Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Tissue uniform refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

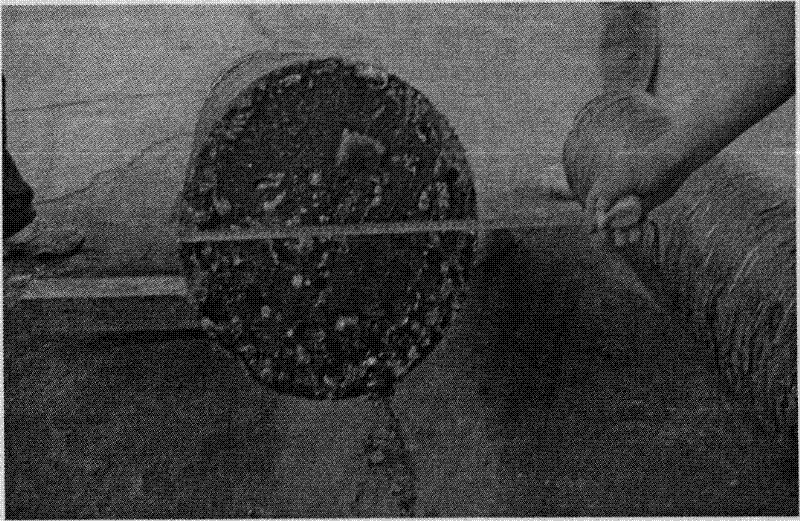

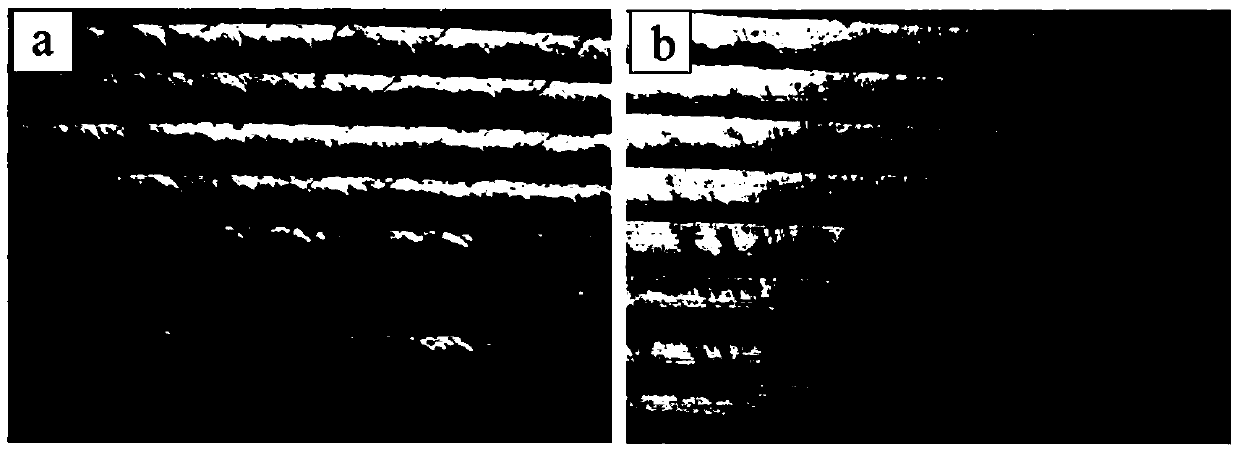

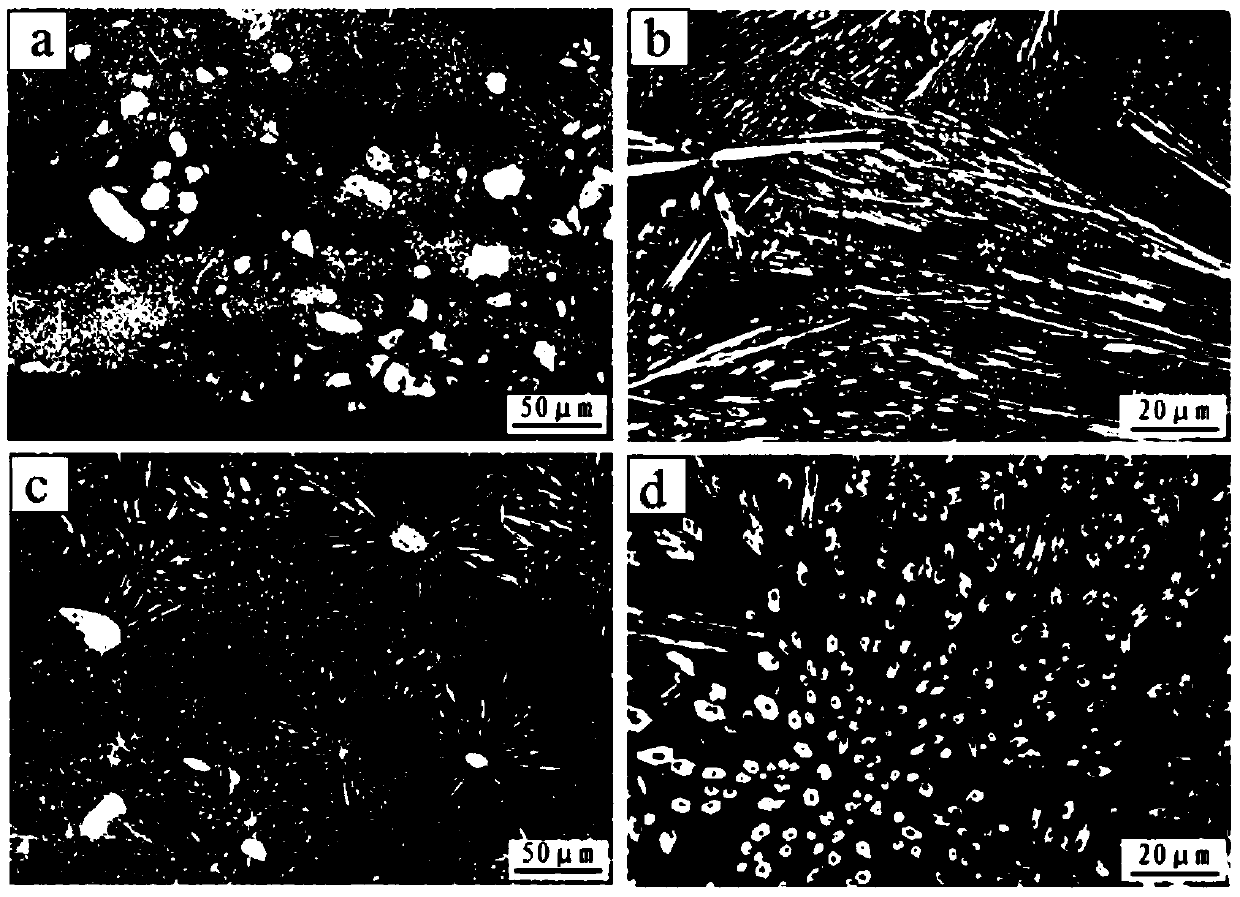

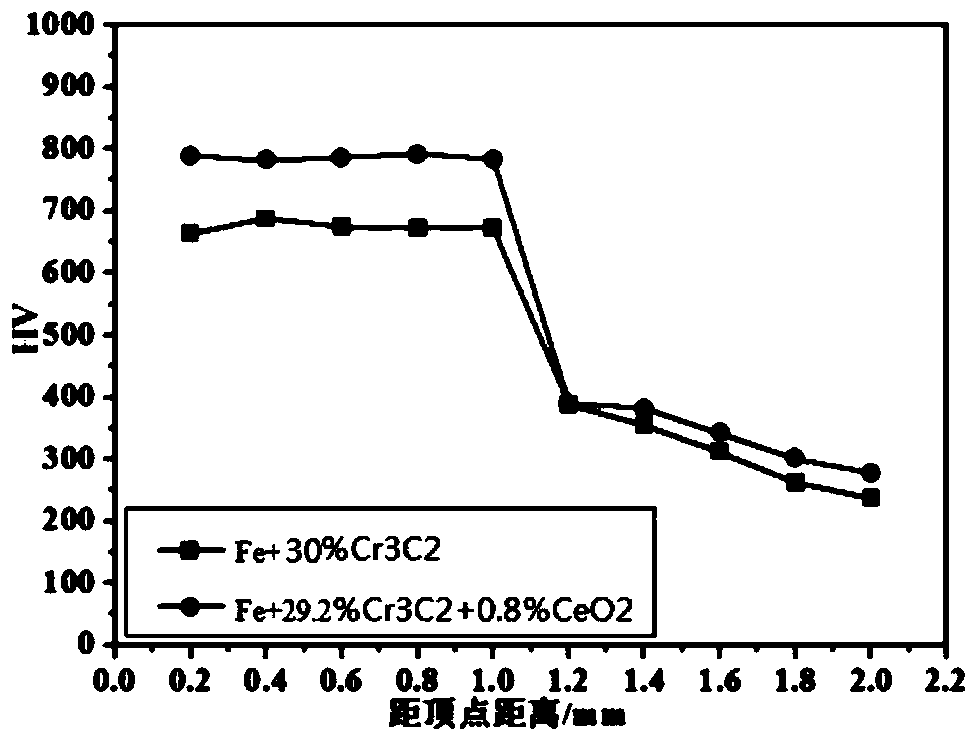

Iron-based Cr3C2 laser-cladding coating added with CeO2 and preparation method of coating

ActiveCN105112909AHigh hardnessImprove wear resistanceMetallic material coating processesAlloyHardness

The invention discloses an iron-based Cr3C2 laser-cladding coating added with CeO2 and a preparation method of the coating, and belongs to the technical field of surface modification. The coating is prepared by uniformly mixing the following components in percentage by mass for laser-cladding: 65-73% of iron-based self-fluxing alloy powder, 26.5-34% of Cr3C2 alloy powder and 0.5-1% of CeO2 powder. The preparation method comprises the following steps: powder preparation; uniform mixing and drying; preparation and post-treatment of the coating. Through adoption the technical scheme, the rigidity, abrasion resistance and high-temperature oxidation resistance of the coating can be improved; besides, the forming quality and cladding property of the coating can be remarkably improved to inhibit and eliminate bubbles and cracks.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

High-carbon microalloy round steel for fracture splitting connecting rod of automotive engine and production method thereof

InactiveCN102108472AImprove cleanlinessReduce composition segregationTemperature control deviceHigh surfaceChemical composition

