Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

284 results about "Rupture disc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rupture disk, also known as a pressure safety disc, burst disc, bursting disc, or burst diaphragm, is a non-reclosing pressure relief safety device that, in most uses, protects a pressure vessel, equipment or system from overpressurization or potentially damaging vacuum conditions.

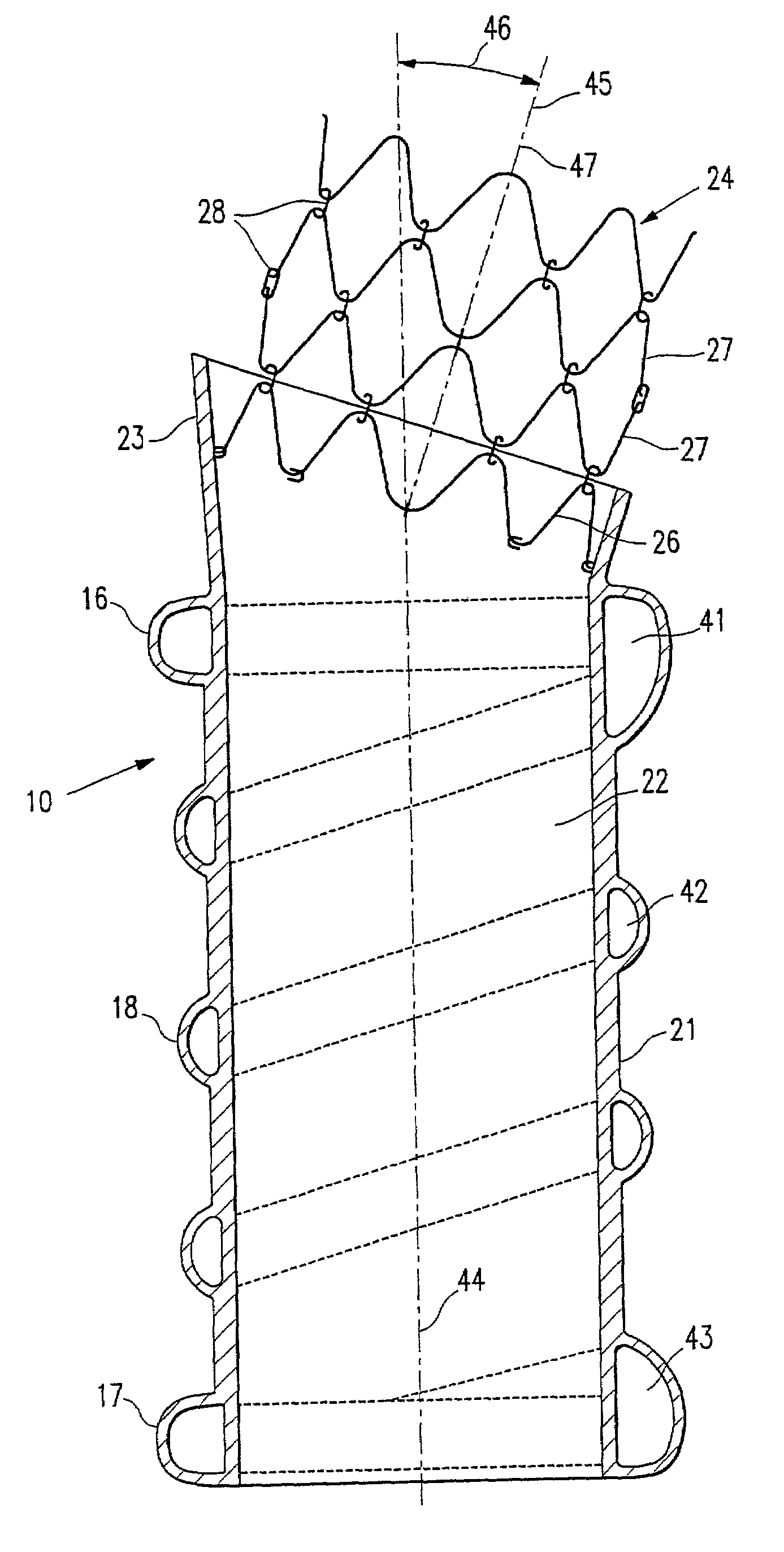

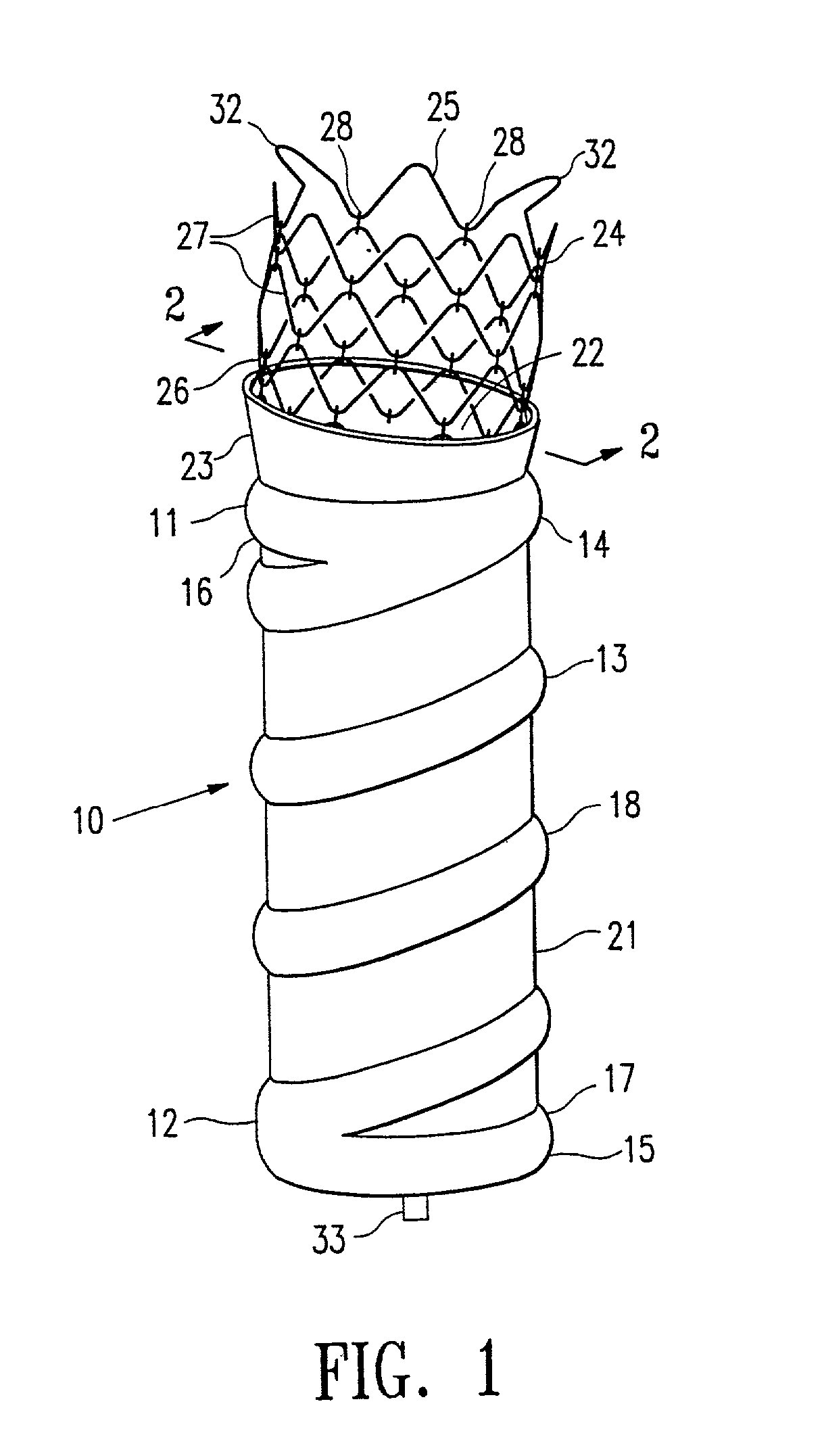

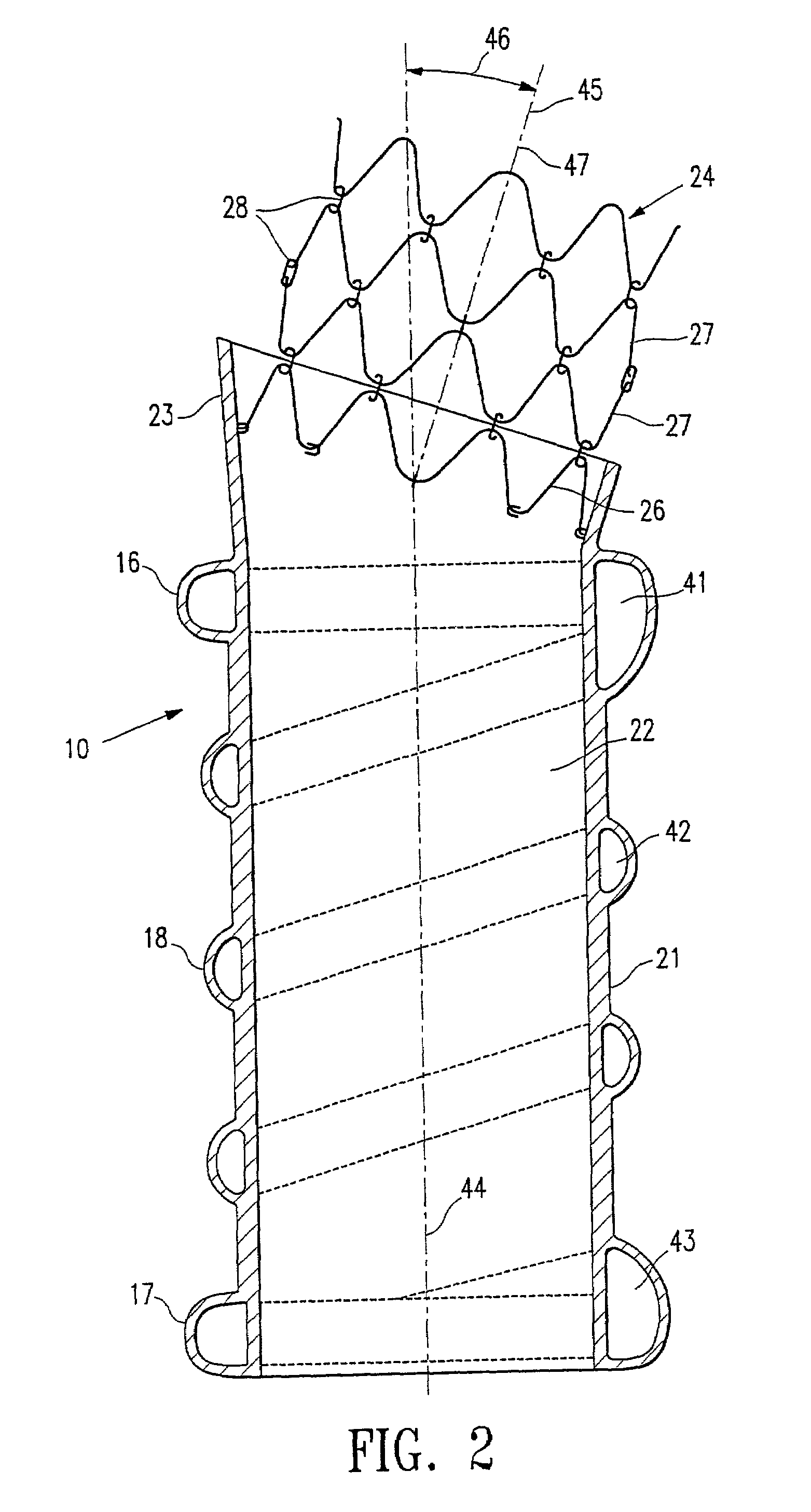

Endovascular graft

InactiveUS7081129B2Increase and decrease diameterIncrease the diameterStentsHeart valvesAxial displacementShape-memory alloy

An endovascular graft which is configured to conform to the morphology of the vessel to be treated and which is made from an inflatable structure having a proximal end with a proximal inflatable cuff and a distal end with a distal inflatable cuff. At least one elongated inflatable channel is disposed between and in fluid communication with fluid tight chambers of the inflatable cuffs which may contain rupture discs therebetween which can be configured to rupture at different pressures. A thin flexible barrier disposed between the inflatable cuffs and the elongated inflatable channel of the frame so as to form a tubular structure defining a longitudinal channel to confine a flow of blood or other fluid therethrough. The graft may also have an expansion member attached to the proximal end of the graft which is preferably made of linked expandable rings of pseudoelastic shape memory alloy which is self expanding and prevents axial displacement of the graft once it is deployed.

