Flexible high-sulfur load self-repairing cathode structure for lithium-sulfur battery and preparation method of flexible high-sulfur load self-repairing cathode structure

A lithium-sulfur battery and self-repairing technology, which is applied in the field of electrochemical batteries, can solve the problems that cannot reflect high specific capacity and high specific energy density, limit the commercial application of lithium-sulfur batteries, and do not consider the application of lithium-sulfur batteries, etc., to achieve relief The effects of mechanical damage resistance, large application value, and strong electrolyte storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] First, use nickel foam as a template (75mm×75mm×1.9mm, the pore size distribution is about 110PPI, and the surface density is about 300g / m 2 ), adopt CVD method, obtain the nickel foam of surface coating graphene, the average thickness of growth graphene film is about 100nm.

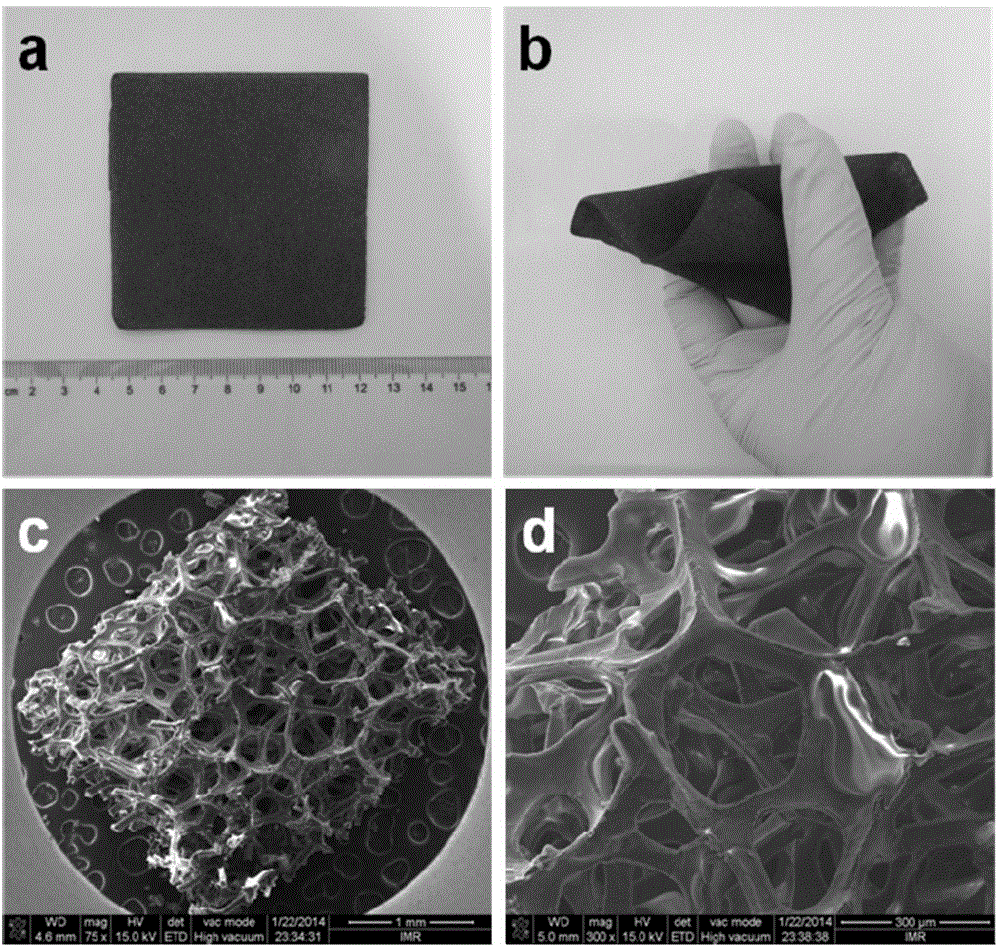

[0036] Then, the polydimethylsiloxane and the dibutyltin dilaurate curing agent were diluted in ethyl acetate according to the volume ratio of (10:1) to obtain a polymer diluent. The high molecular polymer dilution was coated on the graphene-coated nickel foam by pulling and impregnating, and dried and cured in an oven at 80°C for 6 hours. Then put it into 3mol / L hydrochloric acid solution, react at 80°C for 12 hours to dissolve the foamed nickel template, and finally obtain a graphene / polymer flexible foam with self-healing ability. It can be seen from the macroscopic photos that the obtained graphene / polymer completely replicates the morphology and structure of the metal foam template, as shown...

