Electric assistant heating forming device and method for dissimilar material complicated section pipe fittings

A dissimilar material, heat forming technology, applied in the processing of rods or profiles, metal plates or pipes, can solve the problems of easy cracking of welds, deformation and thinning of pipe fittings, and uncoordinated deformation, so as to promote the coordination of deformation and solve the problems of pipe fittings Shape and size changes, increasing the effect of active materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

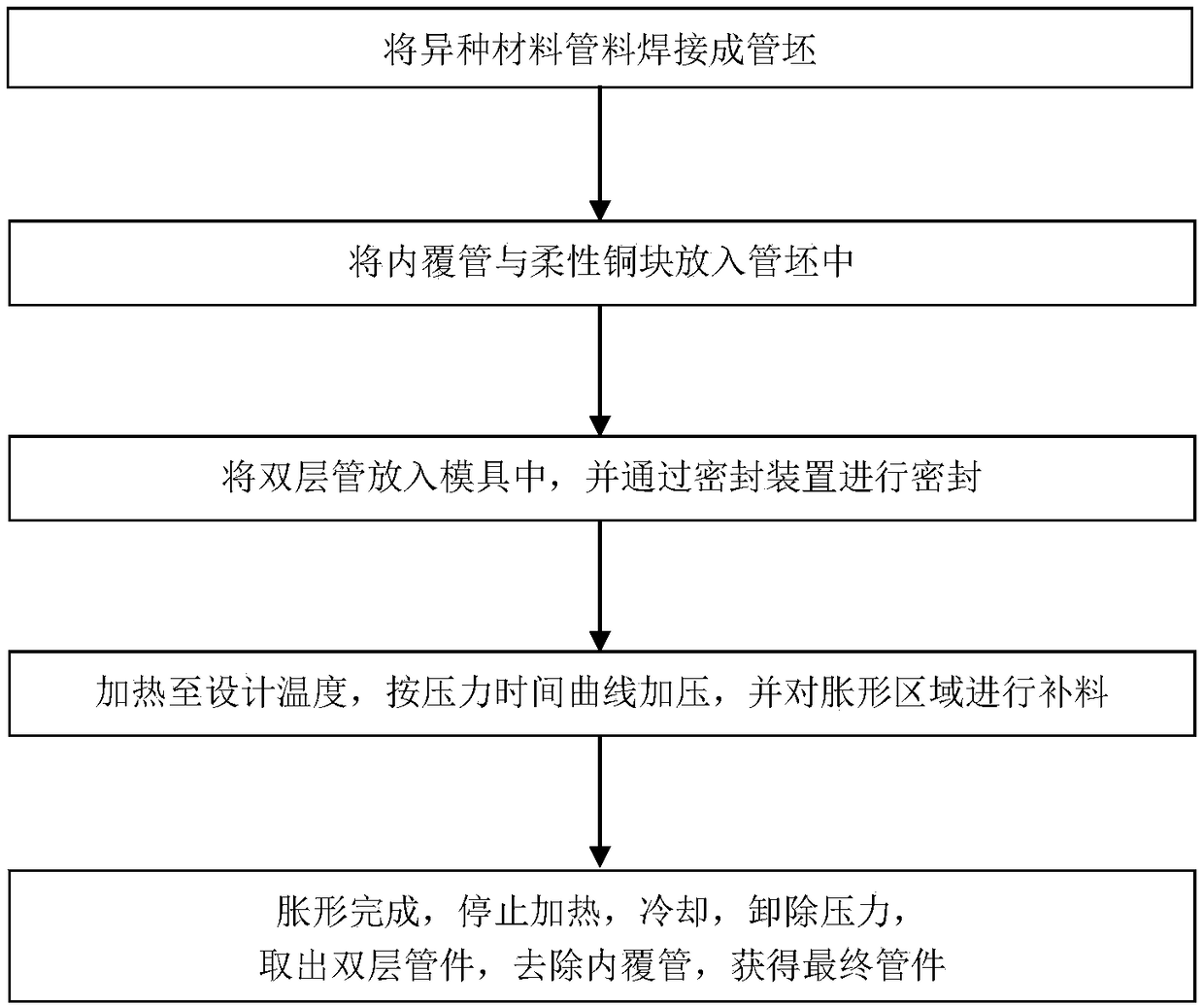

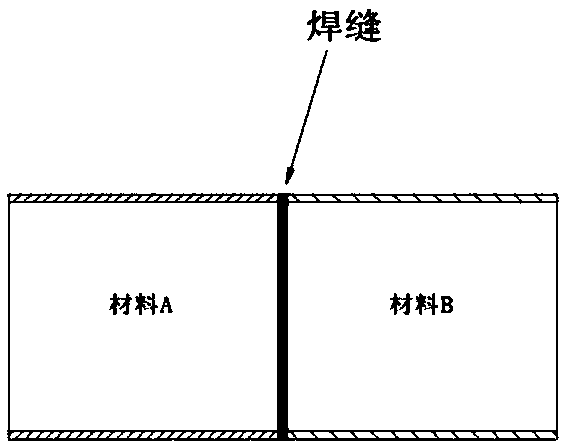

[0058] Such as figure 2 As shown, the tube blank 9 to be processed is formed by welding a tube of material A and a tube of material B;

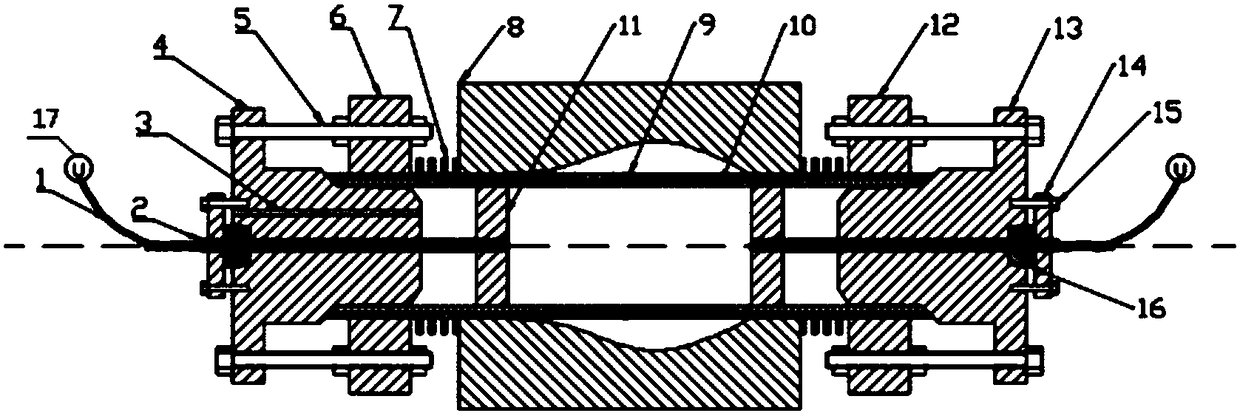

[0059] Such as image 3 The electric-assisted heating inflatable forming device for pipe fittings with complex cross-sections of dissimilar materials shown,

[0060] Including: an inner covering tube 10 with a non-uniformly distributed wall thickness that is placed in the tube blank 9 and matched with the gap, an inflatable forming mold 8 sleeved on the tube blank 9, and an inflatable forming mold 8 sleeved on the tube blank 9 The restraint collars 7 on both sides, the left side indenter 6 and the right side indenter 12 corresponding to the two ends of the tube blank 9 and welded to it, and the left side indenter 6 are connected by bolts 5 and one end extends into the inner cover The left sealing push head 4 in the tube 10, the right sealing push head 13 connected with the right pressure head 12 by bolts 5 and one end extends into the inner cover...

Embodiment 2

[0077] Such as figure 2 As shown, the tube blank 9 to be processed is welded by a pipe fitting of material A and a pipe fitting of material B;

[0078] Adjustable local area electric heating inflatable forming device for complex cross-section pipes of dissimilar materials, such as Figure 7 As shown, the difference between it and the inflatable forming device in the first embodiment is: the structure of the inner cavity of the inflatable forming mold 8 is different, and the inner cavity of the inflatable forming mold 8 in the first embodiment is a circumferential curved surface The cavity, and the inner cavity of the inflatable forming mold 8 in the second embodiment is two circumferentially curved cavities with different cross-sections alternately.

[0079] An adjustable local area electric heating air inflation forming method for pipe fittings with complex cross-sections of dissimilar materials, refer to figure 1 , 2 , 6, 7, and 8. Steps 1 to 5 of this method are the same as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com