Owner:BOSTON SCI CORP

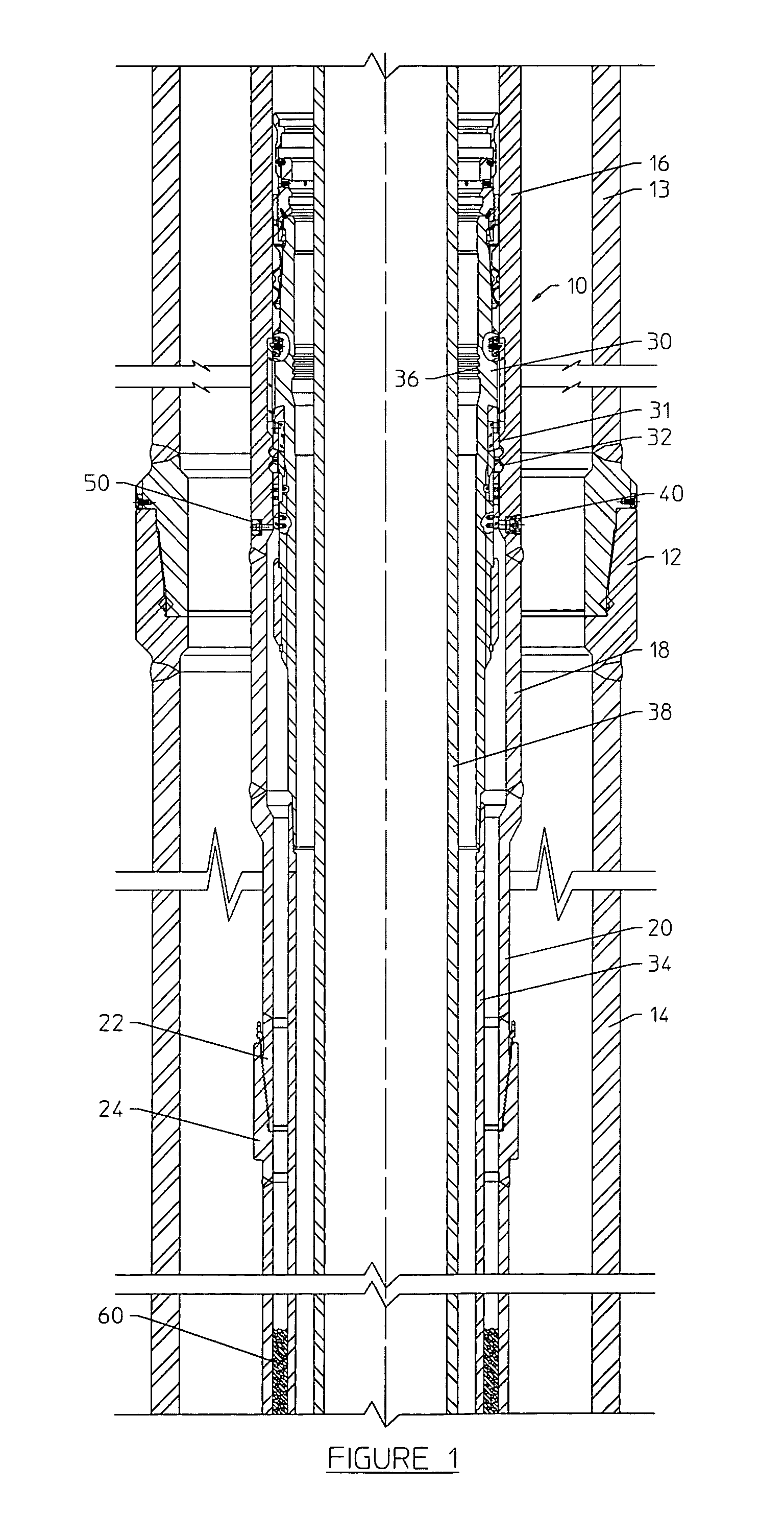

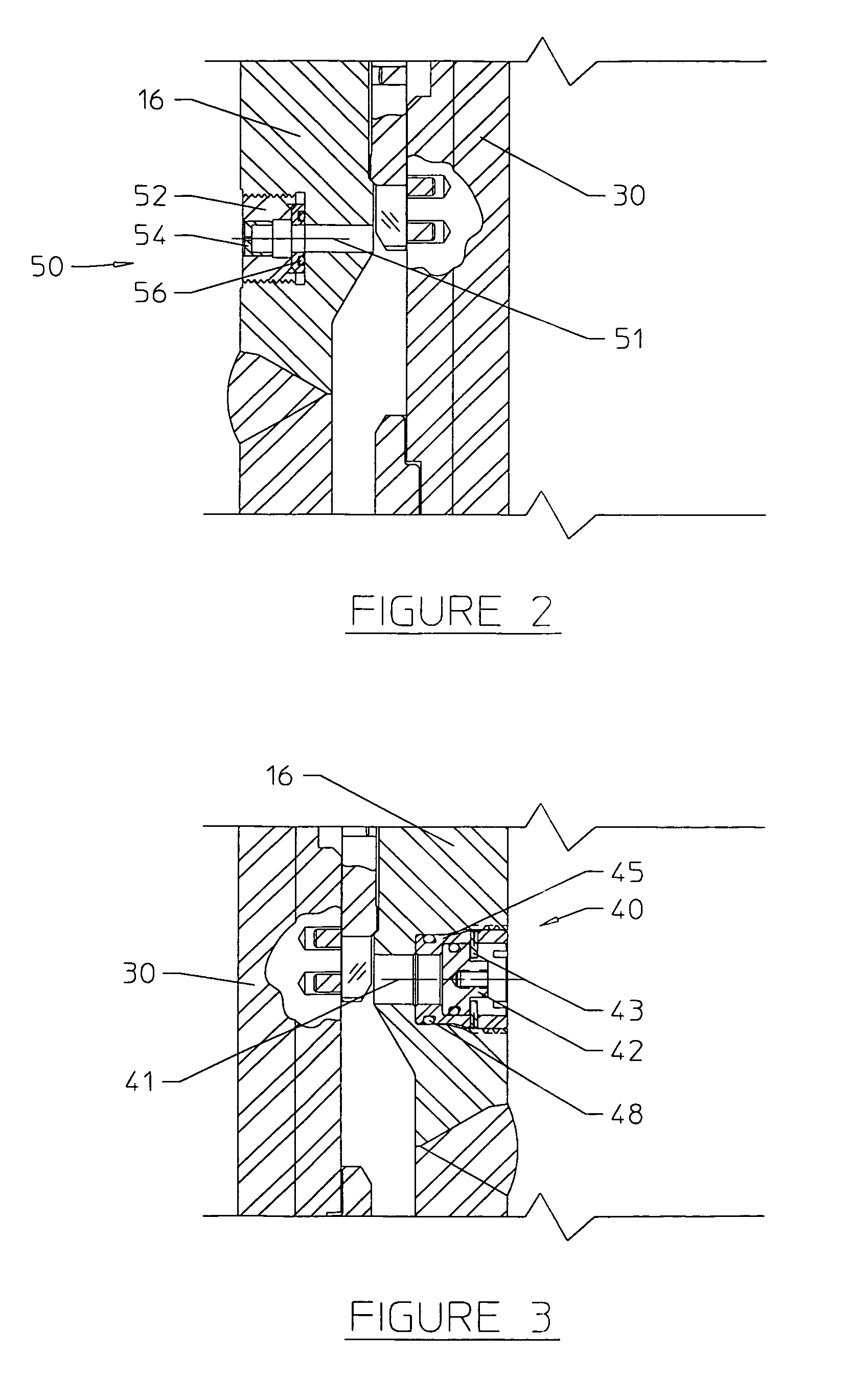

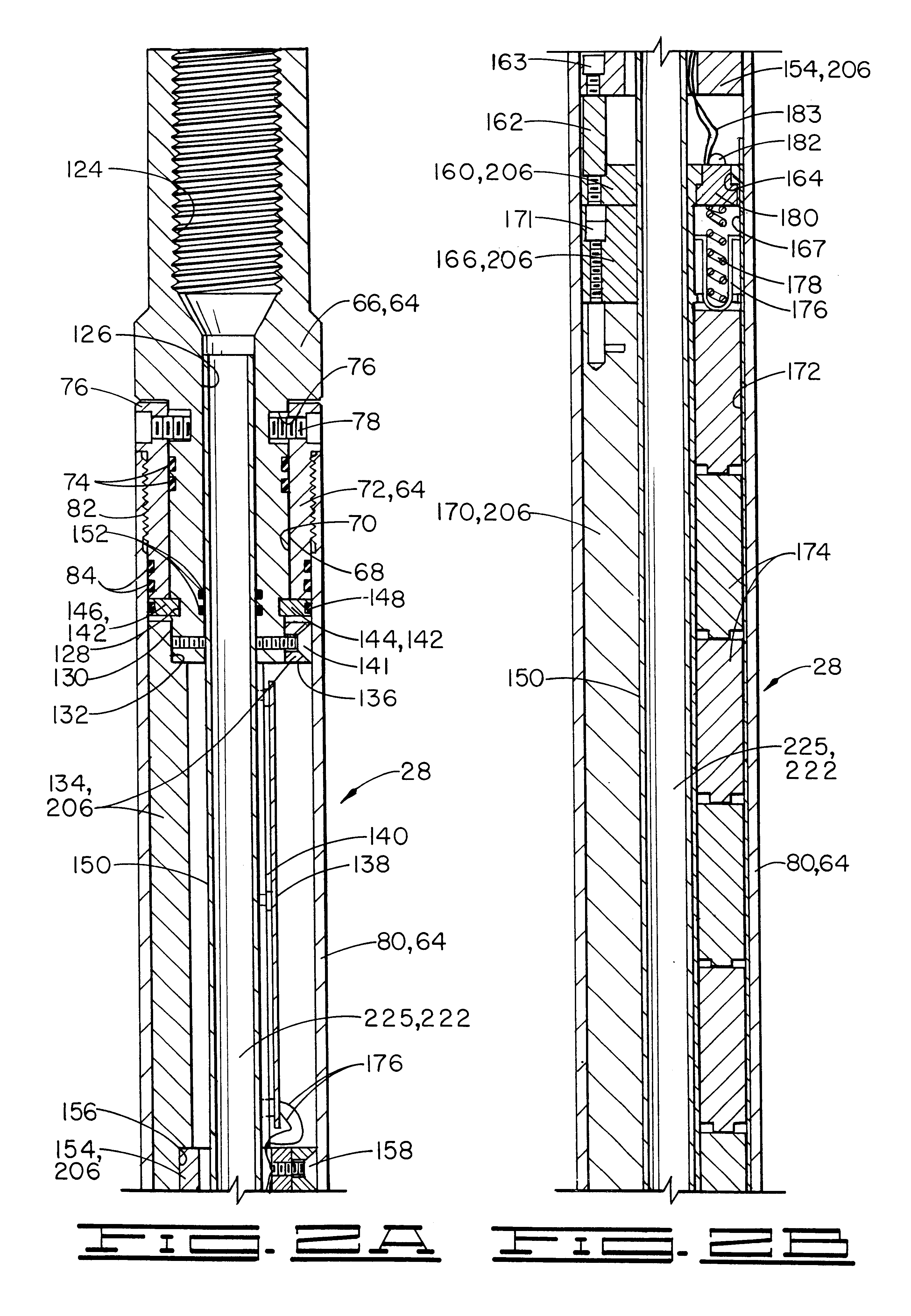

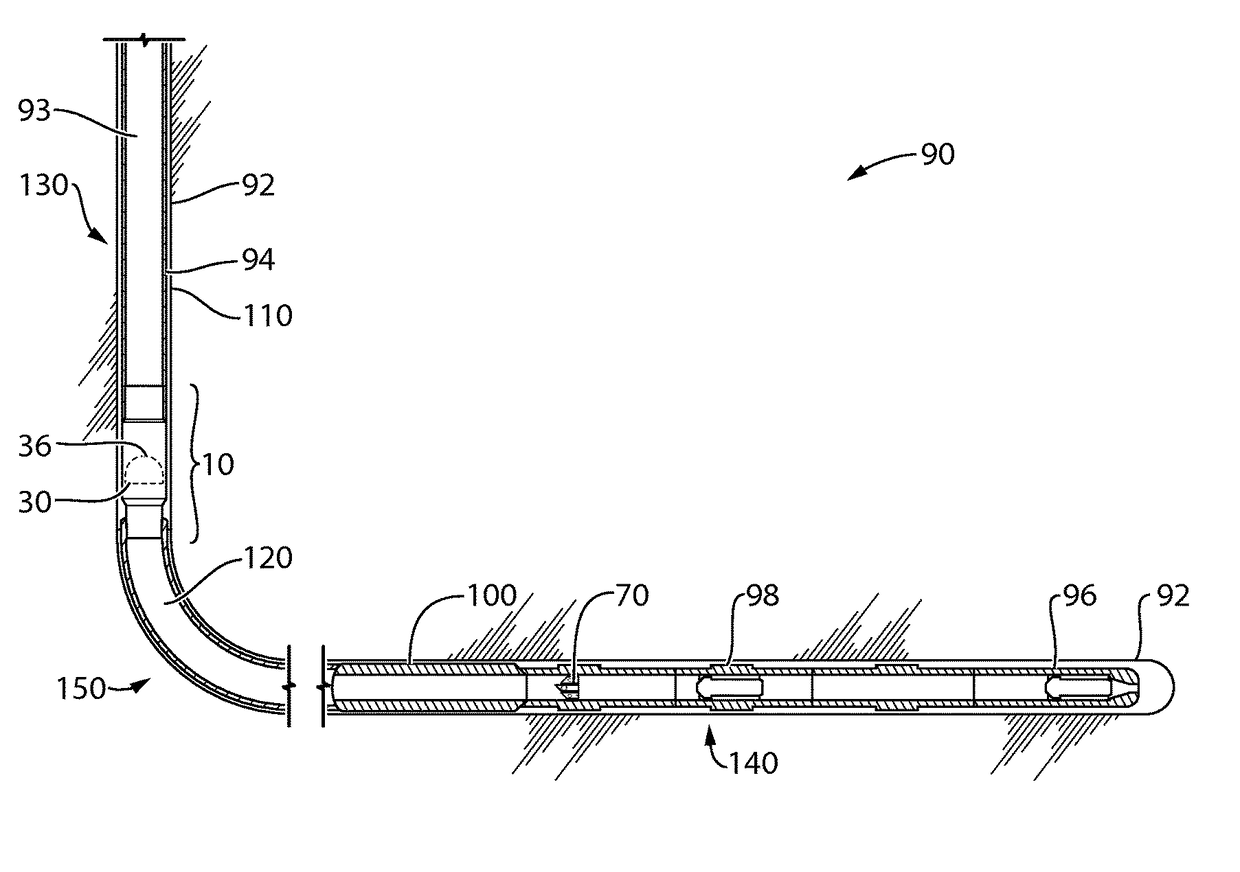

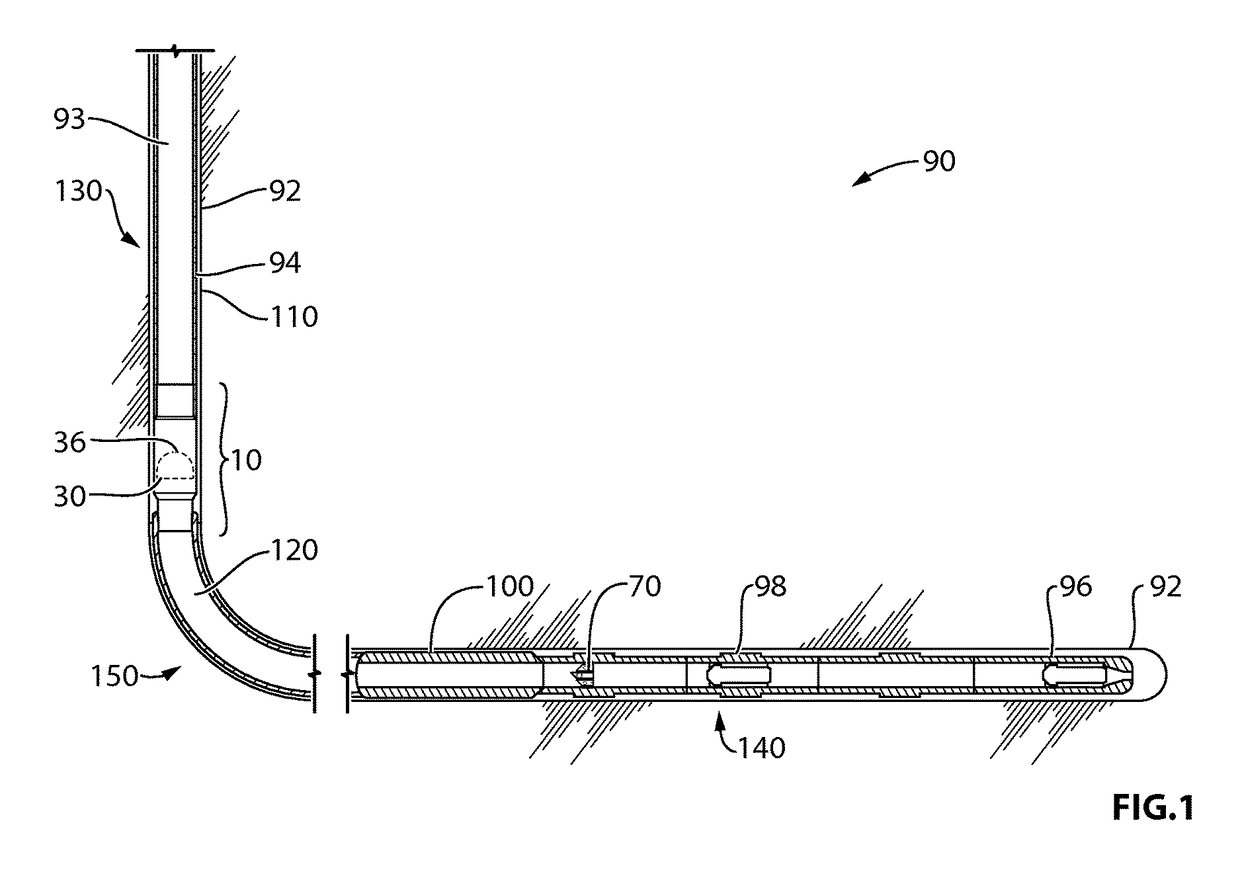

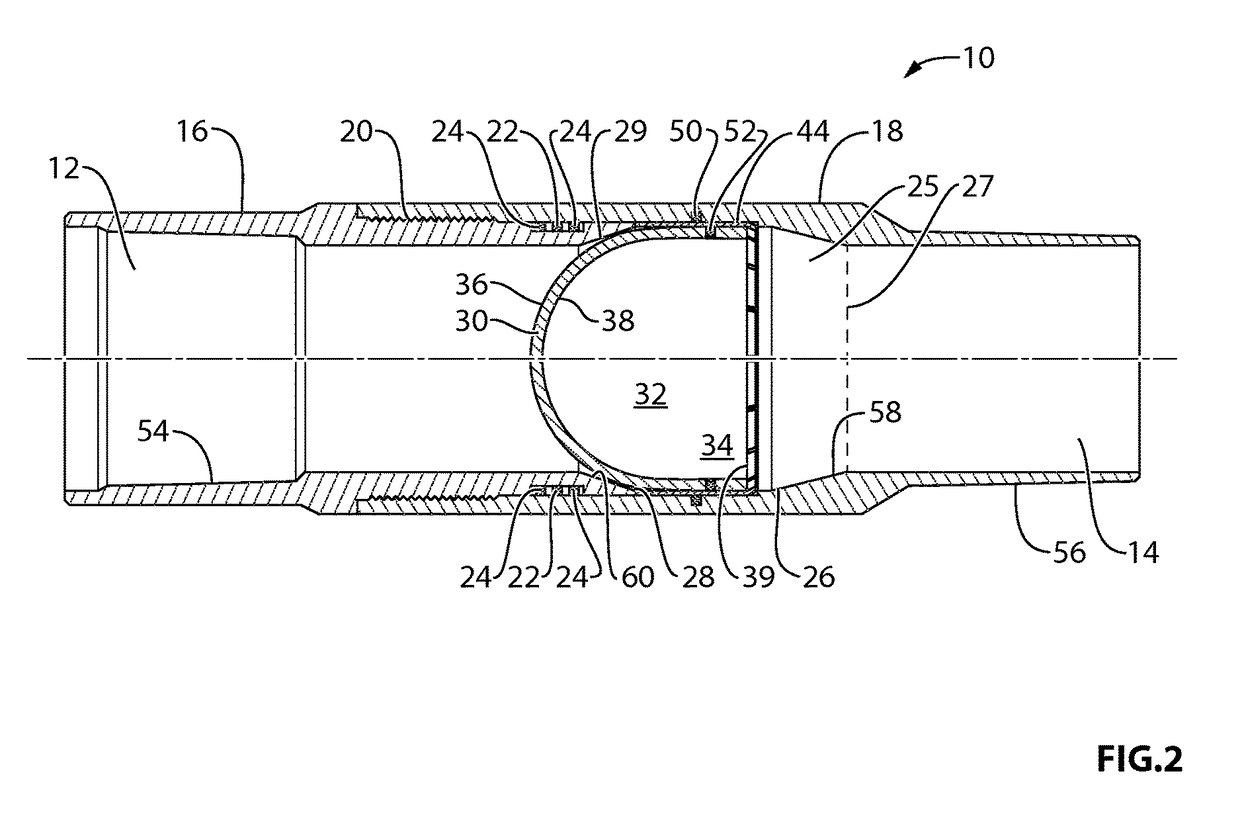

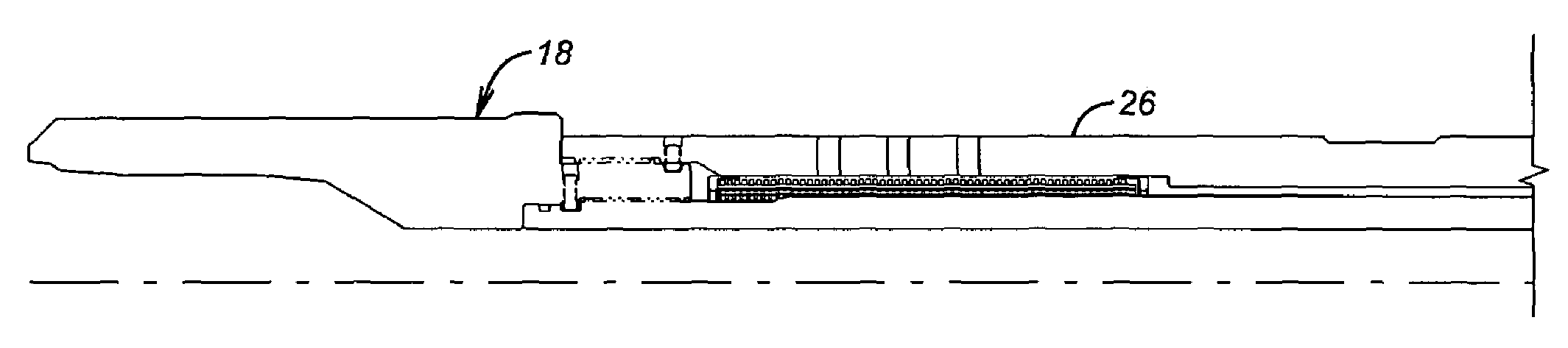

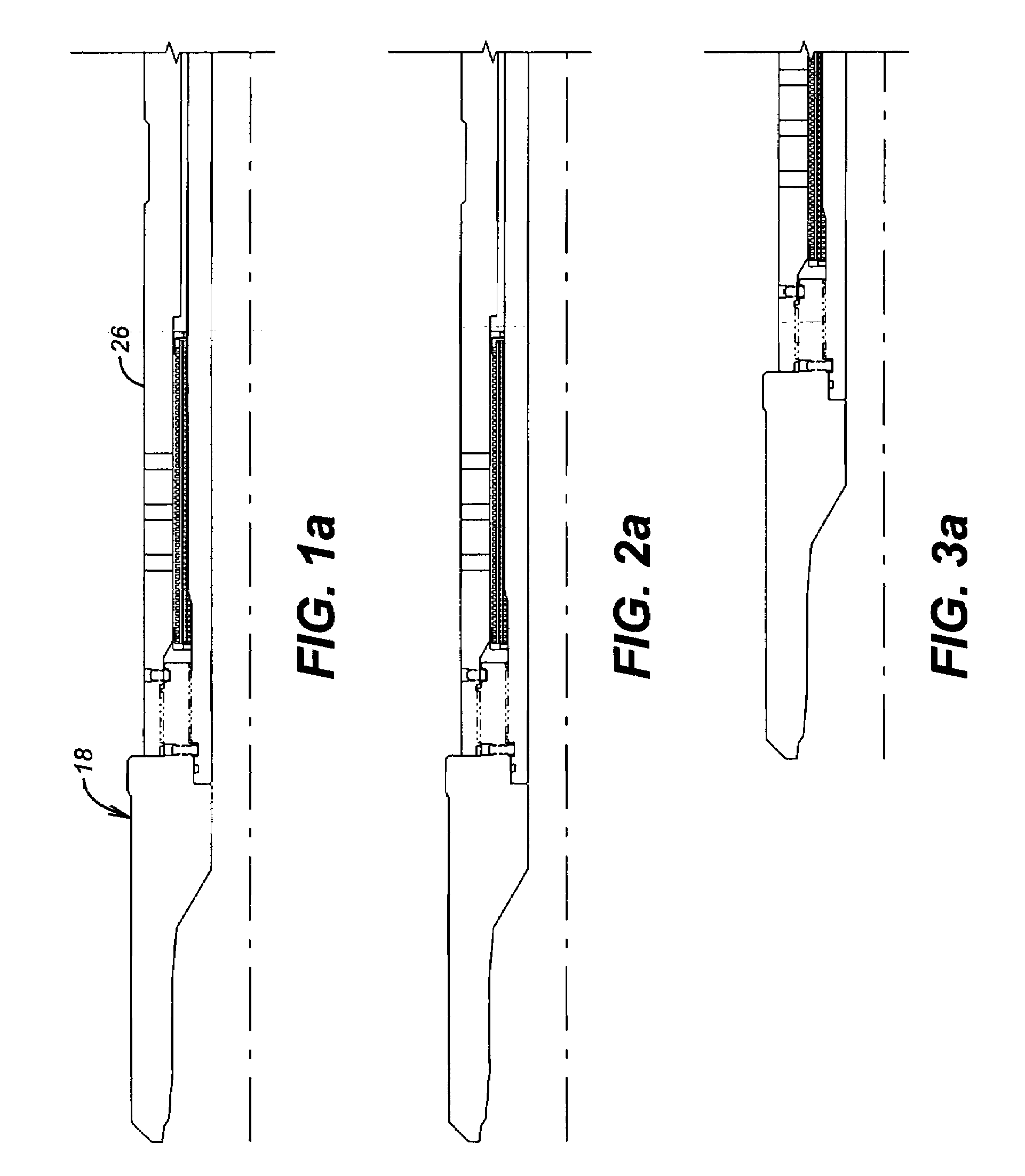

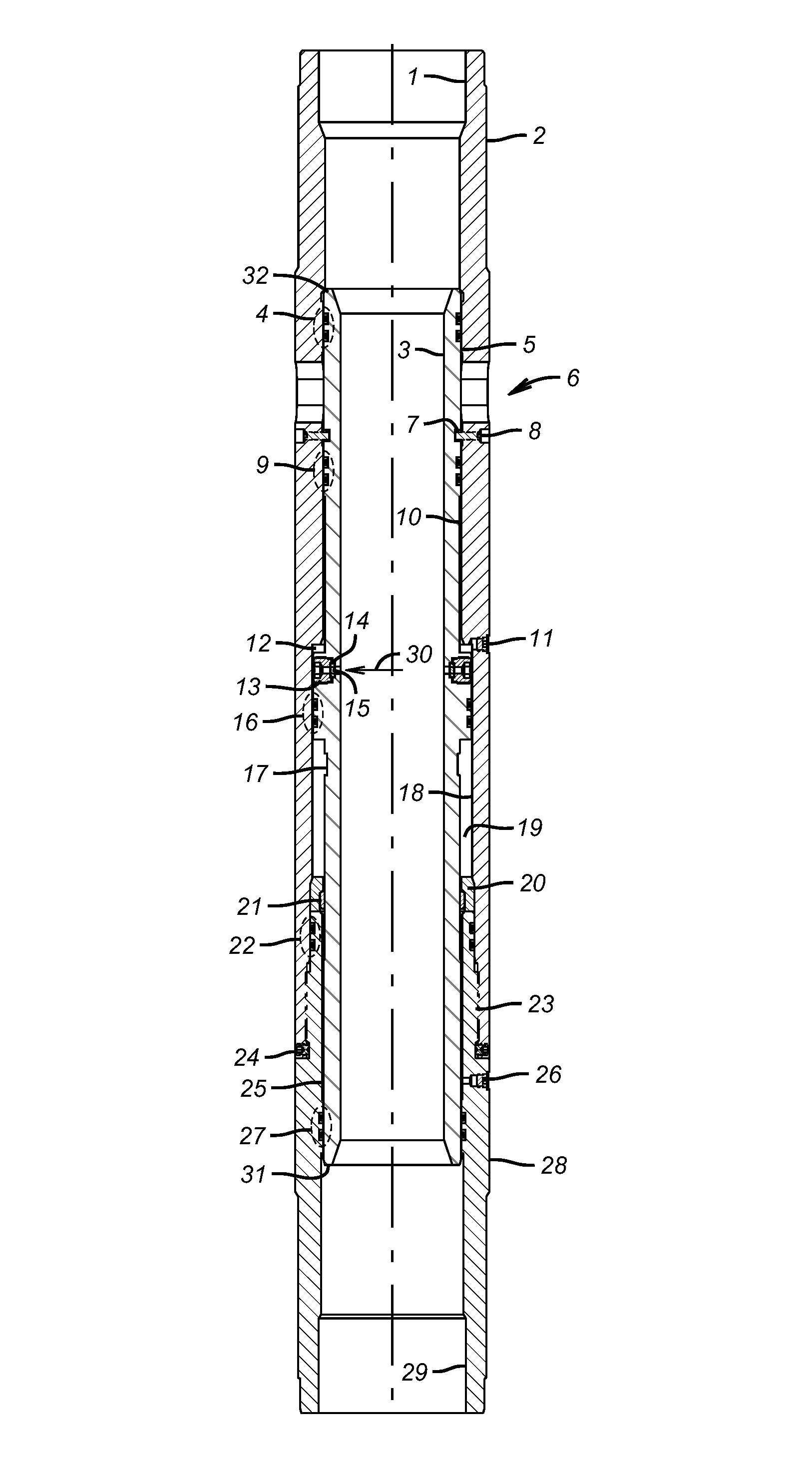

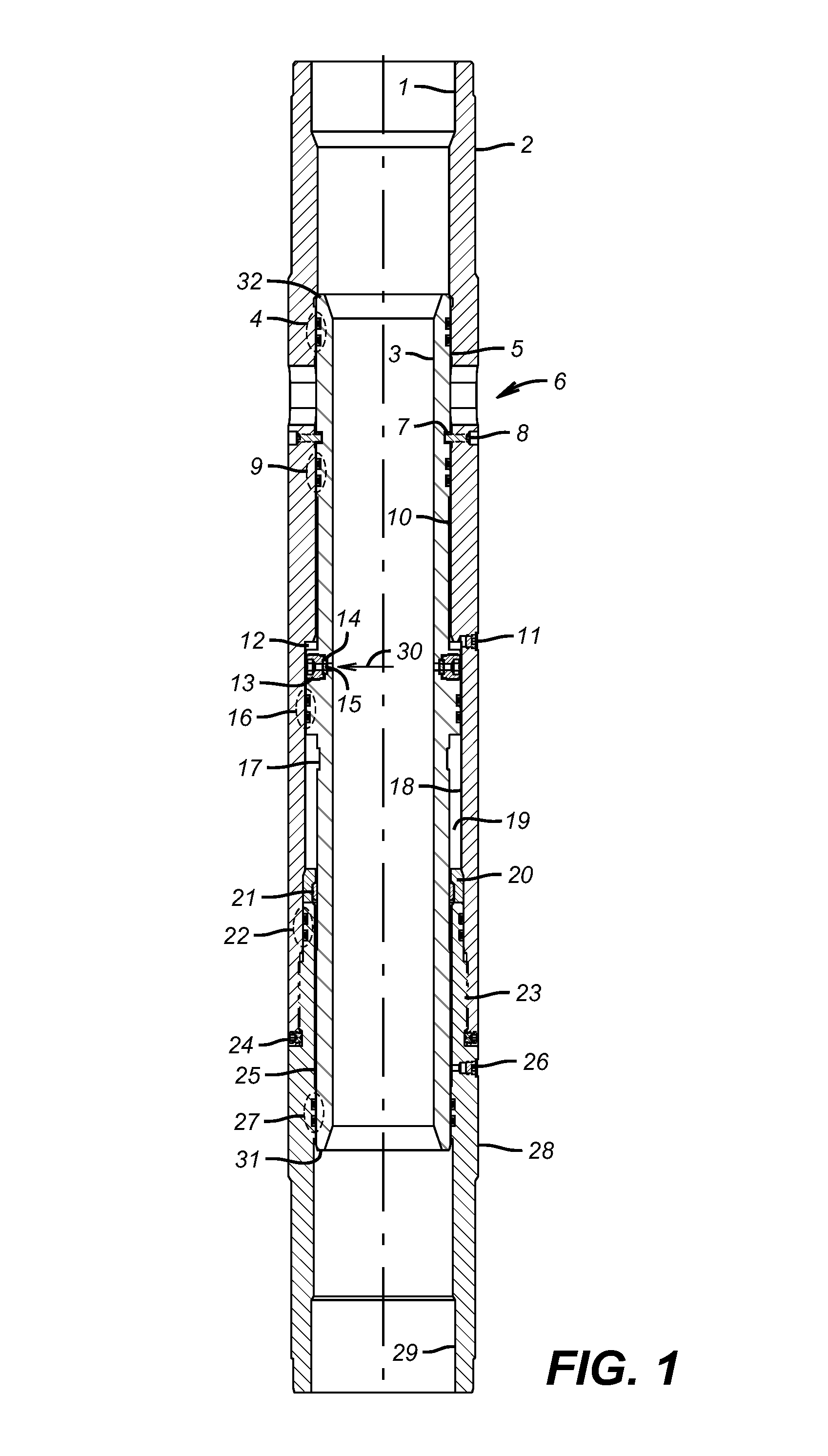

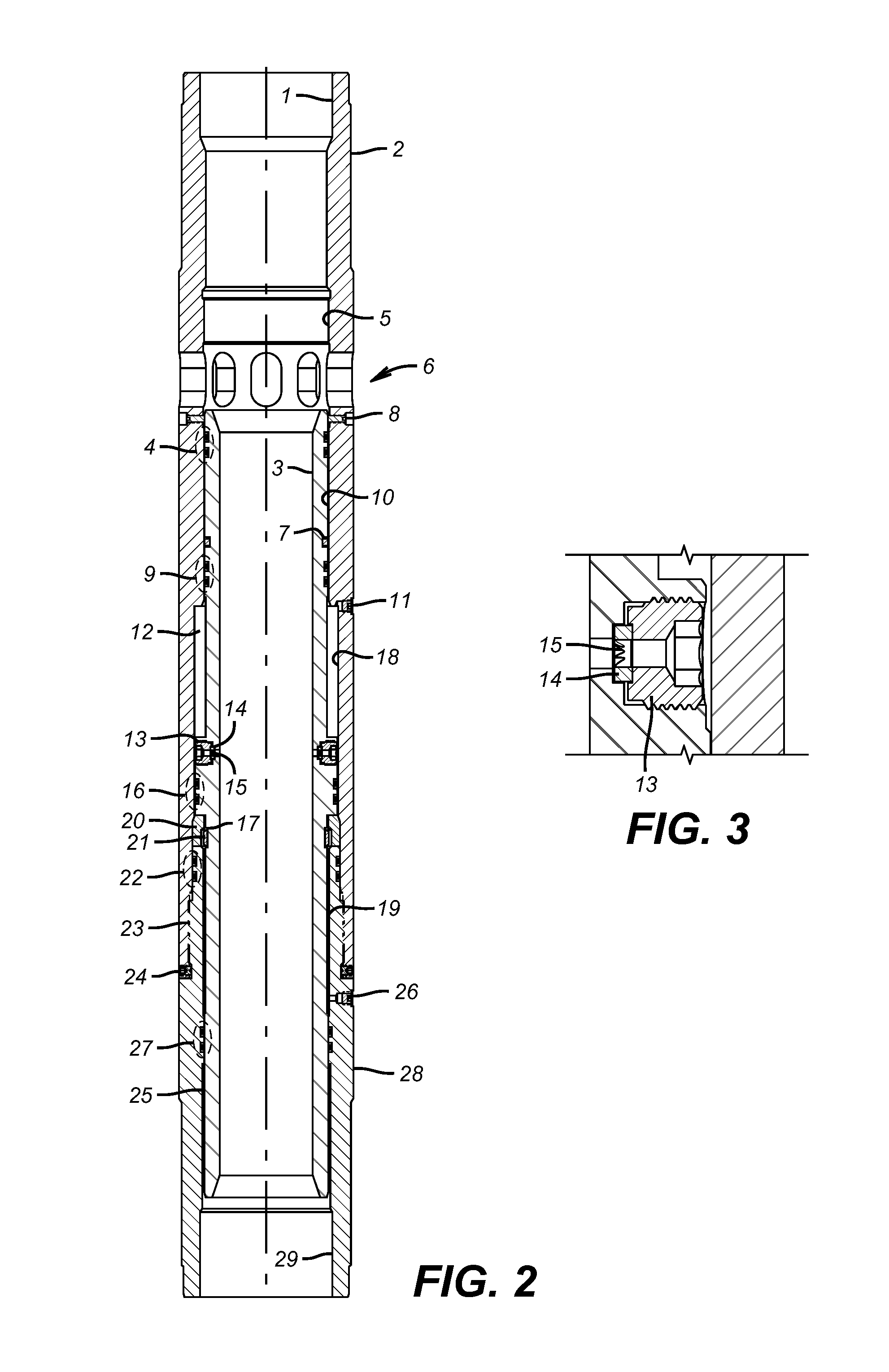

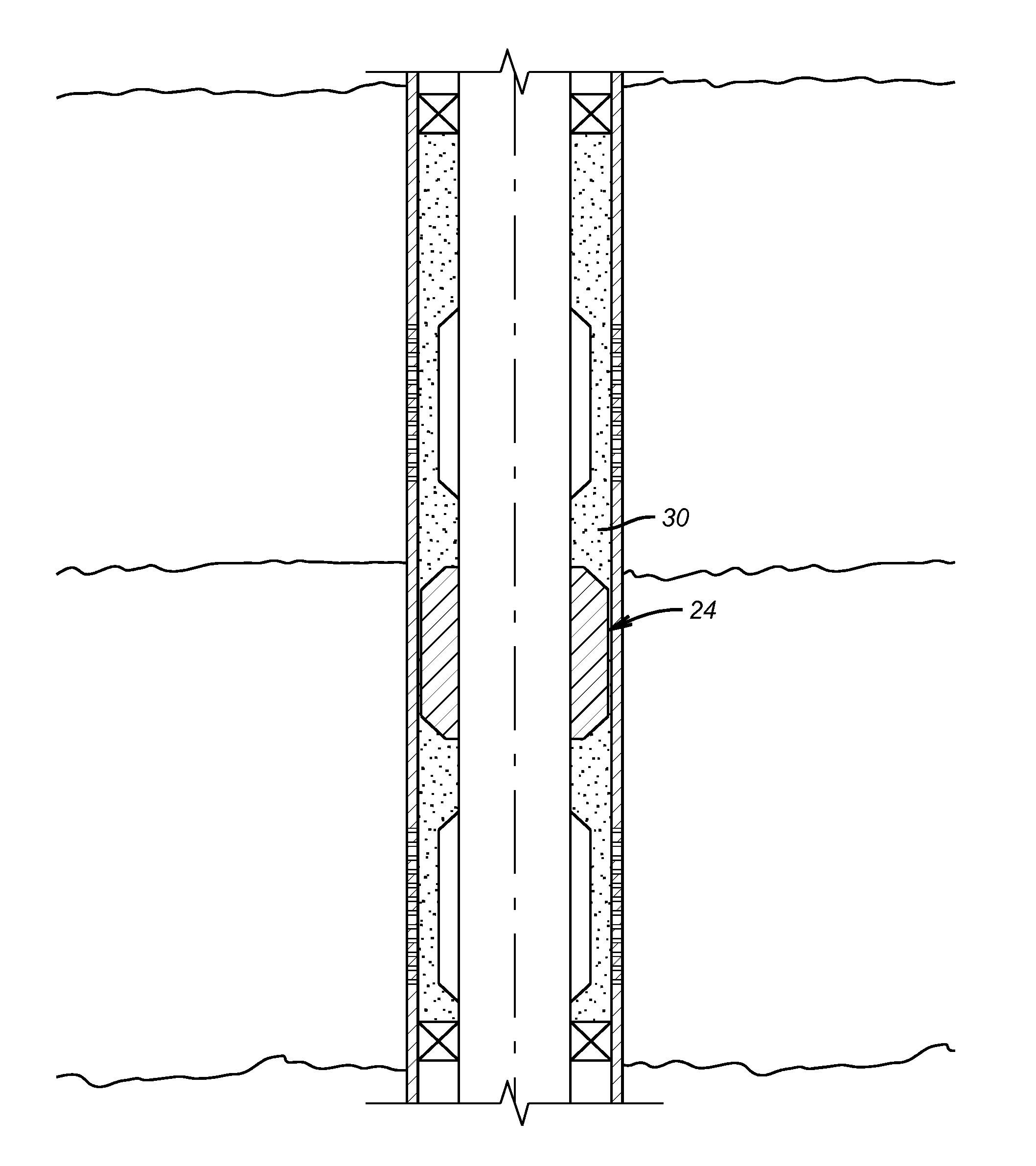

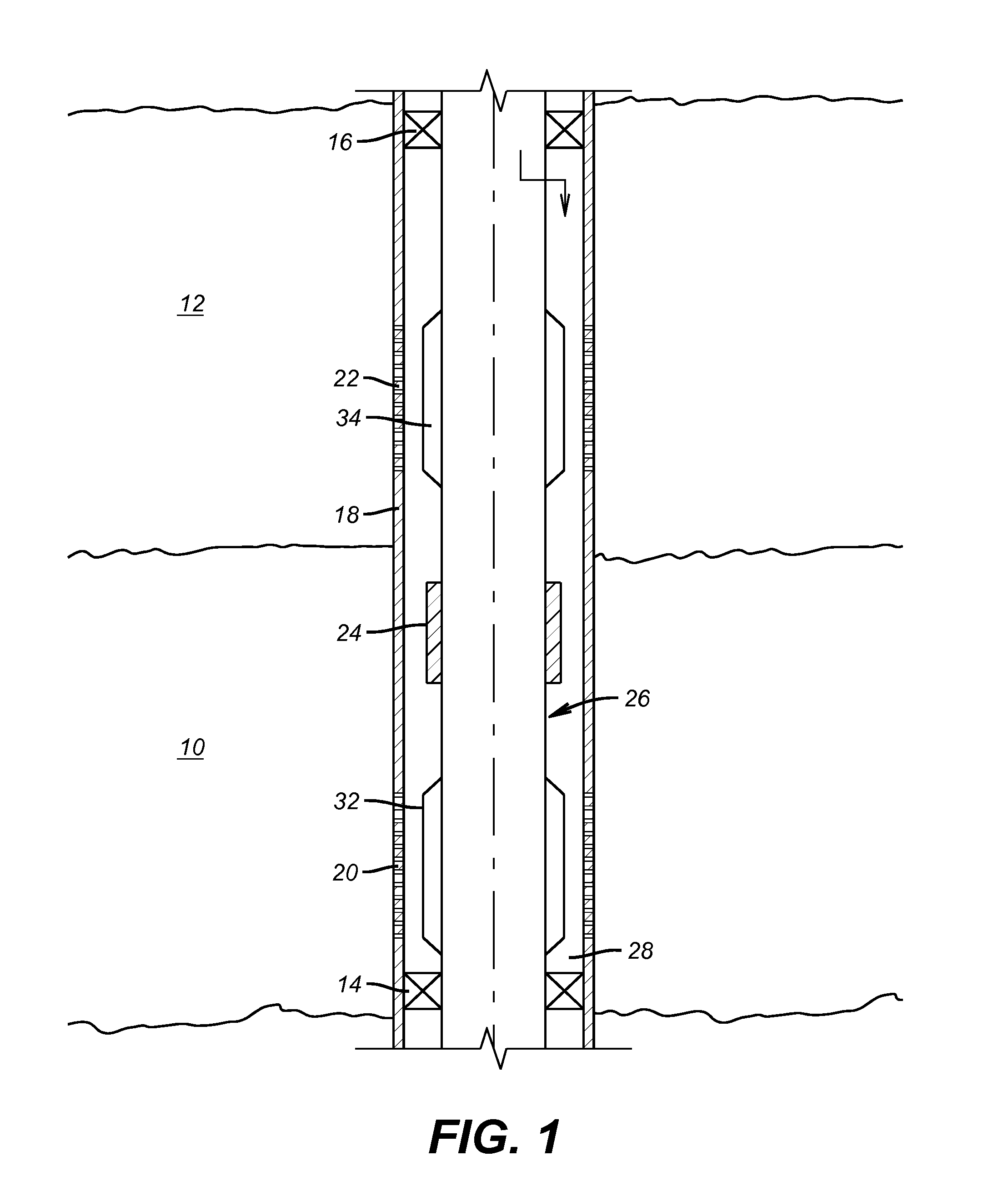

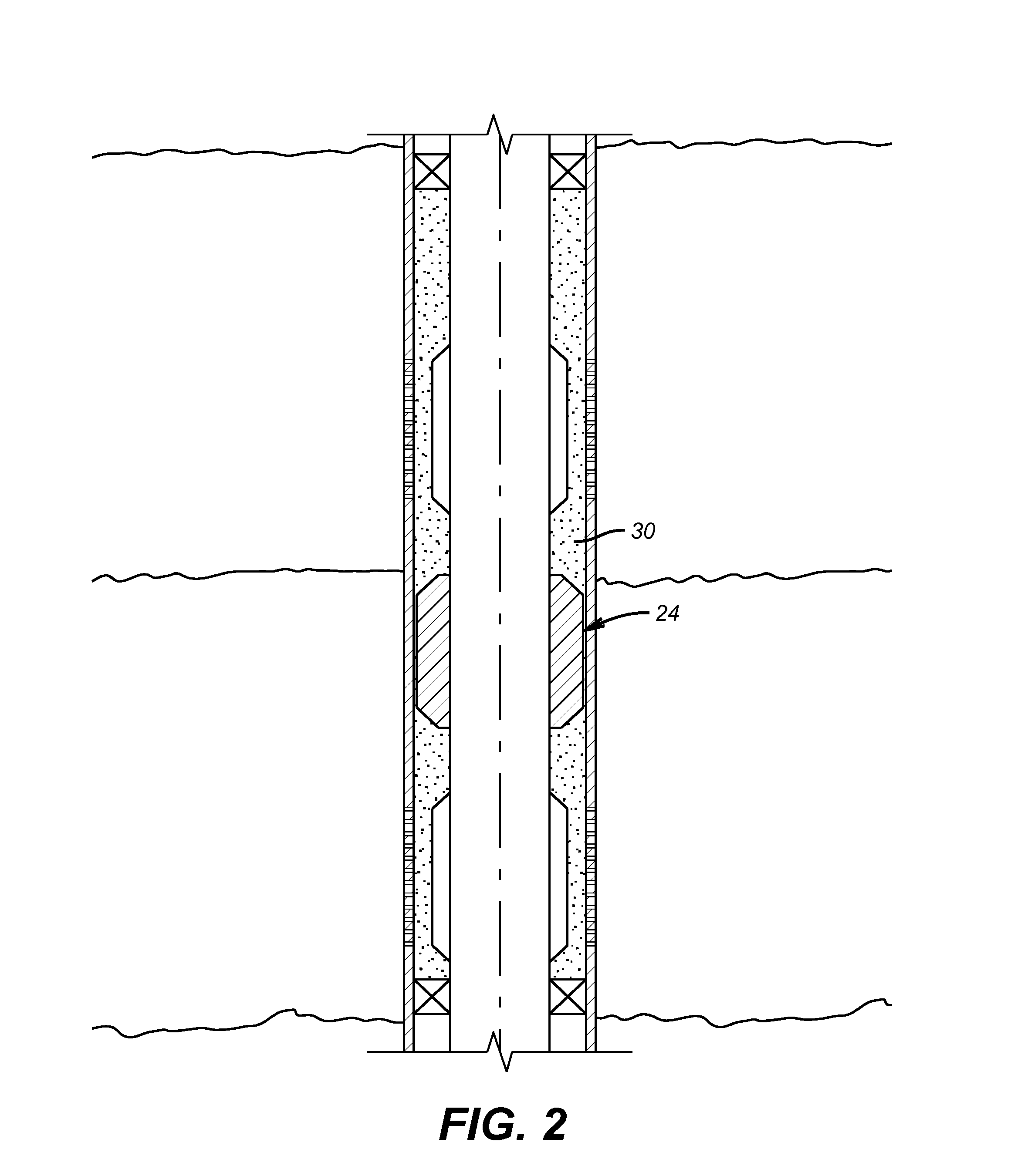

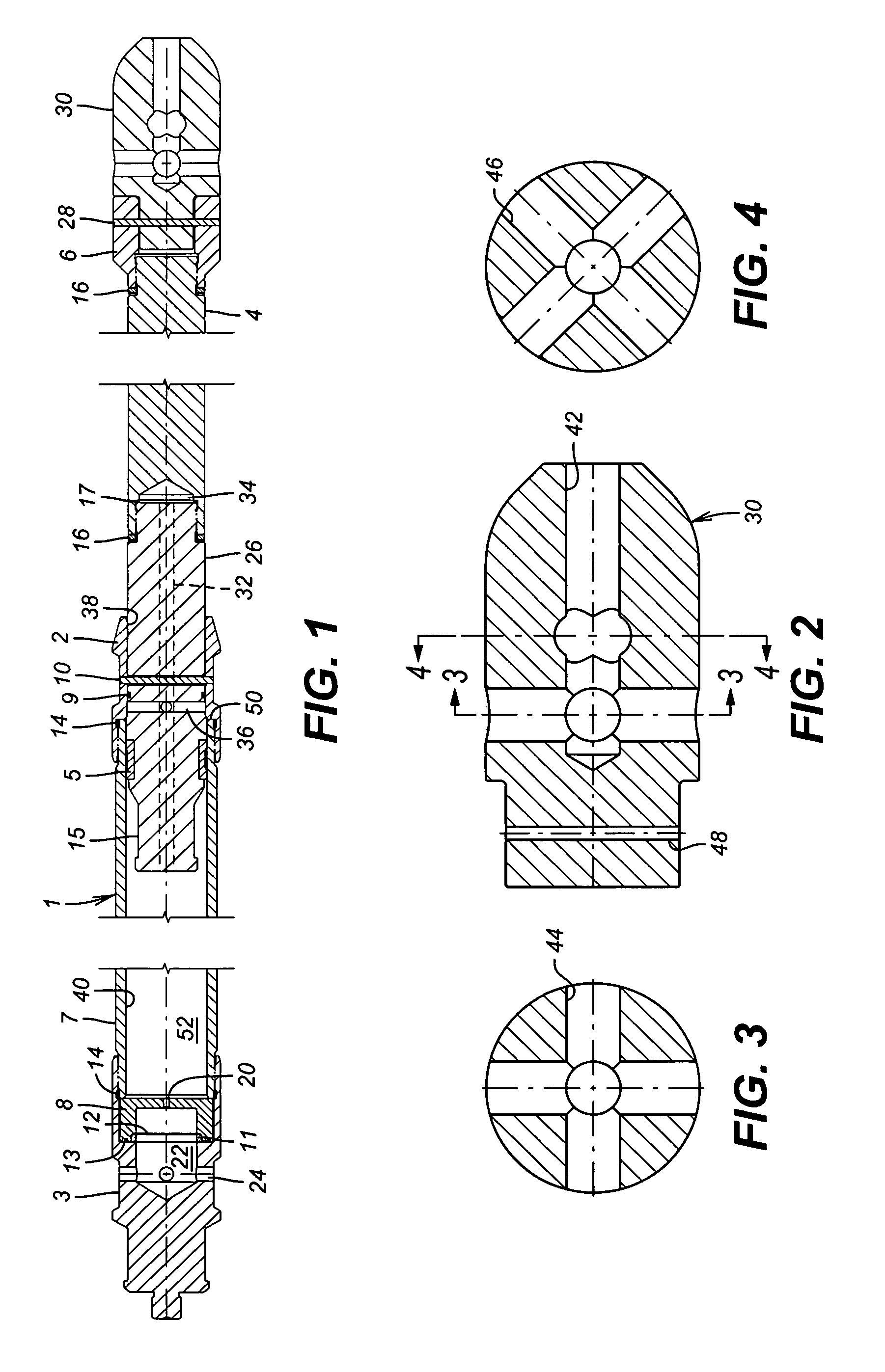

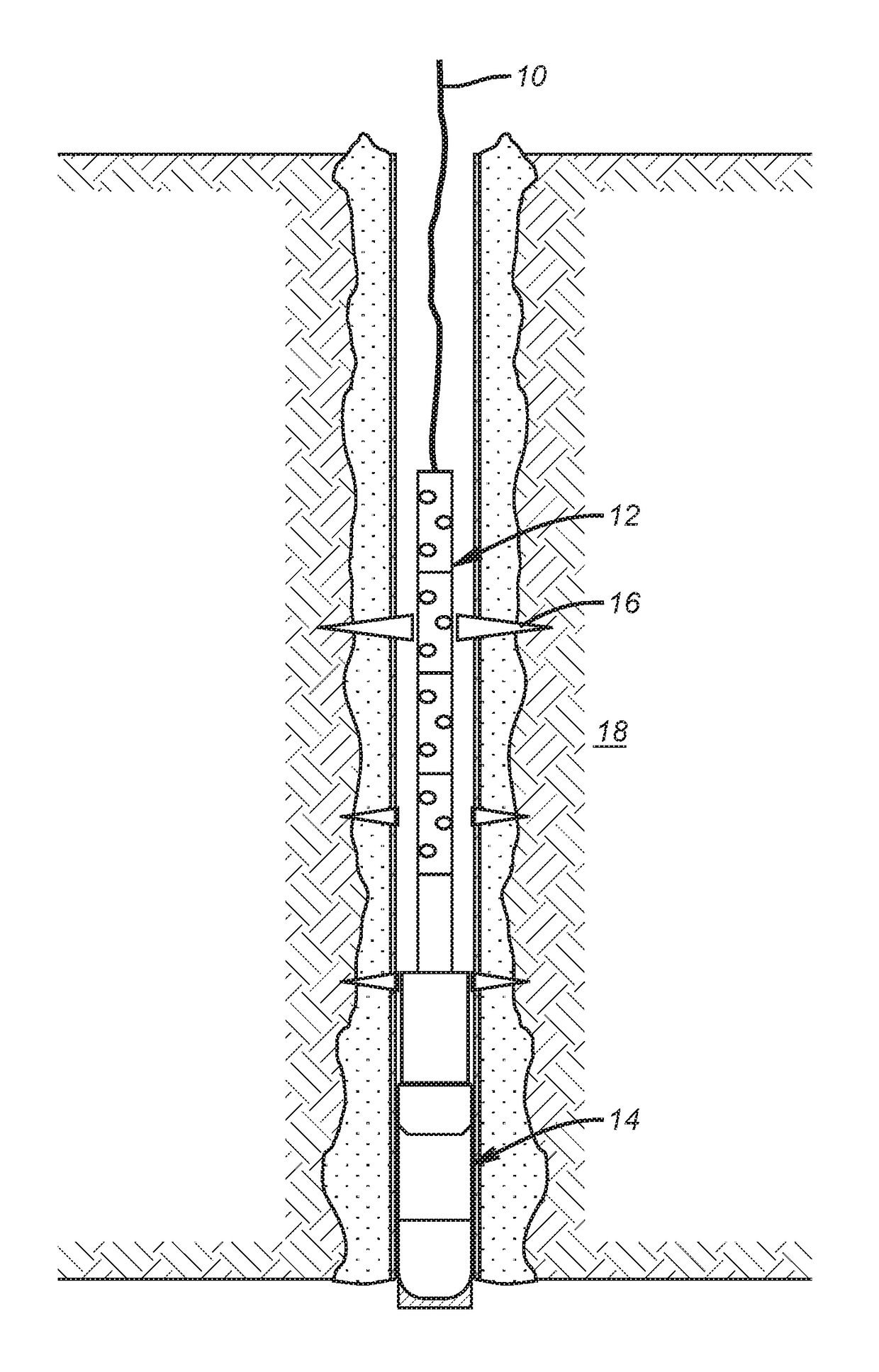

Casing hanger assembly with rupture disk in support housing and method

A casing hanger support assembly supports an inner casing string within a well containing an outer casing string and a production tubing string. The casing hanger support housing supports the casing hanger in the well, with a casing hanger being secured to an upper end of the inner casing string. One or more of a rupture disk and a blowout plug are provided in a wall of the casing hanger support housing for maintaining the desired pressure differential between an annulus within the outer casing string and an annulus exterior of the outer casing string, thereby preventing casing collapse or burst.

