Long-life pavement structure for steel bridge deck and pavement method of pavement structure

A long-life, steel bridge deck technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of large proportion of fine materials, small void ratio, brittle fracture, etc., and achieve the effect of avoiding performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

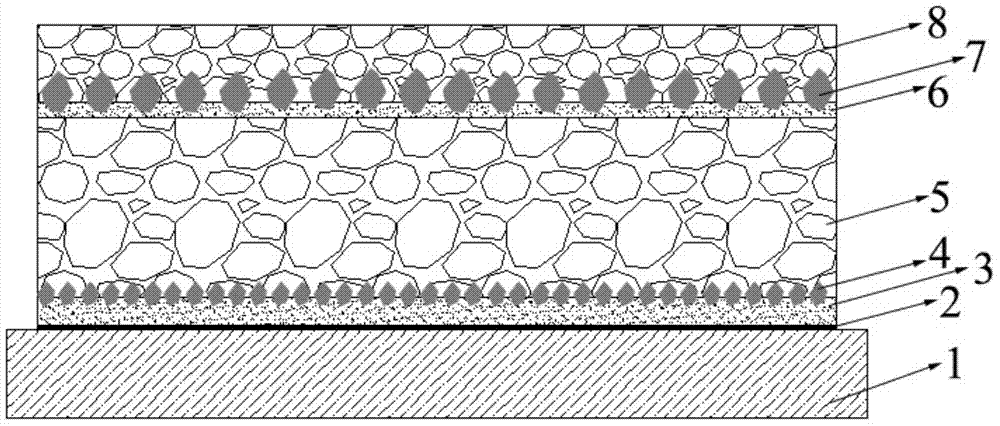

[0046] Such as figure 1 As shown, the steel bridge deck pavement structure of this embodiment is provided with an anticorrosion layer 2, a lower bonding layer 3, a lower crushed stone layer 4, a structural layer 5, and an upper bonding layer on the steel bridge deck 1 from bottom to top. Layer 6, upper gravel layer 7 and wear layer 8; the anticorrosion layer 2 and the structural layer 5 are bonded through the lower bonding layer 3, and the structural layer 5 and the wearing layer 8 are bonded through the upper bonding layer 6; the lower layer The gravel layer 4 is embedded between the lower bonding layer 3 and the structural layer 5 , and the upper crushed stone layer 7 is embedded between the upper bonding layer 6 and the wearing layer 8 .

[0047] The anti-corrosion layer 2 is coated with epoxy zinc-rich paint, which is mainly composed of epoxy resin, polyamide resin, aluminum paste and additives; the thickness of the anti-corrosion layer 2 is 82 μm.

[0048] Both the lower...

Embodiment 2

[0104] The long-life pavement structure for the steel bridge deck used in embodiment 2, except that the aggregate gradation of the epoxy asphalt concrete EA-5 of the wearing layer 8 is different from that of embodiment 1, the preparation and pavement methods of the rest of the materials are all the same as those in embodiment 1. Same as Example 1.

[0105] The aggregate gradation of the epoxy asphalt concrete EA-5 of the wearing layer 8 is shown in Table 18.

[0106] The aggregate gradation of epoxy asphalt concrete EA-5 in table 18 embodiment 2

[0107]

[0108]

Embodiment 3

[0110] The long-life pavement structure for the steel bridge deck used in embodiment 3, except that the aggregate gradation of the epoxy asphalt concrete EA-5 of the wearing layer 8 is different from that of embodiment 1, the preparation and pavement methods of the rest of the materials are all the same as those in embodiment 1. Same as Example 1.

[0111] The aggregate gradation of the epoxy asphalt concrete EA-5 of the wearing layer 8 is shown in Table 19.

[0112] The aggregate gradation of epoxy asphalt concrete EA-5 in table 19 embodiment 3

[0113]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com