Manufacturing method of high-strength aluminum alloy strip for supporting middle plate of mobile phone

The technology of an aluminum alloy strip and a manufacturing method is applied to the manufacturing field of high-strength aluminum alloy strips for mobile phone support mid-plates, which can solve the problems of magnetism, inability to meet stamping and drawing forming, and heavy weight of mobile phone support mid-plates, and achieves crystal-clear performance. The effect of uniform refinement of granular tissue, light weight, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

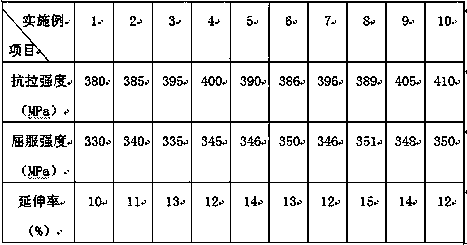

Examples

Embodiment 1

[0020] This embodiment discloses a method for manufacturing a high-strength aluminum alloy strip that can be used for mobile phone support plates, including the following steps:

[0021] (1) Preparation of aluminum alloy melt: determination of chemical composition, the mass percentage of each element in aluminum alloy is: Si: 0.15% or less, Fe: 0.2% or less, Cu: 0.05% or less, Mn: 0.3% or less, Mg: 5.3-6.0%, Cr: less than 0.15%, Zn: less than 0.1%, Ti: less than 0.25%, single impurity: ≤0.05%, total impurity: ≤0.15%, and the rest is aluminum; Take high-purity aluminum ingots with an aluminum content of 99.85%, aluminum-manganese, and aluminum-magnesium intermediate alloys as raw materials, and then put them into a melting furnace, and melt them into aluminum alloy melts at 620°C to 650°C.

[0022] (2) Casting: Cast the aluminum alloy solution according to the casting temperature of 700°C-750°C and the casting speed of 60-65mm / min, air-cool it out of the furnace, saw it into al...

Embodiment 2

[0025] The difference between this example and the previous example 1 is that the mass percentages of the elements in the aluminum alloy in step (1) are Si: 0.15% or less, Fe: 0.2% or less, Cu: 0.05% or less, Mn: 0.3% or less, Mg: 5.3-6.0%, Cr: 0.15% or less, Zn: 0.1% or less, Ti: 0.25% or less, single impurity: ≤0.05%, total impurity: ≤0.15%, and the rest is aluminum. Other steps and parameters are the same as in Example 1.

Embodiment 3

[0027] The difference between this example and Example 1 or 2 is that the mass percentages of the elements in the aluminum alloy in step (1) are Si: 0.15% or less, Fe: 0.2% or less, Cu: 0.05% or less, Mn: 0.3% or less , Mg: 5.3-6.0%, Cr: 0.15% or less, Zn: 0.1% or less, Ti: 0.25% or less, single impurity: ≤0.05%, total impurity: ≤0.15%, and the rest is aluminum. Other steps and parameter are identical with embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com