Owner:DRIL QUIP

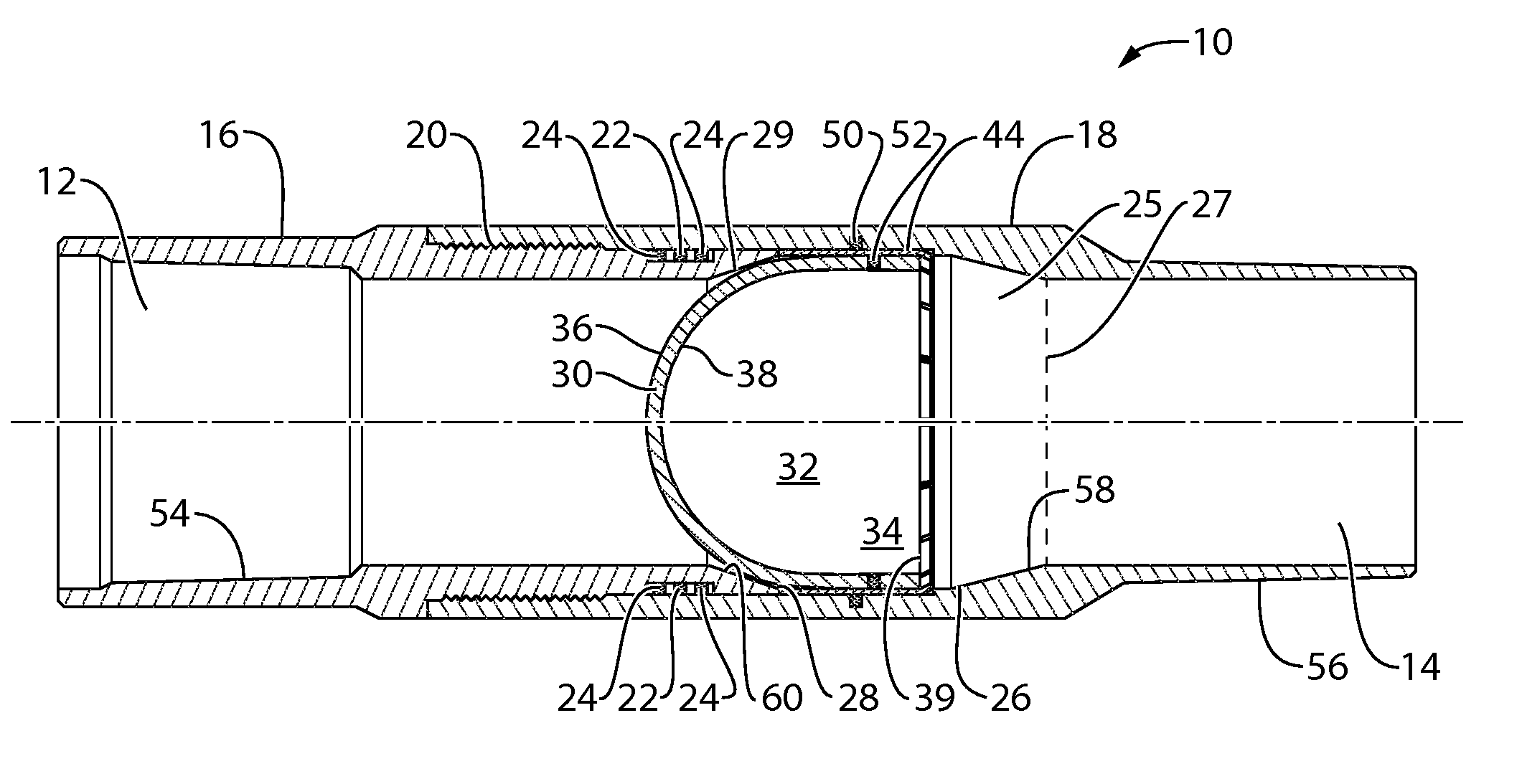

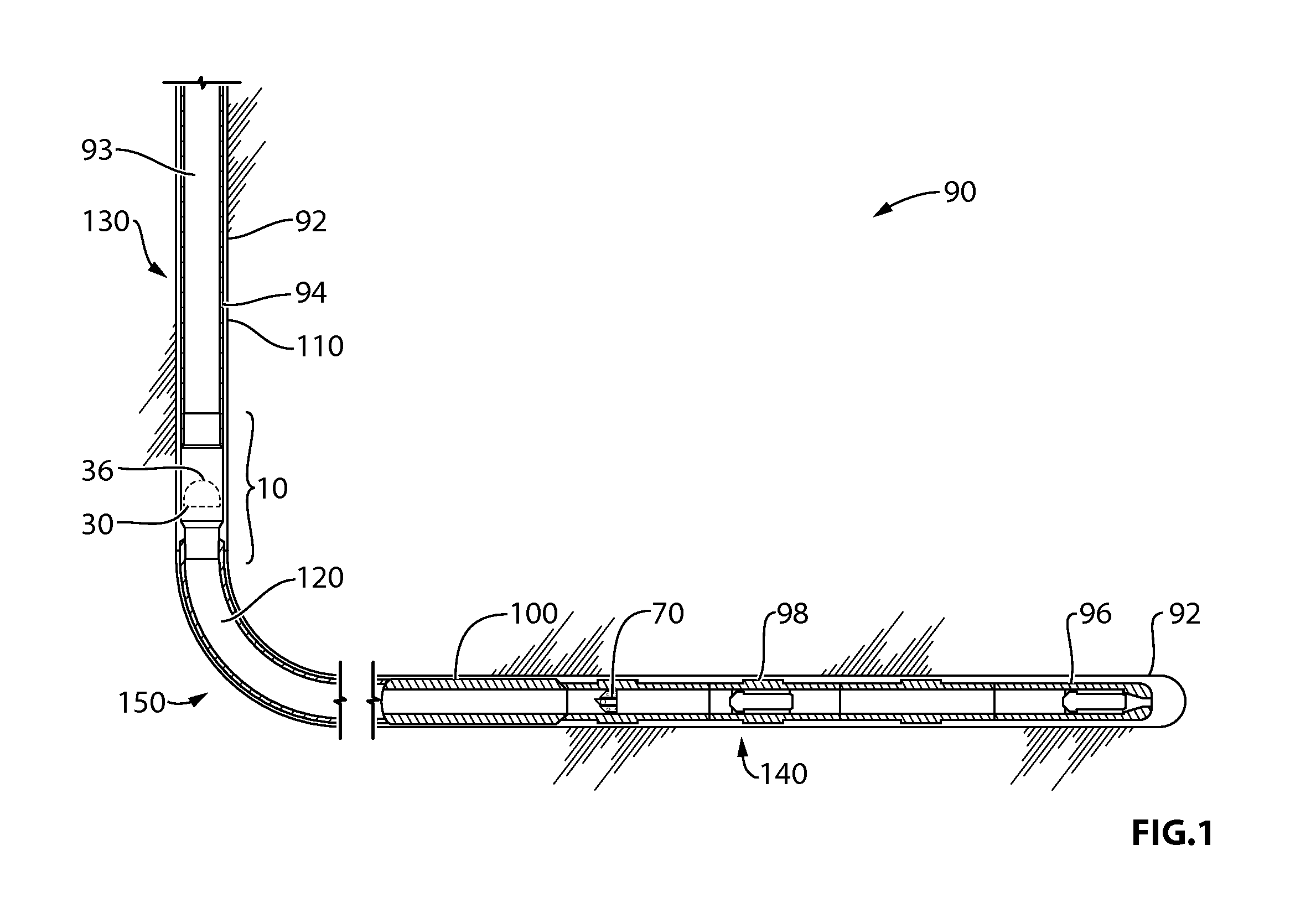

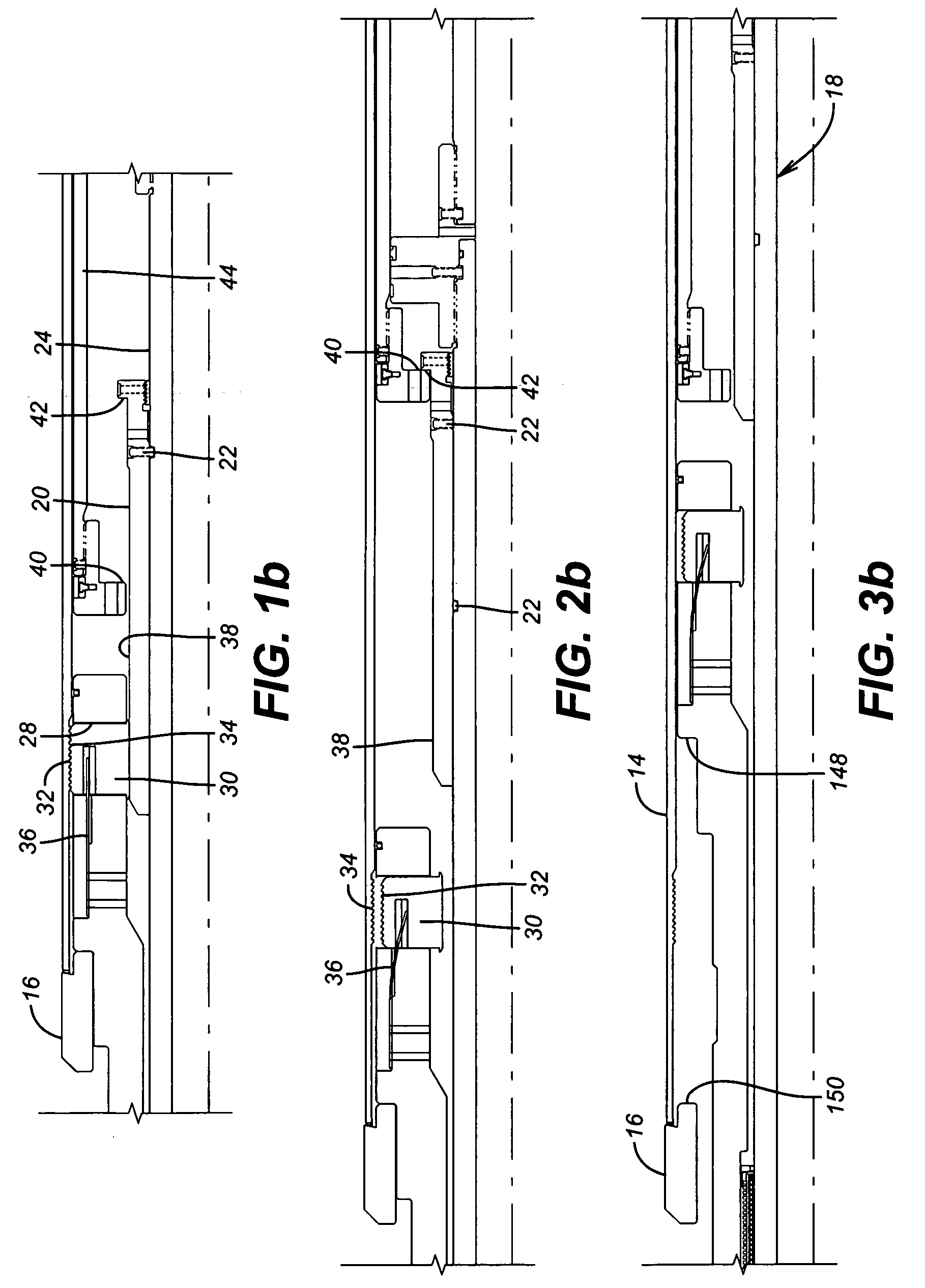

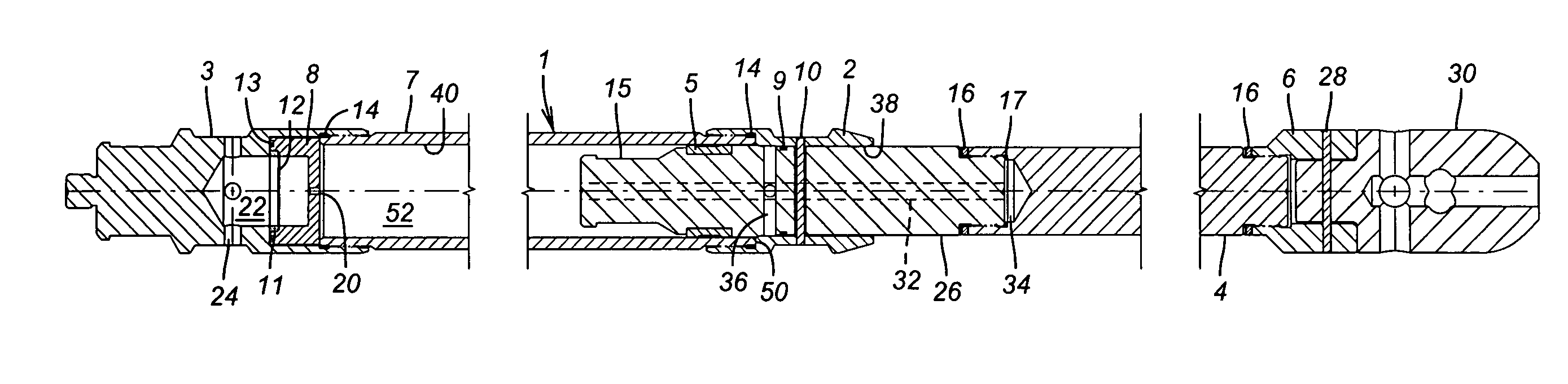

Casing float tool

ActiveUS20140216756A1Lower requirementReduce pressureDrilling rodsFluid removalCasing stringEngineering

A rupture disc assembly and a float tool incorporating the rupture disc assembly is disclosed. The rupture disc assembly may include a rupture disc assembly comprising a rupture disc, an upper tubular portion and a lower tubular portion, and a securing mechanism for holding the rupture disc between the upper and lower tubular portions. A float tool for creating a buoyant chamber in a casing string may include the rupture disc assembly and a sealing device for sealing the lower end of the casing string, the buoyant, sealed chamber may be created there between. In operation, applied fluid pressure causes the rupture disc to move downward. The rupture disc may be shattered by contact with a surface on the lower tubular portion. Full casing internal diameter may be restored in the region where the rupture disc formerly sealed the casing.

Owner:NCS MULTISTAGE

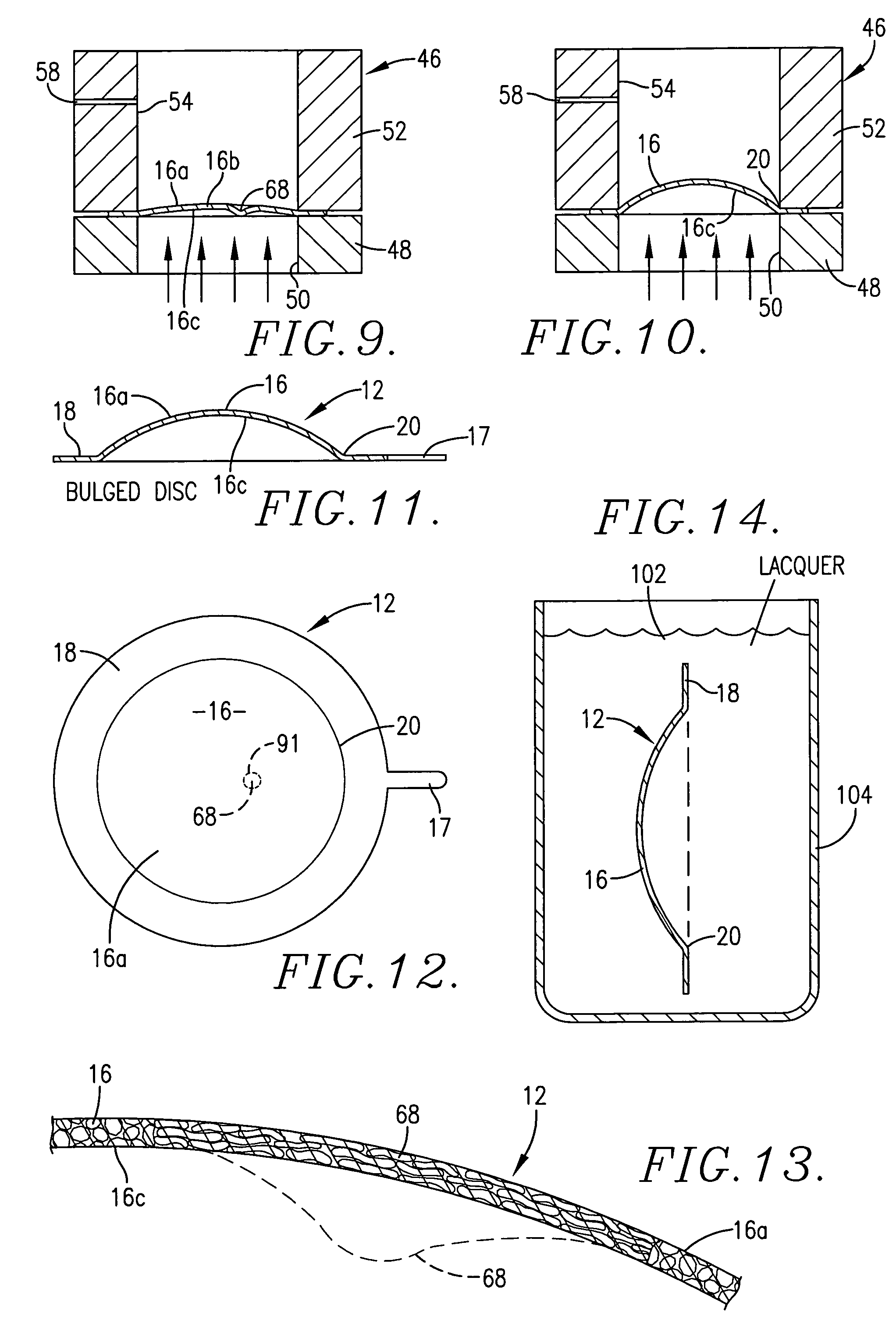

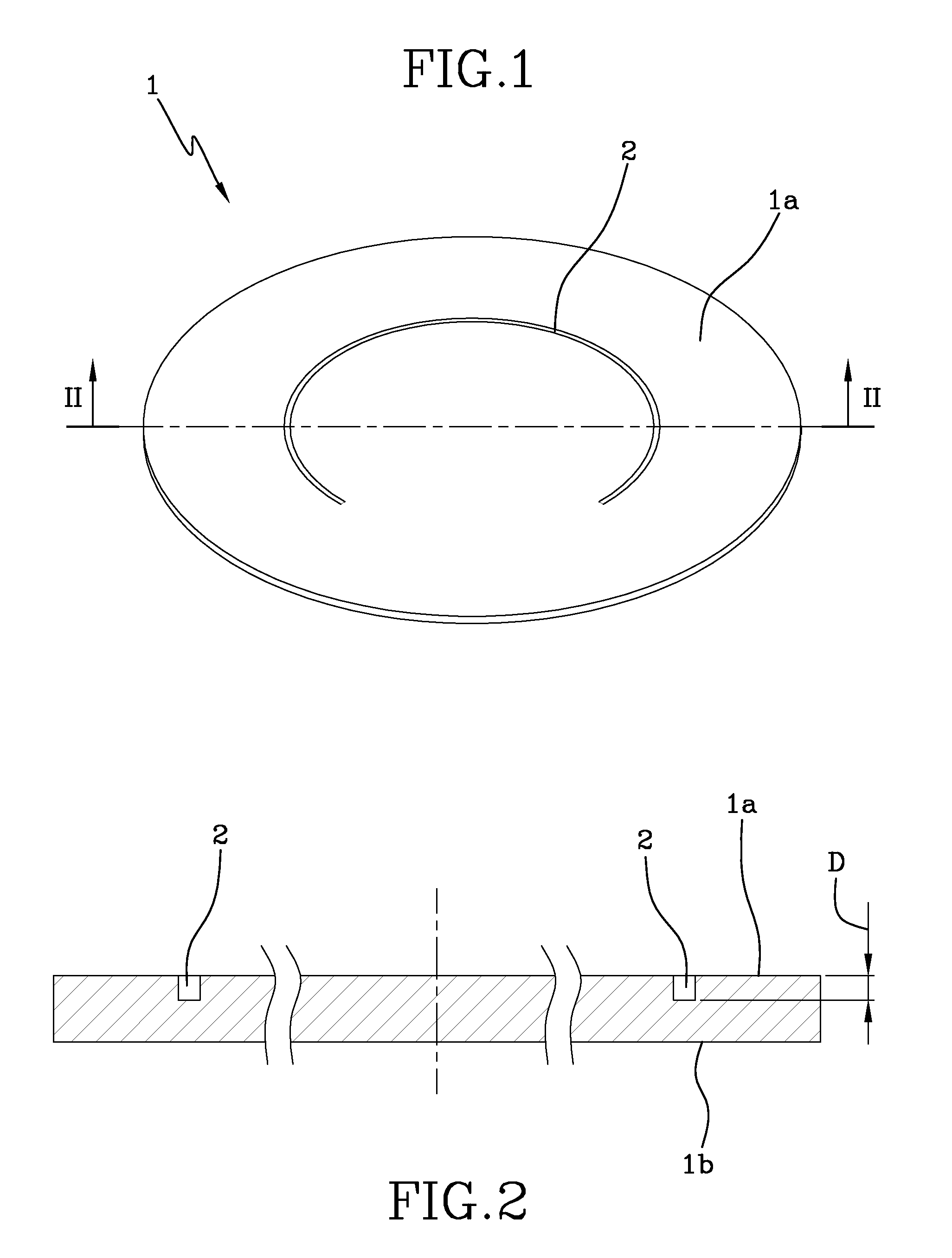

Controlling the rated burst pressure of a rupture disc through the use of control scores on the disc dome

ActiveUS20100140264A1Reducing reversalReducing buckling pressureLarge containersEqualizing valvesCircular discRadial position

A rupture disc for use in a pressure relief system includes a dome having a concave and a convex side and a circumferential flange associated therewith. At least one control score is formed or otherwise produced in the dome at a radial position between an apex of the dome and an outer circumference of the dome. At least one of a depth, a width, a length and the radial portion of the at least one control score is selectively controlled so that the depth, width, length, and / or radial position of the at least one control score controls the pressure at which the dome will start to collapse.

Owner:CONTINENTAL DISC CORP

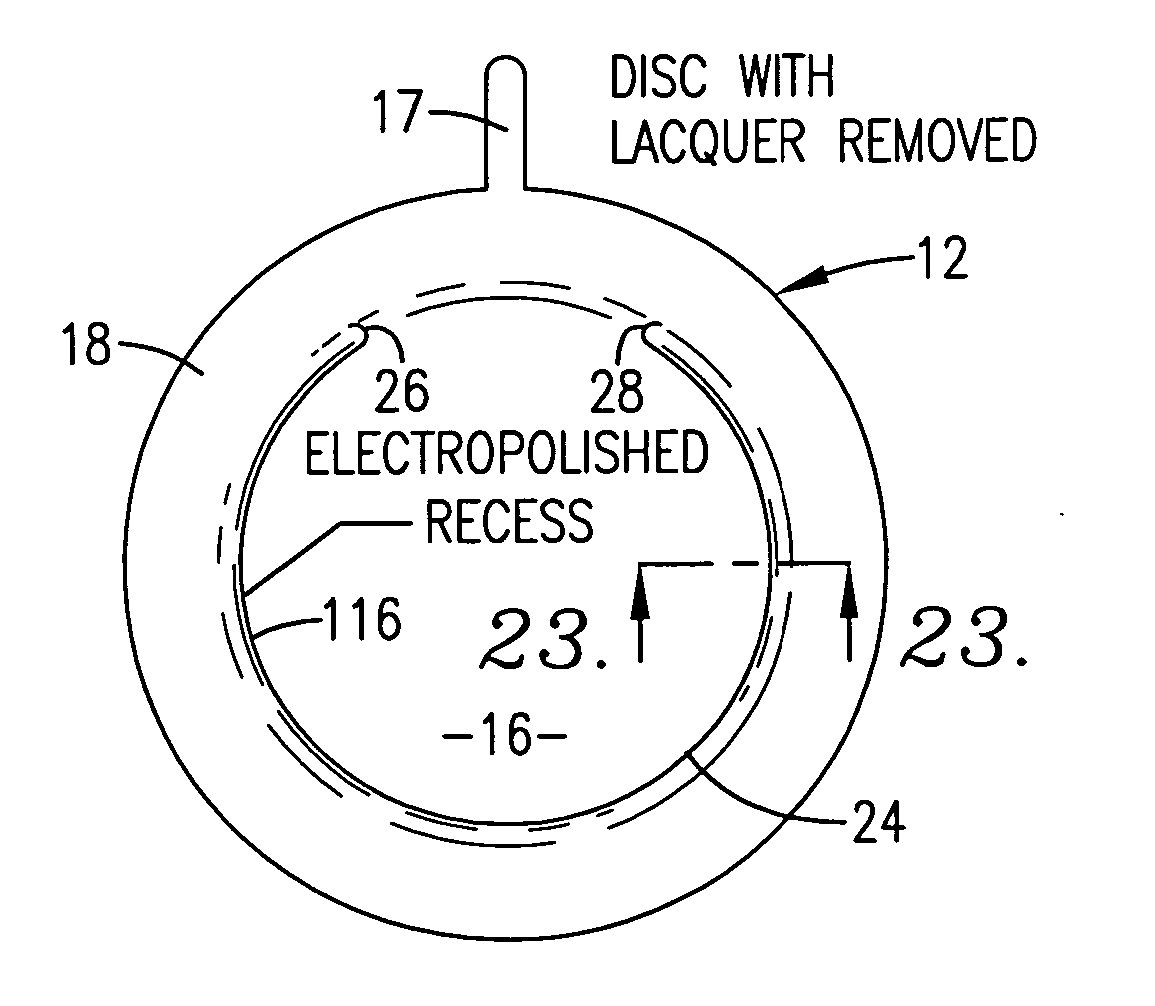

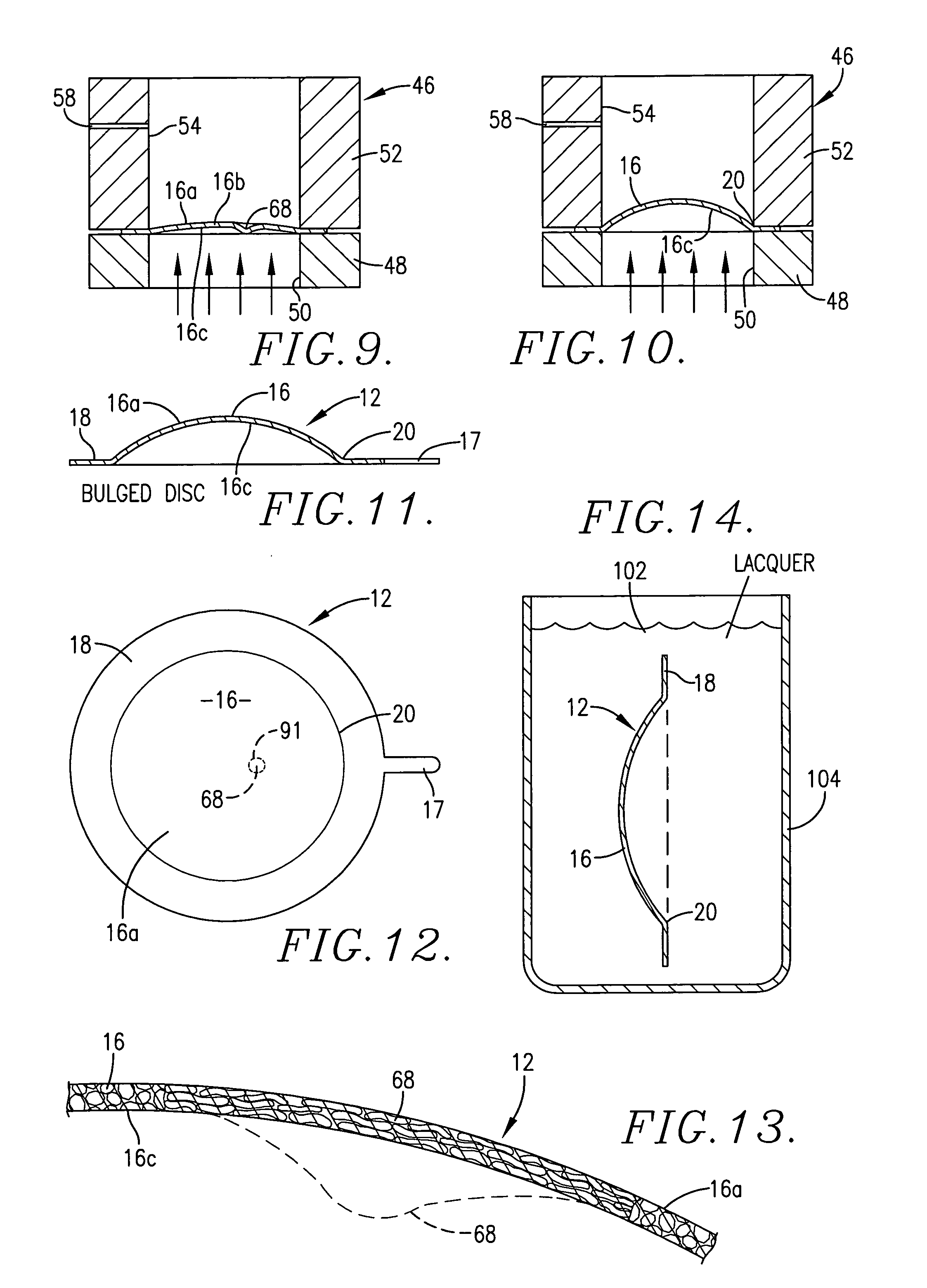

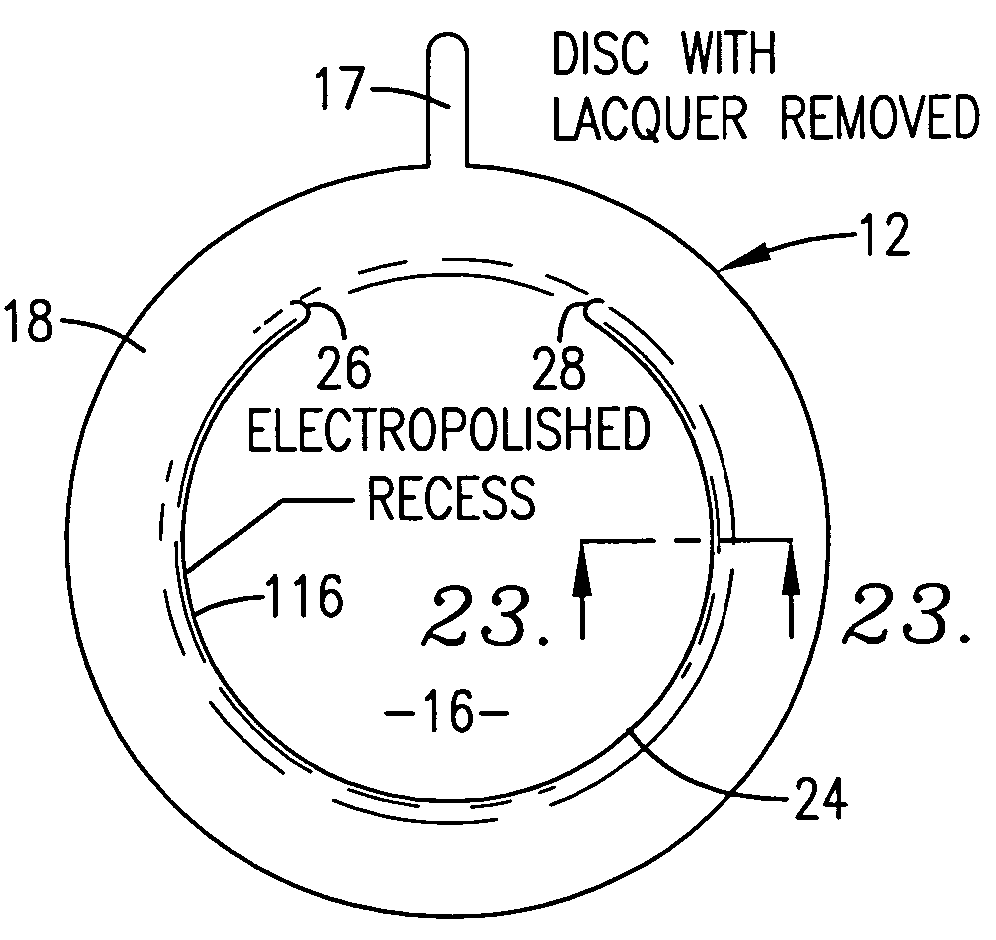

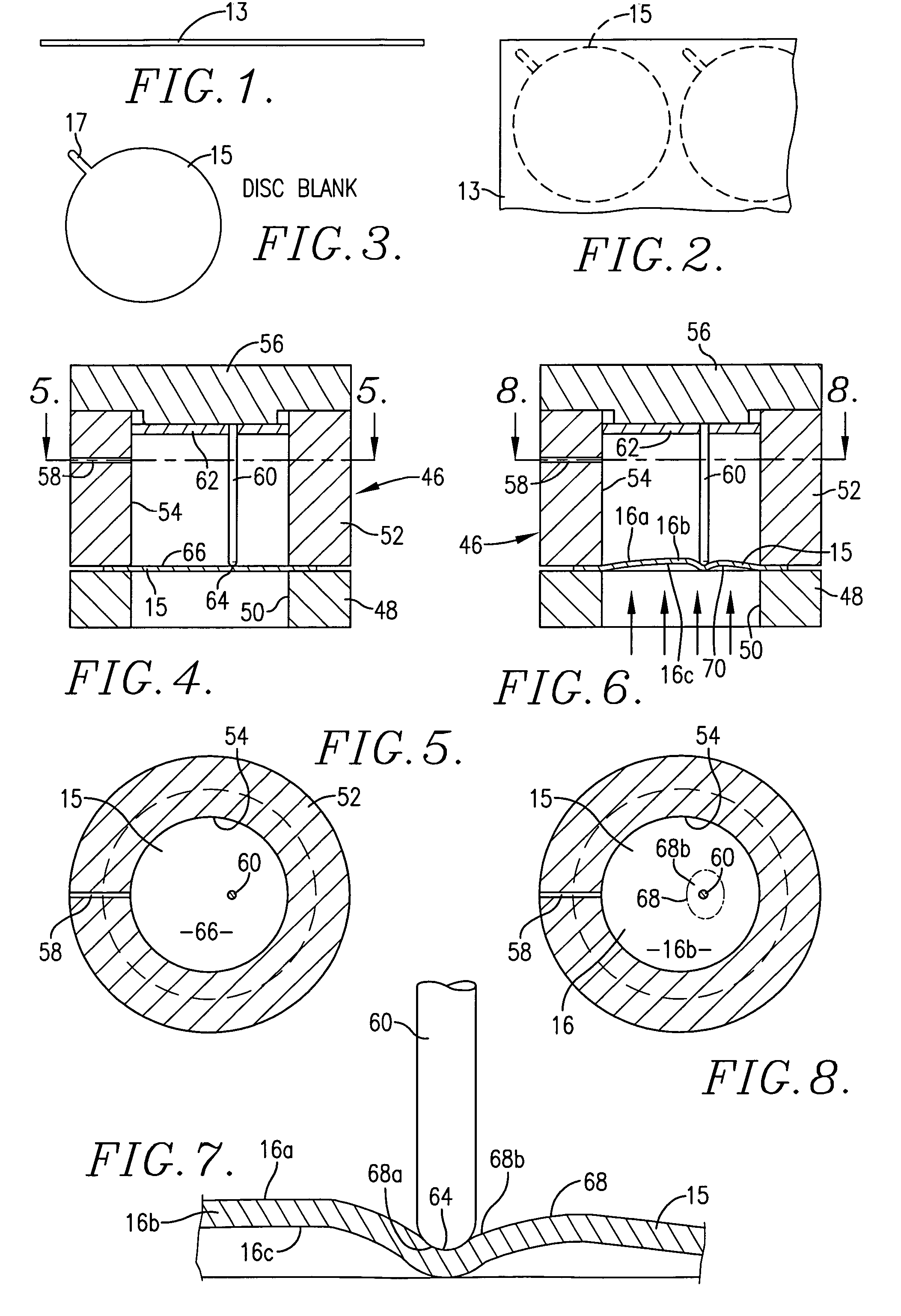

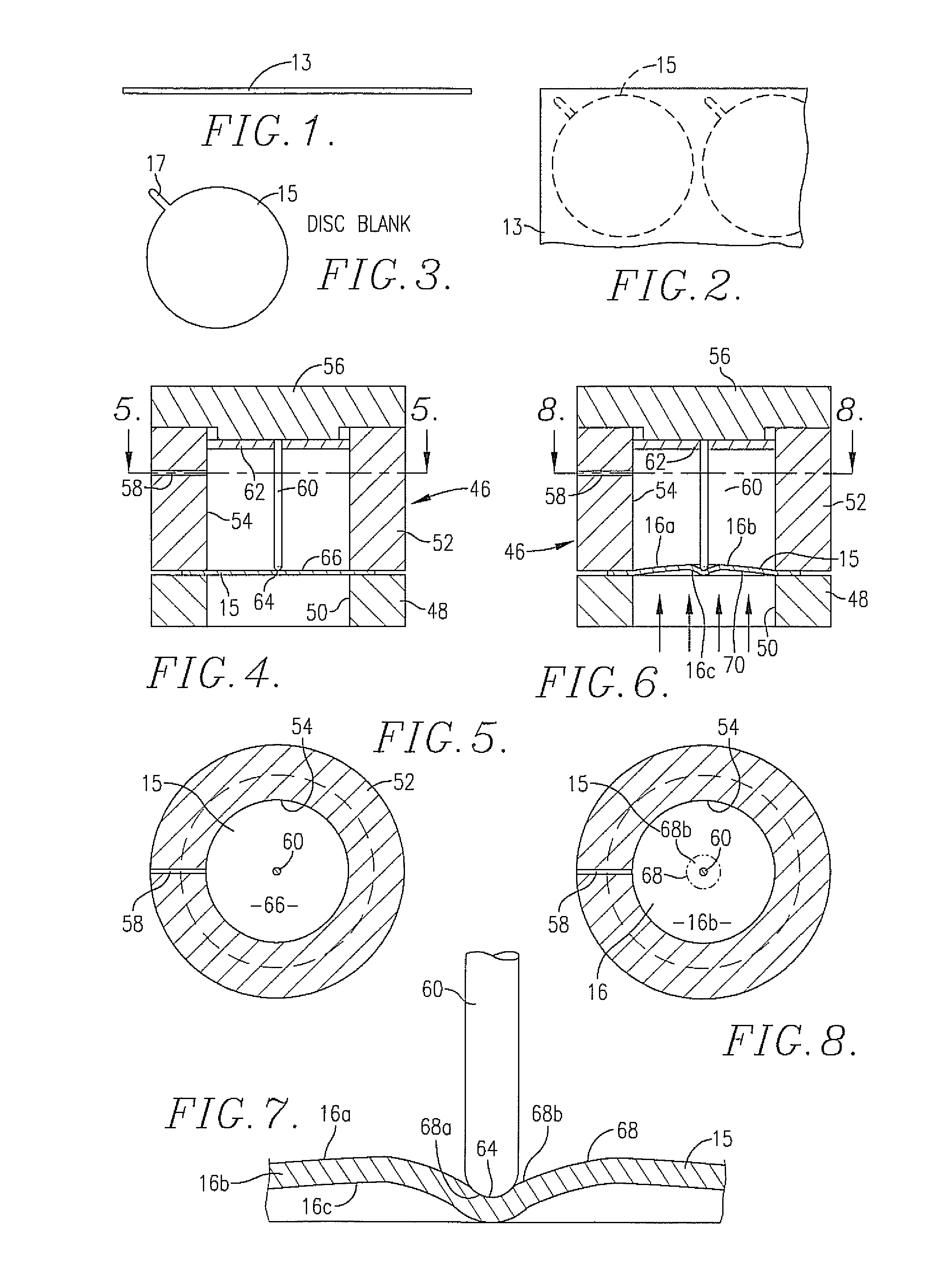

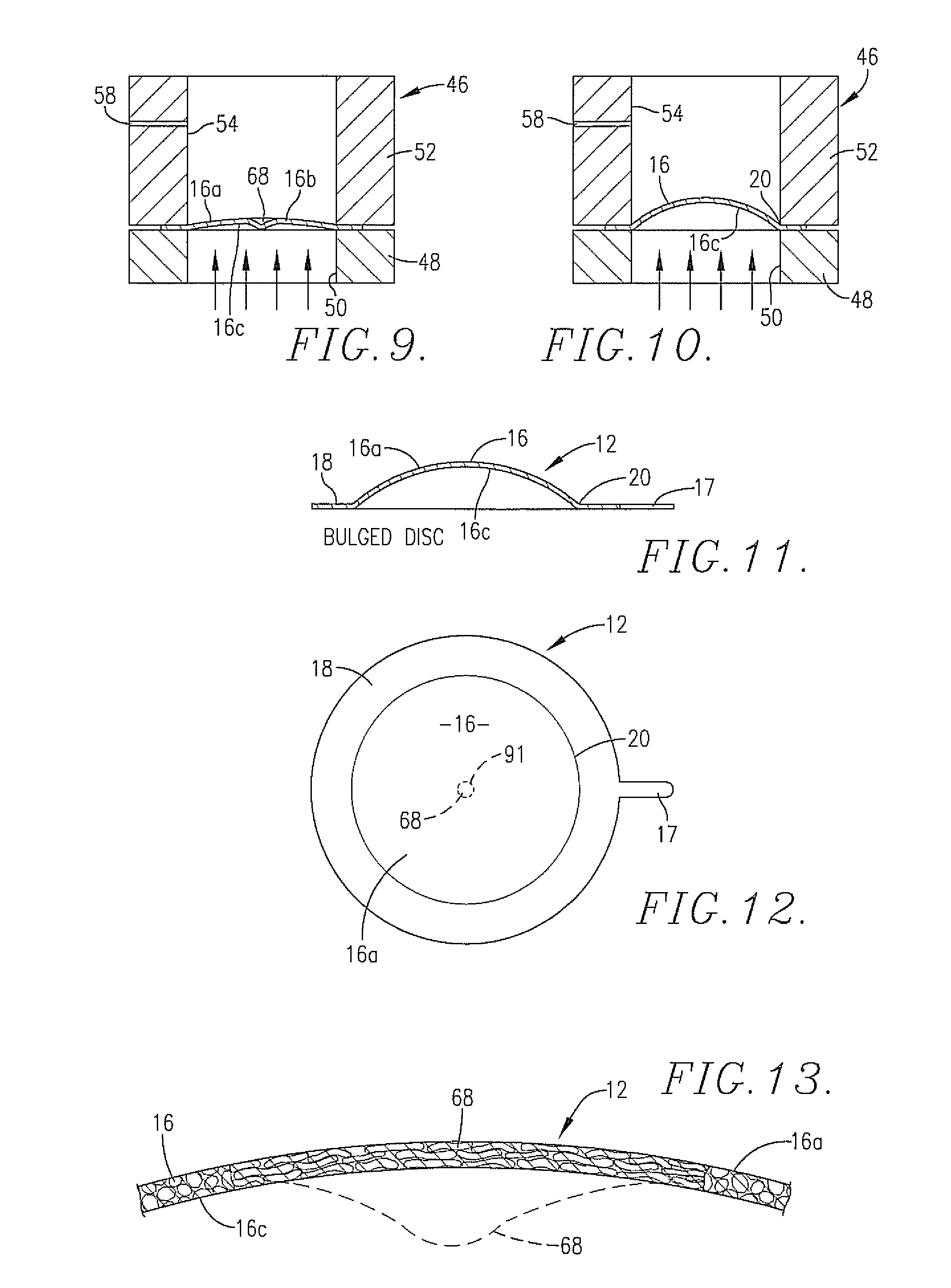

Reverse acting rupture disc with laser-defined electropolished line of weakness and method of forming the line of weakness

InactiveUS20060237457A1Constant heightTaller in heightLarge containersEqualizing valvesResistEngineering

A reverse acting rupture disc is provided having a laser defined electropolished line-of-weakness recess, and an improved method of forming an electropolished line-of-weakness recess in a reverse acting rupture disc that assures full opening of the disc upon reversal. A rupture disc blank is pre-bulged, final bulged, and then provided with a layer of resist material. A laser is used to remove at least a portion of the layer of resist material corresponding to a desired line-of-weakness recess in the concave face of the bulged rupture disc. The disc is then subjected to an electropolishing operation to remove metal from the lased area of the rupture disc, thereby forming a lustrous polished line-of-weakness recess in the disc of desired configuration and of a predetermined depth that is related to material thickness. The electropolished line of weakness is defined by spaced opposed channel portions separated by a central raised crown portion wherein the channel portions are of greater depth than the crown portion. The burst / reversal pressure of the disc having an electropolished line-of-weakness recess may be selectively controlled by varying the pre-bulging pressure on the disc.