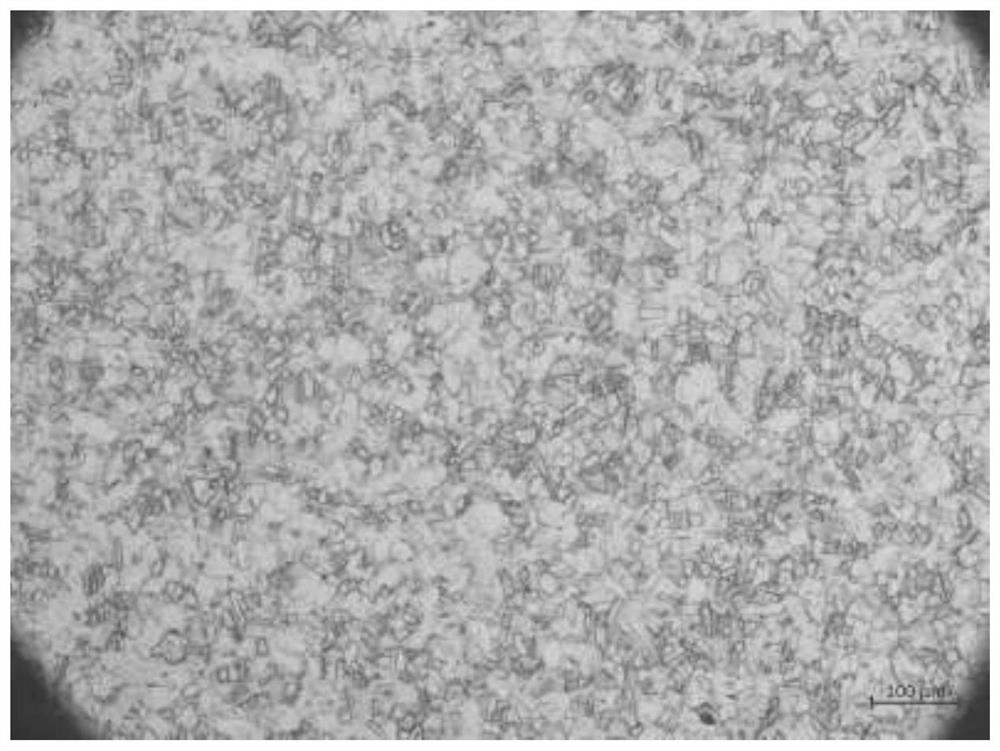

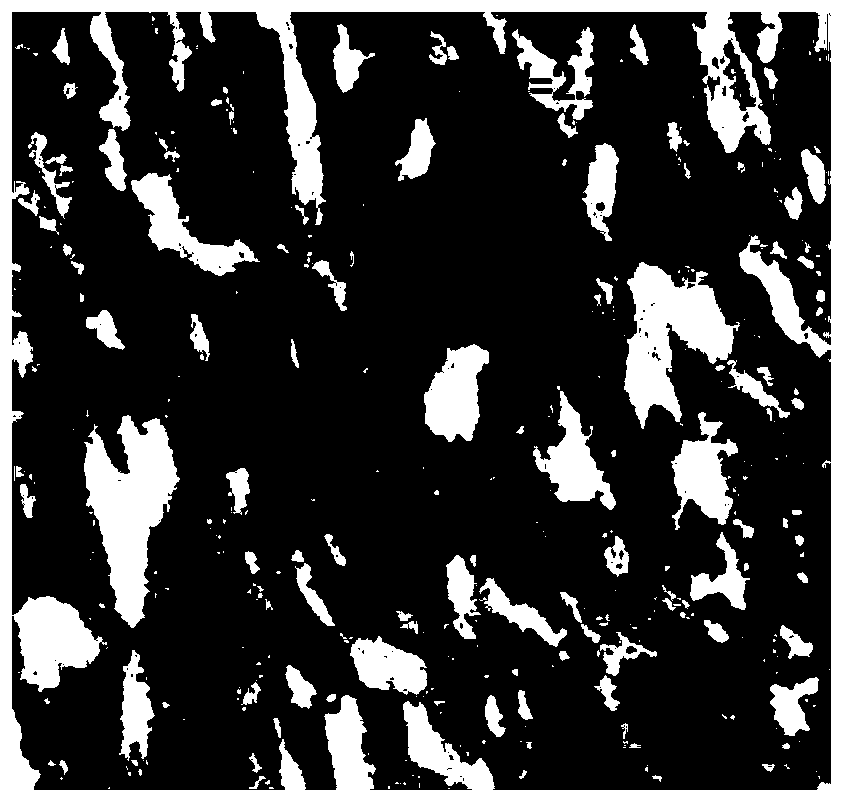

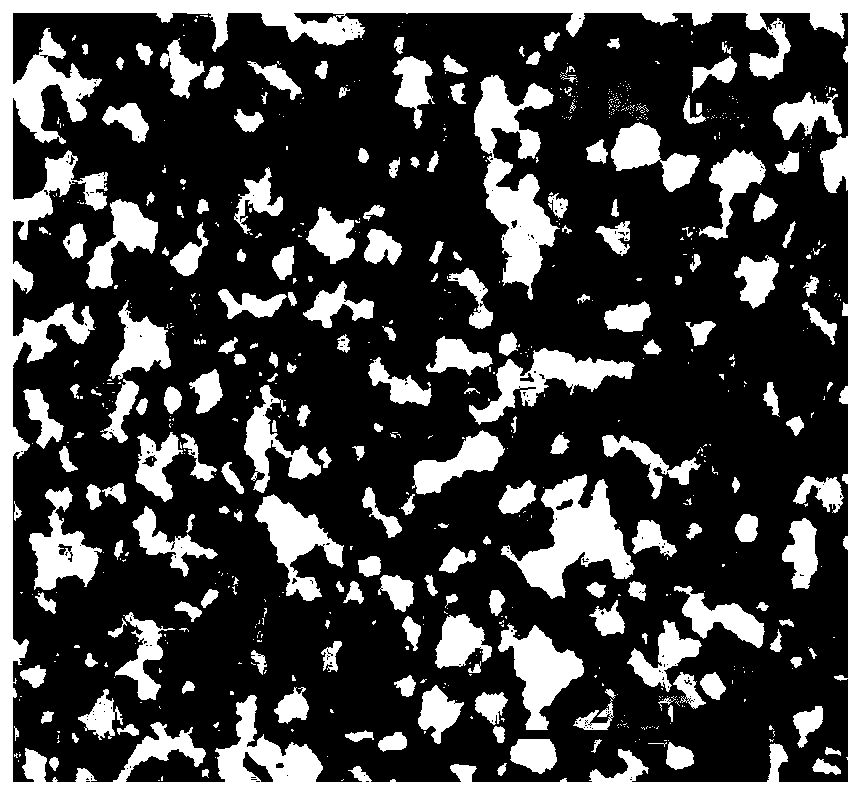

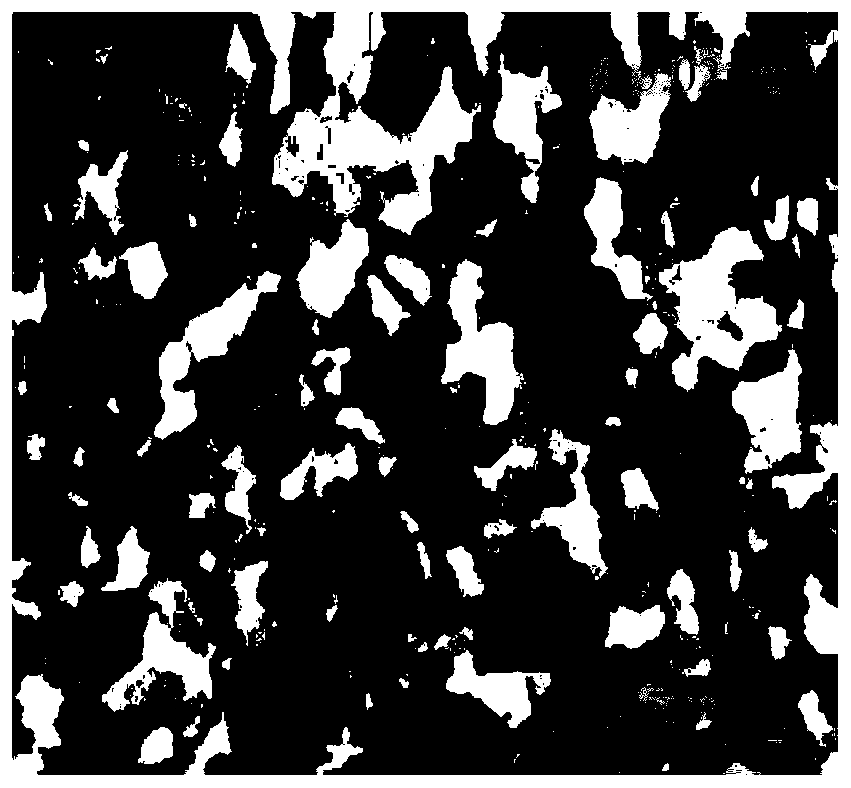

The invention discloses high-carbon microalloy round steel for a fracture splitting connecting rod of an automotive engine and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.60 to 0.80 percent of C, 0.17 to 0.37 percent of Si, 0.30 to 0.90 percent of Mn, 0.020 to 0.60 percent of P, 0.050 to 0.080 percent of S, 0.015 to 0.0300 percent of N, one or several of microally elements V, Nb, Ti and B, and the balance of Fe and inevitable impurities. The production method of the high-carbon microalloy round steel comprises: (1) steel tapping by high catching carbon; (2) vacuum degassing (VD) vacuum treatment; (3) treatment in ladle furnace (LF); (4) execution of a continuous casting process; and (5) heating and rolling of continuously cast blank, and execution of a segmental cooling process of high-temperature quick cooling and low-temperature slow cooling. The high-carbon microalloy round steel provided by the invention has the characteristics of high cleanness, small composition segregation, low crack sensitivity, uniform and fine texture and high surface quality, and the provided production method has the characteristics of low production cost, energy conservation, simple process route, high maneuverability and simplicity of control.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Clean steel and manufacturing method

InactiveCN101096736AReduce heat lossQuality assuranceTemperature control deviceMetal rolling arrangementsMetallurgyImpurity

The invention discloses clean steel and its manufacturing method, which comprises the following parts: C<=0.0030%, Si<=0.0030%, 0.10%-0.30%Mn, P<=0.0030%, S<=0.0030, 0.01%-0.06%Al, Ti<=0.09%, Nb<=0.05%, N<=0.0030%, O<=0.0030%, H<=0.0002%, Fe and unavoidable impurity. The method comprises the following steps: desulfurizing hot iron; bessemerizing; refining outside the furnace; casting the middle sheet plate blank continuously; loading hotly and directly; heating the furnace; roughing down; planishing; cooling lamellar flow; batching; cleaning with acid ; rolling coldly; annealing ( flattening; shearing ). The invention reduces the inclusion content in the steel by controlling the proper content of C, Mn, P, S, N, O, and H, which makes the inclusion shape fine and dispersing, the composition homogeneous and the structure homogeneous, and guarantees the integrated property.

