Preparation method of molybdenum tube

A technology of molybdenum tube and molybdenum powder, which is applied in the field of refractory metal tube preparation, can solve the problems of difficult production, low density of molybdenum tube billet, uneven grain structure and density of molybdenum tube target, and achieve easy processing and good Deformability, easy welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

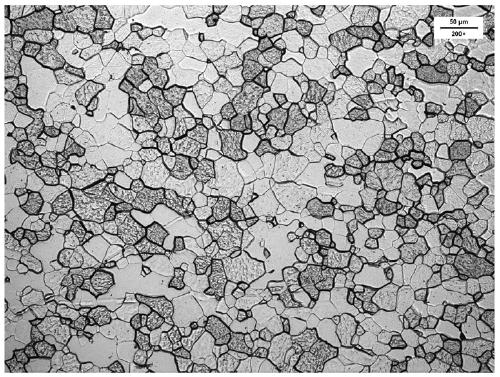

Embodiment 1

[0041] Select 124Kg of molybdenum powder with a Fibonacci particle size of 2.8 μm; put the molybdenum powder into a stainless steel sheath, and fully vibrate it on a vibrating platform; heat the vibrated stainless steel sheath to 750°C, and evacuate until the vacuum degree is higher than 1 ×10 -2 Pa, keep warm for 2 hours, cool with the furnace, and use argon arc welding for sealing welding; place the sealed stainless steel sheath in a hot isostatic pressing furnace, and the supporting mandrel is a molybdenum alloy rod. Hot isostatic pressing under the condition of 160MPa for 2 hours, and cooled with the furnace, prepared a molybdenum tube blank with an inner diameter of 130mm, an outer diameter of 185mm, and a length of 900mm, and its density was tested to be 10.12g / cm 3 ; Place the molybdenum tube blank in an intermediate frequency induction furnace, heat it at 1250°C for 30 minutes, and then take it out of the furnace for hot extrusion. The extrusion ratio is 2, and the ext...

Embodiment 2

[0043] Select 331Kg of molybdenum powder with a Fibonacci particle size of 3.2μm; put the molybdenum powder into a stainless steel sheath, and fully vibrate it on a vibration platform; heat the vibrated stainless steel sheath to 850°C, and evacuate until the vacuum degree is higher than 5 ×10 -3 Pa, keep warm for 1.5 hours, cool with the furnace, and seal welding with argon arc welding; place the stainless steel sheath for sealing welding in a hot isostatic pressing furnace, and the supporting mandrel is a tungsten alloy rod. Hot isostatic pressing for 3 hours under the condition of 180MPa, and cooled with the furnace to prepare a molybdenum tube billet with an inner diameter of 135mm, an outer diameter of 227mm, and a length of 1250mm. The density was 10.13g / cm after testing. 3 ; Place the molybdenum tube blank in an intermediate frequency induction furnace, heat it at 1300°C for 50 minutes, and then take it out of the furnace for hot extrusion. The extrusion ratio is 2.4. Th...

Embodiment 3

[0045] Select 493Kg of molybdenum powder with a Fibonacci particle size of 3.0 μm; put the molybdenum powder into a stainless steel sheath, and fully vibrate it on a vibration platform; heat the vibrated stainless steel sheath to 800°C, and evacuate until the vacuum degree is higher than 5 ×10 -3 Pa, keep warm for 2.5 hours, then cool with the furnace, and use argon arc welding for sealing welding; place the sealed stainless steel sheath in a hot isostatic pressing furnace, and the supporting mandrel is a tungsten alloy rod. Hot isostatic pressing for 3 hours under the condition of 200MPa, and cooled with the furnace to prepare a molybdenum tube billet with an inner diameter of 135mm, an outer diameter of 244mm, and a length of 1500mm, and its density was tested to be 10.13g / cm 3 ; Place the molybdenum tube blank in an intermediate frequency induction furnace, heat it at 1350°C for 60 minutes, and then take it out of the furnace for hot extrusion. The extrusion ratio is 3, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com