Owner:FIKE CORP

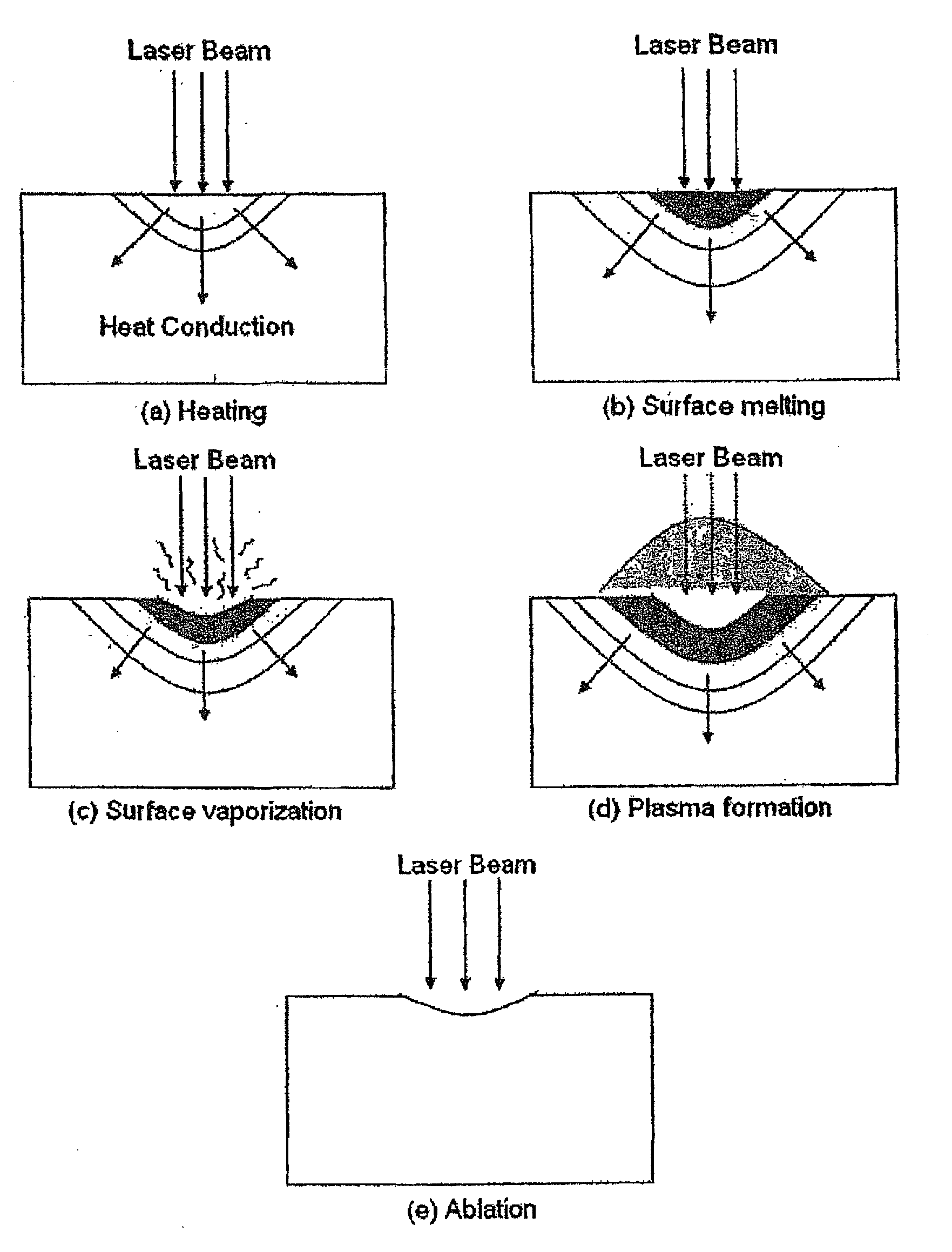

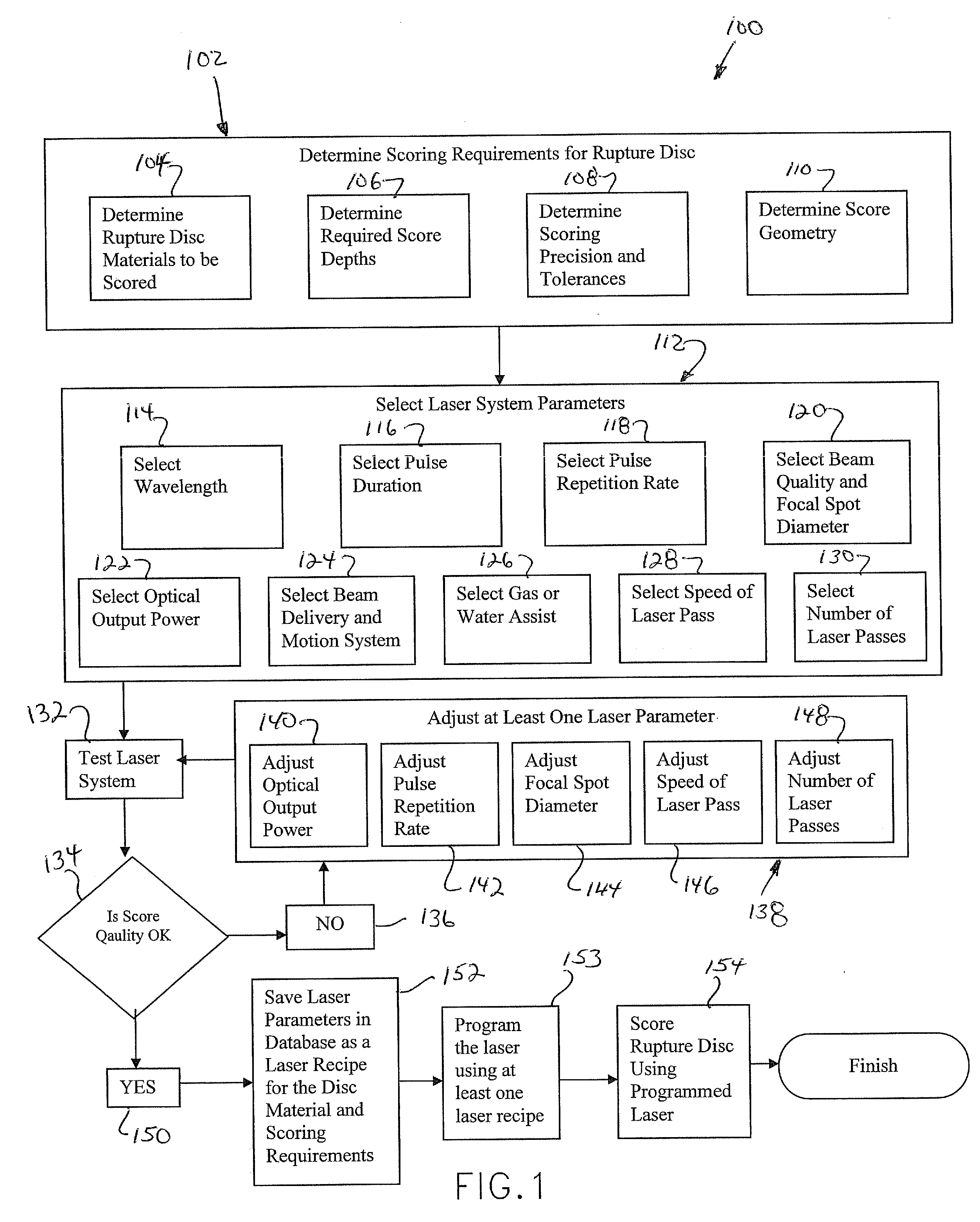

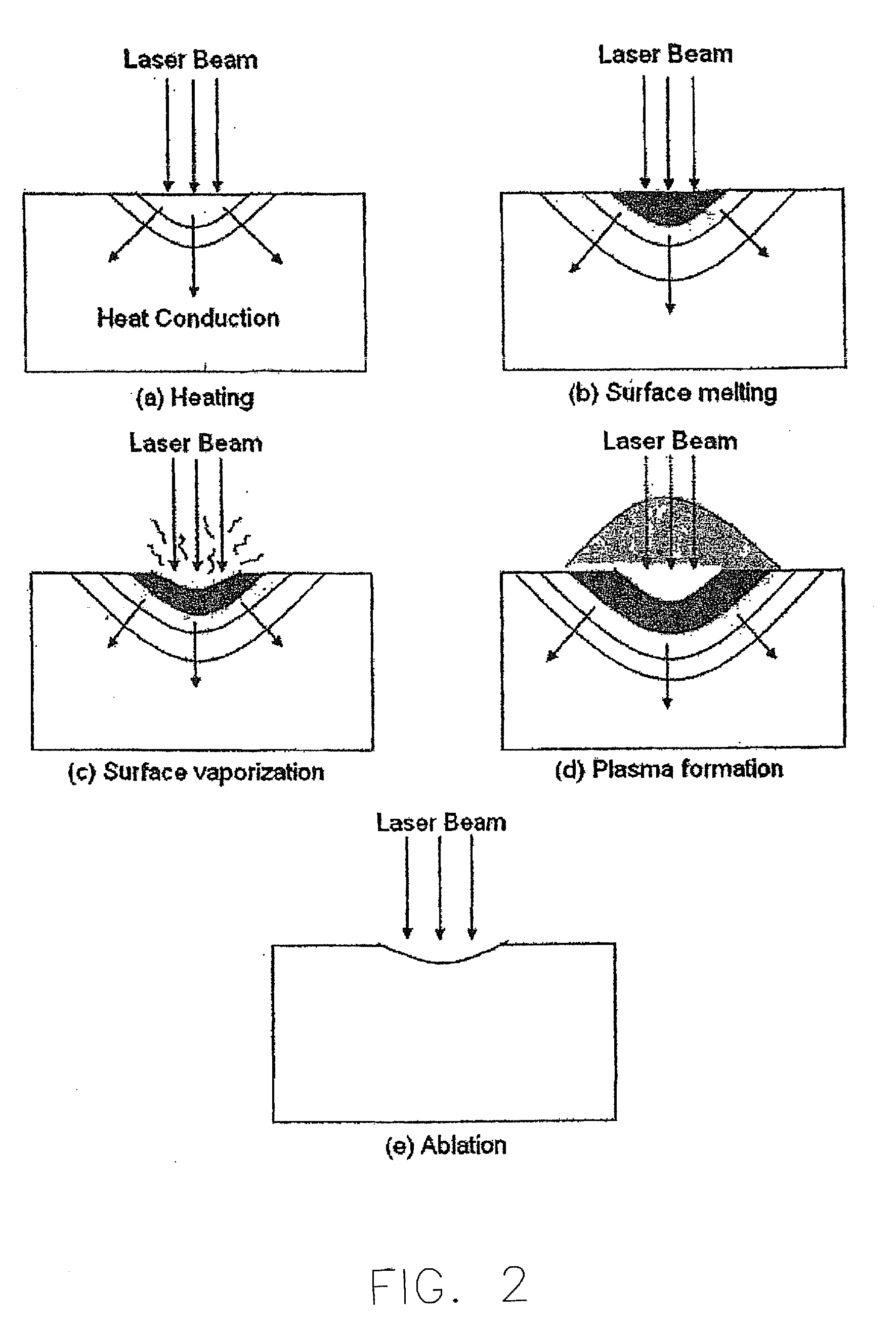

Machining score lines in a rupture disc using laser machining

InactiveUS20100140238A1Maximizes laser powerReduces heat affected zoneEqualizing valvesSafety valvesHeat-affected zoneLaser processing

A method of forming a score line in a rupture disc using a laser is provided, wherein the method includes selecting a wavelength for the laser that maximizes absorption of the laser radiation by the disc material, selecting a pulse duration for the laser that maximizes a peak power of the laser, selecting a pulse repetition rate for the laser that reduces a heat affected zone of the rupture disc during ablation, and selecting the speed of relative motion between the laser and the rupture disc. The score line is ablated in the rupture disc using the laser to remove material from the rupture disc as vapor without melting or oxidizing disc material adjacent the material being removed.

Owner:CONTINENTAL DISC CORP

Wireless coiled tubing joint locator

A wireless coiled tubing joint locator for locating joints or collars in a production tubing string. An electromagnetic coil assembly or giant magnetoresistive digital field sensor senses the increased mass of a pipe joint, and provides a signal to an electric circuit which generates a signal received by a pilot solenoid valve. The solenoid valve momentarily opens a pilot passageway which activates a piston to close a circulation port in the joint locator, resulting in an increase in a surface pressure reading observable by the operator. In one embodiment, a rupture disk is provided so that pressure cannot be applied to any downhole tool below the joint locator prematurely. A seat sleeve prevents premature communication of fluid to the rupture disk but can be opened by dropping a ball into the joint locator. A second embodiment may be used for either logging or washing operations or both. The electronic circuit can provide a selected one of a plurality of time delays. A fixed test period in the circuit delays activation of the time delay so that the joint locator may be tested before it is run into the well. The electric circuit and power supply are provided in a removable case.

Owner:HALLIBURTON ENERGY SERVICES INC

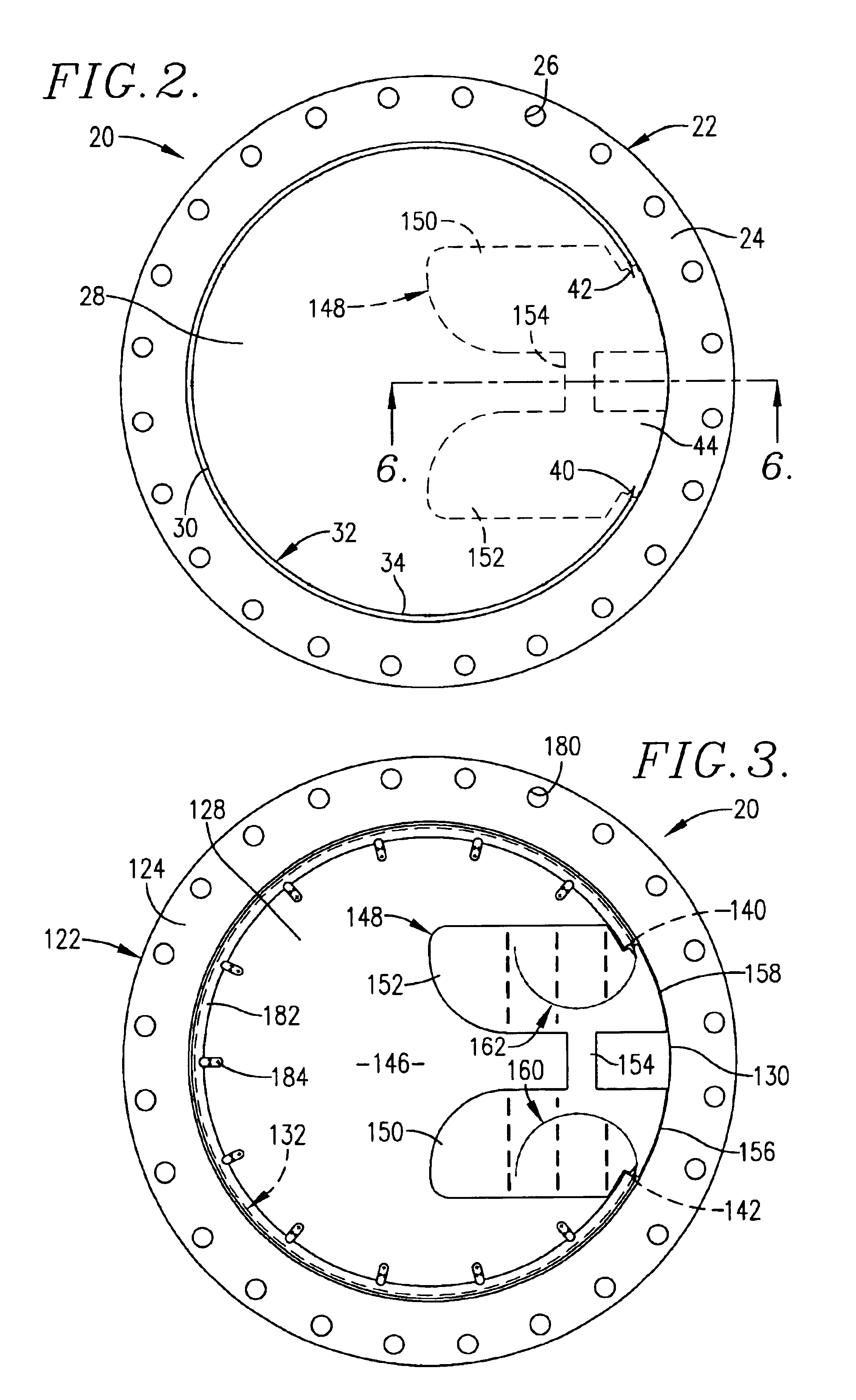

Reverse buckling sanitary rupture disc assembly

InactiveUS6945420B2Flat surfaceAltered grain structureLarge containersEqualizing valvesEngineeringRupture disc

A metal reverse buckling sanitary rupture disc is provided having a central bulged section in which the convex surface of the bulged section is relatively smooth and of substantially uninterrupted configuration. A small segment region of the central bulged section is strain hardened by plastic deformation causing the segment region to have greater residual stress than the remainder of the central bulged section. When the disc is subjected to an overpressure condition against the convex surface of the bulged section sufficient to effect reversal of the bulged section, such reversal commences at the higher residual stress segment region of the bulged section.

Owner:FIKE CORP

Casing float tool

A rupture disc assembly and a float tool incorporating the rupture disc assembly is disclosed. The rupture disc assembly may include a rupture disc assembly comprising a rupture disc, an upper tubular portion and a lower tubular portion, and a securing mechanism for holding the rupture disc between the upper and lower tubular portions. A float tool for creating a buoyant chamber in a casing string may include the rupture disc assembly and a sealing device for sealing the lower end of the casing string, the buoyant, sealed chamber may be created there between. In operation, applied fluid pressure causes the rupture disc to move downward. The rupture disc may be shattered by contact with a surface on the lower tubular portion. Full casing internal diameter may be restored in the region where the rupture disc formerly sealed the casing.

Owner:NCS MULTISTAGE

One Trip Liner Running, Cementing and Setting Tool Using Expansion

A tool is provided that allows in a single trip advancing the liner while more hole is made until the liner is properly positioned. Slips are actuated into the inside of the liner to grasp it as a swage is released to move to support the liner to the surrounding tubular. With the liner supported in the hole, the running tool can be picked up to test the release feature and then set down again for cementing. The tool is then picked up higher to release a flapper and re-pressurized to set a seal adjacent the support previously engaged by swage operation. The flapper has a rupture disc blown and the tool is removed. An emergency release is provided.

Owner:BAKER HUGHES INC

Reverse acting rupture disc with laser-defined electropolished line of weakness and method of forming the line of weakness

A reverse acting rupture disc is provided having a laser defined electropolished line-of-weakness recess, and an improved method of forming an electropolished line-of-weakness recess in a reverse acting rupture disc that assures full opening of the disc upon reversal. A rupture disc blank is pre-bulged, final bulged, and then provided with a layer of resist material. A laser is used to remove at least a portion of the layer of resist material corresponding to a desired line-of-weakness recess in the concave face of the bulged rupture disc. The disc is then subjected to an electropolishing operation to remove metal from the lased area of the rupture disc, thereby forming a lustrous polished line-of-weakness recess in the disc of desired configuration and of a predetermined depth that is related to material thickness. The electropolished line of weakness is defined by spaced opposed channel portions separated by a central raised crown portion wherein the channel portions are of greater depth than the crown portion. The burst / reversal pressure of the disc having an electropolished line-of-weakness recess may be selectively controlled by varying the pre-bulging pressure on the disc.