Owner:ANGANG STEEL CO LTD

Magnesium alloy electromagnetic low-temperature semicontinuous casting method

The magnesium alloy electromagnetic low-temp. semicontinuous casting method includes the steps of melting magnesium, adding compound fire-resisting elements, adding alloy elements, heat-insulating, standing still and semicontinuous casting under the electromagnetic field. It utilizes the addition of compound fire-resisting elements to implement smelting of magnesium alloy free from coverage or protection so as to shorten technological process and raise melt quality, and utilizes the application of electromagnetic field and optimization of crystallizer structure to implement the low-temp. and high-speed semicontinuous casting of magnesium alloy.

Owner:NORTHEASTERN UNIV

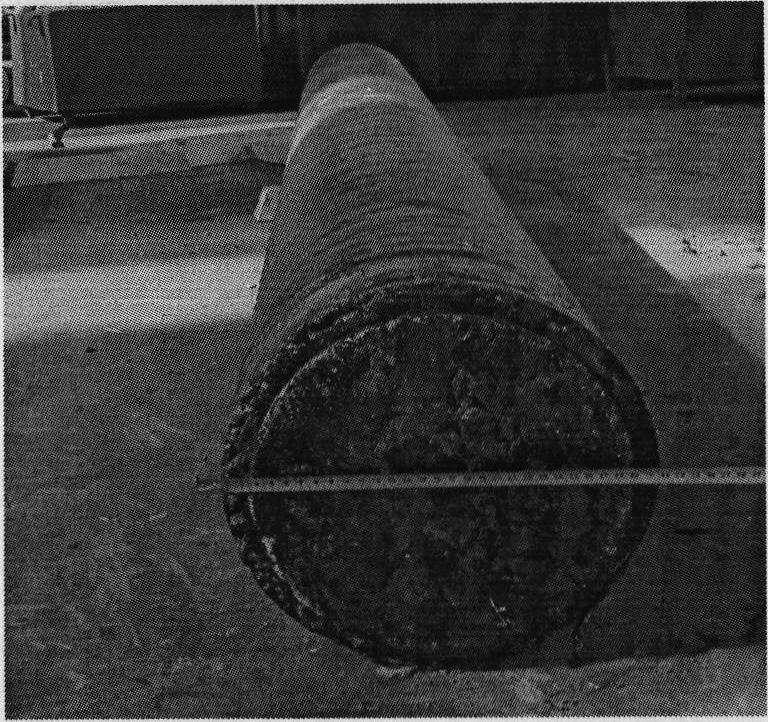

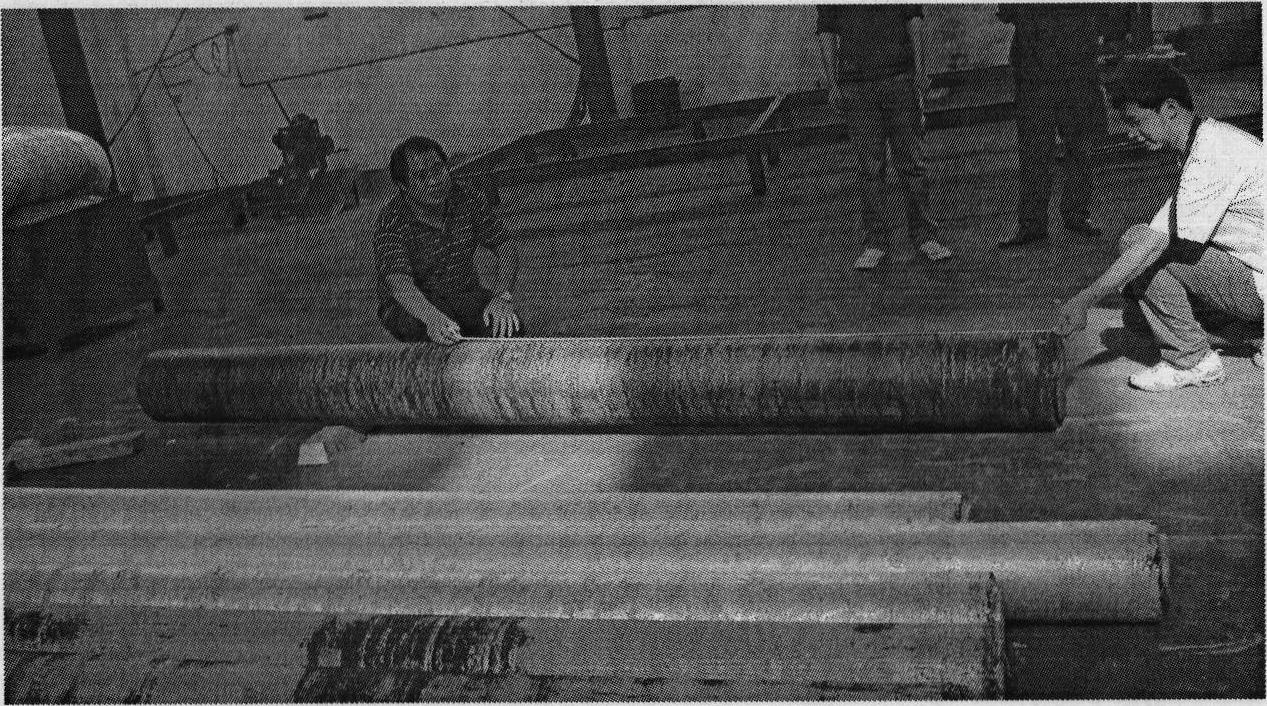

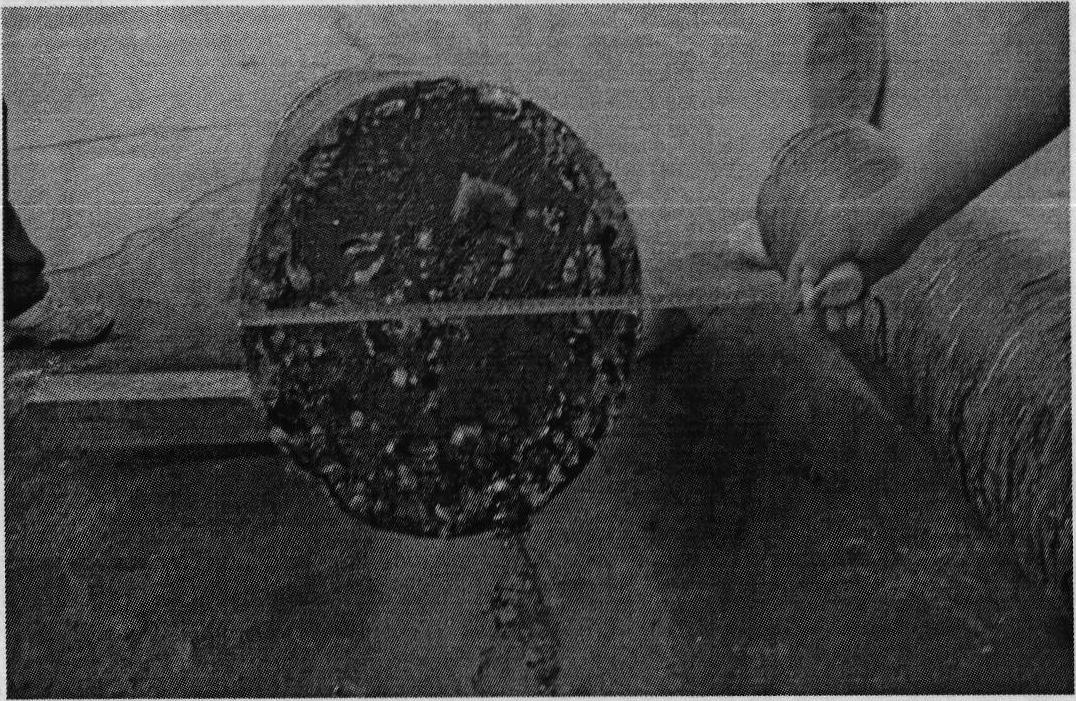

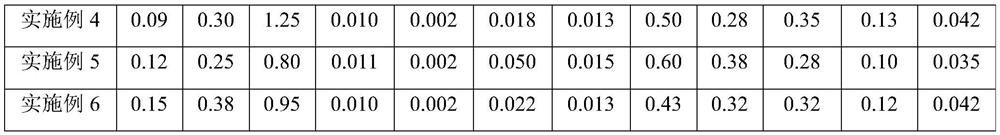

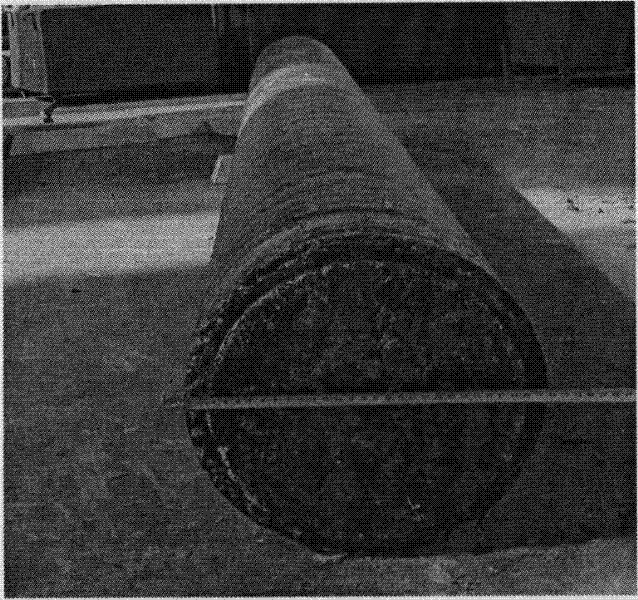

Oversized high-strength heatproof magnesium alloy ingot blank semicontinuous casting technique

The invention relates to an oversized high-strength heatproof magnesium alloy ingot blank semicontinuous casting technique. The alloy comprises the following components by weight percent: 6-13% of Gd, 2-6% of Y, 0.3-0.8% of Zr and the balance of Mg and irremovable impurity elements. The technique comprises the steps of melting magnesium ingots, adding solvents, adding alloy elements, refining, degassing, removing impurities, preserving heat and standing, and semicontinuously casting under the low casting speed by using a counter-pressure gas fluid-guiding method at low temperature and under low cooling speed. In the invention, technique parameters such as the casting temperature, the cooling speed, the ingot pulling speed, the inner liquid level height of a crystallizer, and the like are controlled to obtain the oversized high-strength magnesium alloy ingot blank with flat and smooth surface, refining and uniform tissue and no solute segregation, and the diameter of the ingot blank is from 220 mm to 505 mm. The length of the ingot is 1000-5000 mm. The invention meets the requirements for the oversized ingot blank required by high-strength heatproof magnesium alloy materials in the fields of aerospace, information electronics, communications and transportation, and the like.

