Titanium boride nanowhisker reinforced titanium-based composite material and preparation method thereof

A technology of titanium-based composite materials and nano-whiskers is applied in the field of metal-based nano-structure composite materials, which can solve the problems of insignificant strengthening effect and low plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

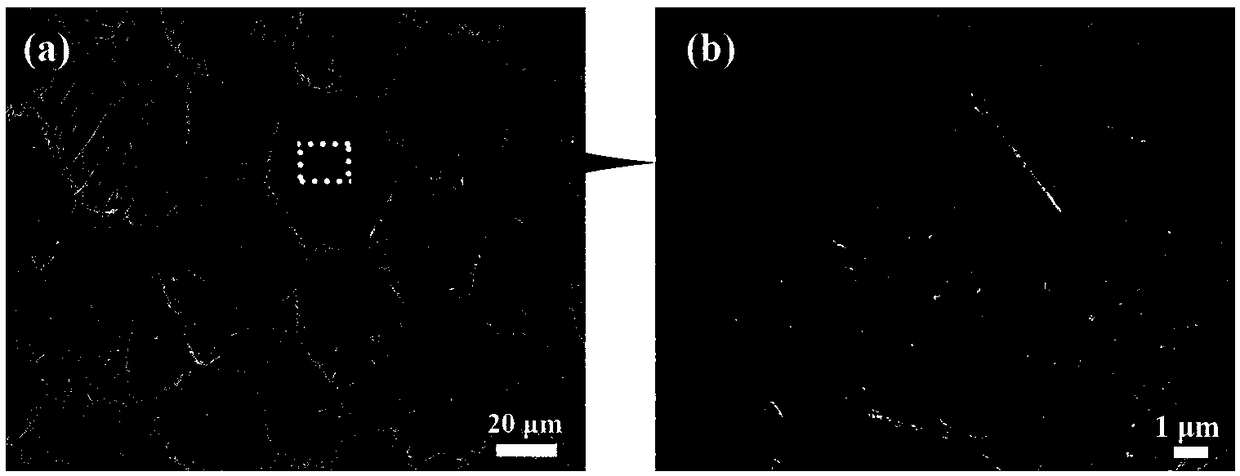

[0031] Proportion the Ti6Al4V powder with a particle size of 45-75 μm and the nano-boron (B) powder with a particle size of 100 nm, so that the TiB content in the titanium matrix after reaction is 5 vol.%. The ball makes the ball-to-material ratio 2:1, and argon (Ar) is sealed in the container as a protective gas; the stainless steel container is placed on the Turbula mixer, the speed is 150rmp, and the mixing time is 4h; the mixed powder is taken out and placed into a graphite mold, and then discharge plasma sintering at 30MPa and 1000°C for 7 minutes to obtain a TiB nano-whisker strengthened α+β-Ti alloy-based composite material; the length of the nano-whiskers is 5-30 μm, and the diameter is 50-300 nm. The aspect ratio is greater than 60. Its microstructure is as figure 1 shown.

[0032] The room temperature tensile strength of the obtained composite material is 1285MPa, the yield strength is 1140MPa, and the elongation is 7%. Compared with Ti6Al4V without TiB, its streng...

Embodiment 2

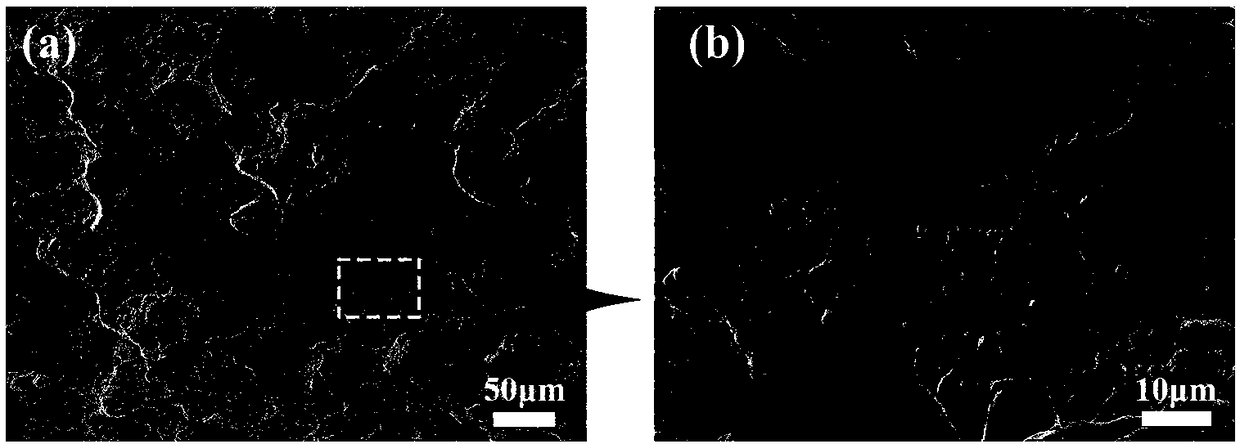

[0034] Pure Ti powder with a particle size of less than 45 μm and nano-B with a particle size of 50 nm 4C powder proportioning, make the TiB content after the reaction in the titanium matrix be 6.2vol.%; Proportioning powder is placed in the stainless steel container, and add stainless steel iron ball and make ball material ratio be 2:1, and argon (Ar ) is used as a protective gas and sealed in the container; the stainless steel container is placed on the Turbula mixer, the speed is 150rmp, and the mixing time is 4h; the mixed powder is taken out, placed in a graphite mold, and then discharged plasma sintering at 35MPa and 1100°C After 7 minutes, the TiB nano-whisker-strengthened Ti-based composite material is obtained; the nano-whiskers have a length of 5-30 μm, a diameter of 50-300 nm, and an aspect ratio greater than 60.

[0035] The room temperature tensile strength of the obtained composite material is 870MPa, the yield strength is 730MPa, and the elongation is 16%. Compa...

Embodiment 3

[0037] Mix pure Ti powder with a particle size of less than 45 μm and Fe powder with a particle size of less than 10 μm with nano-BN powder with a particle size of 30 nm, so that the composition of the composite material is Ti-0.25BN-2.5Fe; put the proportioned powder into a stainless steel container , and add stainless steel iron balls so that the ball-to-material ratio is 1:2, and argon (Ar) is sealed in the container as a protective gas; the stainless steel container is placed on the Turbula mixer, the rotating speed is 150rmp, and the mixing time is 3h; Take out the mixed powder, put it into a graphite mold, and then discharge plasma sintering at 30MPa and 1000°C for 8 minutes to obtain a TiB nano-whisker-strengthened β-Ti alloy matrix composite material; the nano-whiskers have a length of 5-30 μm and a diameter of 50 ~300nm, aspect ratio greater than 60.

[0038] The room temperature tensile strength of the obtained composite material is 958MPa, the yield strength is 830M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com