Owner:FIKE CORP

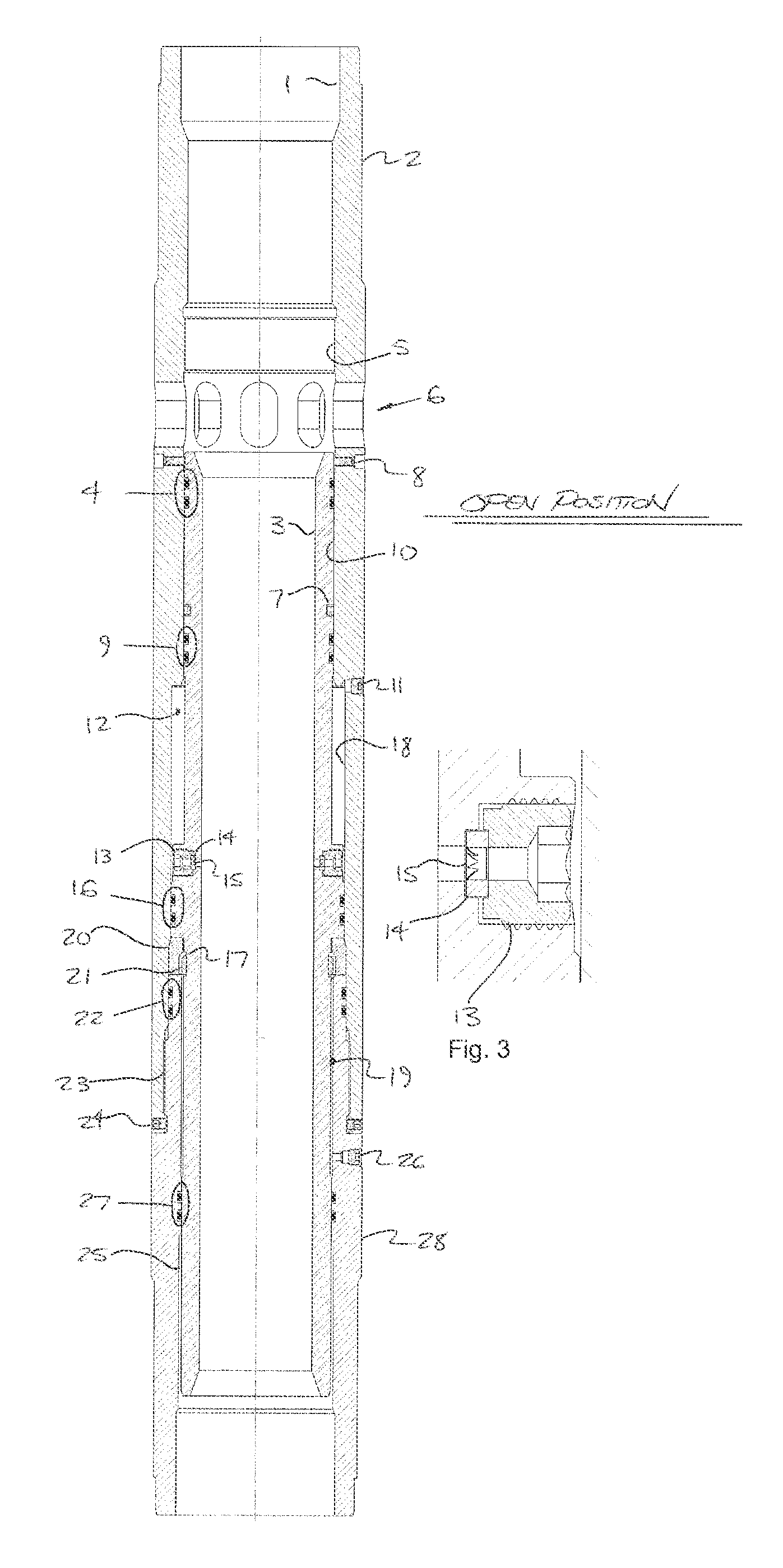

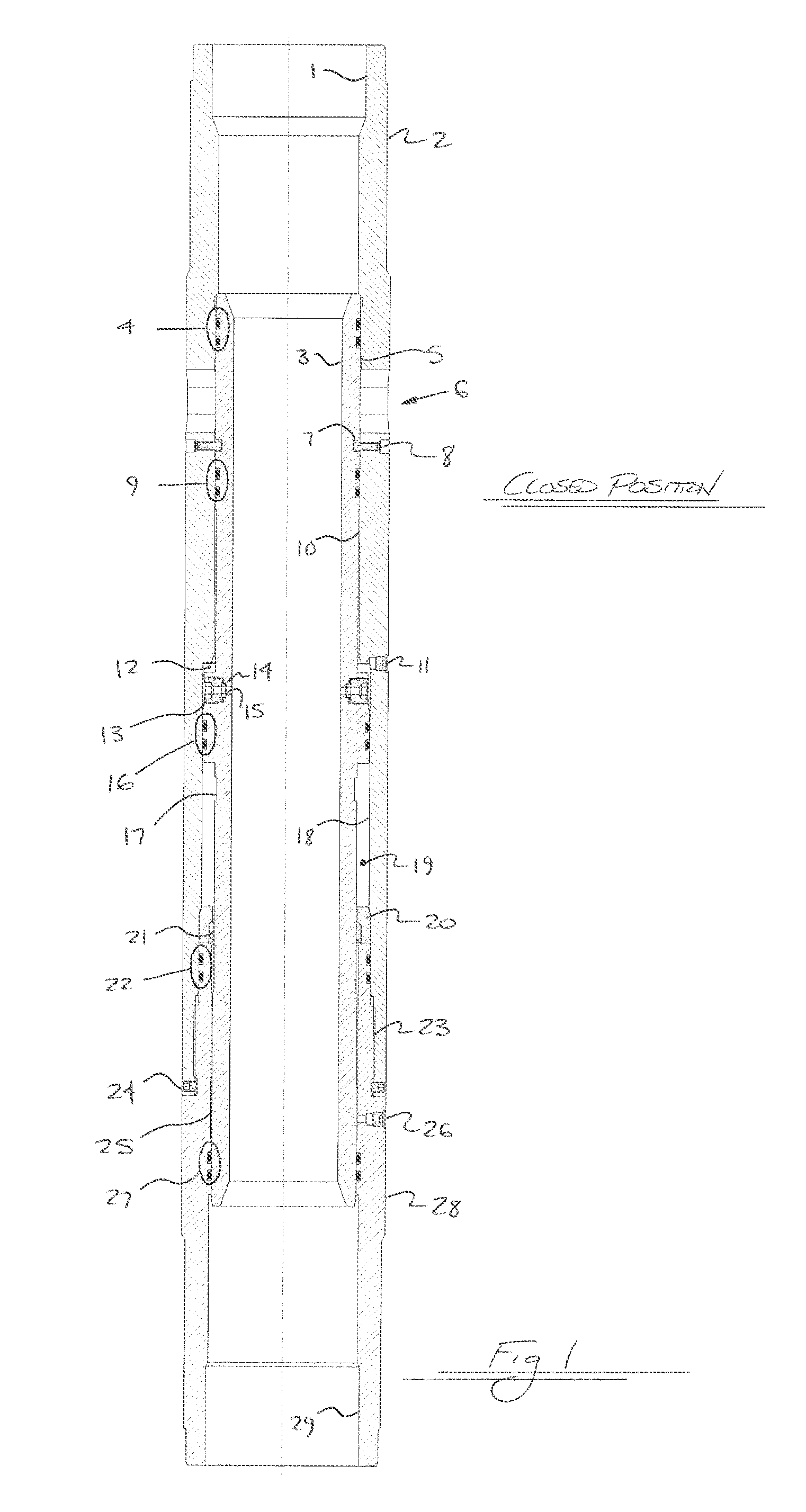

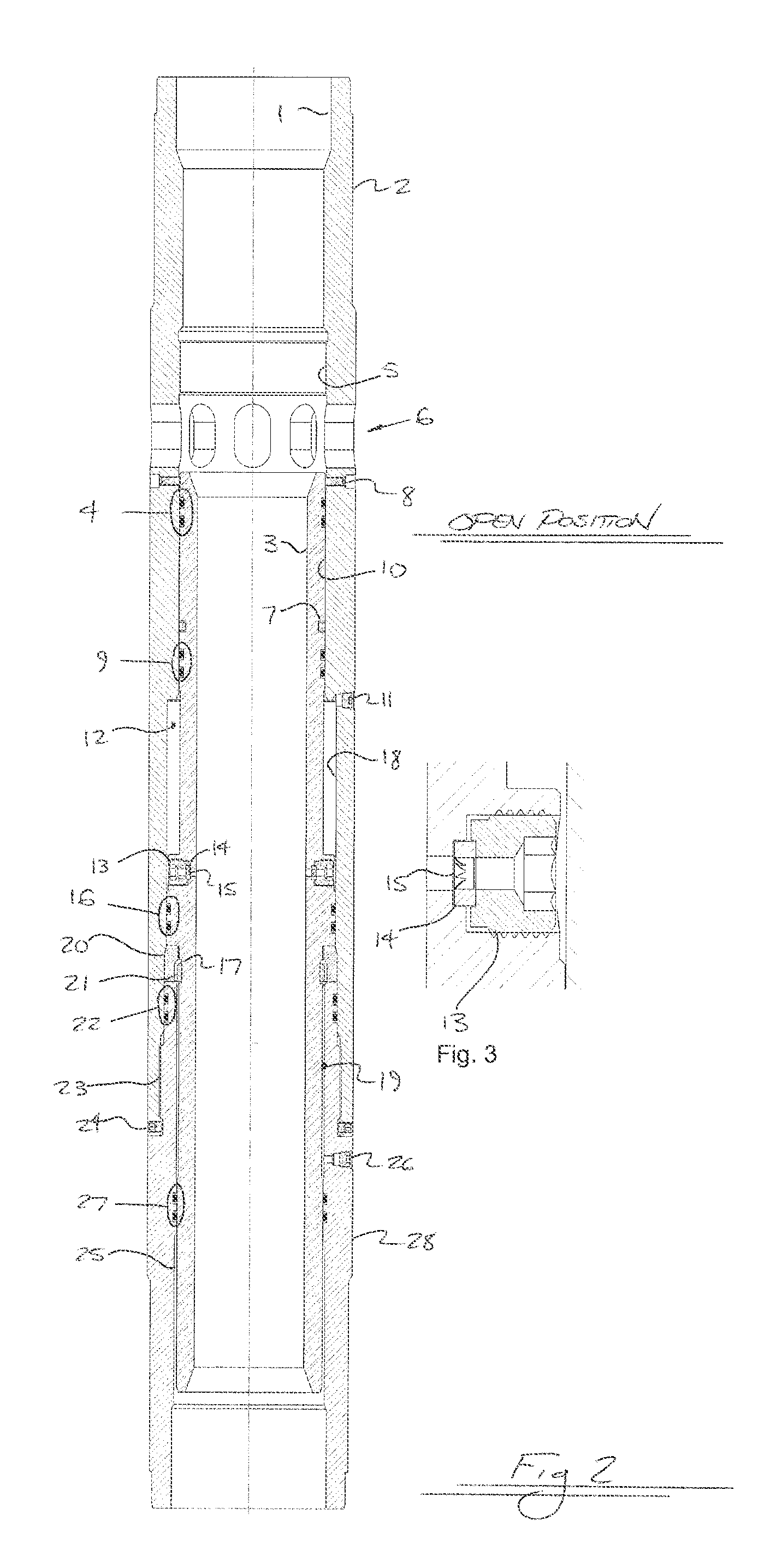

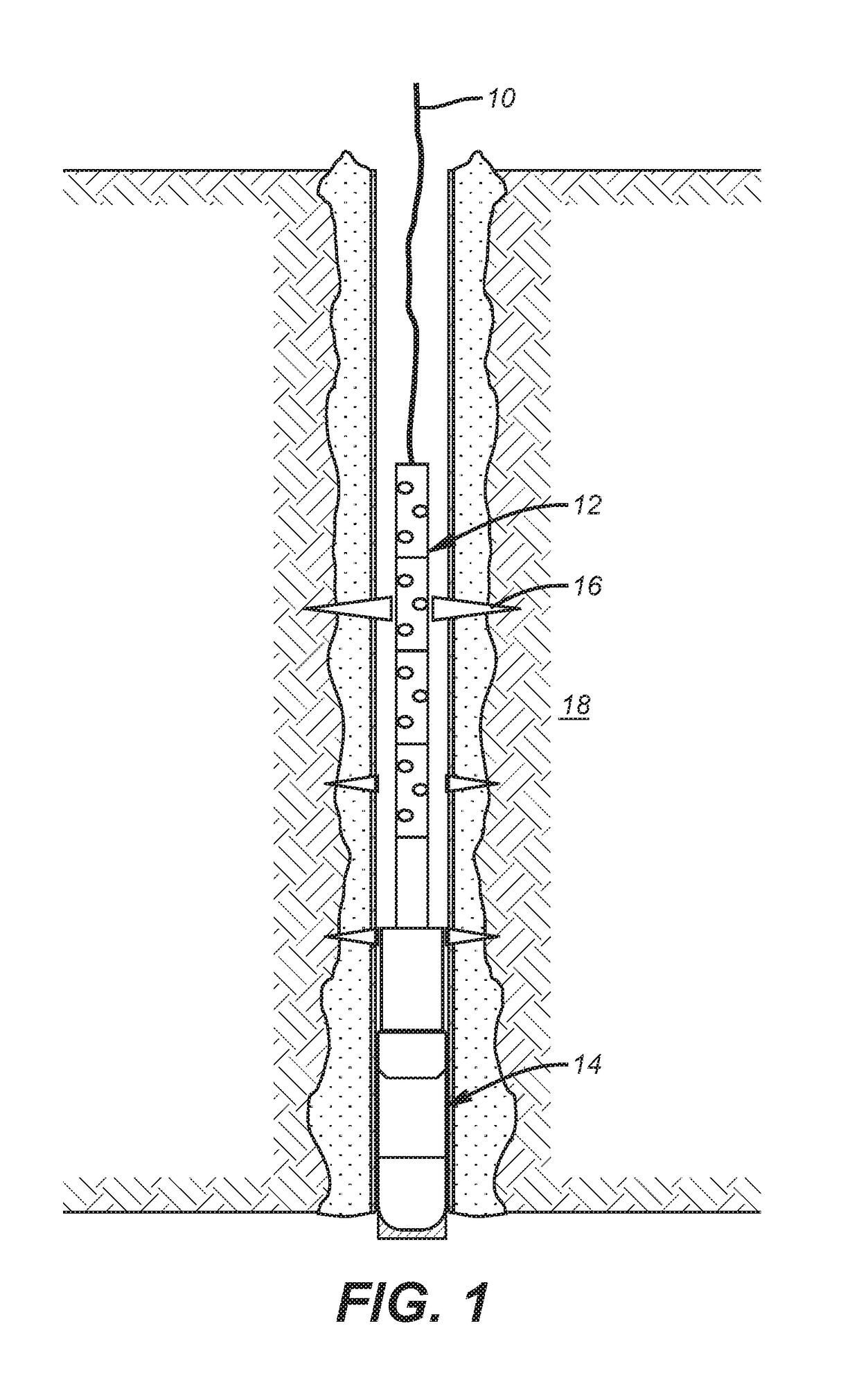

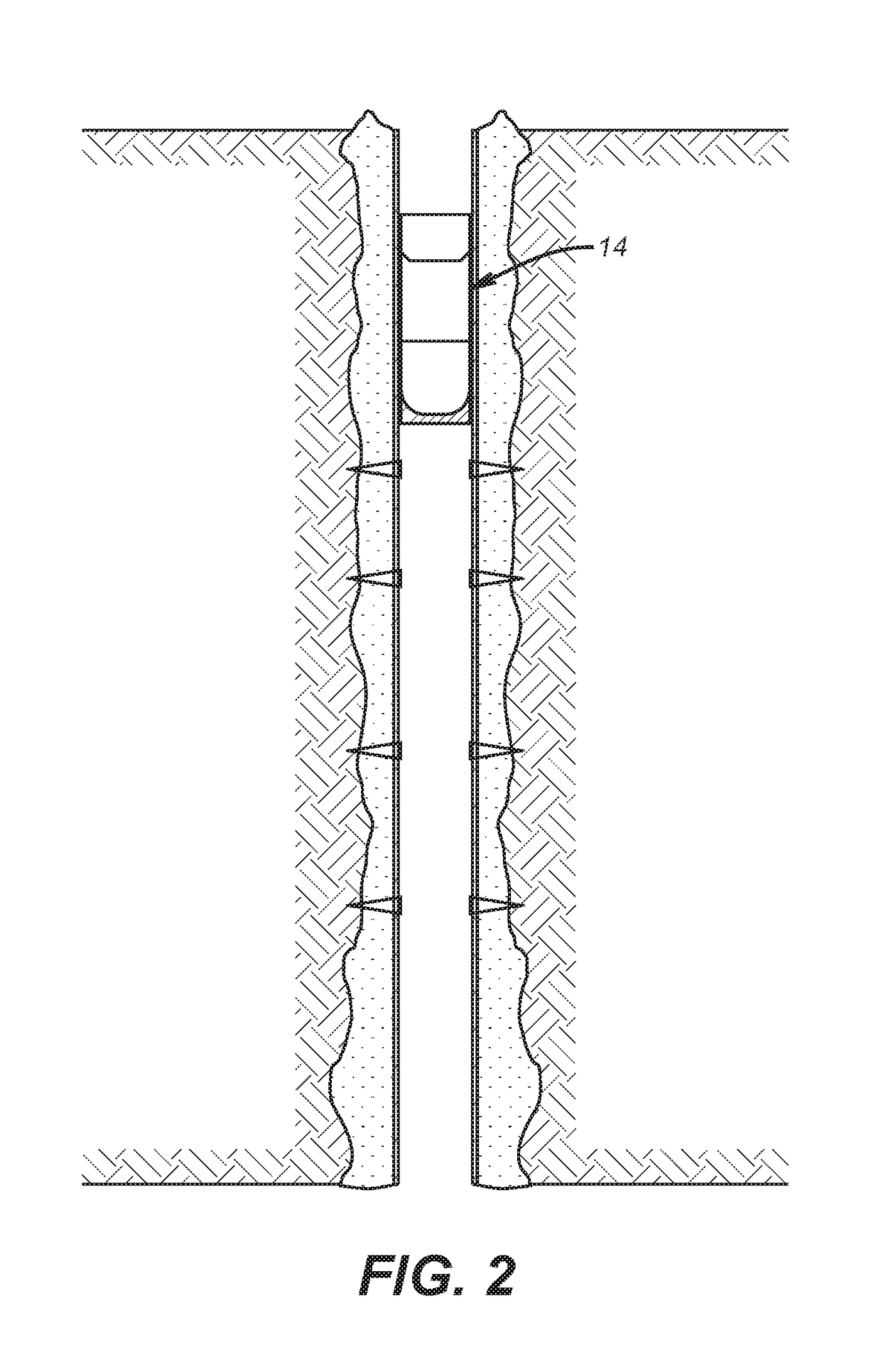

Pressure Actuated Ported Sub for Subterranean Cement Completions

ActiveUS20130025872A1Avoid flexing and bendingConstructionsFluid removalDifferential pressureEngineering

A tubing pressure operated sliding sleeve is used in cementing a tubular string. The sleeve is configured to hold closed as pressure builds to a predetermined value. When pressure is further raised a rupture disc blows and provides access to an integral piston disposed outside the sleeve. The back side of the piston is exposed to a low pressure or atmospheric chamber located between upper and lower seals. The sleeve thickness near the chamber can be made relatively thick to avoid flexing or bending under differential pressure because the net force to shift the sleeve is from differential pressure on the piston rather than the piston areas created by the upper and lower seals.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

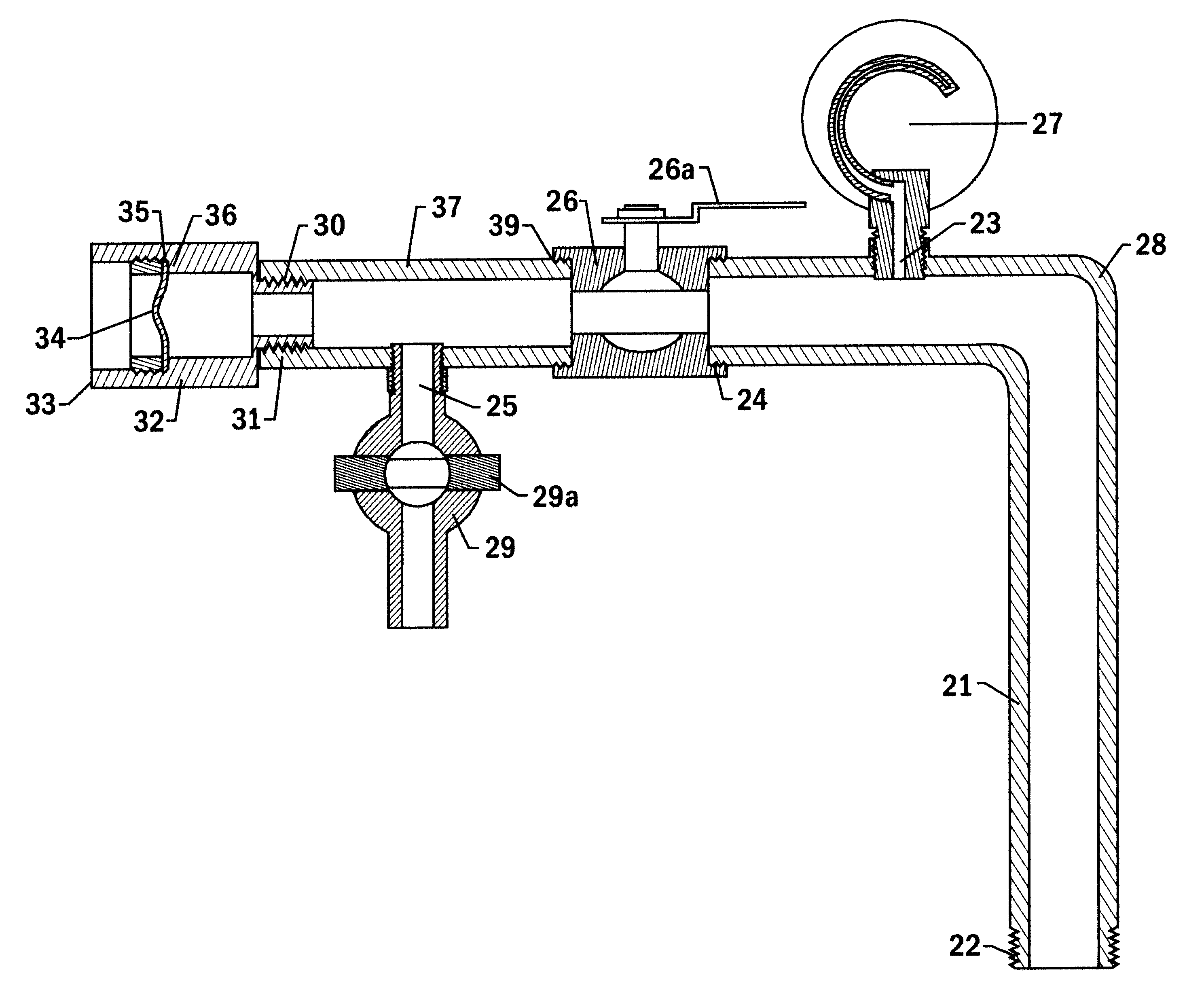

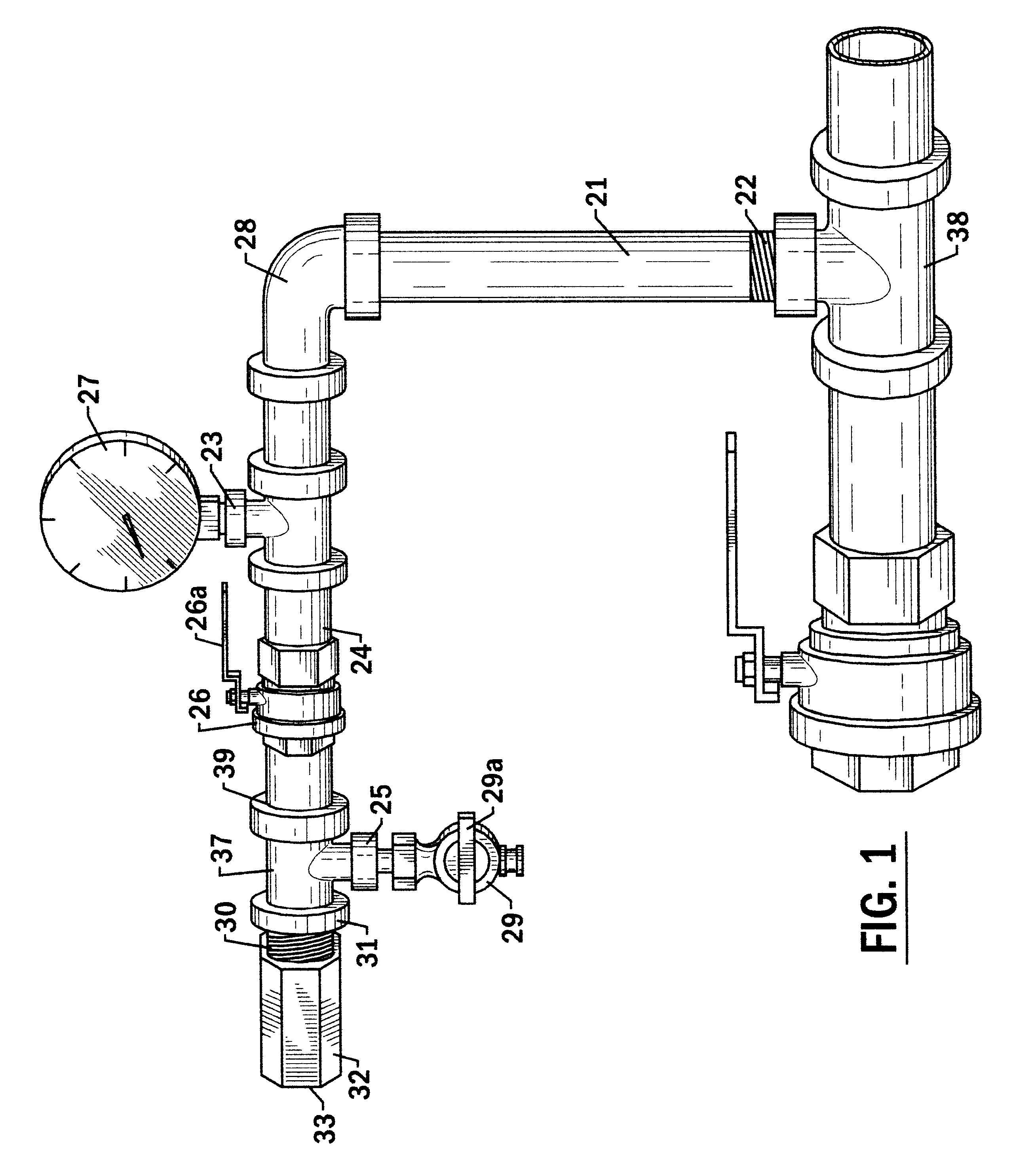

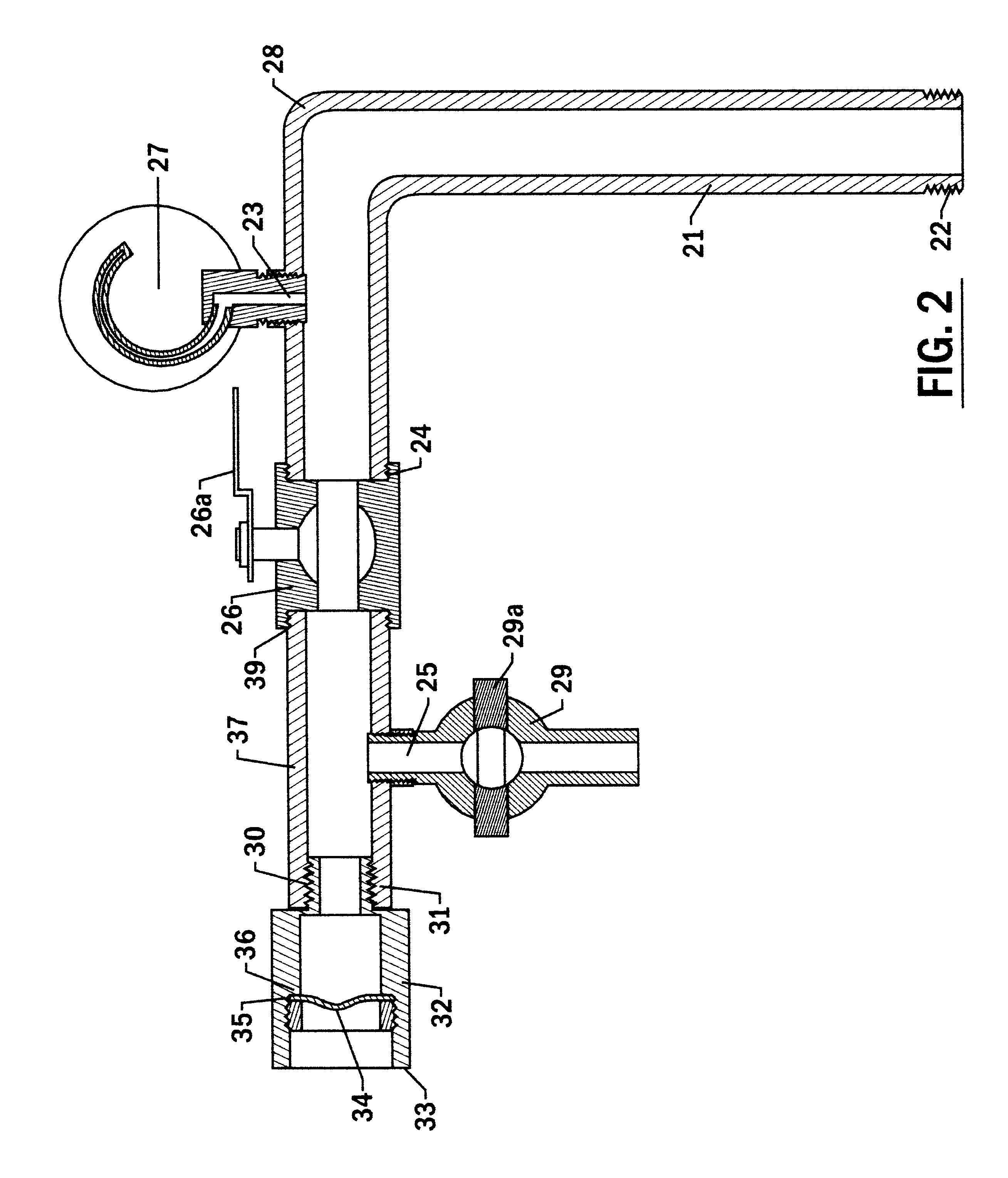

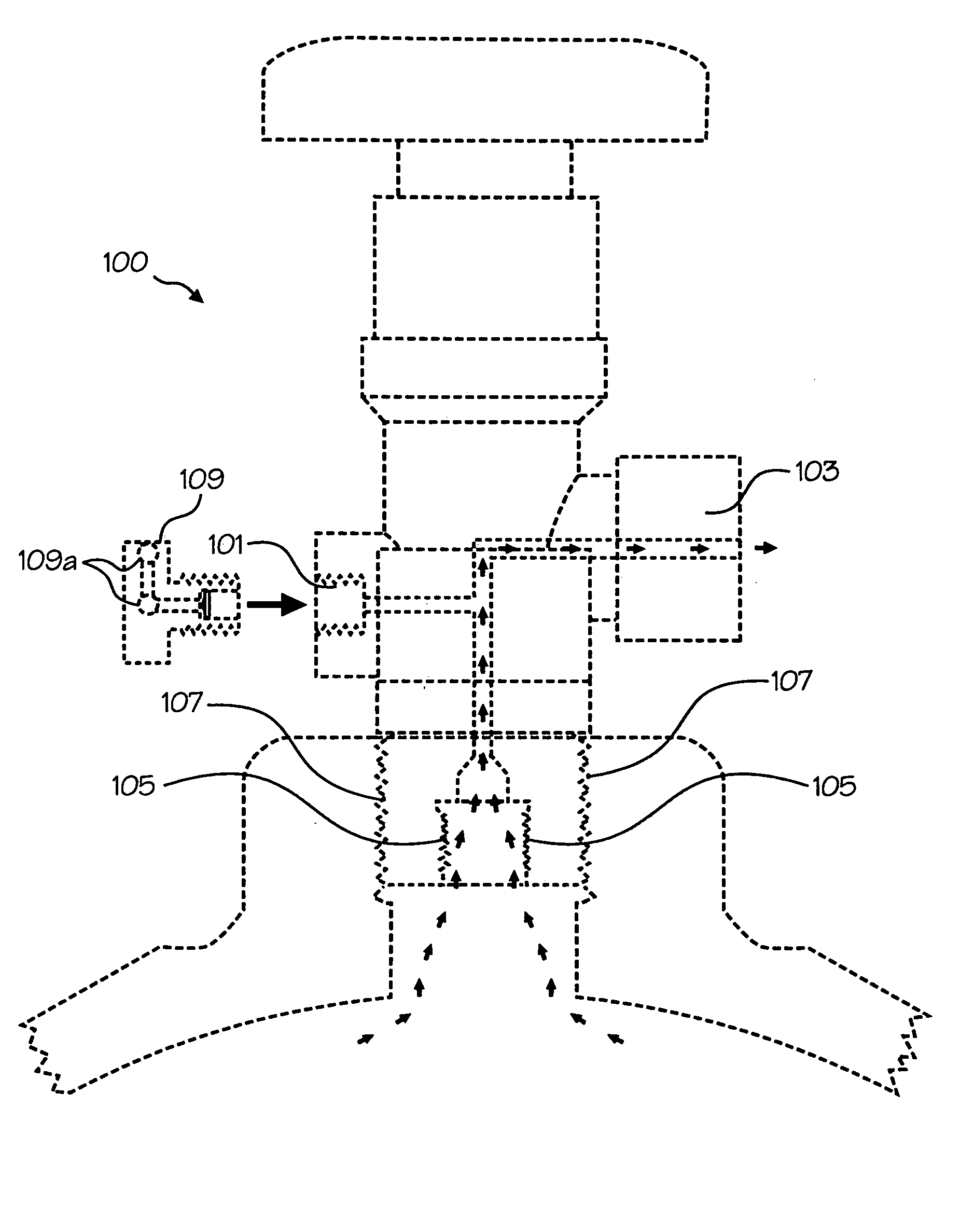

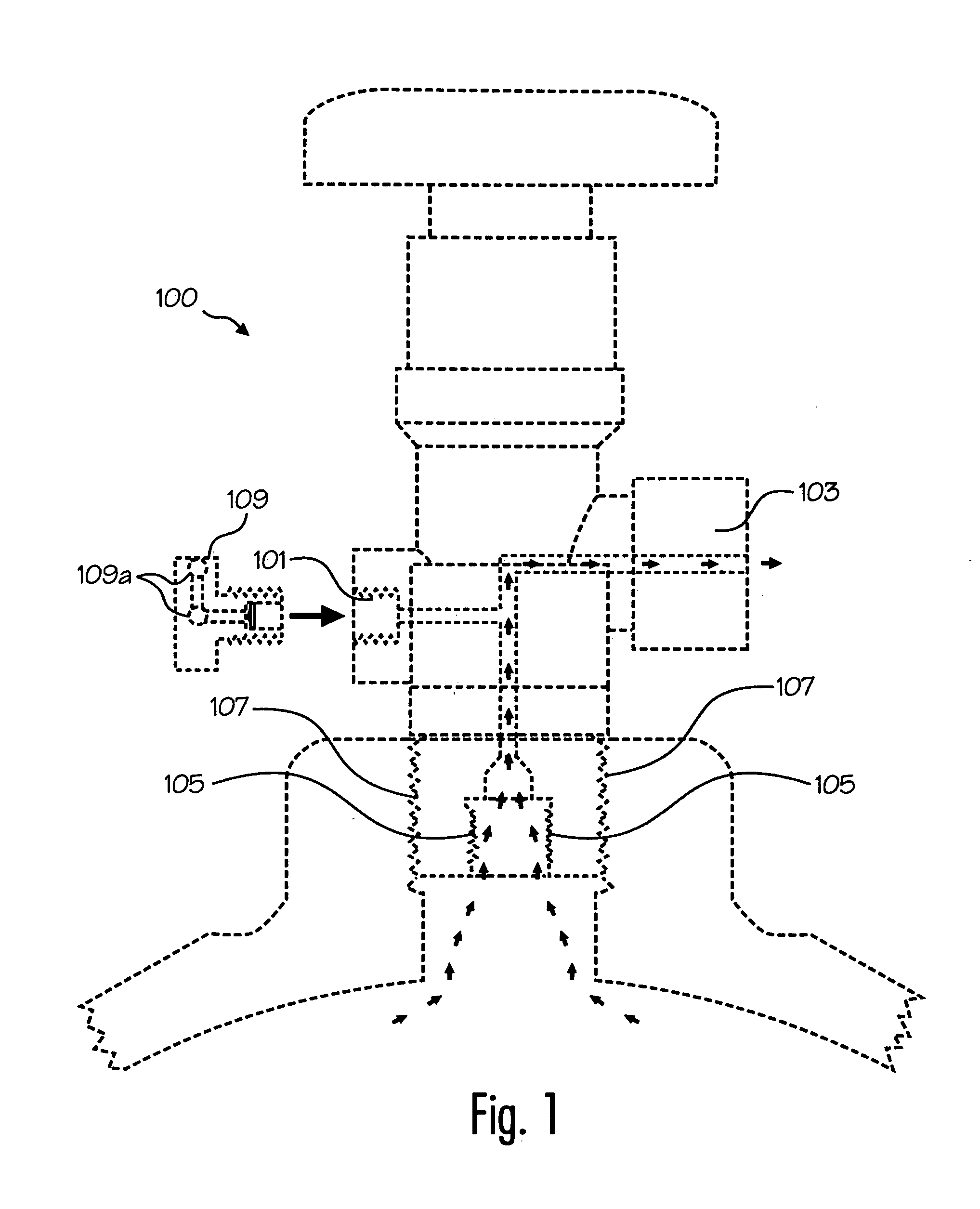

Pressure relief device, system, and method

A pressure relief device and a hydraulic fracturing system having a pressure relief device are provided. In one form, the pressure relief device has a valve body with a linearly extending throughbore between the inlet and outlet thereof. A rupture disc is secured in the valve body so that a frangible dome wall portion thereof has a reverse-acting orientation in the valve body bore. The hydraulic fracturing system includes a pump and a delivery line that receives pressurized fracturing fluid from the pump and delivers it to a well. A pressure relief device is installed along the delivery line. A sensor detects fluid flow downstream of the pressure relief device which allows the pump to be shut down when the downstream fluid flow is detected. The pressure relief device can have a body with a domed rupture disc and the sensor therein.

Owner:OKLAHOMA SAFETY EQUIP

Kinetic antifreeze device

InactiveUS6491109B2Efficient and inexpensivePrevent freezingEqualizing valvesFire rescueIsolation valveSprinkler system

A kinetic antifreeze device for preventing a dry sprinkler system from freezing is disclosed. The kinetic antifreeze device contains a longitudinal pipe for guiding air and water flow connected to a dry sprinkler system pipe at a junction adjacent to a drain valve. The longitudinal pipe provides a pressure gauge, an isolation valve, a bleed off valve and a relief disc for providing over pressure relief. The relief disc is either a bursting disc device or a rupture disc device which remains closed when the dry sprinkler system is contains only air. The relief disc exits or opens upon fire suppression fluid entering the system after a main supply of fire suppression fluid is actuated by the dry sprinkler system and the pressure increases due to the presence of fire suppression fluid in the dry sprinkler system.

Owner:CHRISTENSON JOEL P +1

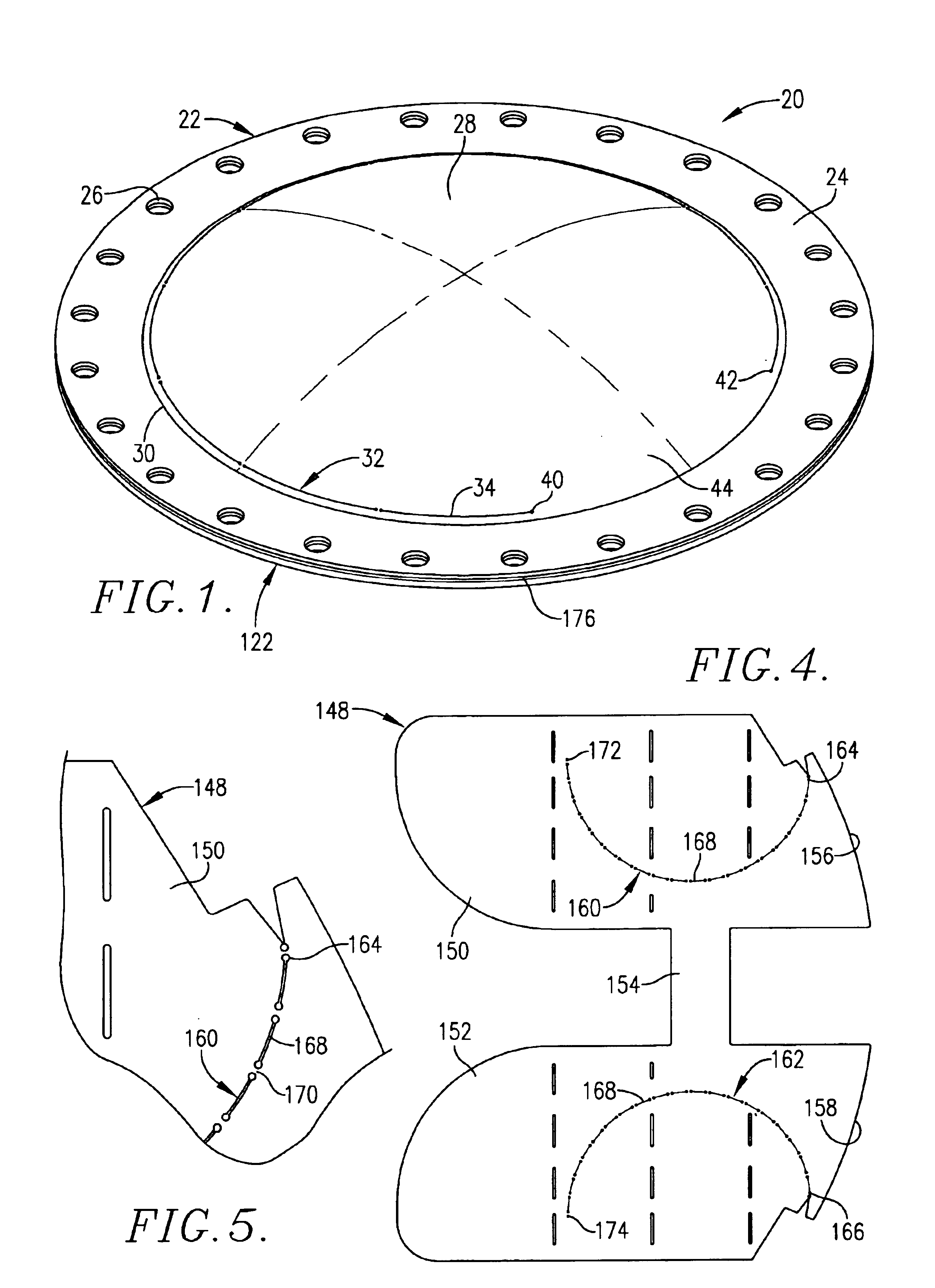

Rupture disc with machined line of opening

ActiveUS20090302035A1Uniform grain structureLarge containersEqualizing valvesMilling cutterGrain structure

A reverse acting rupture disc and methods of forming the same are provided. Generally, the rupture disc comprises a bulged portion and a circumscribing flange area surrounding the bulged portion. The bulged portion includes a mechanically formed line-of-opening recess comprising a singular channel. In certain embodiments, the mechanical process by which the recess is formed utilizes a high-speed mill which removes a portion of metal from the bulged portion of the disc without disrupting the substantially uniform metallic grain structure of the metal adjacent the channel.

Owner:FIKE CORP

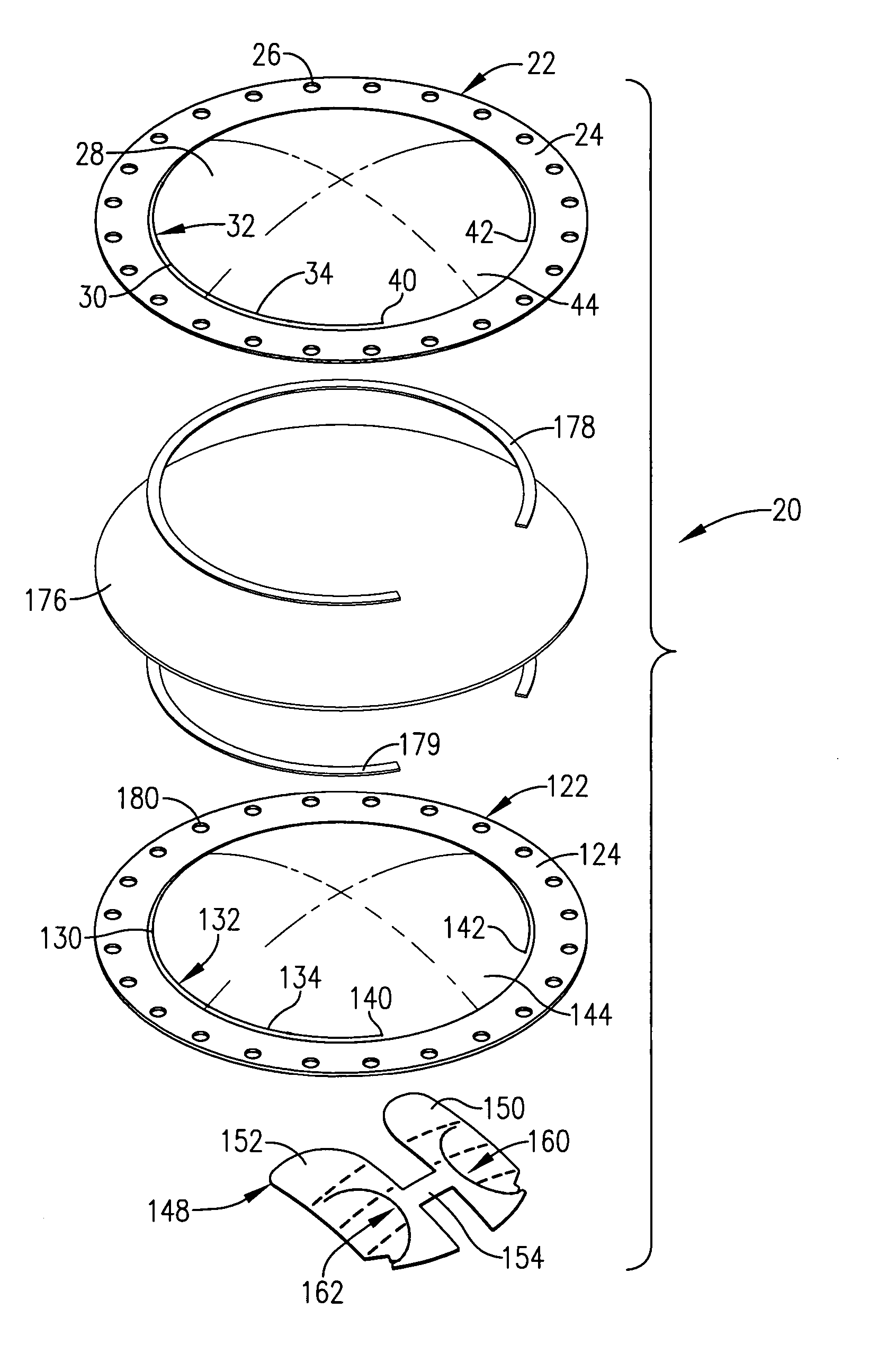

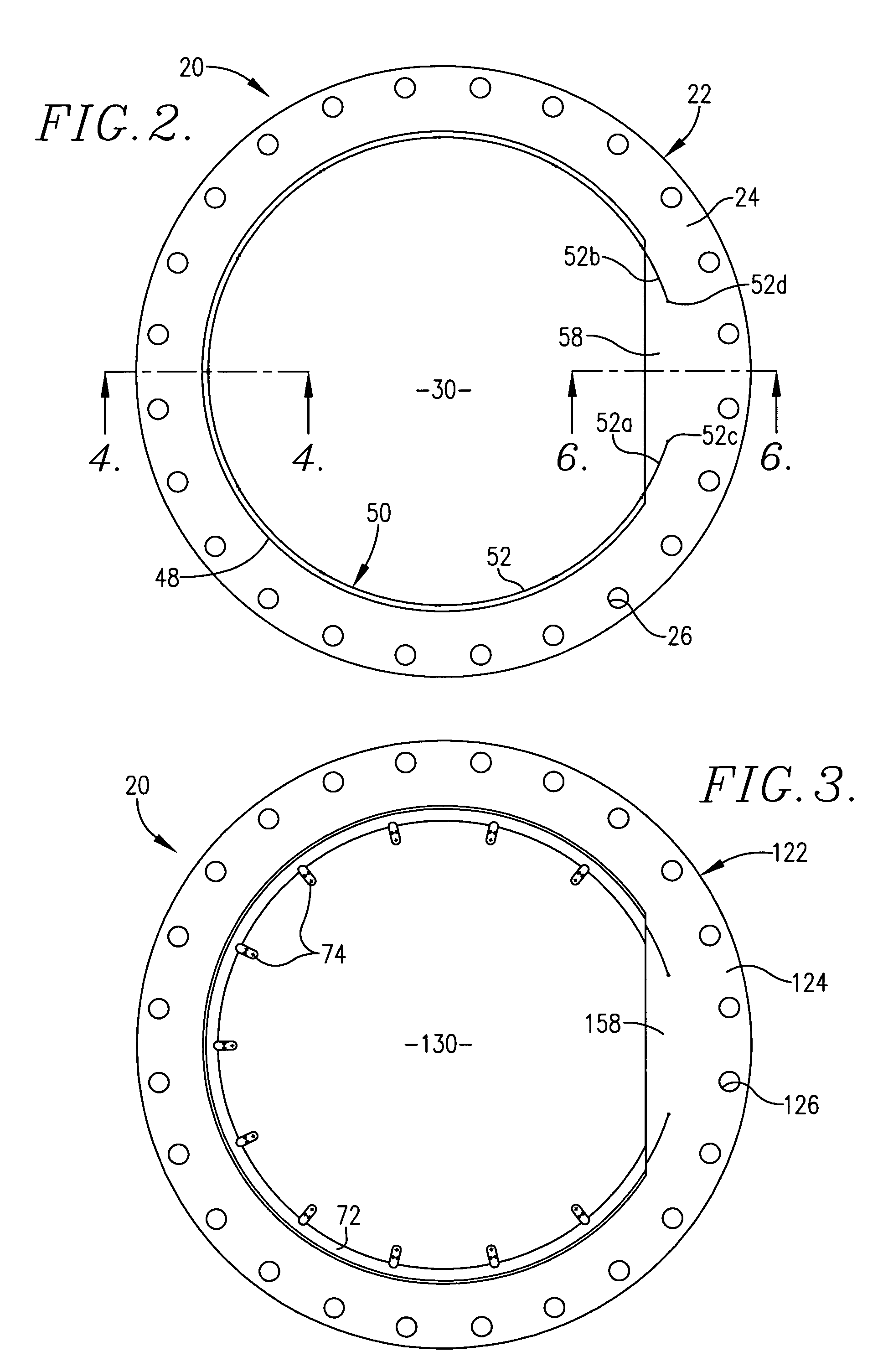

Non-fragmenting pressure relief apparatus

A non-fragmenting pressure relief apparatus includes a rupture disc having a central bulged or flat section and a peripheral flange portion. Certain embodiments of the invention have a butterfly shaped element having two wing panels attached to the underside of a rupture disc of the apparatus. A line of weakness of major length extends around the periphery of the central section of a disc and C-shaped end region lines of weakness in the wing panels, which define a hinge portion of the disc therebetween, first converge and then diverge from one another, and connect with the major line of weakness. Application of an overpressure to the rupture disc apparatus causes the entire line of weakness to sever including the end region lines of weakness whereby divergence of the opening force at the hinge portion of the disc prevents separation of the central section of the disc from the peripheral portion of the disc. In another embodiment, the butterfly shaped element is omitted and the C-shaped end region lines of weakness are provided in the central section of the disc.