Owner:CENT SOUTH UNIV

Clean steel smelting method of anti-S steel oil well pipe

InactiveCN101643882AQuality assuranceGuaranteed performanceElectric furnaceProcess efficiency improvementElectric arc furnaceChemical composition

The invention provides a clean steel smelting method of an anti-S steel oil well pipe, which relates to a smelting and preparing technology of an oil well pipe blank used in a corrosive oil-gas fieldenvironment. Clean steel comprises suitable chemical compositions by weight percent: 0.20-0.35 percent of C, not more than 1.00 percent of Si, not more than 0.60 percent of Mn, not more than 0.015 percent of P, not more than 0.010 percent of S, not more than 1.50 percent of Cr, 0.15-1.0 percent of Mo, 0.01-0.06 percent of Als, not more than 0.09 percent of Ti, not more than 0.05 percent of Nb, notmore than 0.0030 percent of N, not more than 0.0030 percent of O, not more than 0.0002 percent of H and Fe and the balance of unavoidable impurities. The clean steel smelting method adopts the following production technical lines by aiming at the clean steel with the compositions: choosing matching materials; smelting in an arc furnace; refining in an LF furnace; refining in a VD furnace; continuously casting in an arc shape; controlling hydraulic pressure and casting in full protection. The clean steel smelting method reduces the impurity content in the steel by controlling the proper content of C, Mn, P, S, Cr, Mo, N, O, H, and the like, the impurities are smaller and dispersive by the control of a subsequent technology, the component distribution is more uniform, tissues are evenly thinned, and the combination property of the anti-sulfur oil well pipe is ensured.

Owner:朝阳西姆莱斯石油铸钢管件有限公司 +1

High-strength cold-roll-forming structural steel and method for producing same

InactiveCN1970811AInhibition of segregationFast solidificationTemperature control deviceMetal rolling arrangementsMolten steelHeating furnace

The invention discloses a high-strength cool-bent moulding structural steel and manufacturing method, which comprises the following parts: 0.03-0.12% C,0.08-0.50% Si,1.20-1.95% Mn,not more than 0.02% P,not more than 0.006% S, 0.05%-0.15% Mo,0.005-0.055% Als,0.03-0.07% Nb,0.08-0.15% Ti,0.01-0.05% V ,0.0008-0.004% Ca and Fe and inevitable impurity with Ceq not more than 0.42%. The making method is characterized by the following: controlling the fusing point of smolten steel over 15-30 deg.c; casting continuously; setting drawing speed of casting bland at 1.5-4.0m / min and blank thickness between 100 and 200mm; heating in the furnace directly; setting the even heating temperature at 1100-1250 deg.c, fine-rolling temperature at 940-1070 deg.c and outlet temperature at 840-920 deg.c; freezing rapidly after 0-7s; setting the coiling temperature at 500-610 deg.c with yielding strength of steel board over 700Mpa and drawing-proof strength between 750 and 950Mpa and extending rate over 17%.

Owner:ANGANG STEEL CO LTD

Iron-based alloy powder for manufacturing diesel engine piston ring groove applied to low-speed and heavy-load ships through laser

InactiveCN106480380AHigh hardnessImprove wear resistanceMetallic material coating processesWear resistantComponents of crude oil

The invention discloses iron-based alloy powder for manufacturing a diesel engine piston ring groove applied to low-speed and heavy-load ships through laser. The iron-based alloy powder is characterized by comprising the following components in percentage by weight: 0.1-0.2% of C, 14.0-17.0% of Cr, 1.0-1.3% of Si, 1.4-2.0% of Ni, 0.2-0.5% of Mn, 0.8-1.2% of Mo, 1.0-1.5% of B and the balance of Fe. Through the iron-based alloy powder, a high-hardness and wear-resistant material suitable for the piston ring groove is designed by analyzing different element characteristics in the material; the powder contains high amount of chromium and proper amount of boron, silicon, boron, nickel and molybdenum, so that the effect of uniformly refining the structure is achieved; the hardness and the wear resistance of a cladding layer can be improved; the requirements of the diesel engine piston ring groove on the comprehensive properties such as corrosion resistance and wear resistance and the like of the cladding layer are met.

Owner:沈阳大陆激光工程技术有限公司

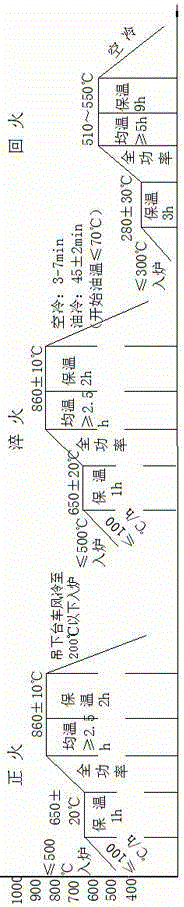

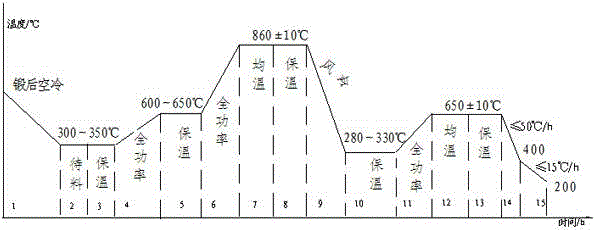

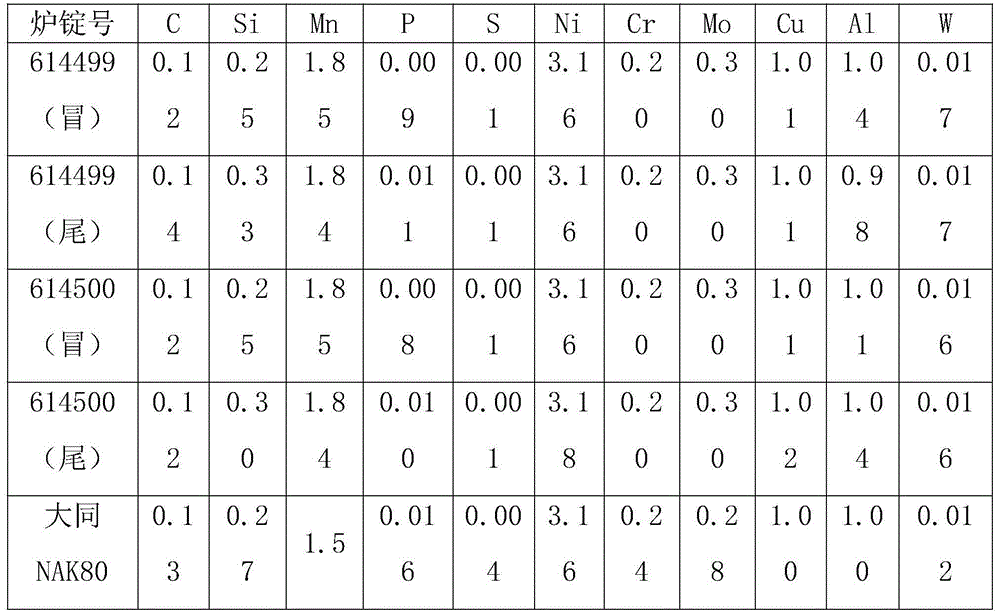

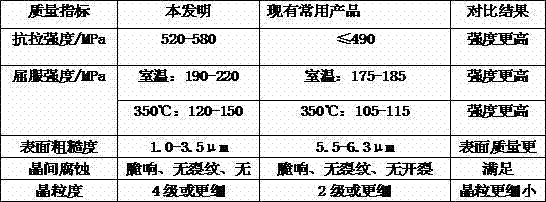

Production method of NAK80 high-grade mirror surface plastic rubber mold material for mobile phone mold

ActiveCN104611642AEliminate tail segregationEliminate riser shrinkage defectsProcess efficiency improvementElectric furnaceMicrostructureMaterials processing

The invention relates to a production method of an NAK80 high-grade mirror surface plastic rubber mold material for a mobile phone mold. The method includes the steps of: batching, electric furnace smelting, vacuum refining, vacuum pouring, electrode billet forging, electroslag remelting, square steel forging, normalizing and hydrogen diffusion annealing, and pre-hardening heat treatment. The method provided by the invention overcomes the disadvantages that the processability, polishing performance and use performance of domestic NAK80 plastic rubber mold materials cannot meet the requirement of an A2 level mirror surface for the mobile phone mold, and provides the production method of the NAK80 high-grade mirror surface plastic rubber mold material for the mobile phone mold. The produced mold material has a pure inside and uniform microstructure, and processing and polishing verification prove that the processability, polishing performance and use performance of the mold material all meet the A2 level mirror surface requirement.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Flange for wind power drum and manufacturing technique thereof

ActiveCN103045960APrevent precipitationGuaranteed corrosion resistanceFlanged jointsTemperingChemical composition

The invention provides a flange for a wind power drum, and a manufacturing technique thereof. The flange comprises the chemical compositions in percentage by weight: 0.15-0.22 percent of C, 0.55-0.65 percent of Si, 0.65-0.75 percent of Mn, 5-8 percent of Ni, 4-6 percent of Cr, 0.65-0.85 percent of Nb, 0.25-0.45 percent of Cu, 0.05-0.07 percent of N, 0.05-0.07 percent of Mo, 0.7-0.9 percent of Al, 0.02-0.03 percent of S, 0.08-0.09 percent of Ti, 0.01-0.04 percent of V, 0.002-0.003 percent of B, 1-2 percent of rare earth lanthanide series and the balance of Fe. According to the invention, with the heating processing procedures of two-time normalization and two-time tempering, the excellent corrosion resistance of the flange is ensured, and meanwhile, high tensile strength and high yield strength are achieved; and the flange is ensured to have smaller surface roughness, more uniform and stable tissue, and less air holes and sand holes.

