Slab-column structure hollow slap with mixed use of filling rod and filling box

A plate-column structure and filler rod technology, which is applied to floors, building components, building structures, etc., can solve the problems of large hollowness and no structural large hollowness, and achieve large hollowness, light weight, and the development of building technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is realized in the following manner:

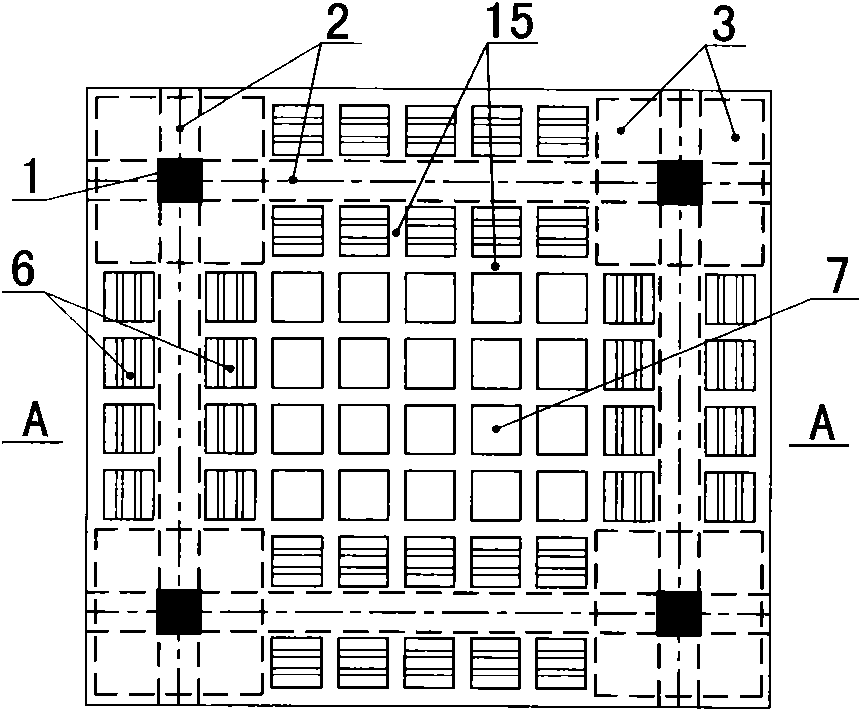

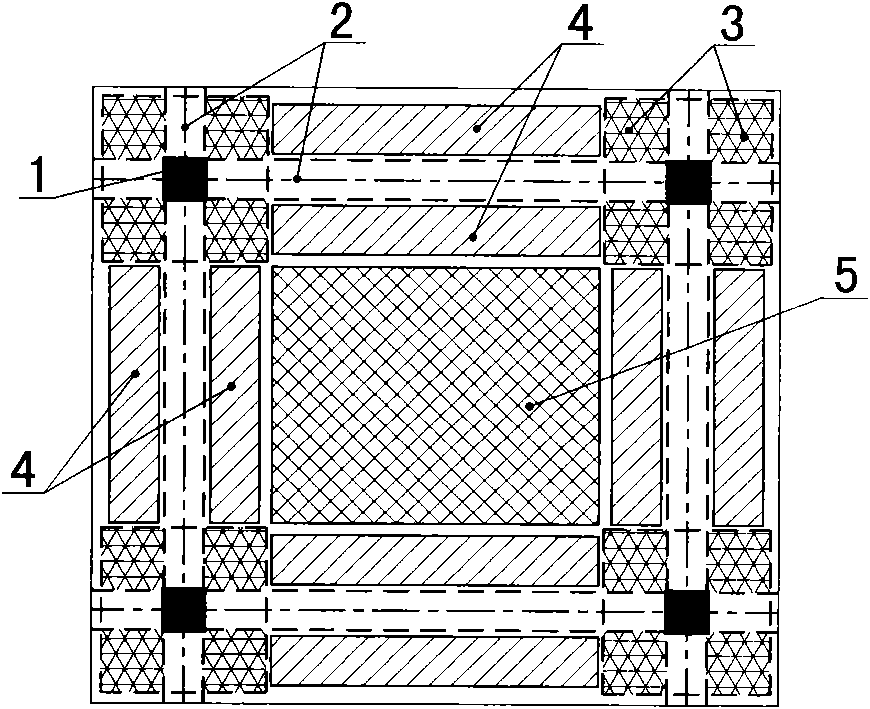

[0031] exist Figure 1-Figure 3 In the shown embodiment, a hollow slab with a slab-column structure mixed with filled rods and filled boxes includes a column (1), a beam (2), a solid area around the column (3), a hollow area around the beam (4), a central The hollow area (5) is characterized in that a filling rod combination block (6) is installed in the beam side hollow area (4), the length direction of the filling rod is the orientation of the filling rod combination block, and the filling rod in the beam side hollow area (4) The orientation of the combination block (6) is consistent with the direction of the adjacent beam (2), the filling box (7) is installed in the central hollow area (5), and the filling rod combination block (6) and the filling box (7) are located on the upper reinforcement (8) and the lower layer of reinforcement (9), permanently buried in the concrete (10).

[0032] exist Figure 4-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com