Owner:FIKE CORP

Prevention of unwanted material accumulations

In one embodiment, the invention provides a rupture disk assembly having a rupture disk and a rupture disk holder. The rupture disk holder has a first annular member downstream of the rupture disk, a second annular member upstream of the rupture disk, and an optional third annular member upstream of the second annular member. An outer peripheral portion of the rupture disk is sandwiched between the first and second annular members; and, if a third annular member is present, (a) the second annular member is sandwiched between the outer peripheral portion of the rupture disk and the third annular member, and (b) the third annular member includes a fluid port aimed at the rupture disk. However, if the third annular member is not present, the second annular member includes a fluid port aimed at the rupture disk. In another embodiment, the invention provides an equipment access assembly having an equipment access cover, an equipment access cover mount, and an annular member between the equipment access cover and cover mount. The annular member includes a fluid port aimed at the equipment access cover. In yet another embodiment, the invention provides a valve mounting assembly having a downstream valve mount, an upstream valve mount, a valve intermediate the downstream and upstream valve mounts, and an annular member intermediate the valve and the upstream valve mount. The annular member includes a fluid port aimed at the valve.

Owner:ROHM & HAAS CO

Pressure actuated ported sub for subterranean cement completions

A tubing pressure operated sliding sleeve is used in cementing a tubular string. The sleeve is configured to hold closed as pressure builds to a predetermined value. When pressure is further raised a rupture disc blows and provides access to an integral piston disposed outside the sleeve. The back side of the piston is exposed to a low pressure or atmospheric chamber located between upper and lower seals. The sleeve thickness near the chamber can be made relatively thick to avoid flexing or bending under differential pressure because the net force to shift the sleeve is from differential pressure on the piston rather than the piston areas created by the upper and lower seals.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

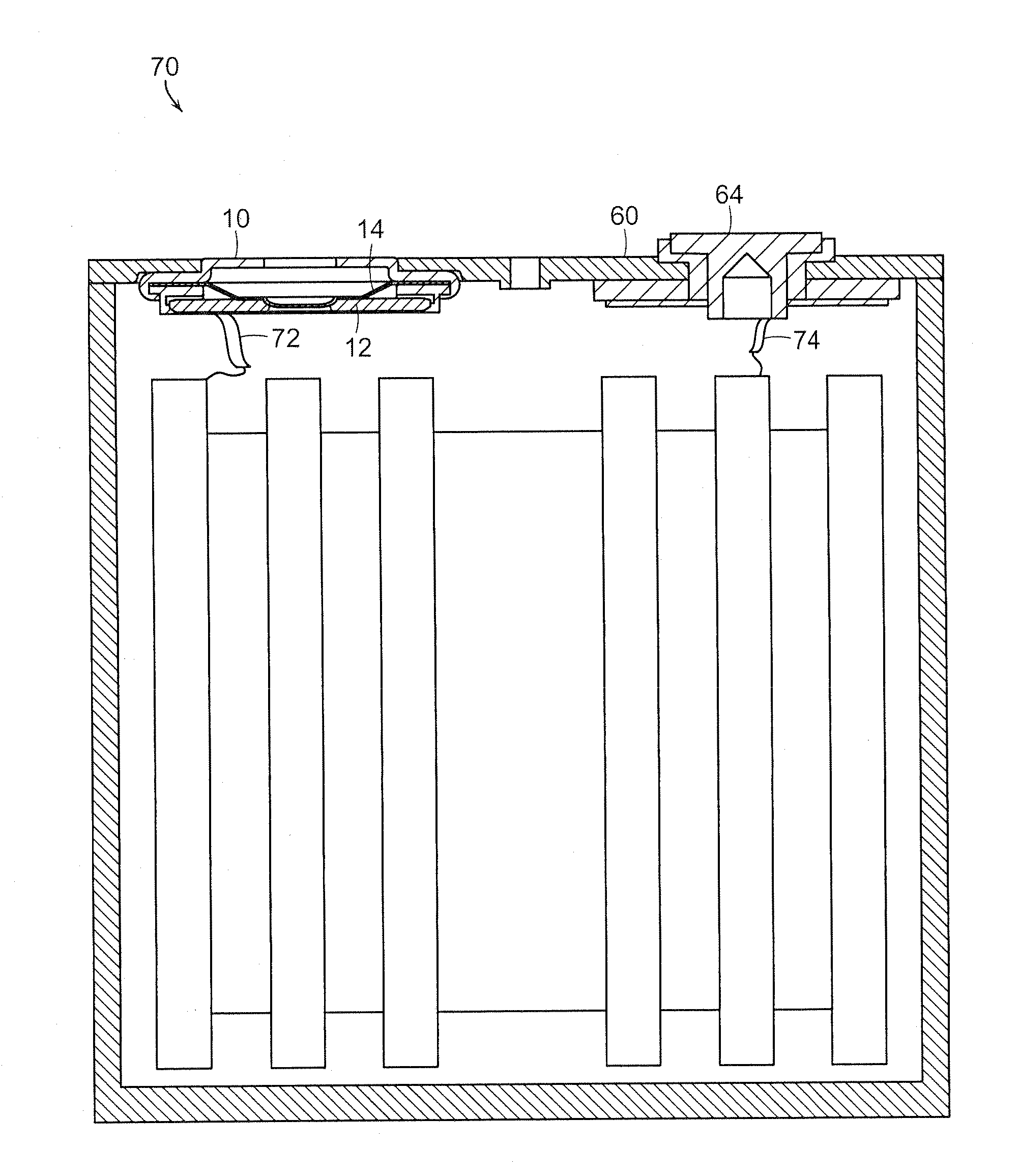

Modular CID Assembly for a Lithium Ion Battery

InactiveUS20100178539A1Reduce manufacturing costIncrease typeFinal product manufacturePrimary cellsElectricityModularity

A modular current interrupt device includes an electrically-conductive rupture disc, an electrically-conductive pressure disc attached to the rupture disc to form an electrical pathway. An electrically-insulating ring partitions a perimeter of the rupture disc from a perimeter of the pressure disc, and a seating element secures the electrically-insulated ring to the pressure disc. At least one of the rupture disc and electrically-insulating ring defines a conduit, whereby exposure of one side of the pressure disc to sufficient force through the conduit causes the pressure disc to separate from the rupture disc to thereby sever the electrical pathway. A low pressure current interrupt device (CID) activates at a minimal threshold internal gauge pressure in a range of, for example, between about 4 kg / cm2 and about 9 kg / cm2. Preferably, the CID includes a pressure disc that includes a frustum having a first end and a second end, a base extending radially from a perimeter of the first end of the frustum, and an essentially planar cap sealing the second end of the frustum. The first end has a broader diameter than the second end, with a cross-section of at least one of the first and second end being non-circular.

Owner:BOSTON POWER INC

Non-fragmenting pressure relief apparatus

Non-fragmenting pressure relief apparatus includes at least one circular rupture disc having a central asymmetric bulged section and a peripheral flange portion. A semi-circular line of weakness extends around the periphery of the bulged section and presents a hinge portion between the ends of the line of weakness. A hold-down member for the rupture disc having an inner opening surrounding the bulged section of the disc is provided with a unitary segment that extends into the inner opening of the hold-down member. The spaced end extremities of the line of weakness extend beneath the hold-down member segment. The hinge portion of the disc upon rupture of the disc bends about a fulcrum defined by the outer margin of the hold-down segment, which in conjunction with deflection of the segment of the hold-down member contributes to anti-fragmentation of the disc.

Owner:FIKE CORP

Non-fragmenting pressure relief apparatus

A non-fragmenting pressure relief apparatus includes a rupture disc having a central bulged or flat section and a peripheral flange portion. Certain embodiments of the invention have a butterfly shaped element having two wing panels attached to the underside of a rupture disc of the apparatus. A line of weakness of major length extends around the periphery of the central section of a disc and C-shaped end region lines of weakness in the wing panels, which define a hinge portion of the disc therebetween, first converge and then diverge from one another, and connect with the major line of weakness. Application of an overpressure to the rupture disc apparatus causes the entire line of weakness to sever including the end region lines of weakness whereby divergence of the opening force at the hinge portion of the disc prevents separation of the central section of the disc from the peripheral portion of the disc. In another embodiment, the butterfly shaped element is omitted and the C-shaped end region lines of weakness are provided in the central section of the disc.

Owner:FIKE CORP

Apparatus for Isolating and Completing Multi-Zone Frac Packs

A plurality of zones is gravel packed together and then isolated from each other in the gravel annulus by formation of a barrier in the gravel annulus. The screen assembly carries a series of chambers internally that are located between the producing zones generally in the area of blank pipe between the zones. The wash pipe has a shifter associated with it so that extraction of the wash pipe after gravel packing will serially shift pistons that reduce chamber volume where the chemical is stored. The chemical will exit through a rupture disc and nozzle and will commingle with the gravel and make an impervious annular barrier.

Owner:BAKER HUGHES INC

Downhole shock absorber with crushable nose

A downhole shock absorber preferably is filled with well fluid in a chamber that is reduced in volume due to impact. A rupture disc can hold the initial non-compressible liquid charge until impact. Upon impact, the rupture disc breaks to allow the fluid to be forced through an orifice to absorb some of the shock that occurs when a string hits a fixed object after dropping in the wellbore. The nose of the shock absorber is a soft material that has voids so that the combination of the softness of the material and the voids allow the nose to reshape until it encounters a surrounding tubular wall and then to collapse inwardly into the voids, making it simple to remove. The nose is releasably mounted to the shock absorber so the two can separate if the nose gets stuck after impact.