Owner:WUXI HUAERTAI MACHINERY MFG

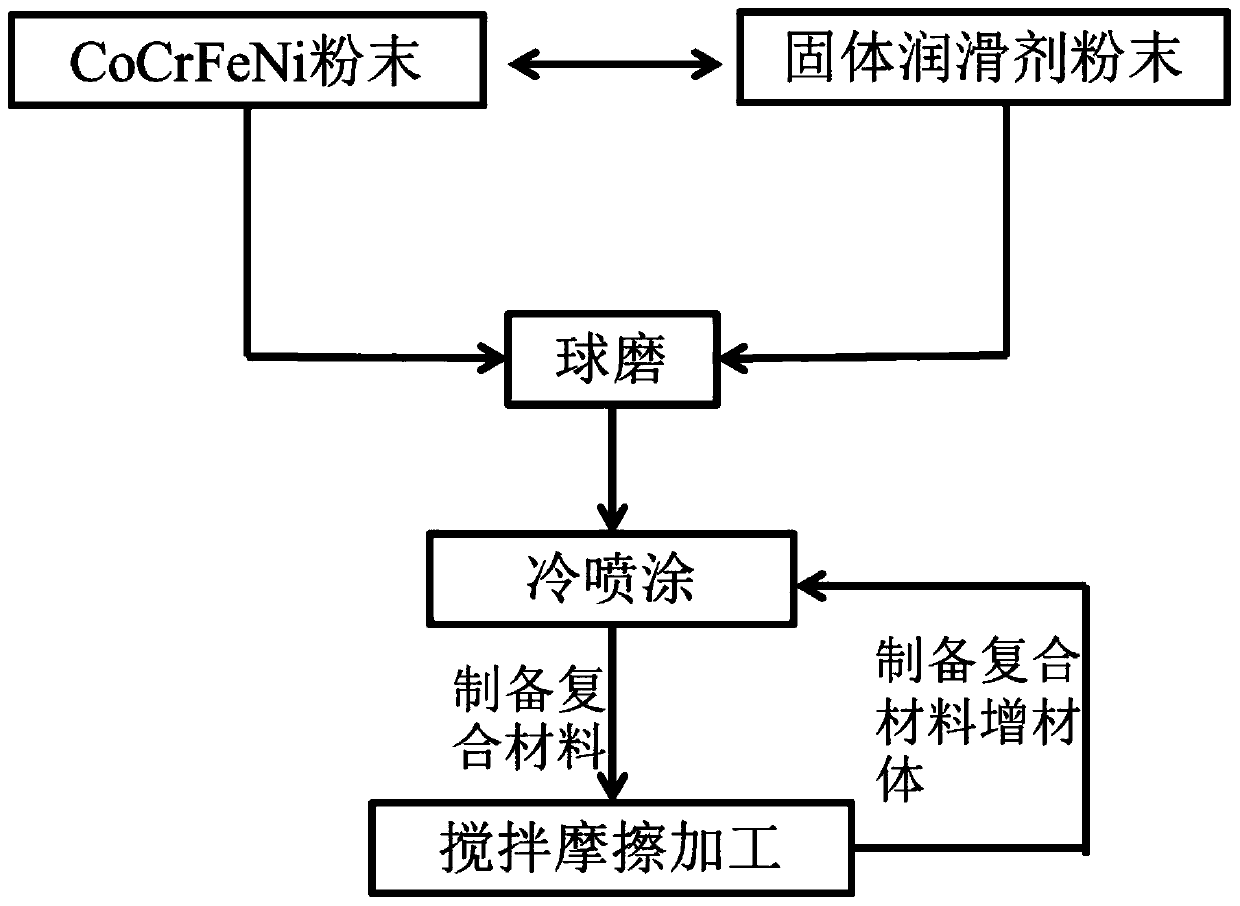

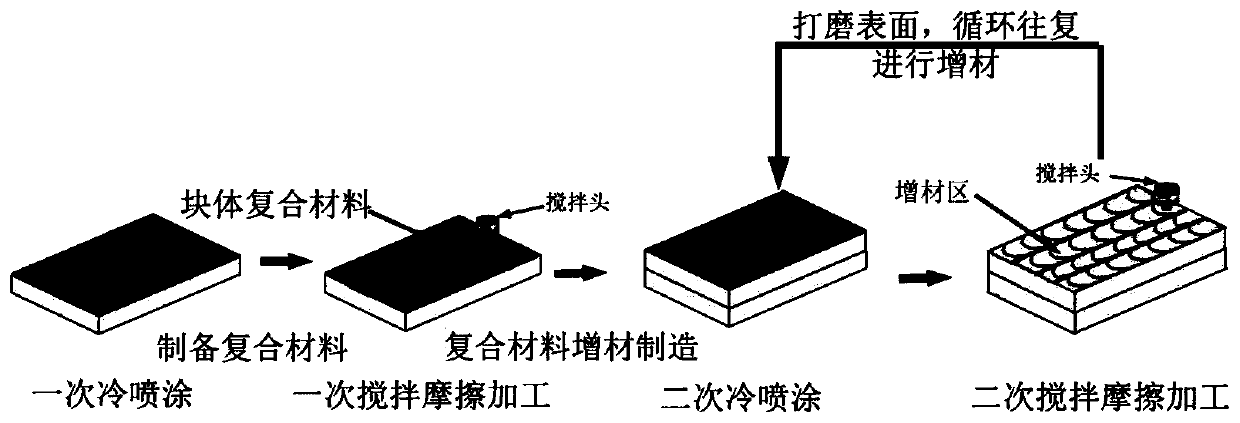

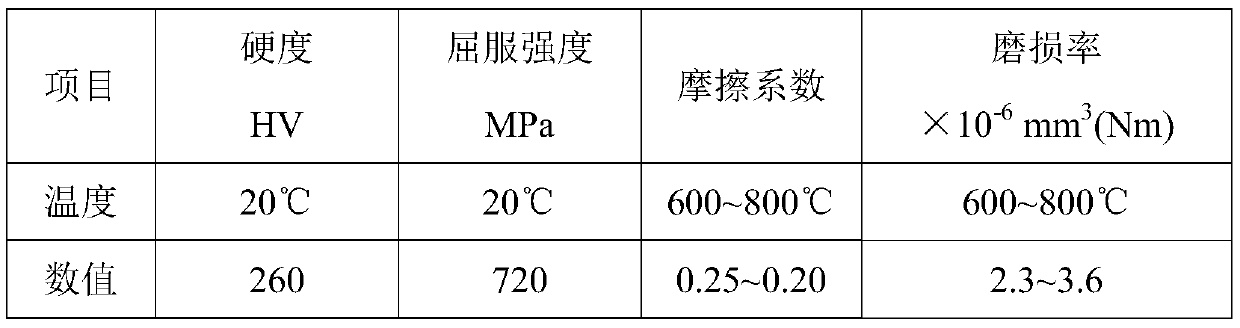

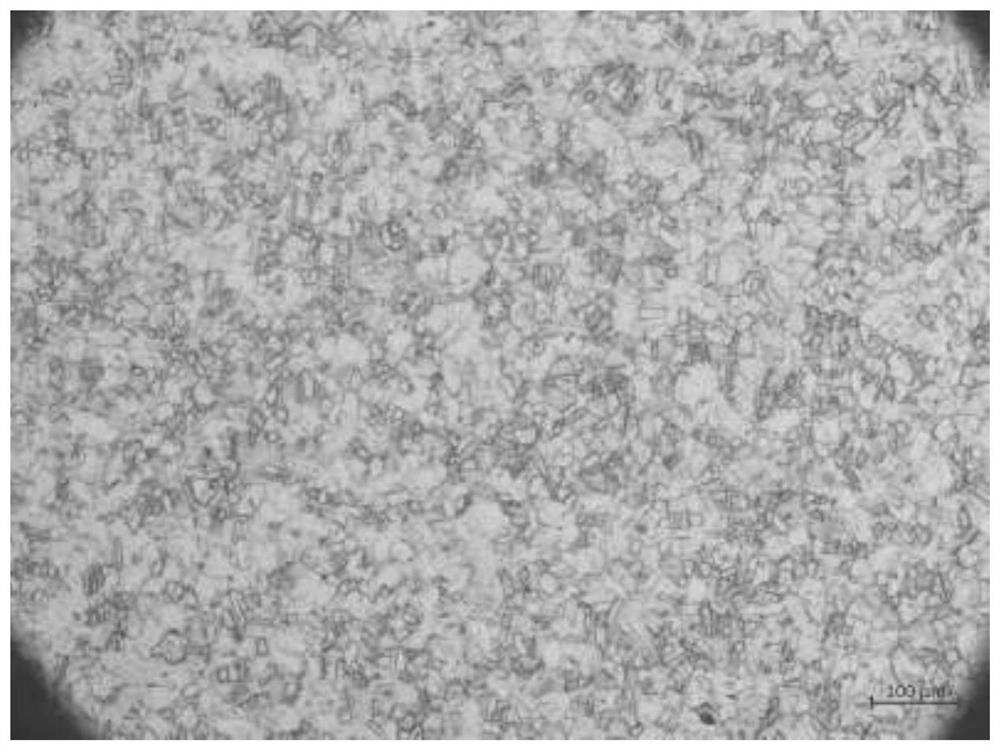

High-entropy-alloy-based self-lubricating composite and preparation method thereof

ActiveCN111575698AGood mechanical propertiesDense tissueAdditive manufacturing apparatusTransportation and packagingHigh entropy alloysFriction stir processing

