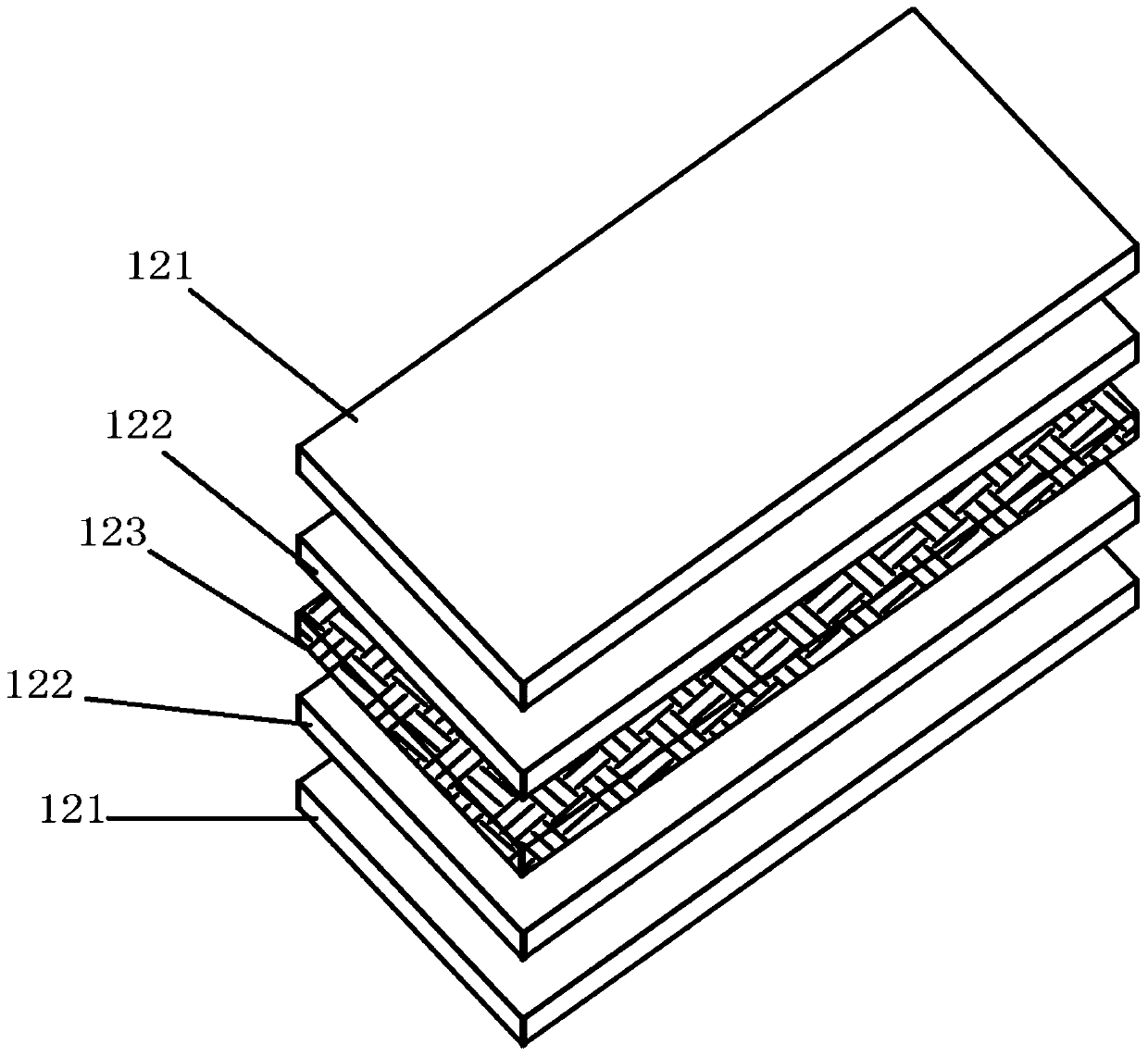

[0033] Such as figure 1 As shown, the fiber metal composite laminate in this embodiment includes two aluminum alloy layers 121, two PEEK resin layers 122 are arranged between the two aluminum alloy layers 121, and a carbon fiber pre-layer is arranged between the two PEEK resin layers 122. Dip layer 123 .