Owner:BAKER HUGHES INC

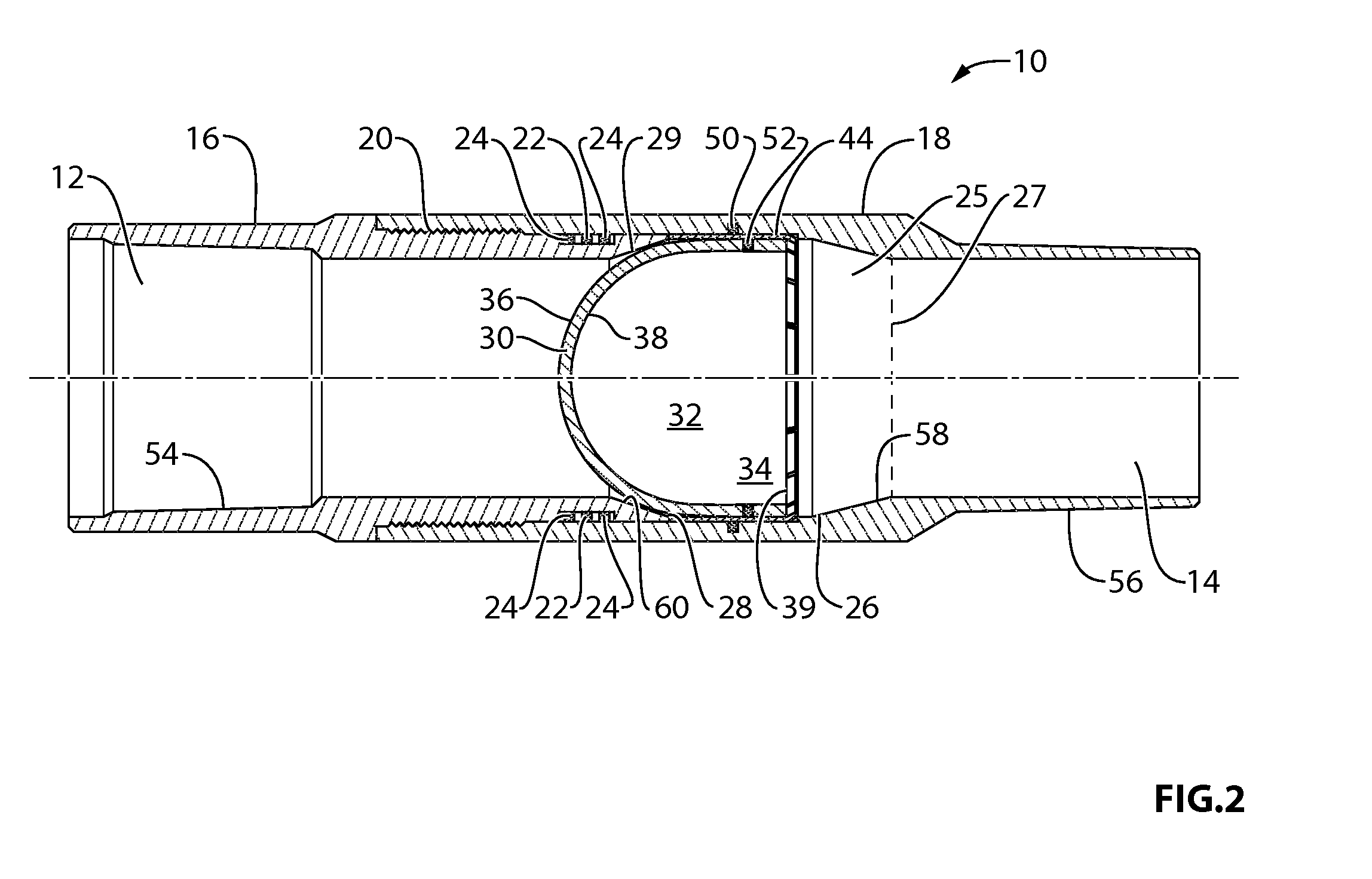

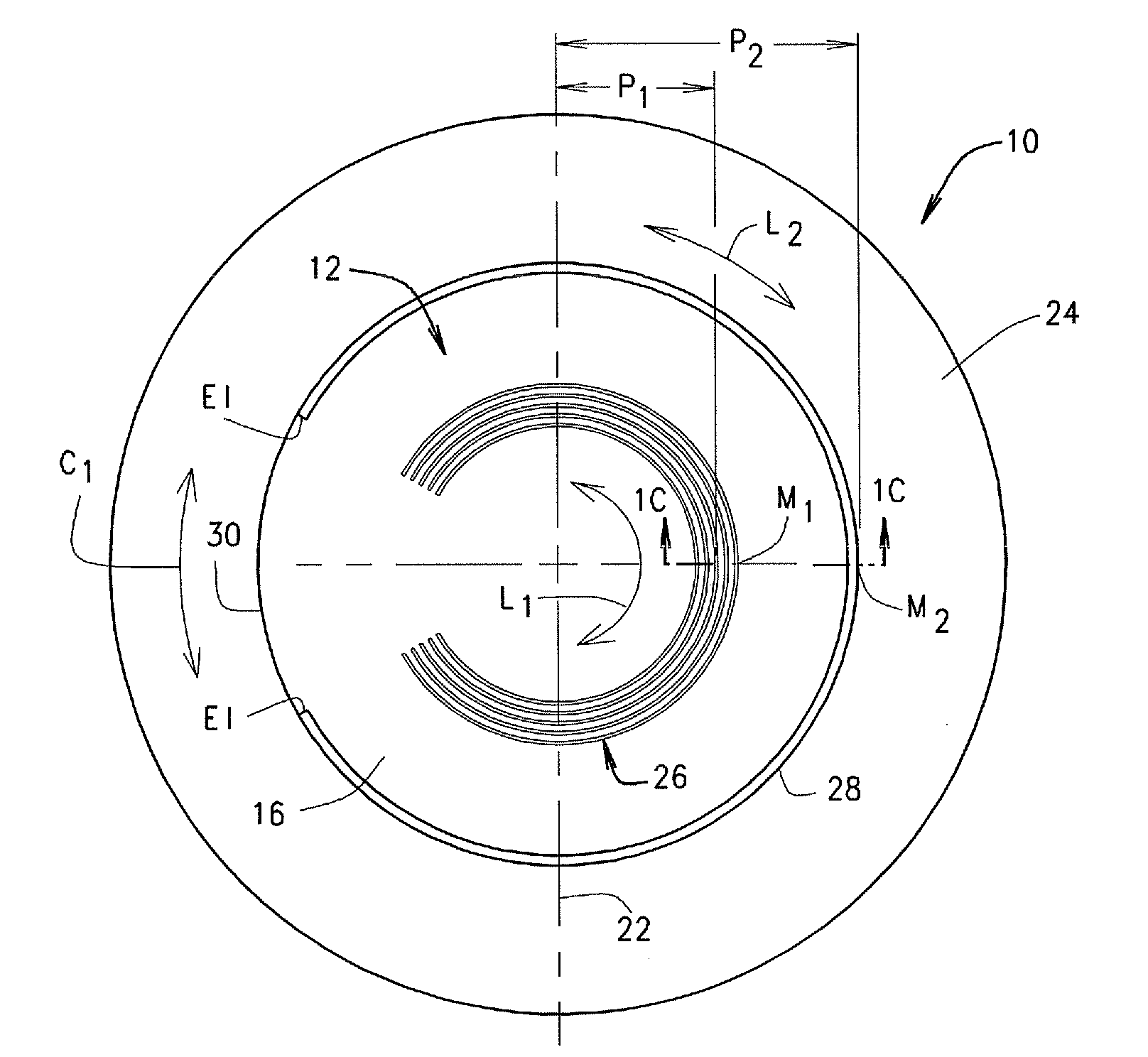

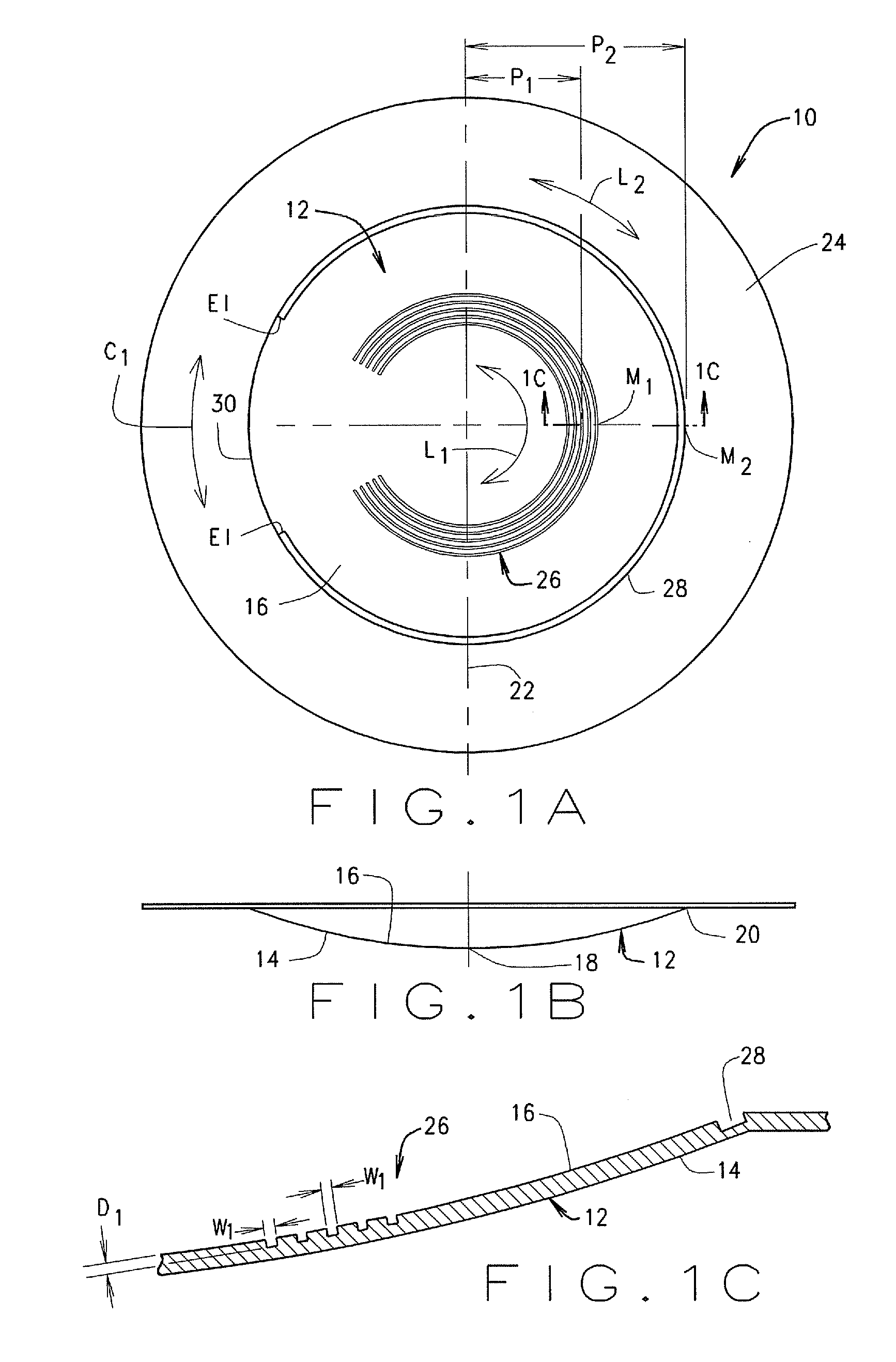

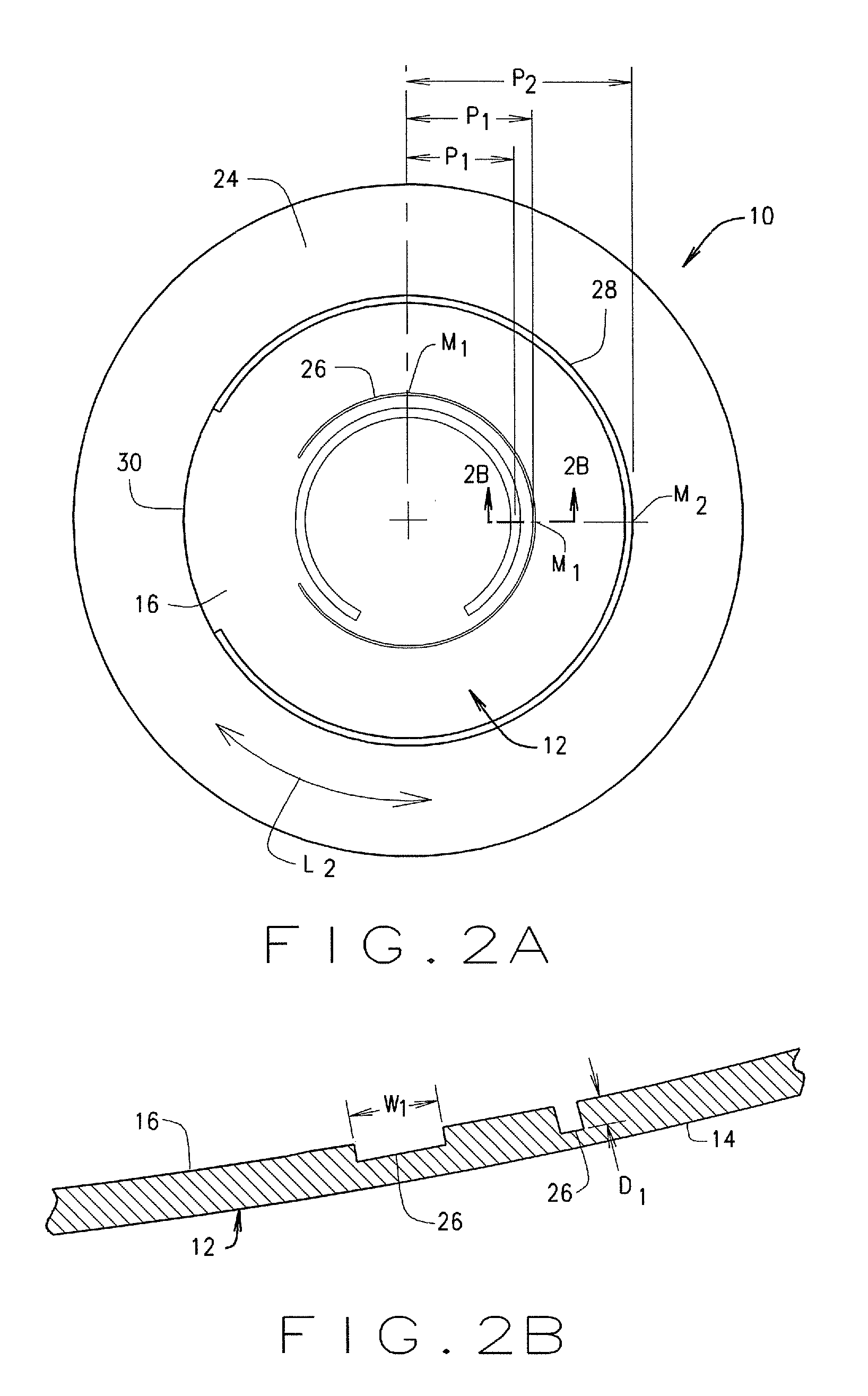

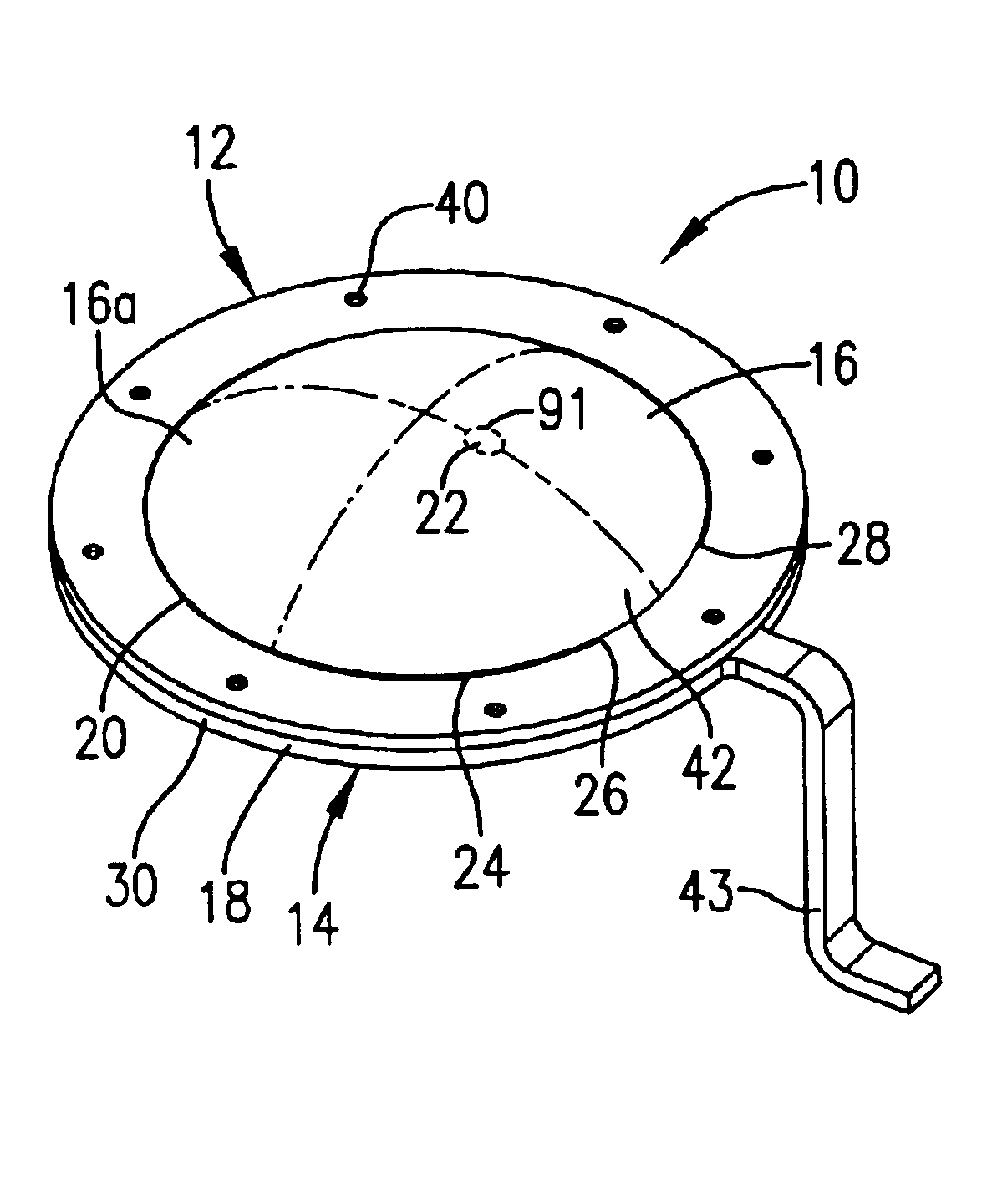

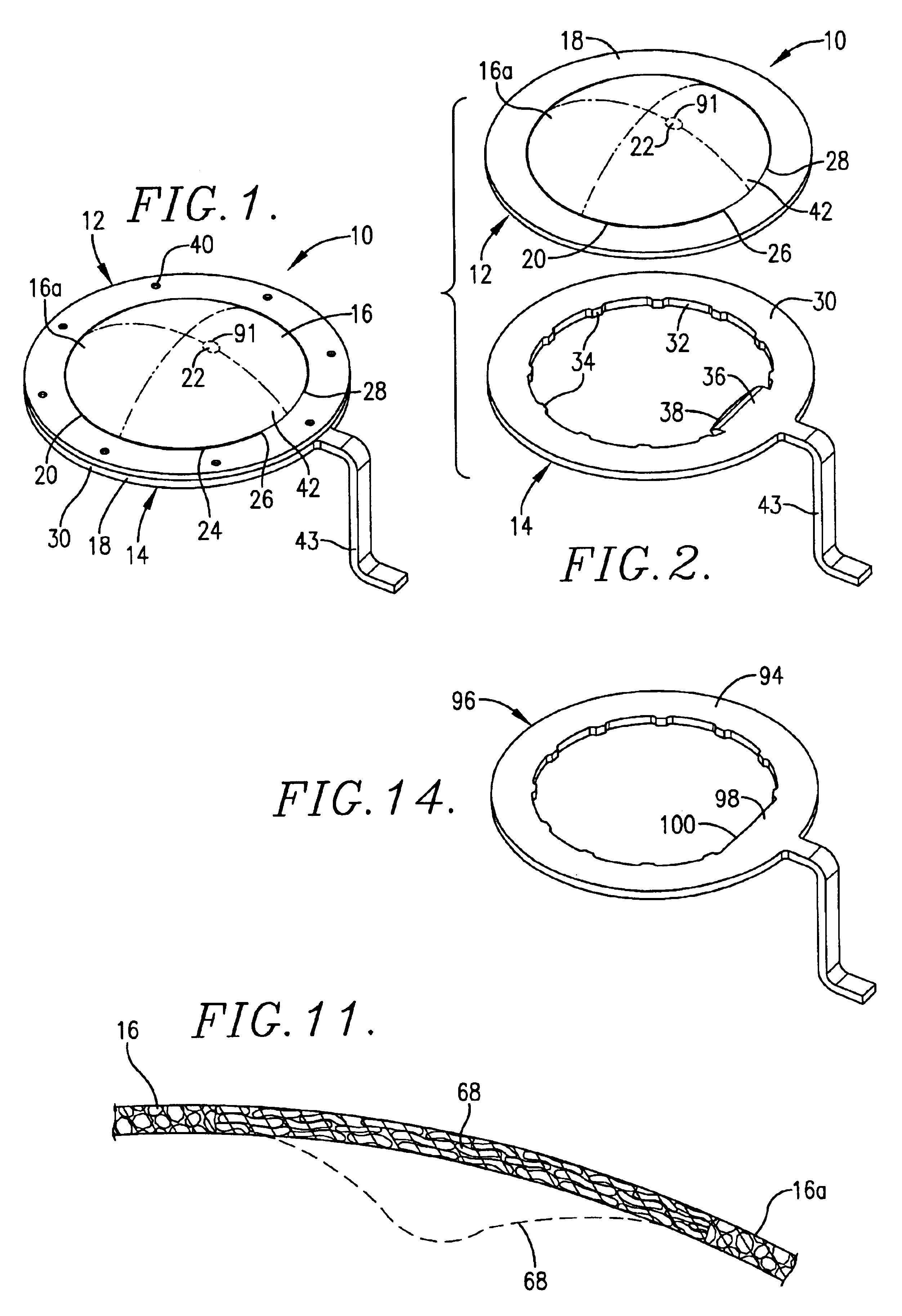

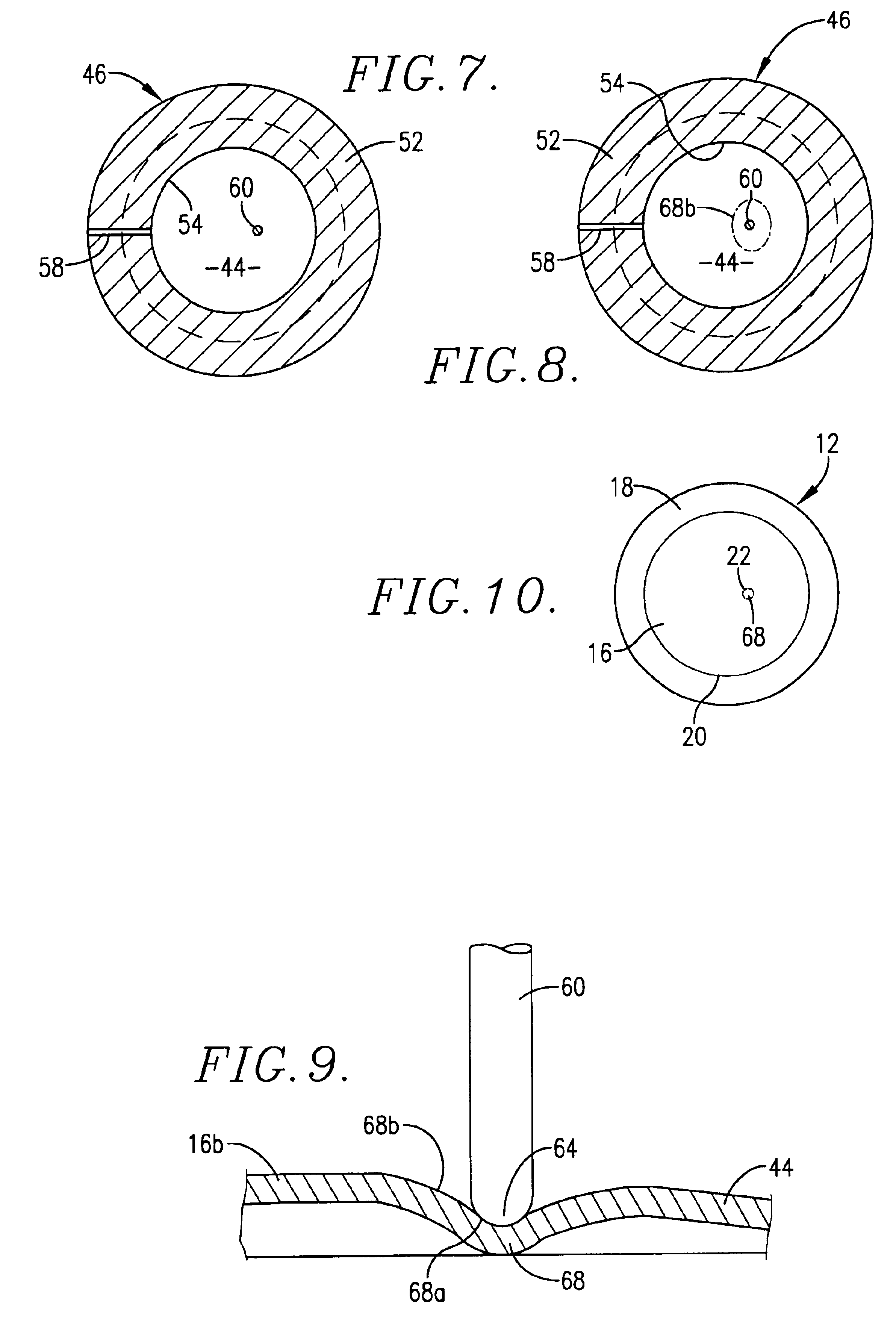

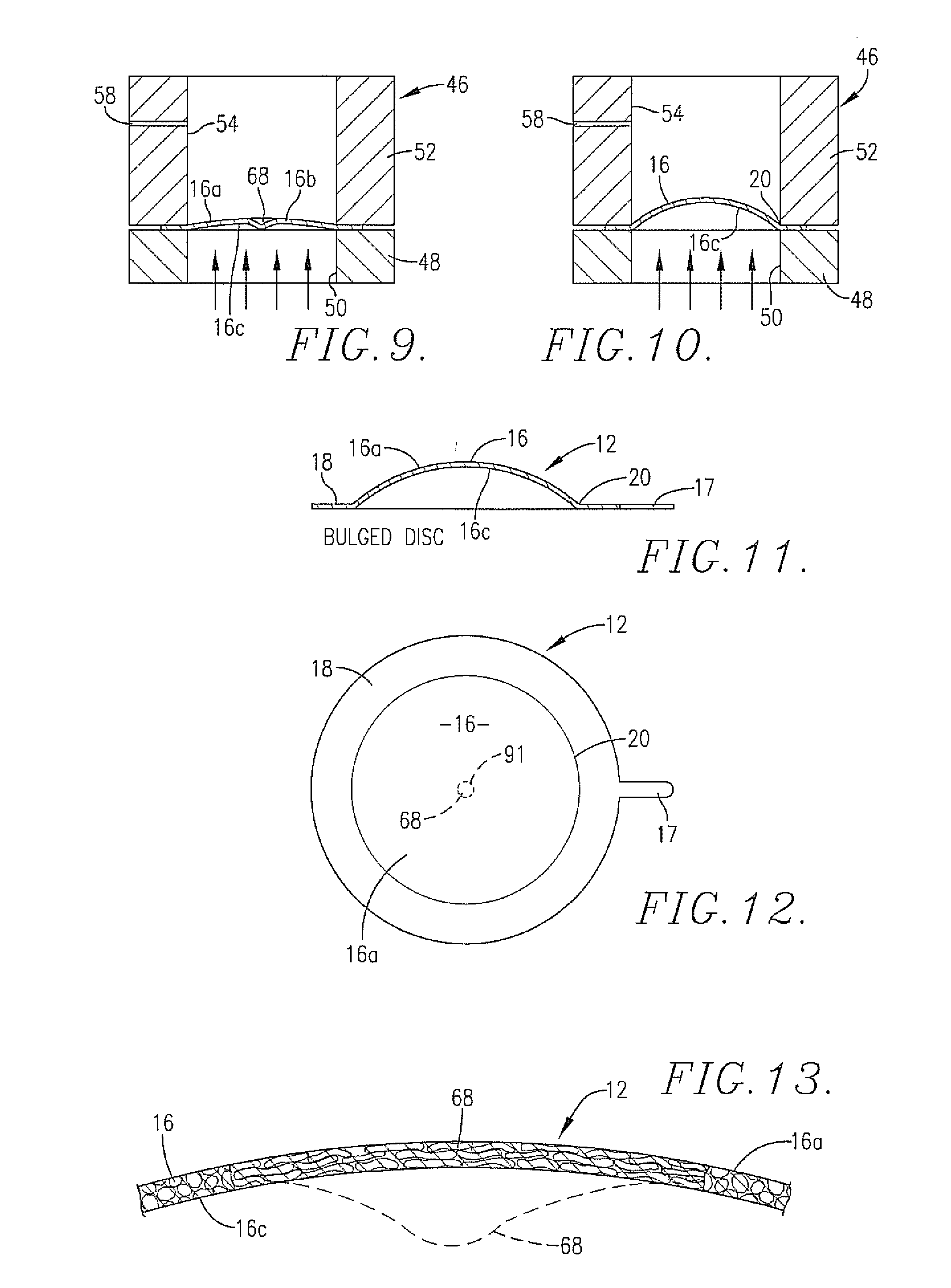

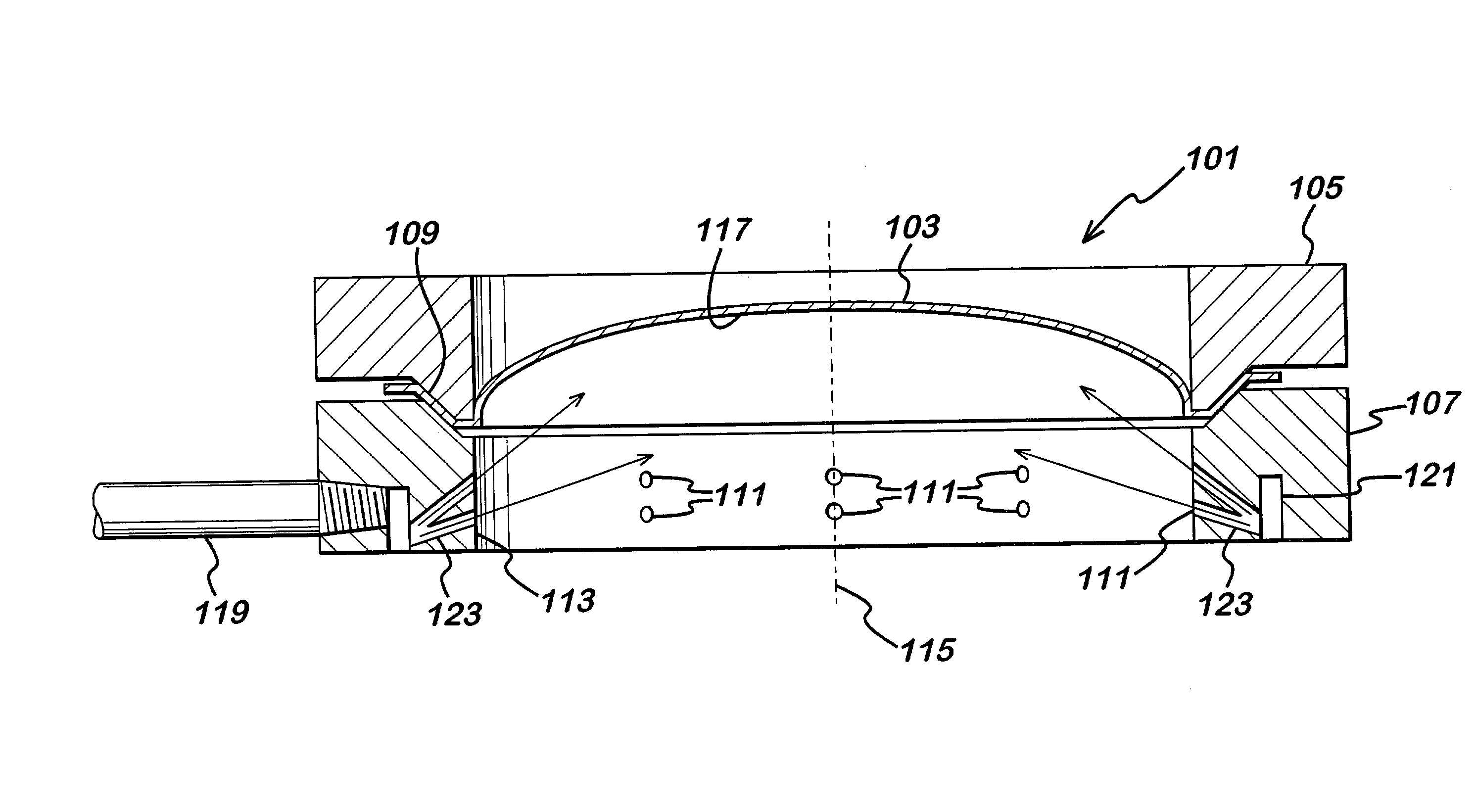

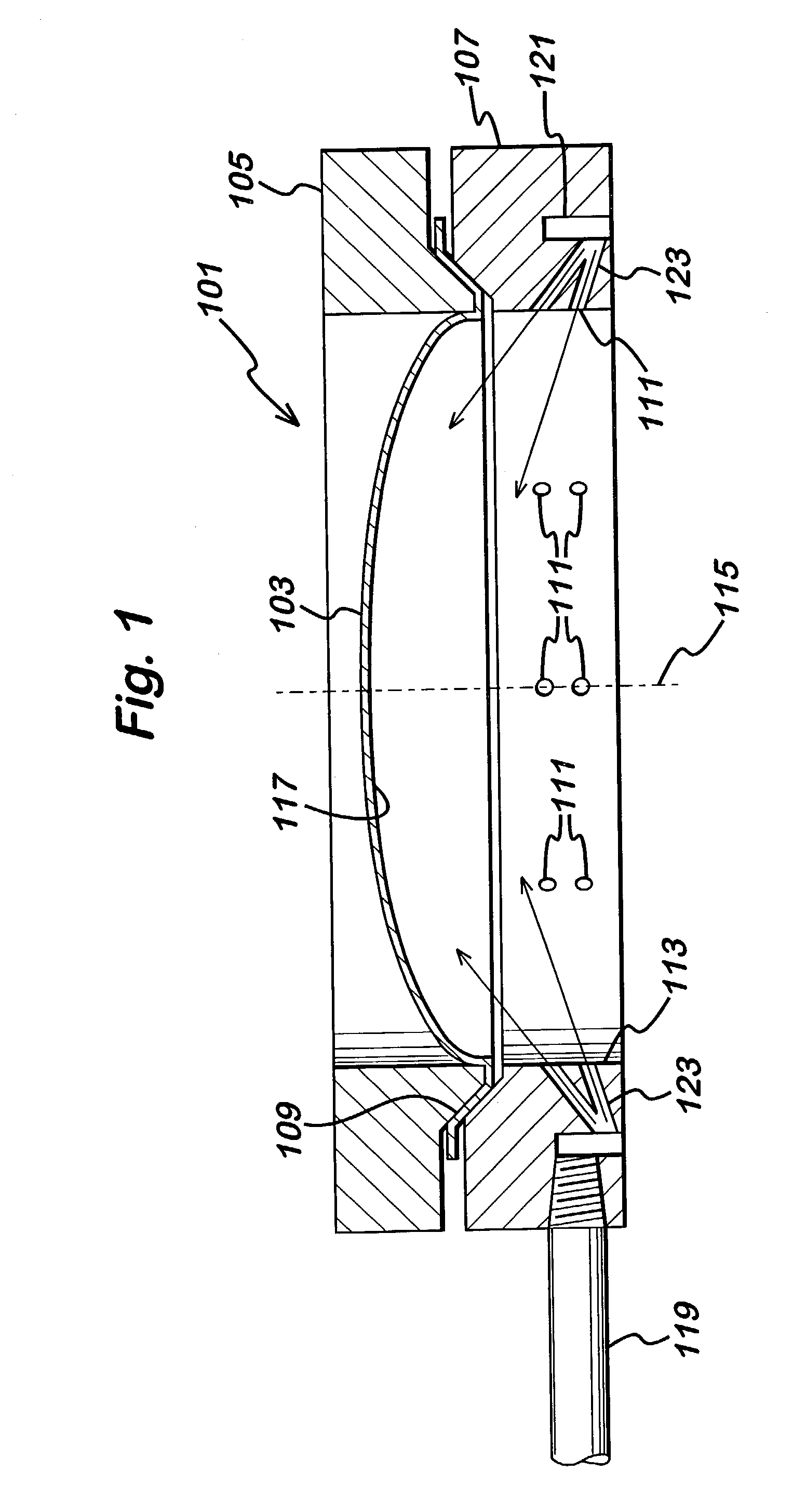

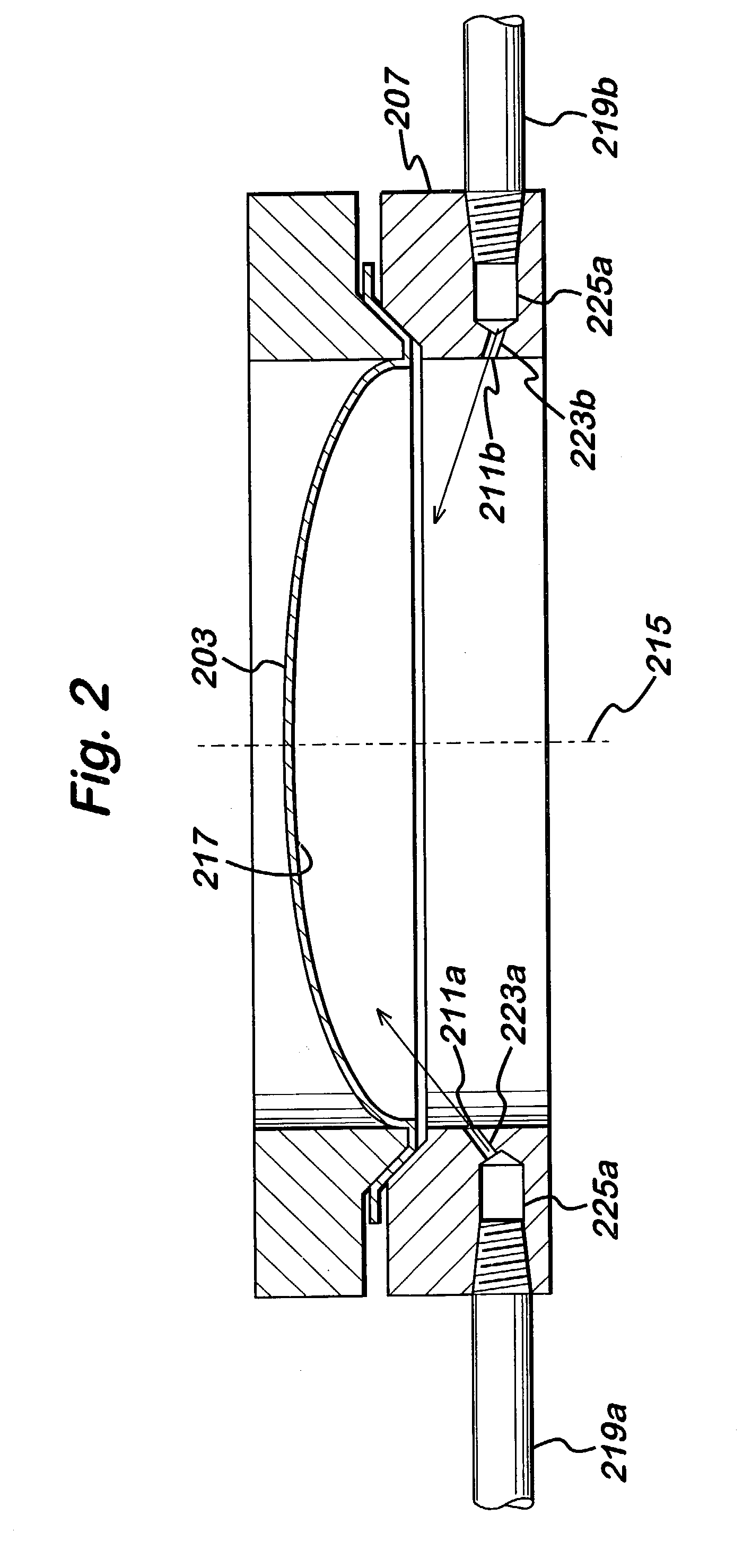

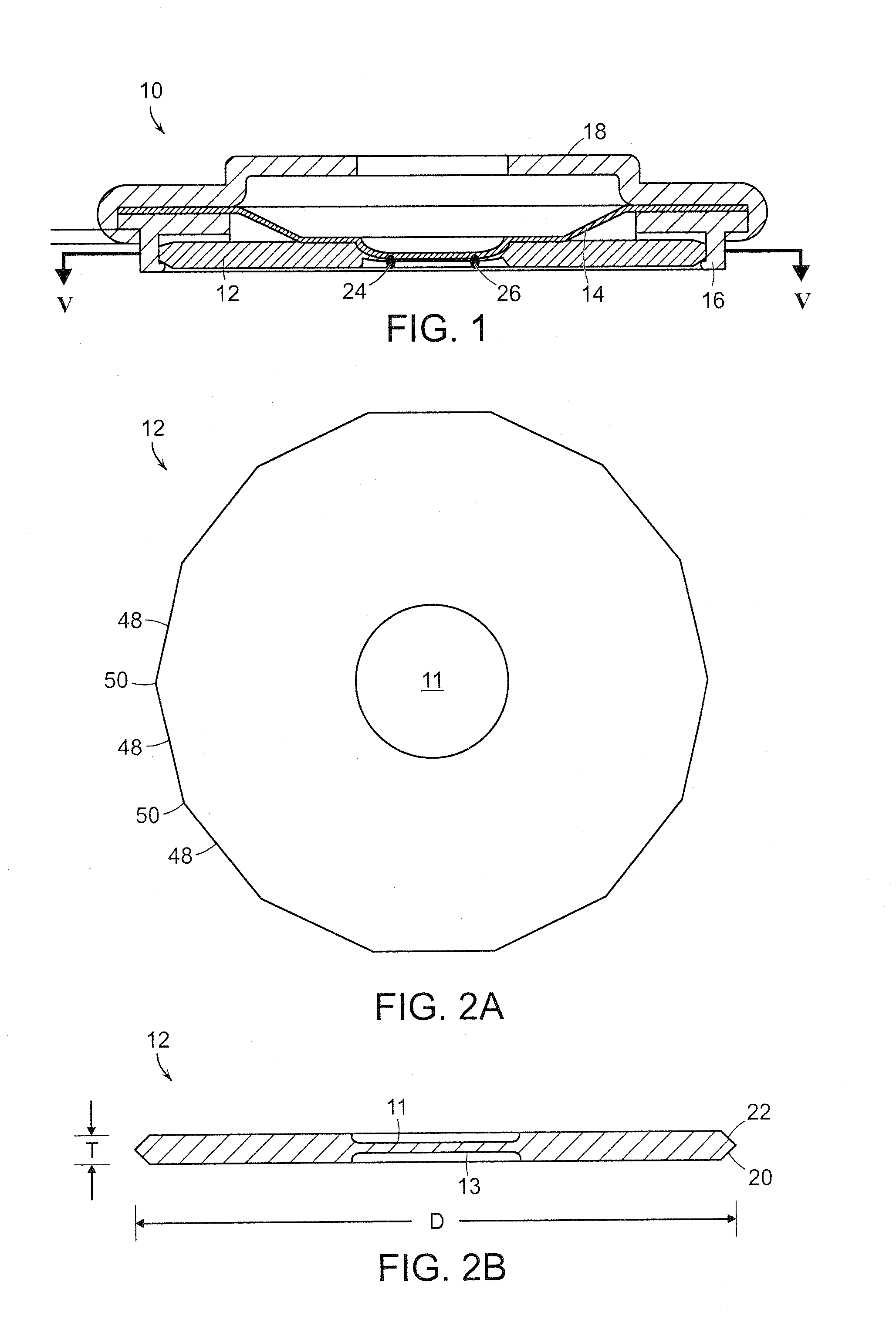

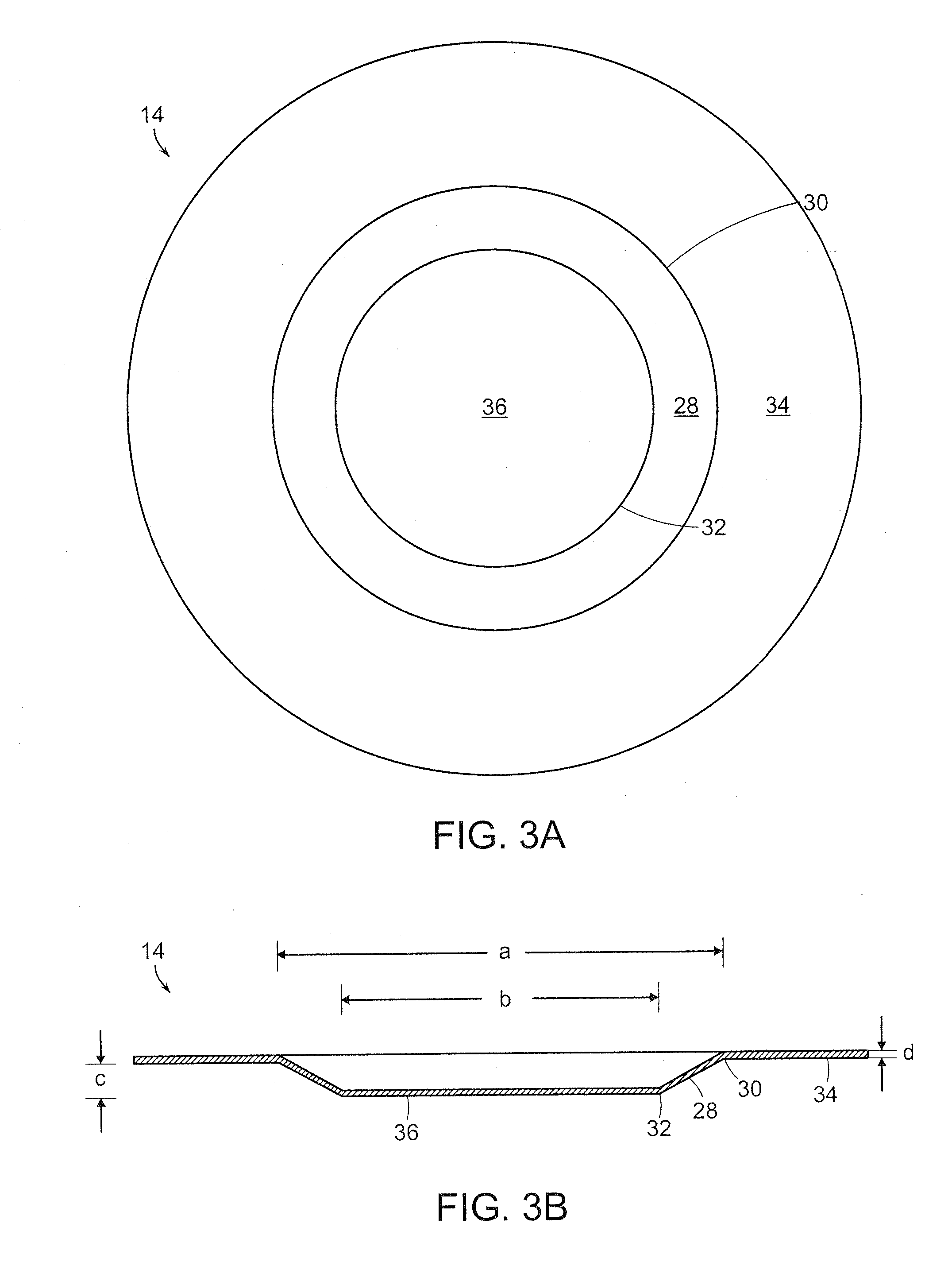

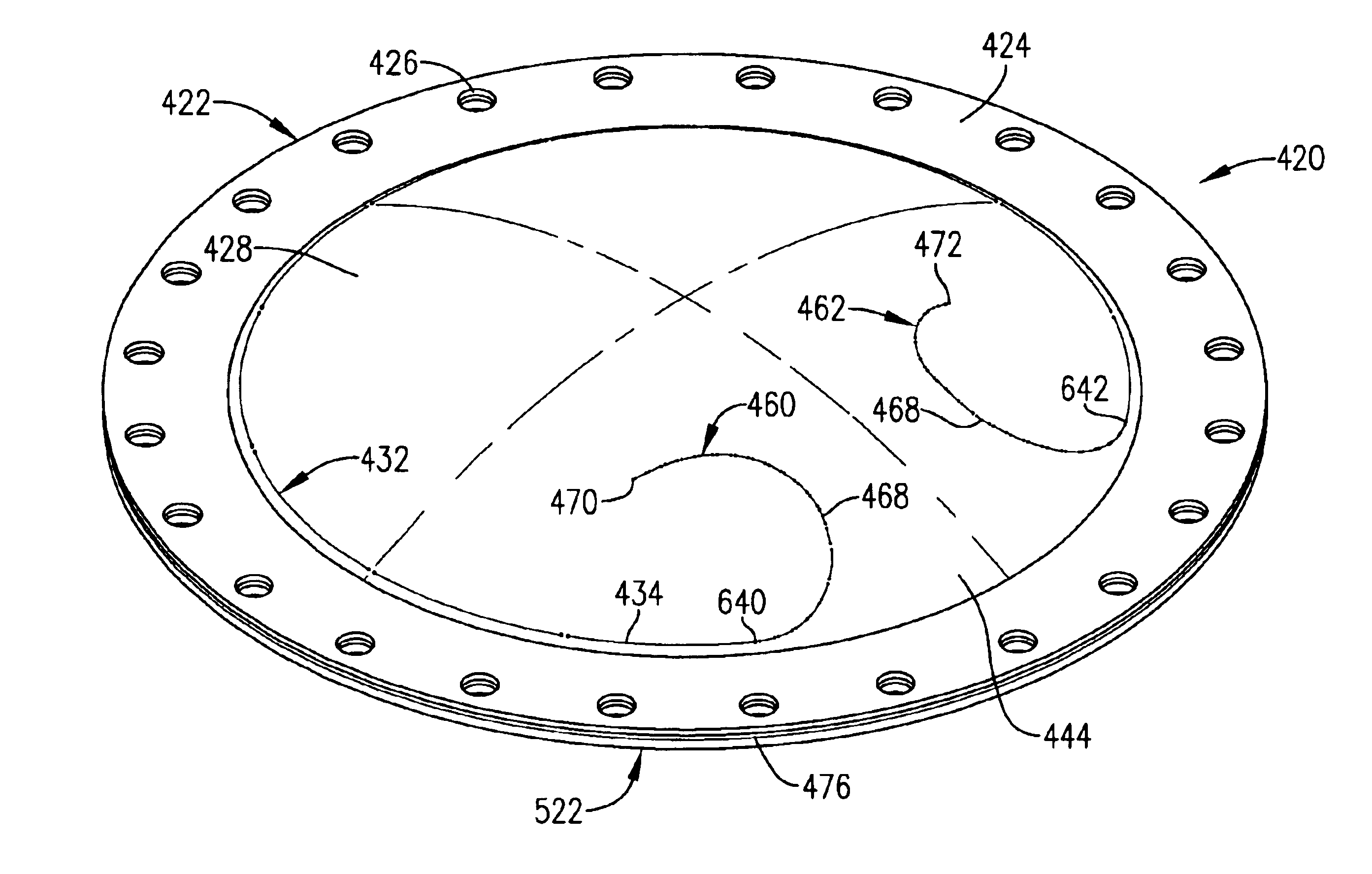

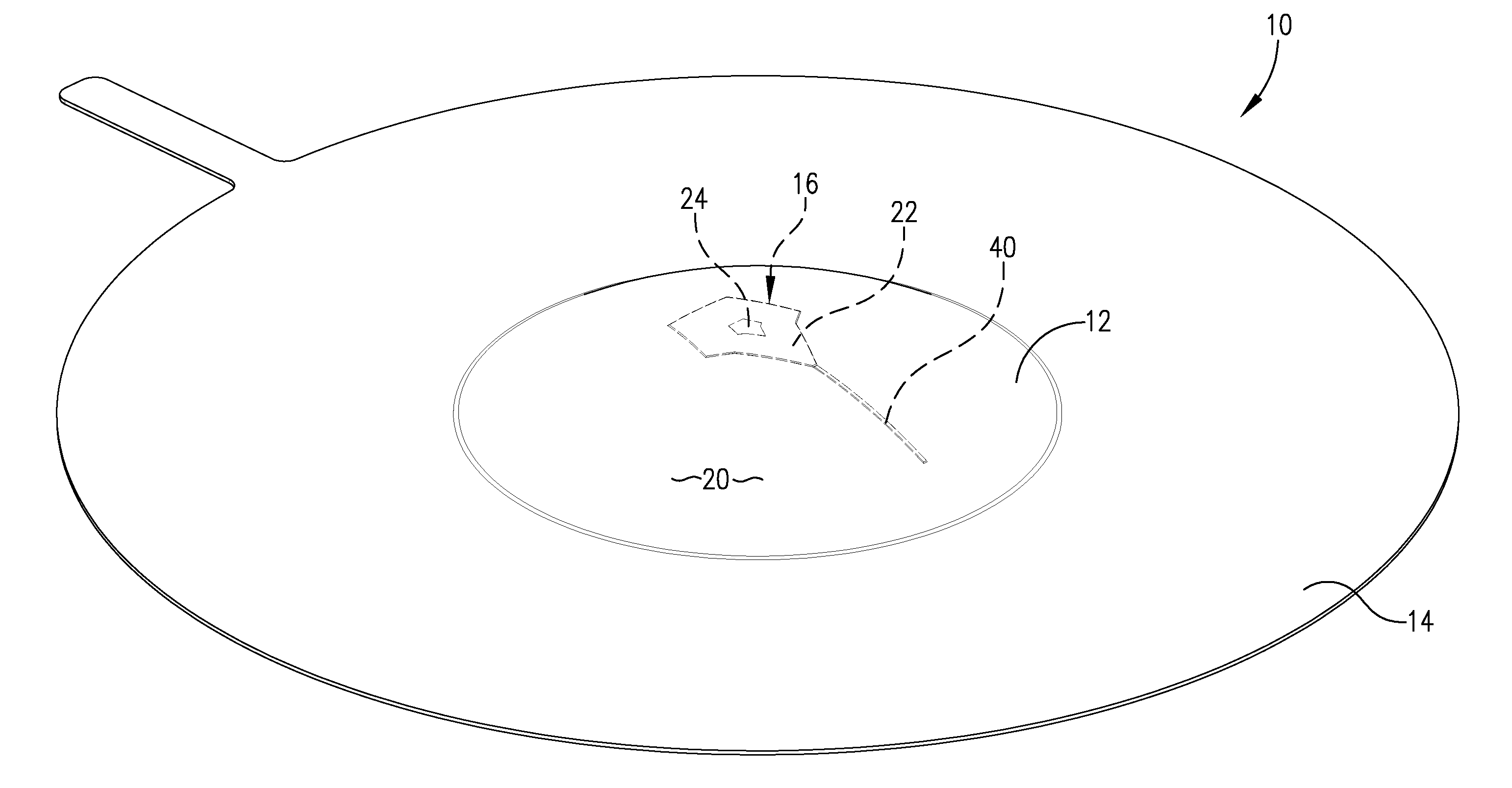

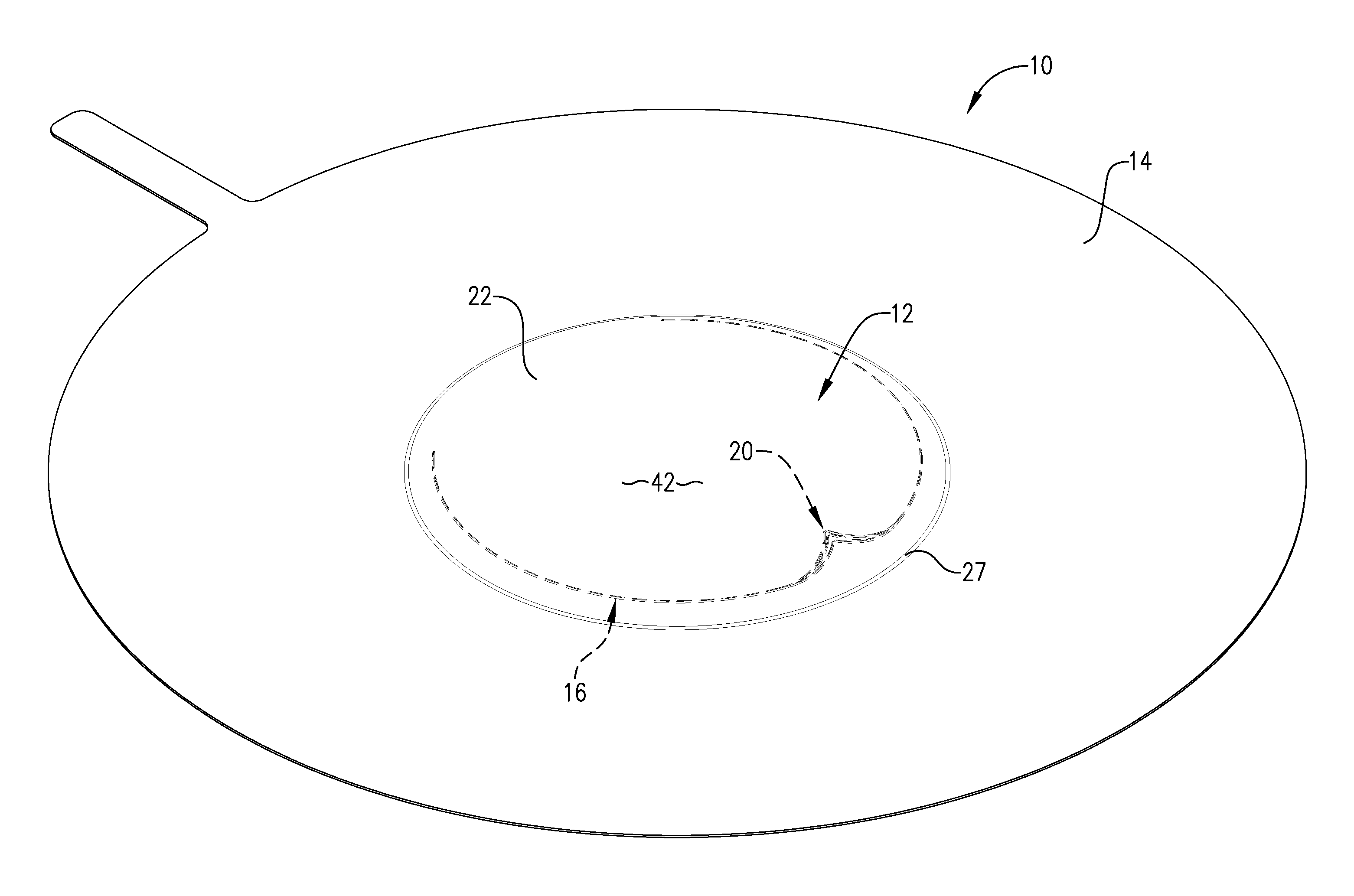

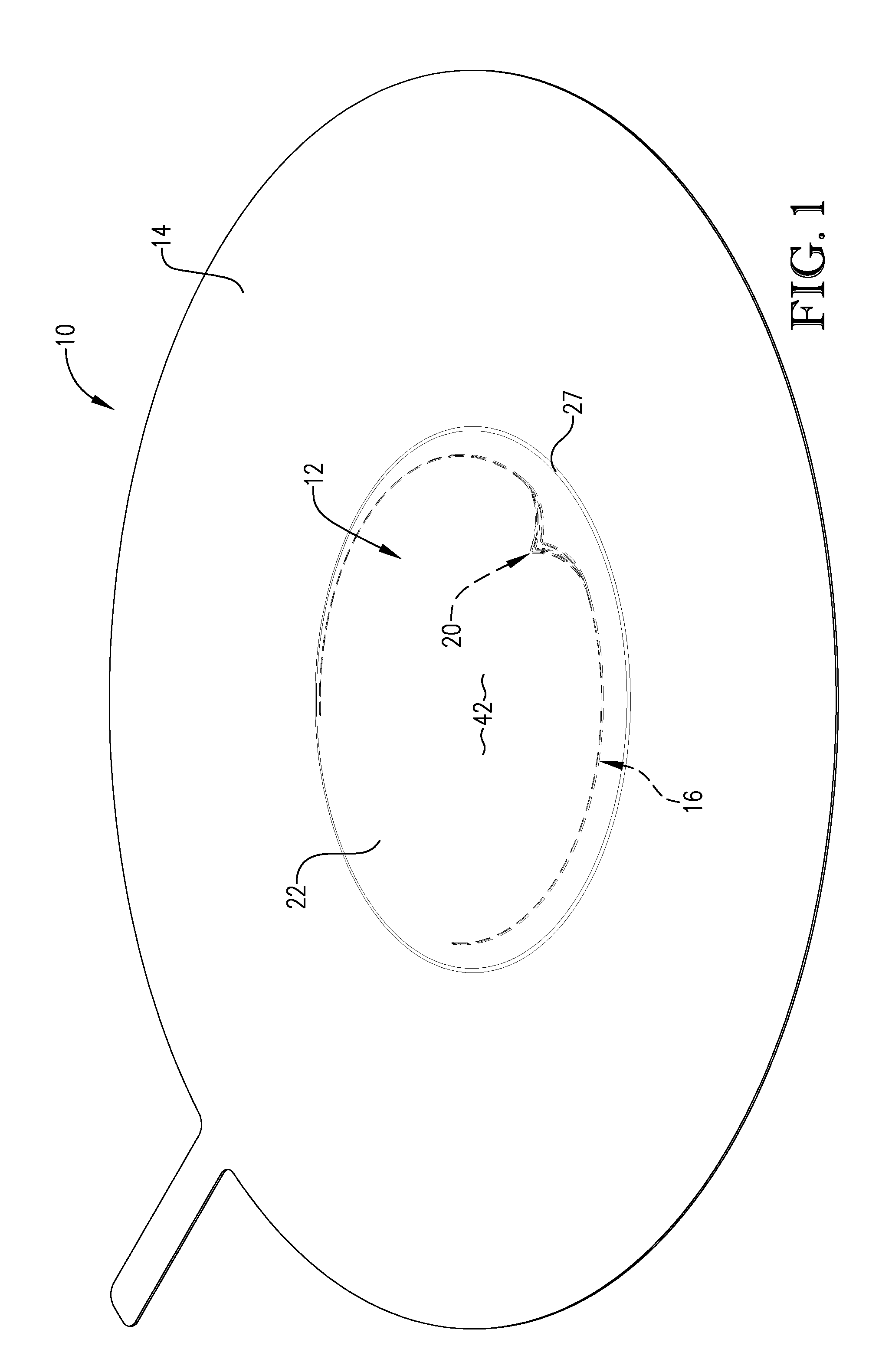

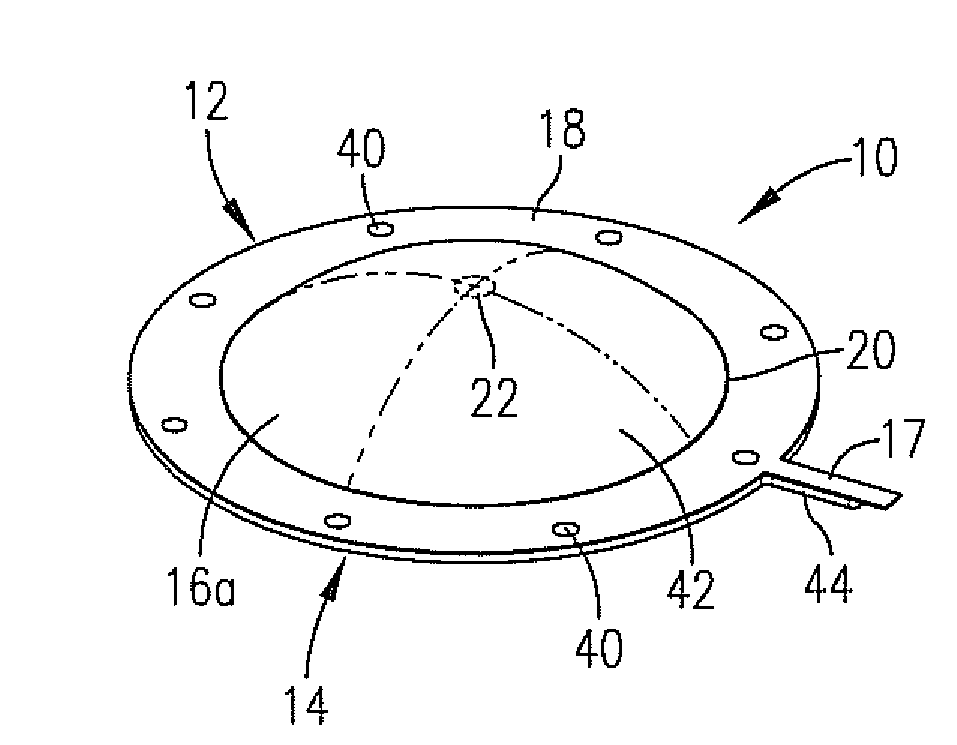

Rupture disc having laser-defined reversal initiation and deformation control features

ActiveUS20140021203A1Easy to optimizeBetter optimizedLarge containersEqualizing valvesWeaknessDeformation control

A reverse-acting rupture disc (10) having a laser-defined reversal initiation feature (16) is provided in the bulged section (12) of the disc. The reversal initiation feature comprises at least a first lased area (22) that has a reduced thickness relative to rest of the bulged section. A second lased area (24) may also be provided within the margins of the first lased area. The second lased area has a depth that is greater than the depth of the first lased area. A line of weakness (40) may be formed in the bulged section that functions to direct reversal of the bulged section toward a particular area of the disc, such as line-of-opening recess (56).

Owner:FIKE CORP

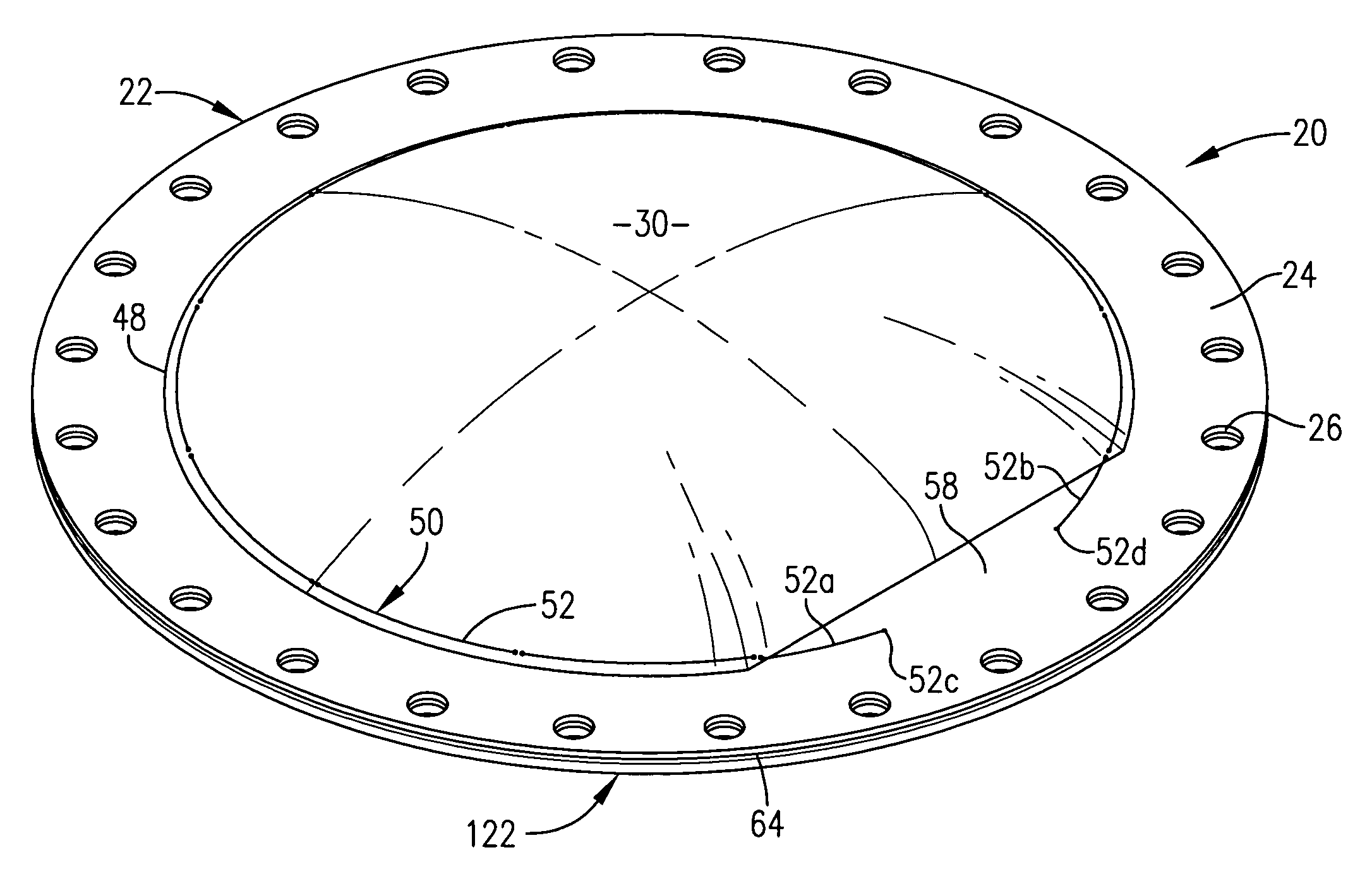

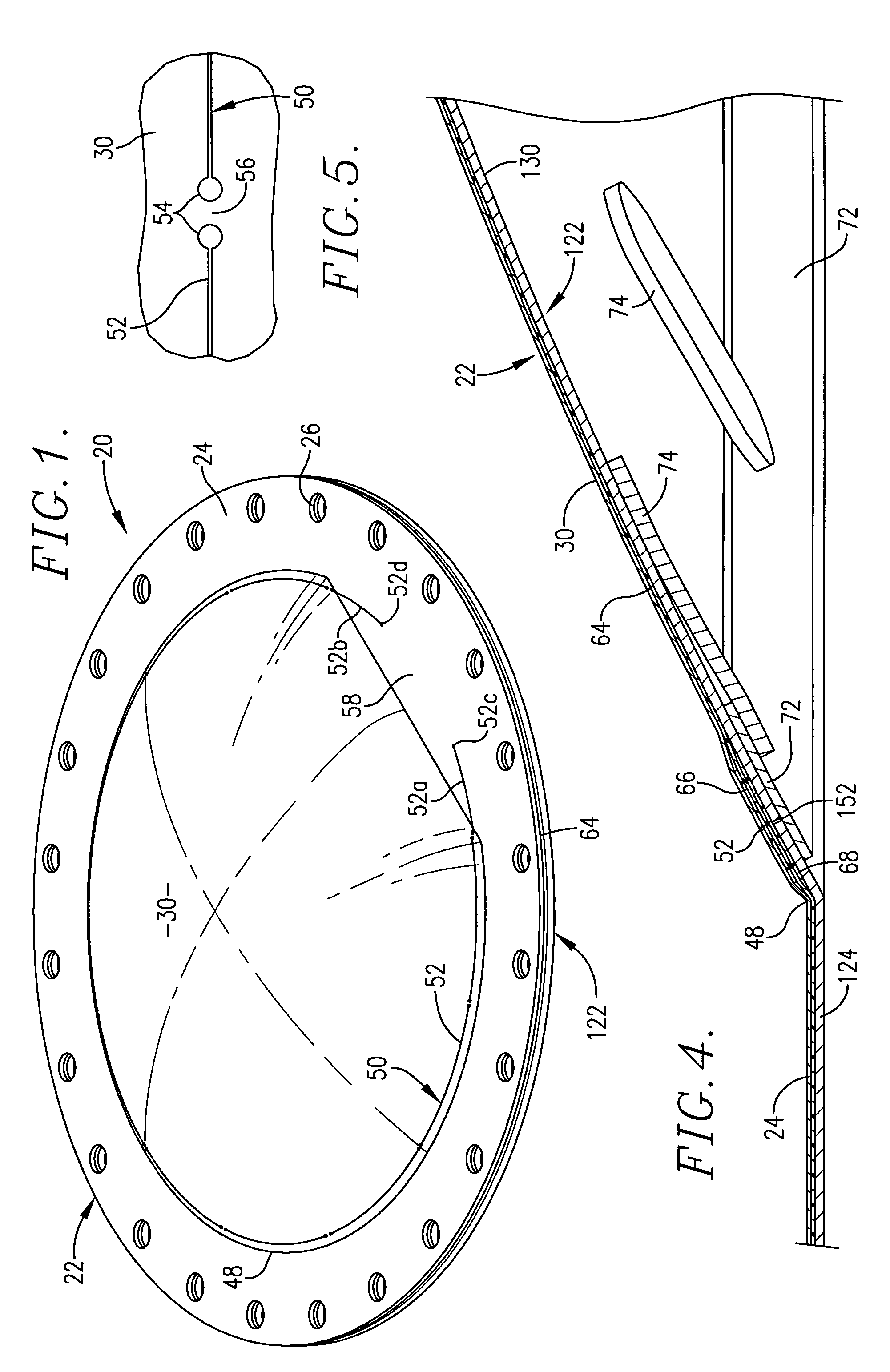

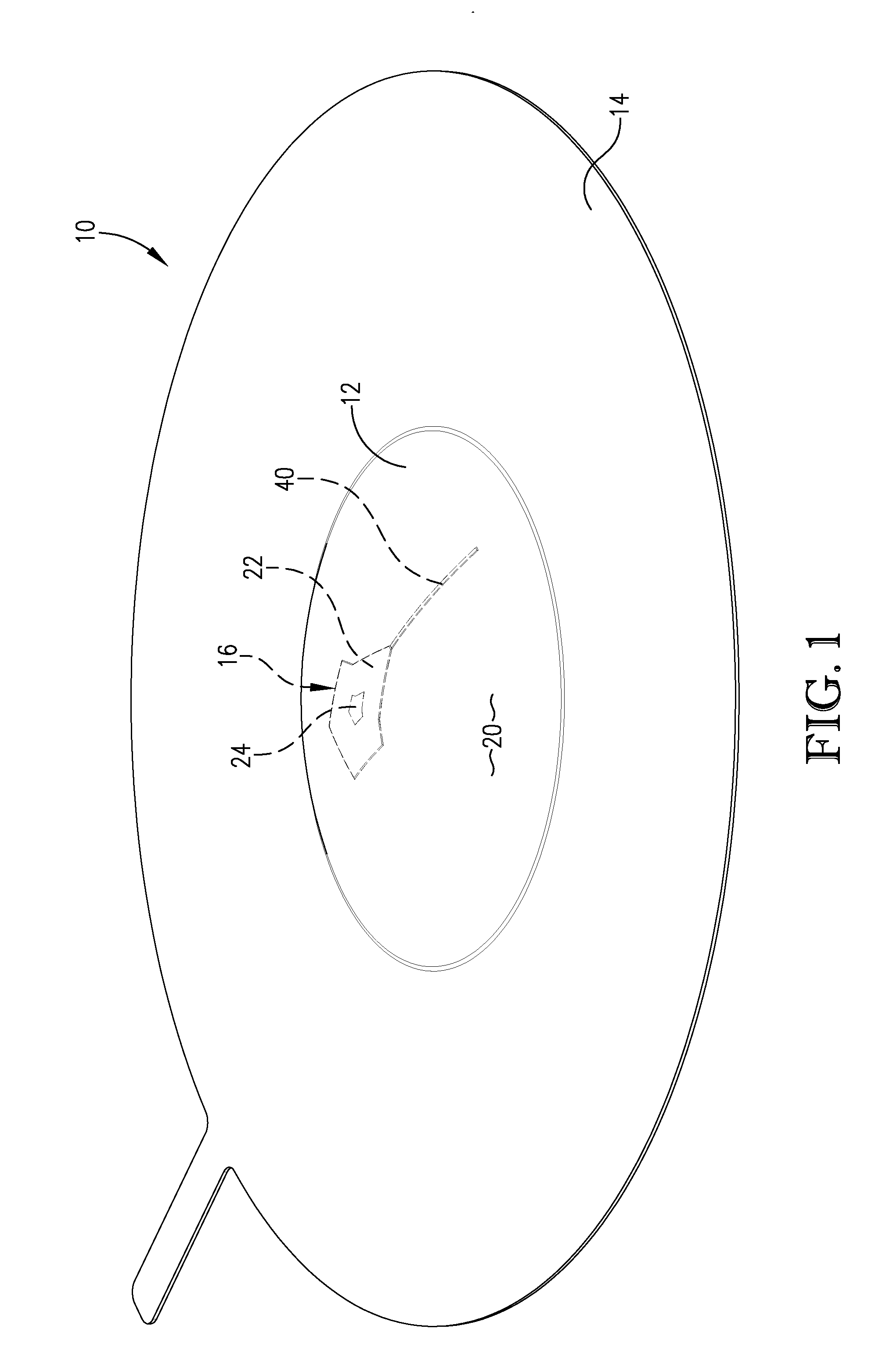

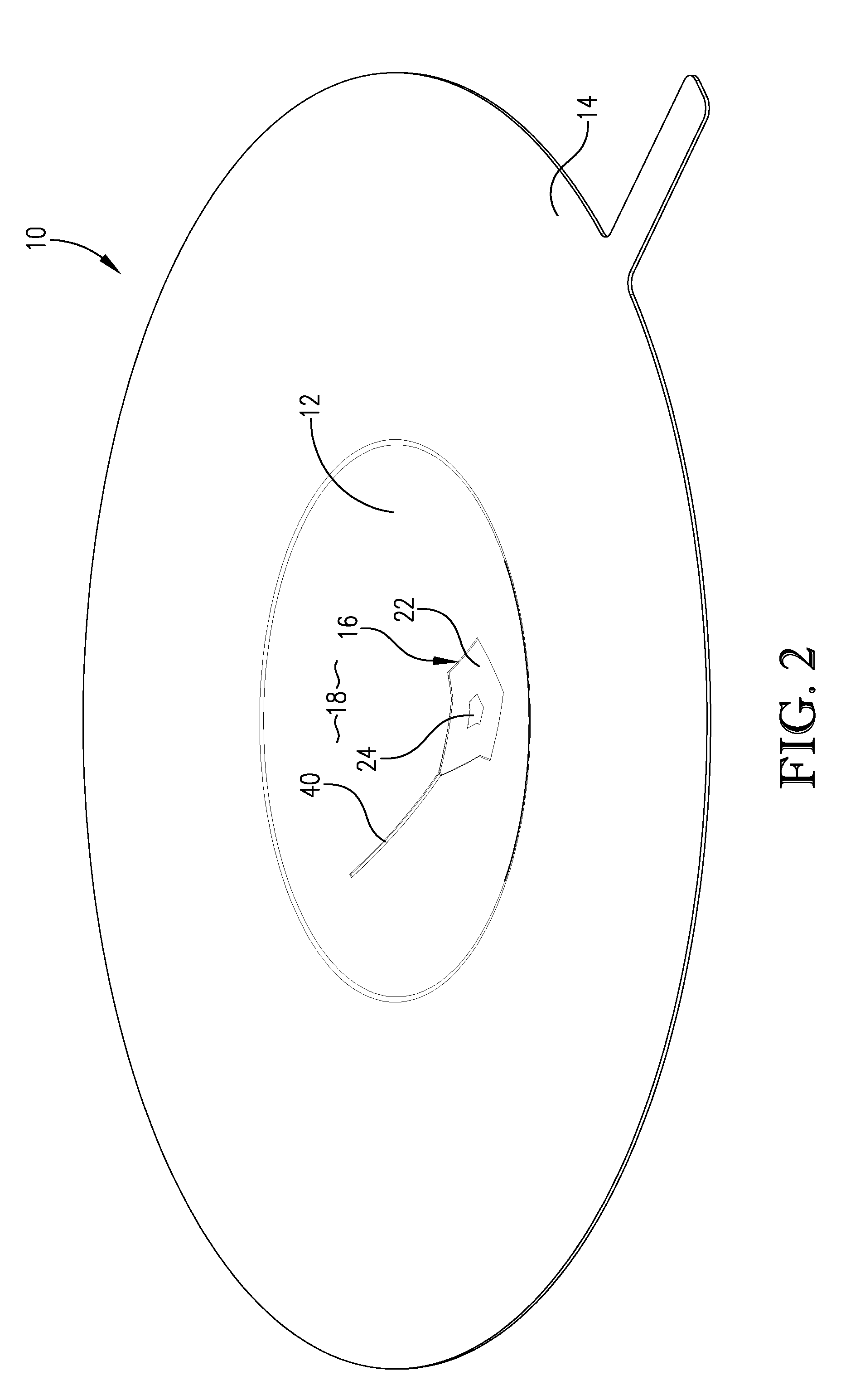

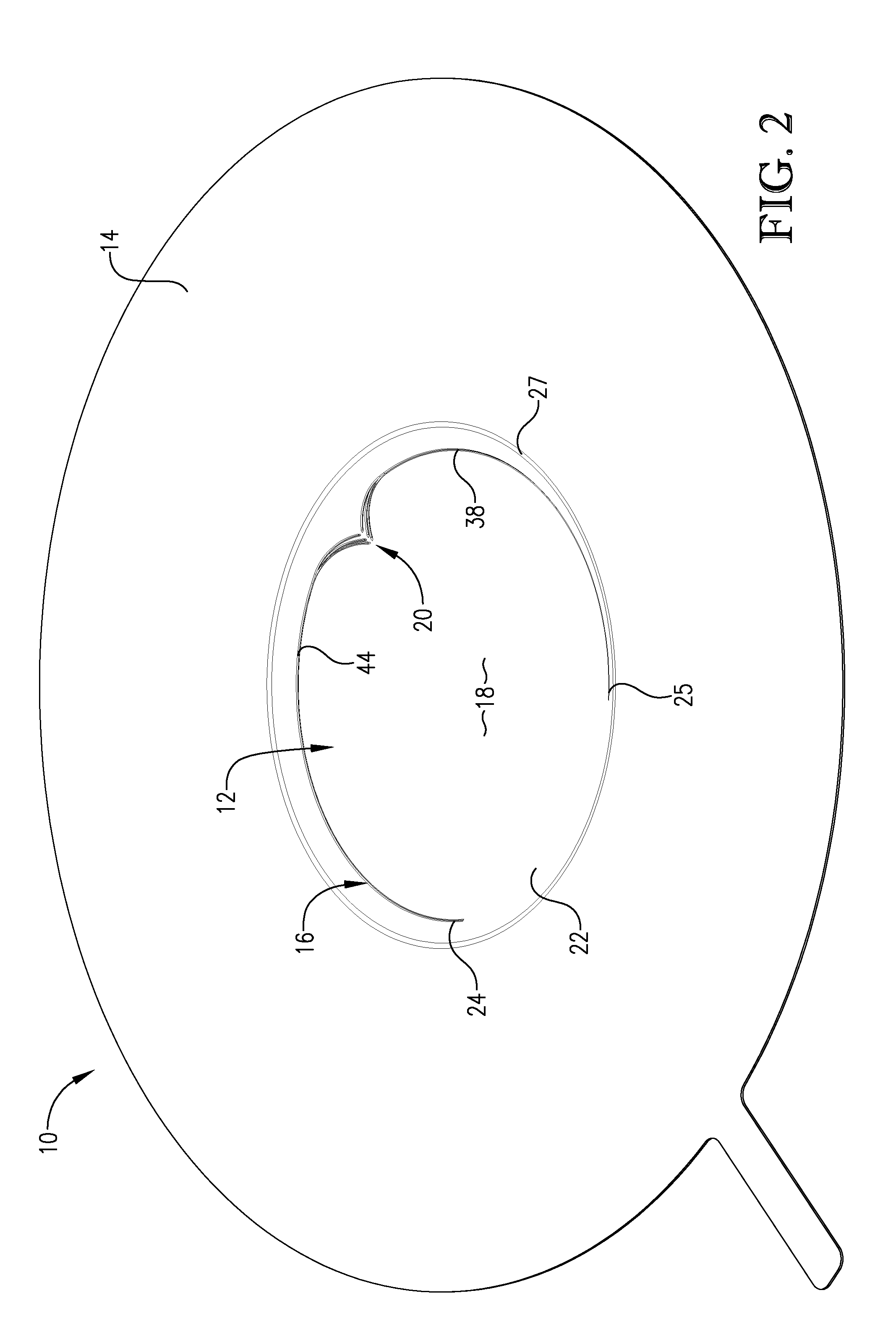

Rupture disc having laser-defined line of weakness with disc opening and Anti-fragmentation control structures

A rupture disc (10) is provided comprising a line of opening (16) formed in at least one face thereof. The line of opening (16) is formed by laser machining of the disc's face and includes at least one disc opening control feature (20). The disc opening control feature (20) may be an opening-initiation feature configured to assist with initial rupture of the disc (10). Alternatively, the opening control feature (20) may be an anti-fragmentation feature configured to dissipate the energy acting upon the disc (10) so as to prevent separation of the petal formed upon opening of the disc.

Owner:FIKE CORP

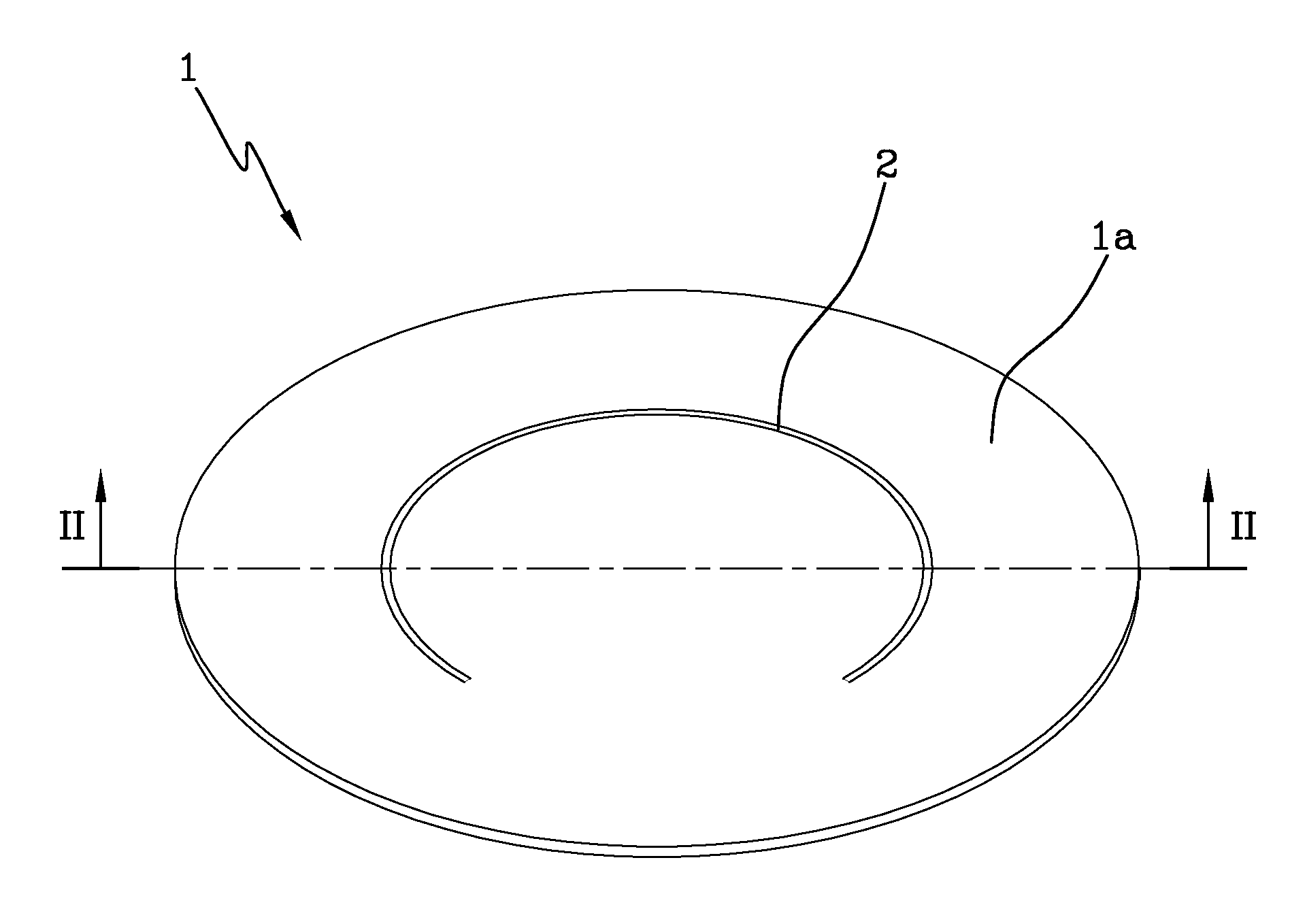

Method for production of safety/rupture discs