The invention discloses a high-entropy-alloy-based self-lubricating composite and a preparation method thereof. The preparation method of the high-entropy-alloy-based self-lubricating composite includes the steps that a four-element high-entropy alloy CoCrFeNi is used as a matrix, a solid lubricant is used as a lubricating phase, the CoCrFeNi and the solid lubricant are ball-milled and mixed and then deposited on a metal substrate through cold spraying to form a sedimentary body, the sedimentary body is subjected to friction stir machining through a stirring head, and the high-entropy-alloy-based self-lubricating composite is obtained, wherein the mass ratio of the CoCrFeNi to the solid lubricant is (2.3-4):1. According to the self-lubricating composite, the high-entropy alloy CoCrFeNi isused as the matrix, excellent mechanical performance of the high-entropy alloy overcomes losses of strength and toughness caused by adding of the solid lubricant, and therefore the prepared high-entropy-alloy-based self-lubricating composite keeps good self-lubricating capacity and has excellent mechanical performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

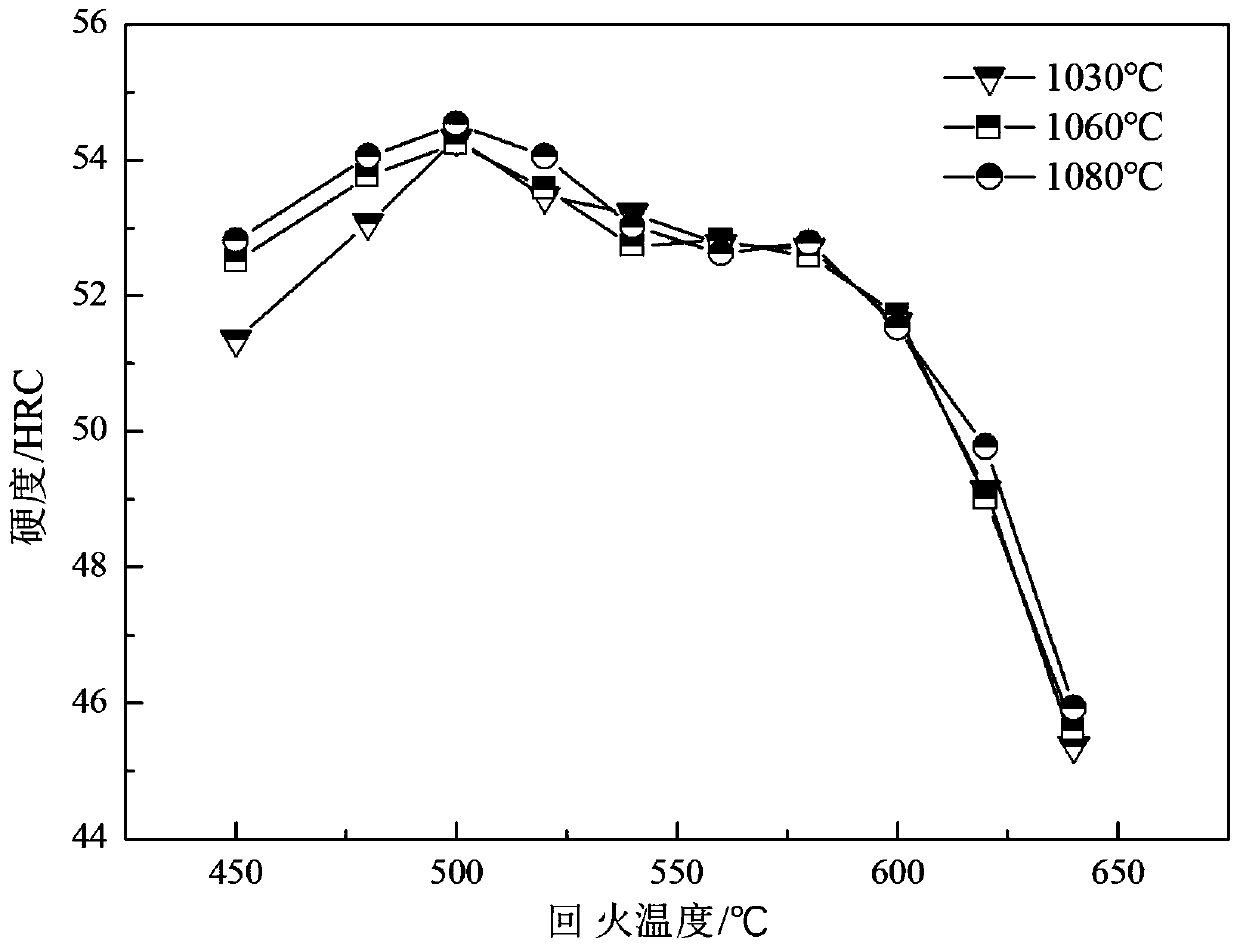

Forging and heat treatment method of 9Cr18MoV steel forging

The invention discloses a forging and heat treatment method of a 9Cr18MoV steel forging. The forging and heat treatment method comprises the following steps: a 9Cr18MoV steel ingot is put in a heat treatment furnace for performing the heat treatment before the forging, and is forged to produce a blank within a certain temperature range after the heat treatment; the 9Cr18MoV steel blank is finally forged within the certain temperature range to obtain the 9Cr18MoV steel forging; the normalization heat treatment is performed for the 9Cr18MoV steel forging; and the tempering heat treatment is performed for the 9Cr18MoV steel forging. The 9Cr18MoV steel forging has excellent corrosion resistance through reasonably controlling various process parameters, so that the 9Cr18MoV steel forging can be successfully applied to the production of such parts as gas turbines.

Owner:GUIZHOU ANDA AVIATION FORGING

Processing technology of chromium-zirconium-copper contact wire for high-speed electrified railway

ActiveCN111799035AIncrease profitReduce energy consumptionApparatus for heat treatmentConductive materialElectric conductanceMachining process

The invention discloses a processing technology of a chromium-zirconium-copper contact wire for a high-speed electrified railway. The method specifically comprises the following steps: upward continuous casting of a chromium-zirconium-copper rod blank, continuous extrusion, solid solution heat treatment, continuous rolling, aging heat treatment, peeling and drawing to obtain a finished product. According to the process, large-length and large-piece-weight industrial production of the chromium-zirconium-copper contact line of the high-speed railway is realized. The product performance is more excellent. The material structure is further refined and uniform through continuous extrusion and rolling. The average grain size is 10-50 [mu]m, the mechanical performance of the material is further improved, the tensile strength Rm reaches 600 Mpa or above, the conductivity is 80% IACS or above, the advantages of being stable and excellent in quality, high in material utilization rate and the like are achieved, a new way is provided for domestication of the chromium-zirconium-copper contact wire, and the method is suitable for wide popularization.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