Embodiment 2

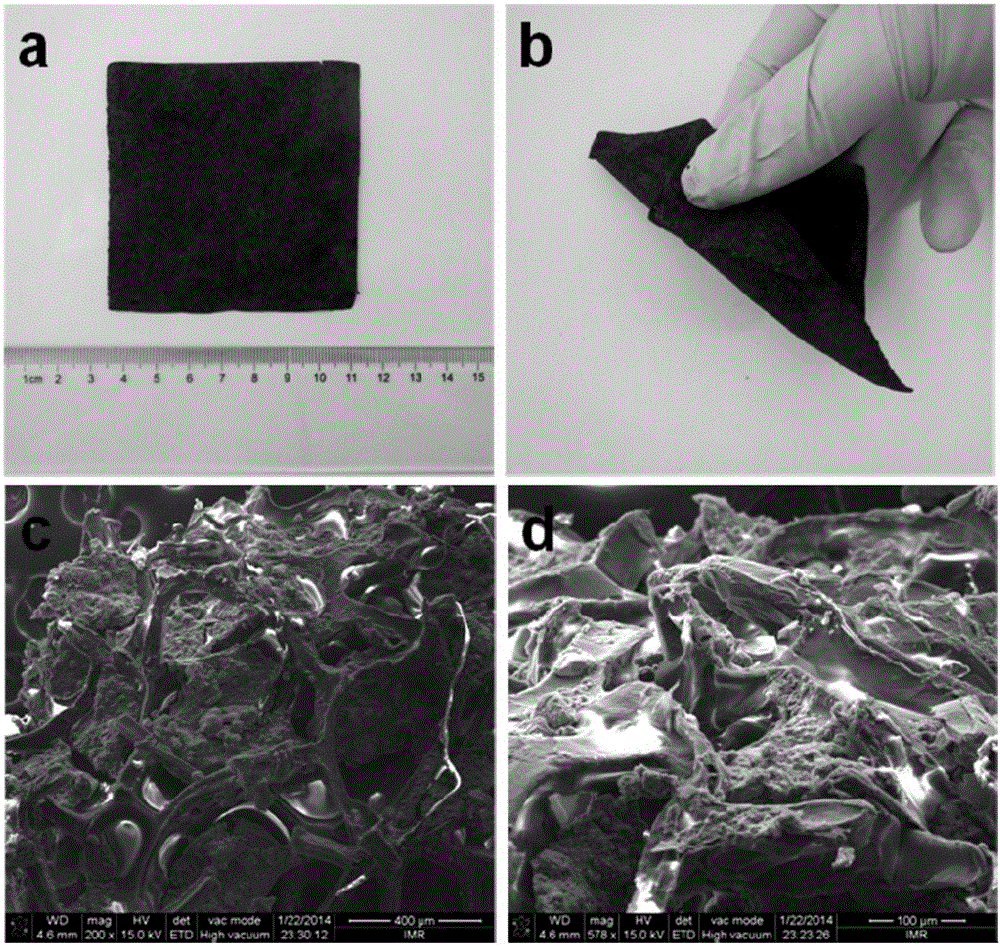

[0042] The difference from Example 1 is that the carbon / sulfur active material slurry formed by mixing sulfur: conductive carbon black: binder (polyvinylidene fluoride) in a weight ratio of 7:2:1 is poured into the The graphene / polymer flexible foam was vacuum-dried at 70°C for 12 hours to obtain a three-dimensional flexible high-sulfur-loaded self-healing cathode for a lithium-sulfur battery. figure 2 (a), the surface density of the active substance sulfur is increased to 6.1mg / cm 2 . Rate performance curves of three-dimensional flexible high-sulfur-loaded self-healing cathodes of lithium-sulfur batteries at different current densities ( Figure 6 ), at 300mA·g -1 Under the highest current density, the initial discharge capacity can reach 1200mAh·g -1 , see the discharge capacity at various current densities Figure 6 , at 6000mA·g -1 Discharge capacity at current density exceeds 500mAh·g -1 , showing superior rate performance, after the rate test continued at 750mA·g ...

Embodiment 3

[0046] The difference from Example 1 is:

[0047] Polydimethylsiloxane and dibutyltin dilaurate were replaced by polyamide-polyester copolymers to enhance the flexibility of the three-dimensional graphene network and impart certain self-healing properties. The reaction process is as follows: the dimer acid is first mixed with diethylenetriamine, and the end of the reactant is NH 2 oligomers. Then the oligomer (M-NH 2 t) React with urea, control the amount of urea added and the reaction time, dilute it with toluene, apply the diluted solution to the graphene-coated nickel foam by spraying, and dry it in an oven at 80°C Cured for 10h. Then put it into 3mol / L hydrochloric acid solution, and react at 80°C for 12 hours to dissolve the foamed nickel template, and a self-healing graphene / polymer flexible foam with dynamic hydrogen bonds can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com