Cold upsetting extrusion composite forming method of automotive non-ferrous metal shell part

A non-ferrous metal and composite forming technology, which is applied in the field of cold heading and extrusion composite forming of non-ferrous metal shell parts for vehicles, can solve problems such as easy cracking of the lubricating film, achieve improved surface adhesion, less processing procedures, and simple processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

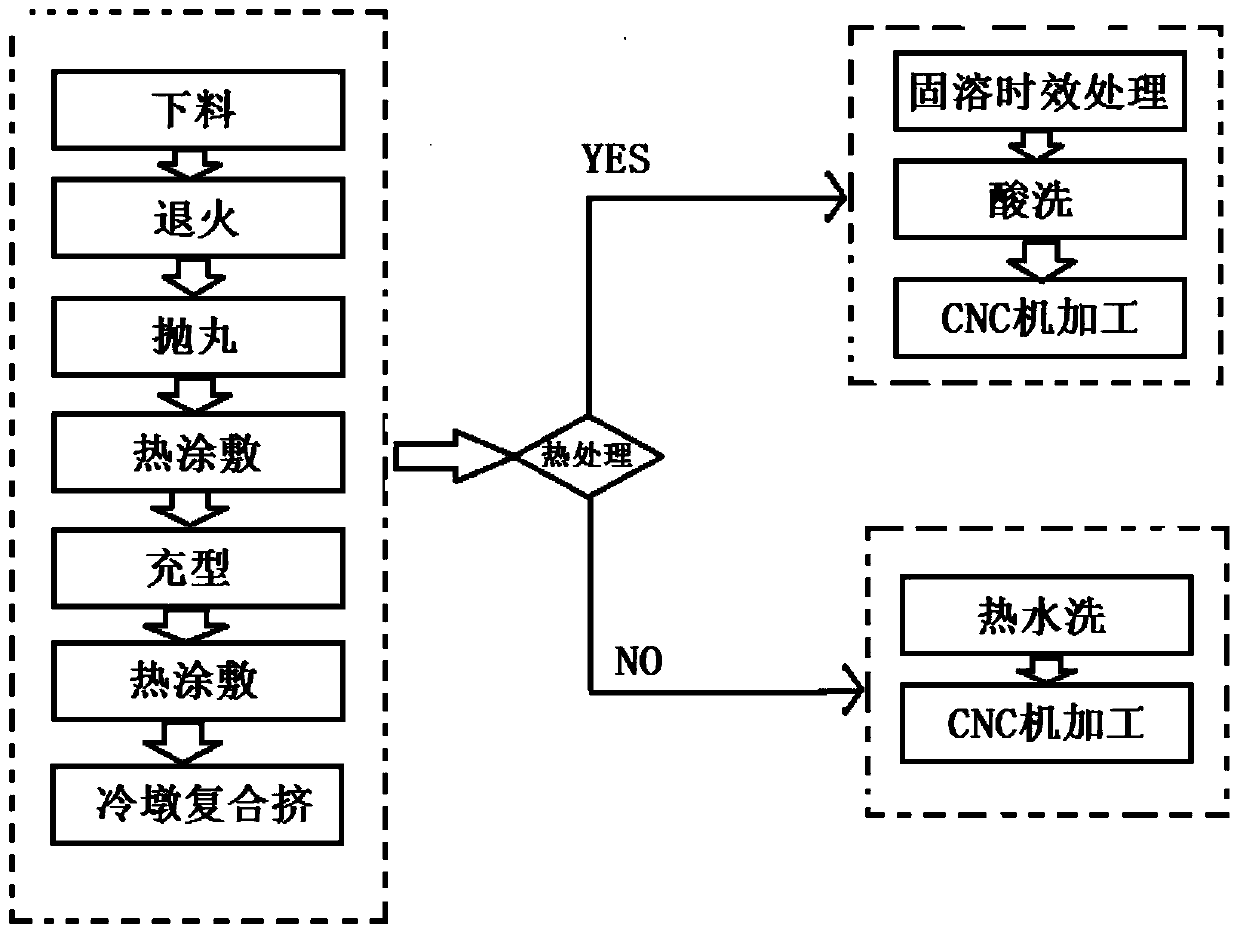

[0054] A cold heading and extrusion composite forming method for non-ferrous metal shell parts for vehicles, the specific steps are as follows figure 2 Shown:

[0055] (1) Using a circular saw machine to cut the non-ferrous metal AA6061 (series 6 aluminum alloy) to produce a non-ferrous metal shell part blank for vehicles with a burr of less than 0.5 mm;

[0056] (2) Carry out annealing treatment to the billet, the annealing temperature is controlled at 500 ° C for 4 hours, and it is directly out of the furnace;

[0057] (3) Use a pellet with a diameter of 0.35 mm to blast the annealed billet for 15 minutes;

[0058] (4) Adopt water-based polymer lubricant III to carry out thermal coating treatment on the surface of the billet after shot blasting treatment, such as figure 1 Shown: After heating the billet to 180°C, soak it with water-based polymer lubricant I for 4 seconds. After treatment, the thickness of water-based polymer lubricant I on the surface of the billet is 4 μ...

Embodiment 2

[0076] A cold heading extrusion composite forming method for non-ferrous metal shell parts for vehicles, the specific steps are as follows:

[0077] (1) AA6082 (series 6 aluminum alloy) is blanked with a circular saw machine to produce a non-ferrous metal shell part blank for vehicles with a burr of less than 0.5 mm;

[0078] (2) Carry out annealing treatment to the billet, the annealing temperature is controlled at 520 ℃ for 4.5 hours, and it is directly out of the furnace;

[0079] (3) Use a pellet with a diameter of 0.35 mm to blast the annealed billet for 15 minutes;

[0080] (4) Use water-based polymer lubricant I to thermally coat the surface of the billet after shot blasting treatment, that is, heat the billet to 220 ° C and use water-based polymer lubricant I to infiltrate for 4 seconds. The thickness of Molecular Lubricant I is 5 μm, and then the blank is dried naturally;

[0081](5) Put the blank processed in step (4) into the filling die, and the filling punch mov...

Embodiment 3

[0088] A cold heading extrusion composite forming method for non-ferrous metal shell parts for vehicles, the specific steps are as follows:

[0089] (1) H62 brass is blanked by a circular saw machine to produce a non-ferrous metal shell part blank for vehicles with a burr of less than 0.5 mm;

[0090] (2) Carry out annealing treatment on the blank, the annealing temperature is controlled at 260-300°C for 2-4 hours, and it is directly out of the furnace;

[0091] (3) Use a pellet with a diameter of 0.35 mm to blast the annealed billet for 15 minutes;

[0092] (4) Use water-based polymer lubricant I to thermally coat the surface of the billet after shot blasting treatment, that is, heat the billet to 180°C and use water-based polymer lubricant I to infiltrate for 4s. The thickness of Molecular Lubricant I is 3 μm, and then the blank is dehydrated and dried for 8 minutes;

[0093] (5) Put the blank processed in step (4) into the filling die, and the filling punch moves down. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com