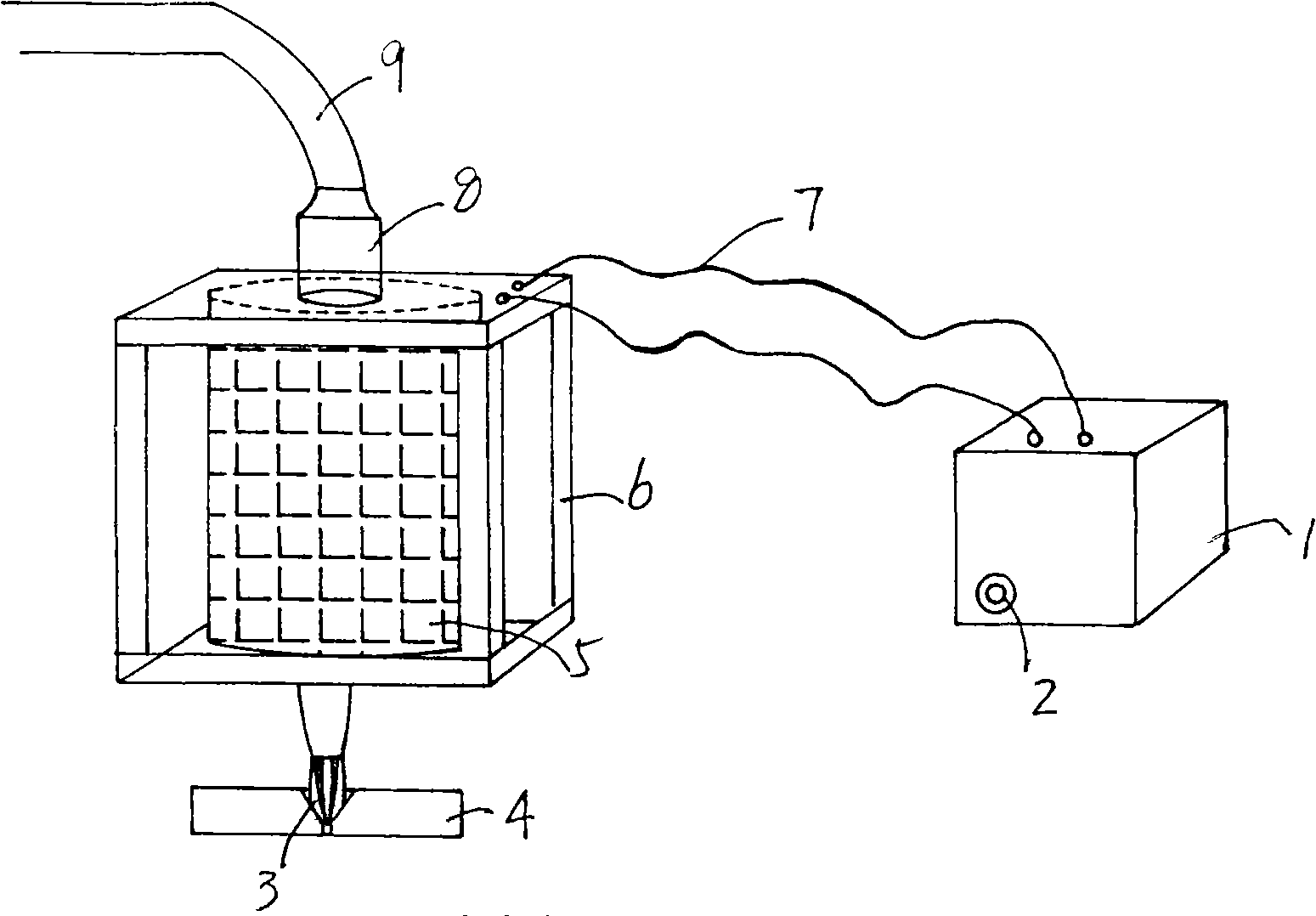

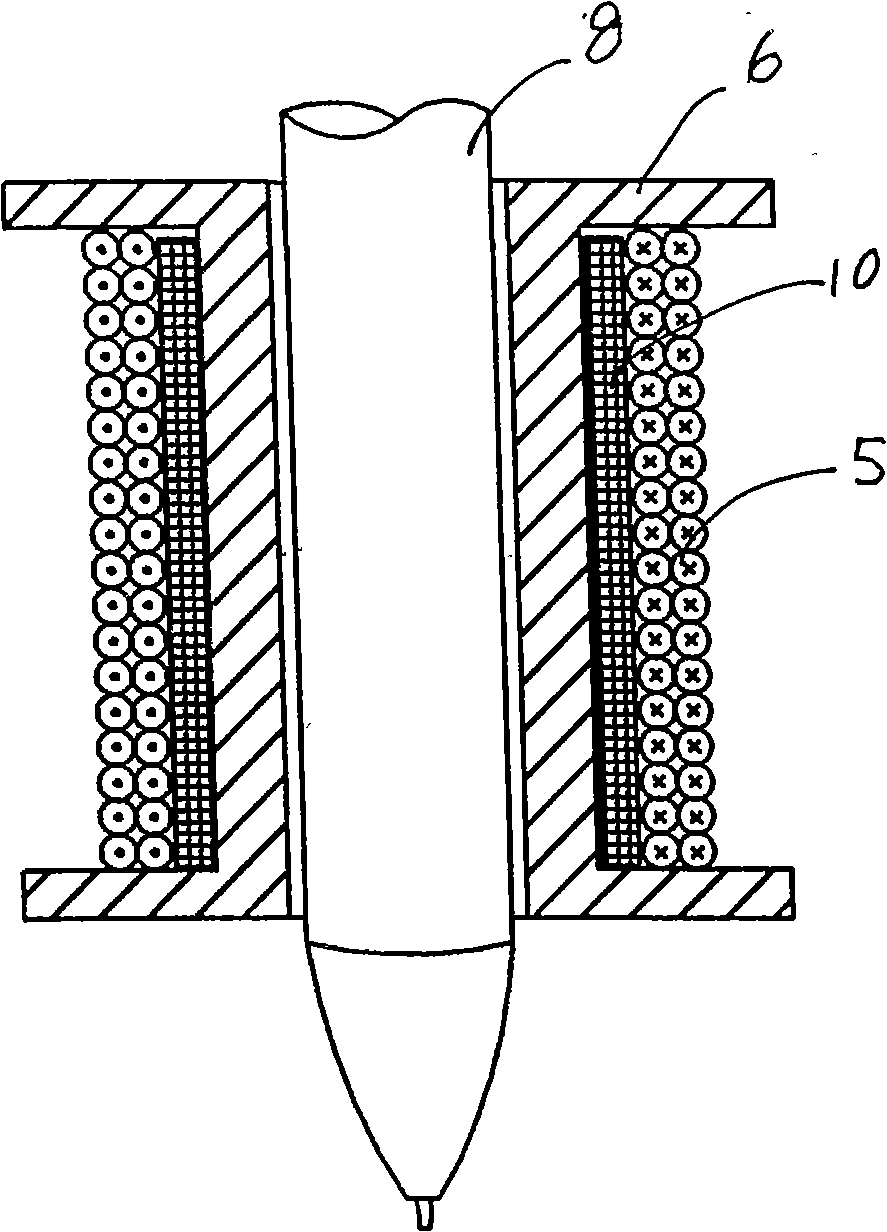

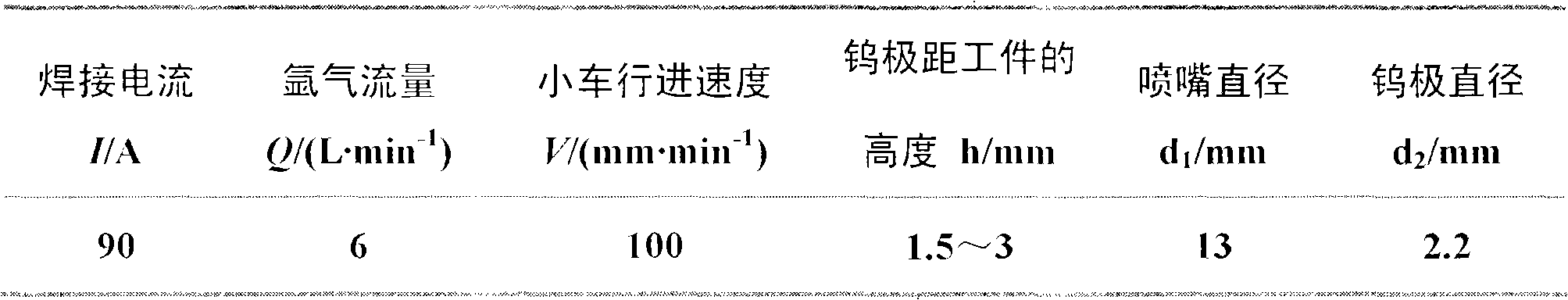

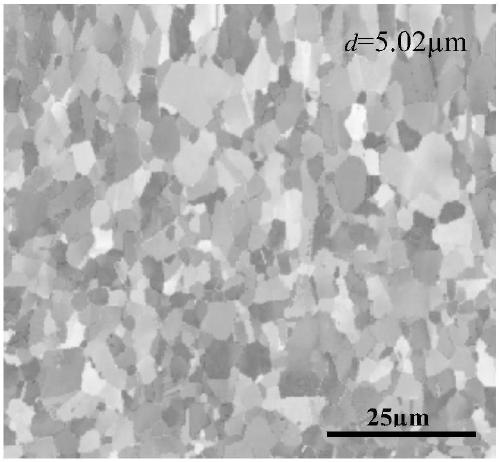

Production method for improving wearing resistance of plasma arc surfacing

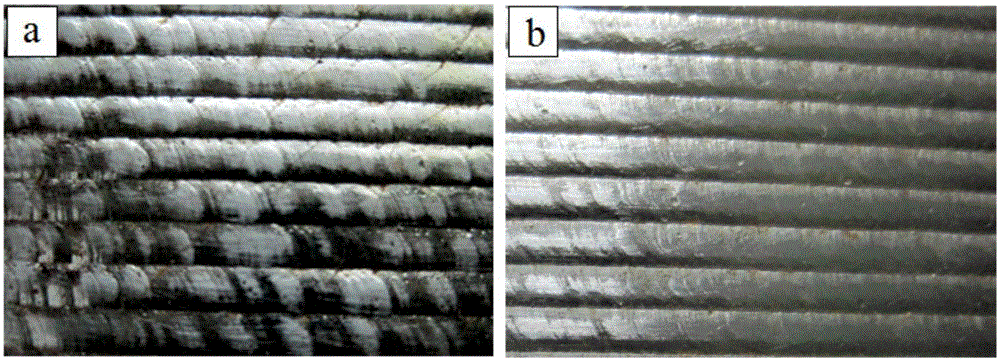

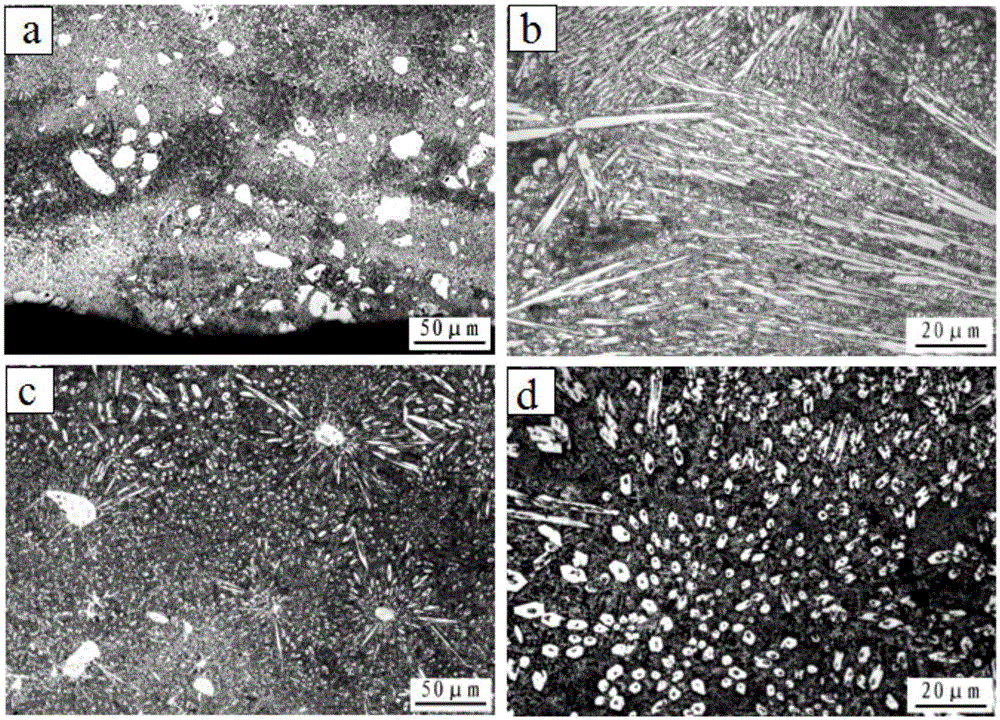

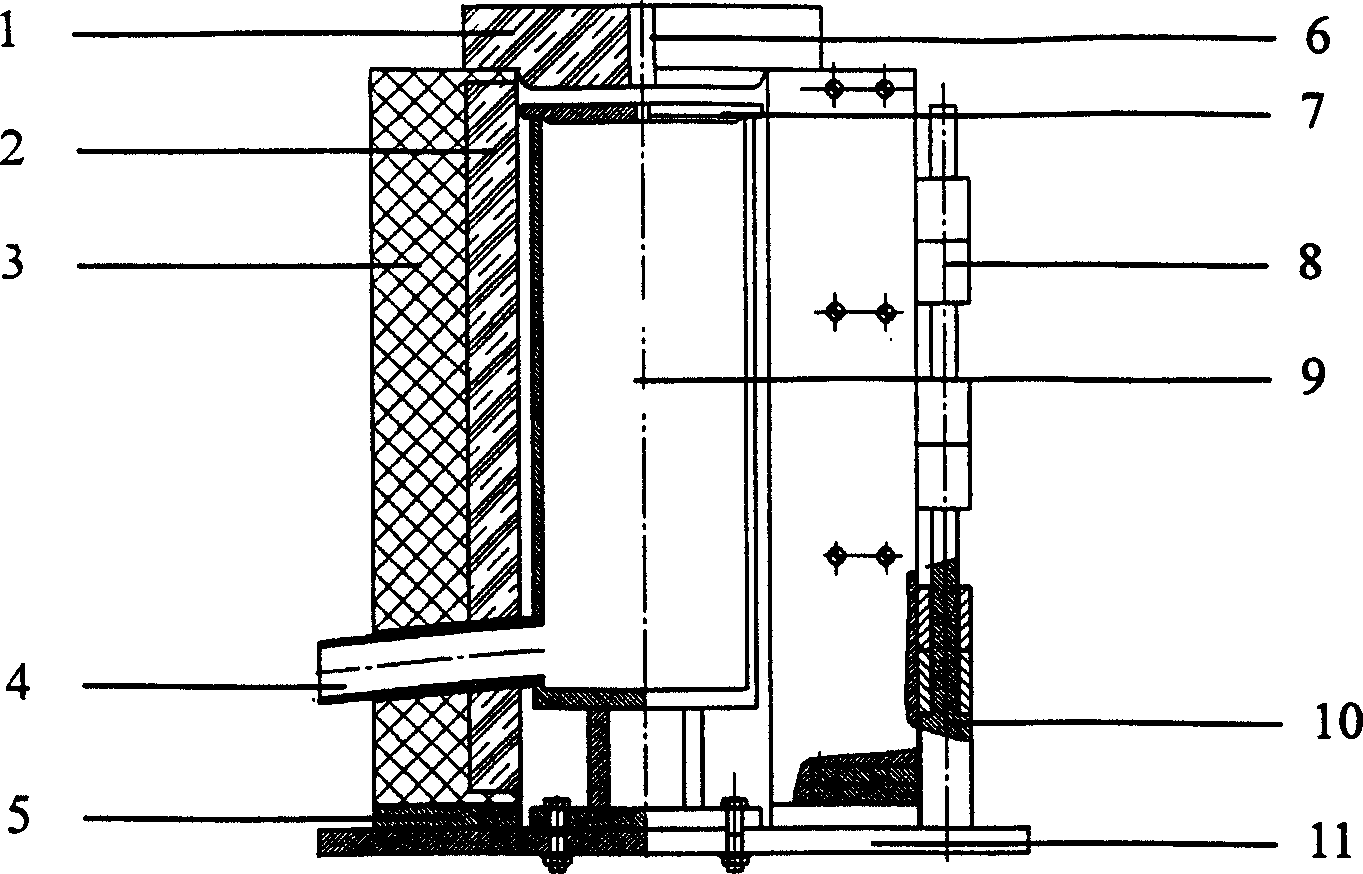

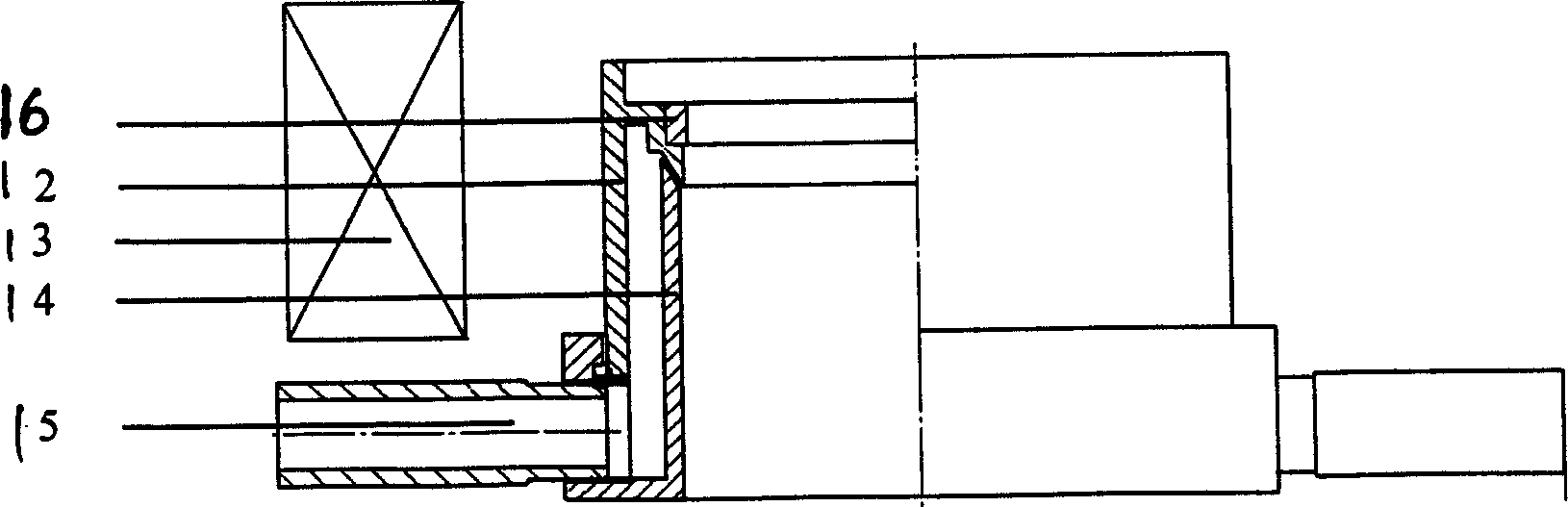

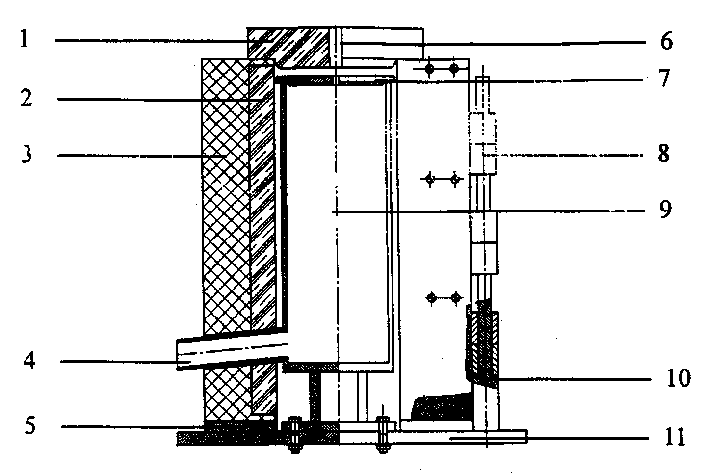

InactiveCN101347857AImprove organizationTissue uniform refinementWelding/cutting auxillary devicesArc welding apparatusBraced frameDistribution pattern

The invention discloses a production method for improving the wear resistance of plasma arc surfacing, which relates to the improvement of a welding processing method of plasma arc surfacing. Based on common surfacing alloy, the invention changes the crystallization process of a surfacing layer by applied magnetic field, and controls the distribution pattern of hard phase in the surfacing layer, thus improving the wear resistance of the surfacing layer. The invention comprises power supply equipment, which is characterized in that the power supply equipment is connected with coils arranged in a braced frame by wires. A plasma welding torch can weld under the action of magnetic lines of force of the coils.

Owner:SHENYANG POLYTECHNIC UNIV