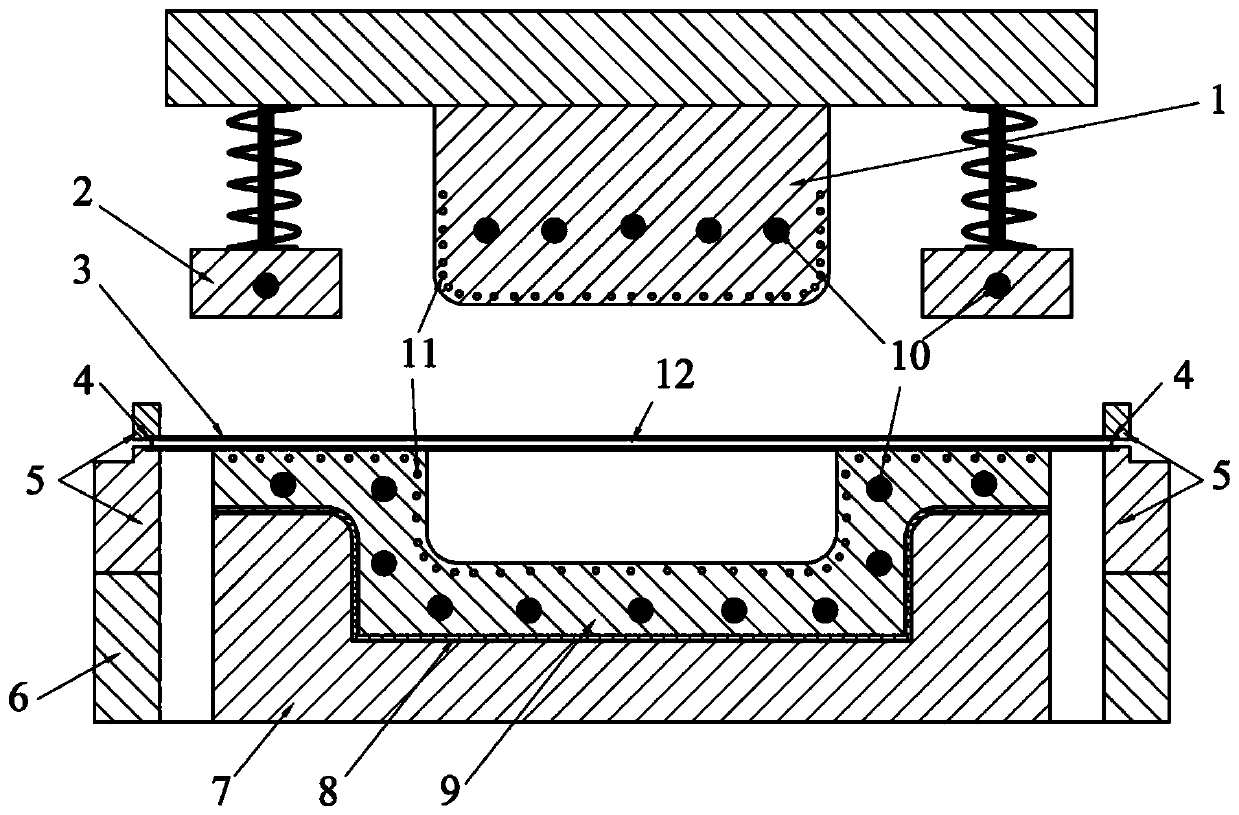

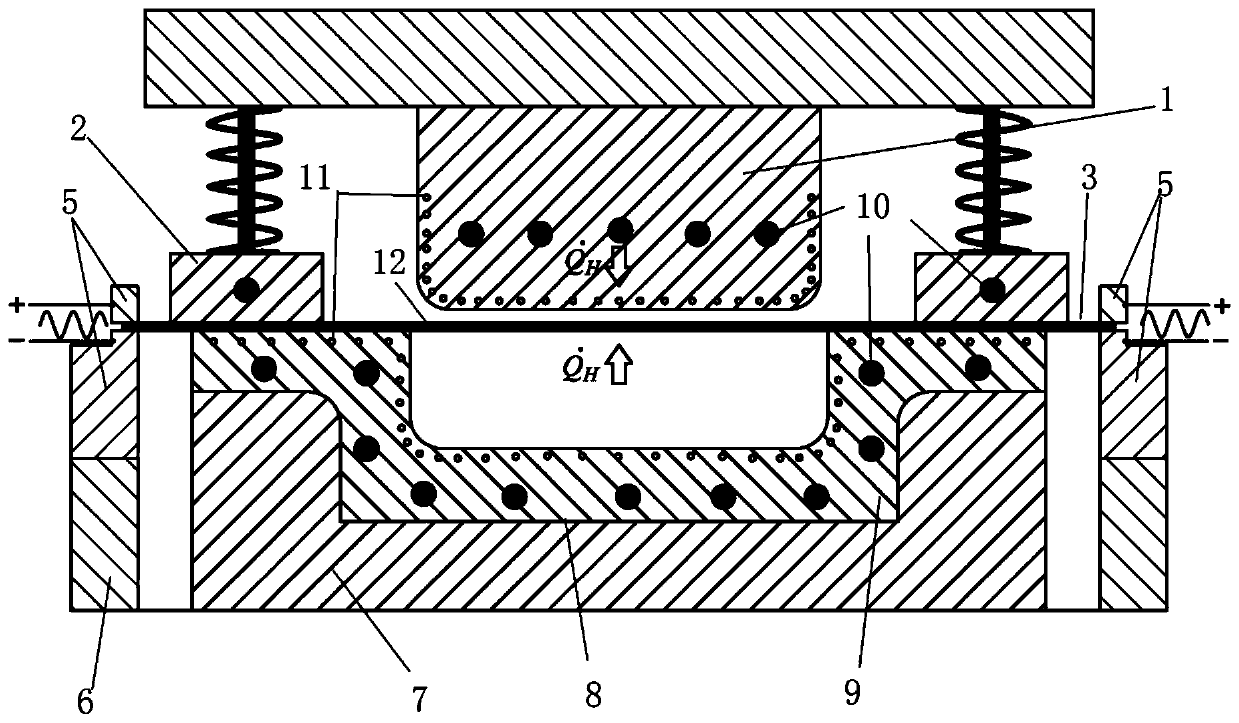

[0034] Such as Figure 2-4 As shown, this embodiment also provides a fiber metal composite laminate forming die for making the above fiber metal composite laminate, including a correspondingly arranged punch 1 and a combined die, the punch 1 is located above the combined die, and the combined The die comprises a lower die 7 and an upper die 9 arranged on the lower die 7, an insulating layer 8 is arranged between the upper die 9 and the lower die 7, the bottom of the punch 1 and the top of the upper die 9 A number of water passage holes 11 are evenly arranged respectively; the side of the punch 1 is provided with a blank holder 2, and the blank holder 2 includes a blank hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com