Anchor rod-steel frame integrated yielding primary support structure and construction method thereof

A technology of primary support and bolt, which is applied in the installation of bolt, earthwork drilling, wellbore lining, etc. It can solve the problems of steel frame being easily twisted and damaged, unreasonable force, and broken bolt, etc., to achieve Avoiding excessive deformation of surrounding rock, reasonable stress, and releasing confining pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific examples, which are only used to explain the present invention, and are not limited to this example. After reading the present invention, all equivalent replacements and modifications made within the principle of the present invention belong to the protection scope of the present invention.

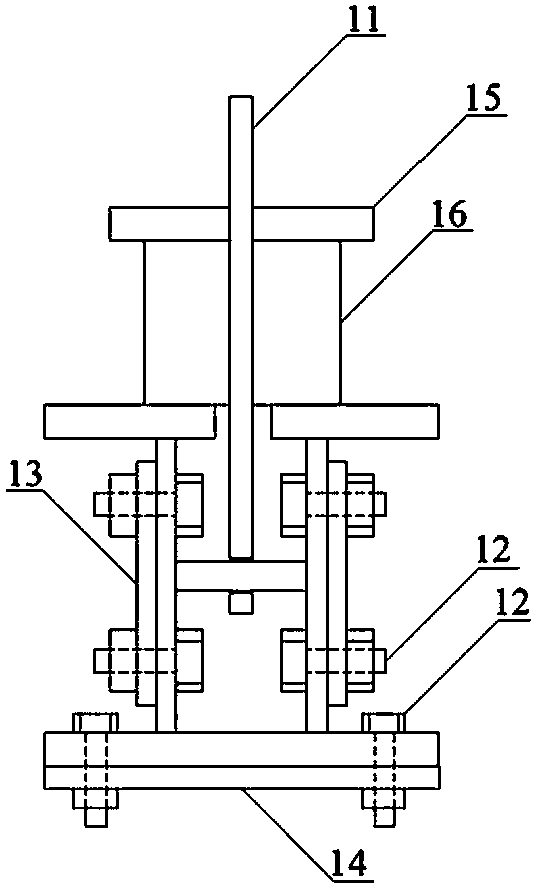

[0018] The present invention relates to an anchor rod-steel frame combined yielding initial support structure and a construction method. The anchor rod-steel frame combined yielding initial support structure includes a steel arch 1, a buckling energy-consuming structure 2, a yielding anchor 3 and The force conversion rod 11, the steel arch 1 is composed of more than two arc-shaped arches 4, and the arc-shaped arches 4 are formed by parallel welding of two H-shaped steels of the same type and length, and the webs and lower flanges at both ends are opened. Bolt holes, high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com