A method for production of safety / rupture discs comprises the steps providing a foil element, selecting a wavelength for a laser beam of a pulse laser within a range of between 800 nanometers and 1800 nanometers, selecting a pulse repetition rate for the laser beam within a range of between 15 KHz and 800 KHz, selecting a pulse duration for the laser beam less than 10 nanosecond and ablating at least one non-through cut in the foil element by directly applying said laser beam to the foil element to remove material from the foil element thereby obtaining a safety / rupture disc.

Owner:DONADON SAFETY DISCS & DEVICES

Method of reducing impact of differential breakdown stress in a treated interval

A uniform interval treatment method features a plug with a breakable member in a passage set above a perforated interval so that pressure above the plug can be build up to the desired pressure that is high enough when the rupture disc breaks to deliver a burst of pressure at a level to overcome differential breakdown stress in the interval. A ball is then dropped on a seat on the same plug and captured so that it will stay on the seat when a gun is removed above. Another gun with a plug are delivered and the gun fired with the previous plug having a landed ball in the seat. The plug is again positioned above the just made perforations and the gun is removed. The rupture disc breaks to uniformly treat the next interval with a pressure to overcome differential breakdown stress of heterogeneous rock in the treated interval.

Owner:BAKER HUGHES INC

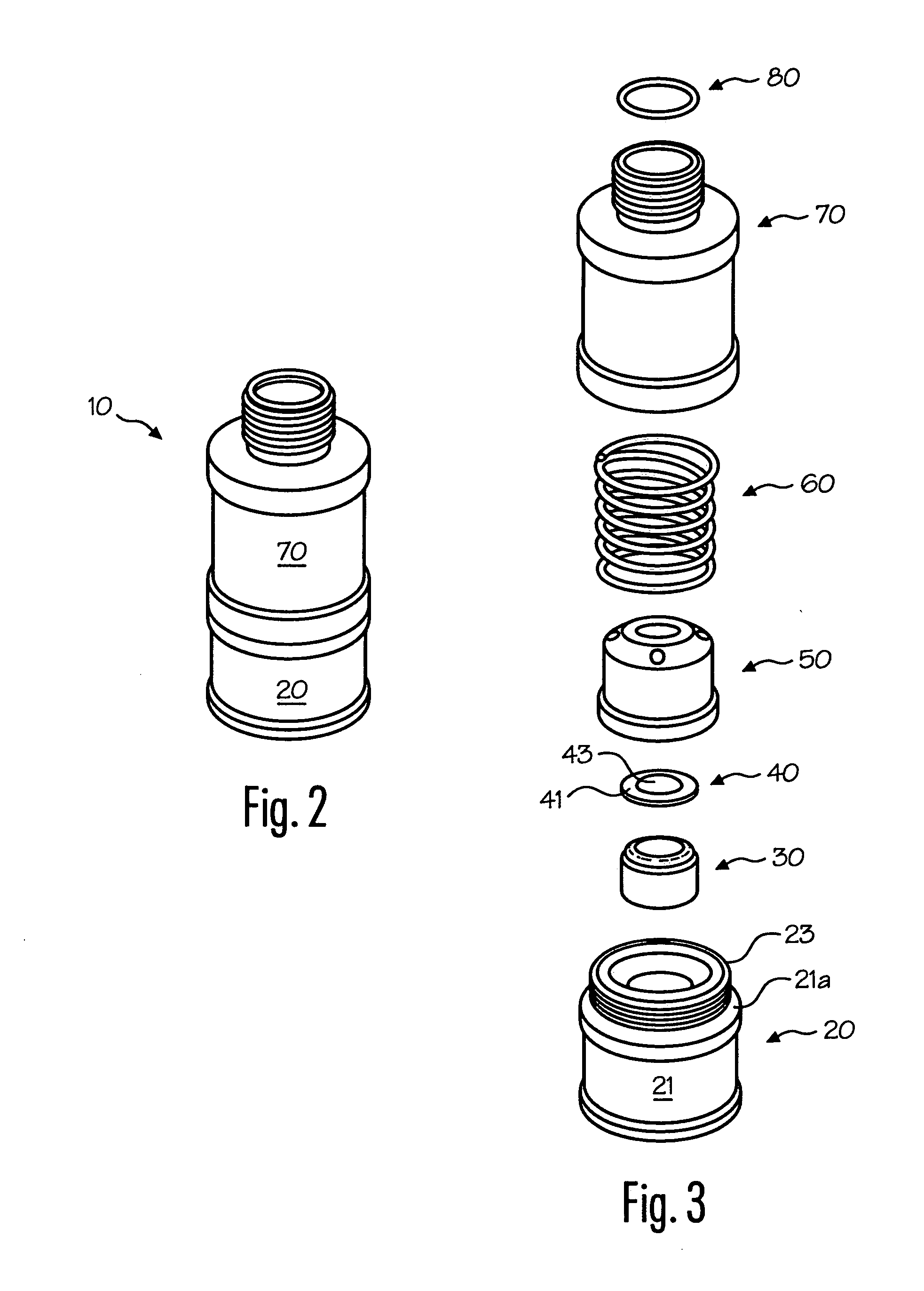

High pressure safety valve, system and method

InactiveUS20080289700A1Reduce gas leakageVessel mounting detailsOperating means/releasing devices for valvesGas cylinderProduct gas

The present invention comprises, in one embodiment, a compression safety valve apparatus adapted to engagingly connect to an existing gas cylinder valve. In one embodiment, the present invention comprises a housing base having a first bore, a rupture disc holding means having a second bore, at least one rupture disk, a piston having at least a third bore, a spring, and an outer housing cylinder having a forth bore, the first bore, the second bore and the third bore all being in gas flow communication with the compressed content of the tank. In operation, for example, during an over-pressurization event occurs, the extreme force of the escaping gas places a force on the bottom surface of the present invention's rupture disc assembly, so that the piston's beveled surface substantially mechanically engages the outer housing's upper ceiling. This mechanical engagement allows gas to continue to escape from the tank through one or more bleeder bores and a gap.

Owner:MASINGALE LEVI D

High pressure fluid system

ActiveUS9285040B2Easy to replaceMinimize the possibilityPlug valvesPositive displacement pump componentsCamHigh pressure

Owner:PSI PRESSURE SYST

Rupture disc with machined line of opening

Owner:FIKE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com