Ultrafine grained Ta material and preparation method thereof

The invention relates to an ultrafine grained Ta material and a preparation method thereof. Grain size of the ultrafine grained Ta material is smaller than or equal to 3 mu m; ultimate strength of thematerial is higher than or equal to 410 MPa, and yield strength is higher than or equal to 300 MPa. The preparation method of the material comprises the following steps: electron beam melting is performed on a Ta source, after ingot casting, an ingot is sheathed in a protective atmosphere; 3D hot-forging cogging is performed, total deformation of cogging is 65%-75%, and cogging temperature is 1150-1250 DEG C; after cogging, a sheath is removed, and low-temperature and high-temperature cross alternate rolling is performed; the ultrafine grained Ta material is obtained. The process is simple, and the prepared Ta ribbon has uniform and quite fine grains and is endowed with favorable strength, plasticity and toughness. The designed and prepared ultrafine grained Ta ribbon is applied to the high-technology fields of electronics, metallurgy, steel, chemical industry, hard alloys, atomic energy, superconducting technology, automotive electronics, aerospace, medical health and scientific research.

Owner:CENT SOUTH UNIV +1

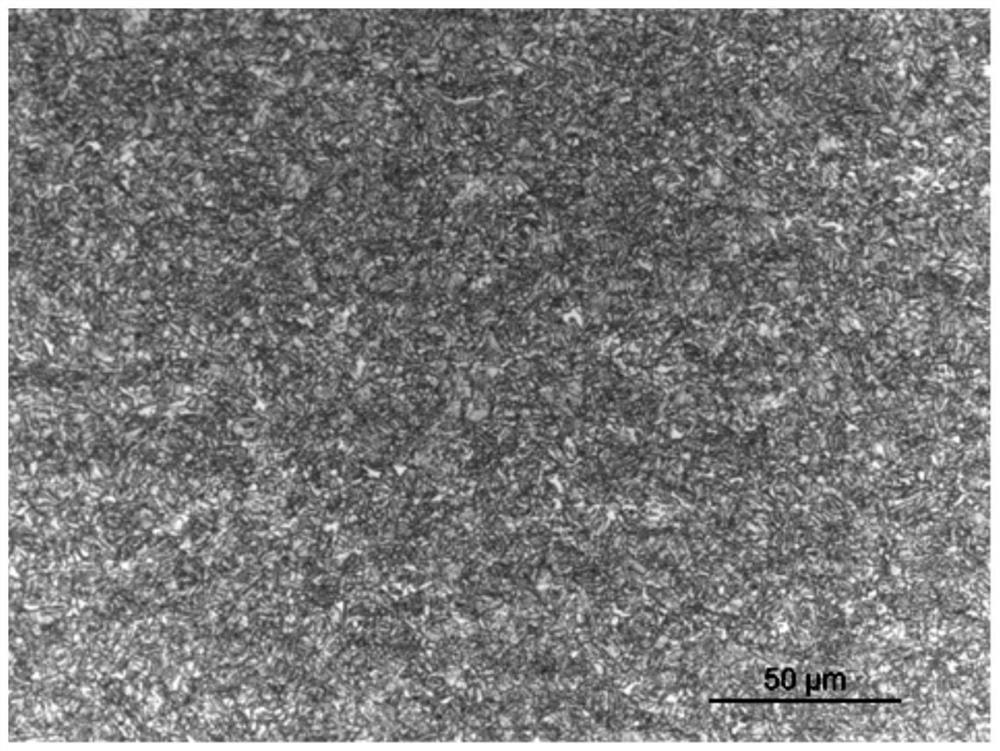

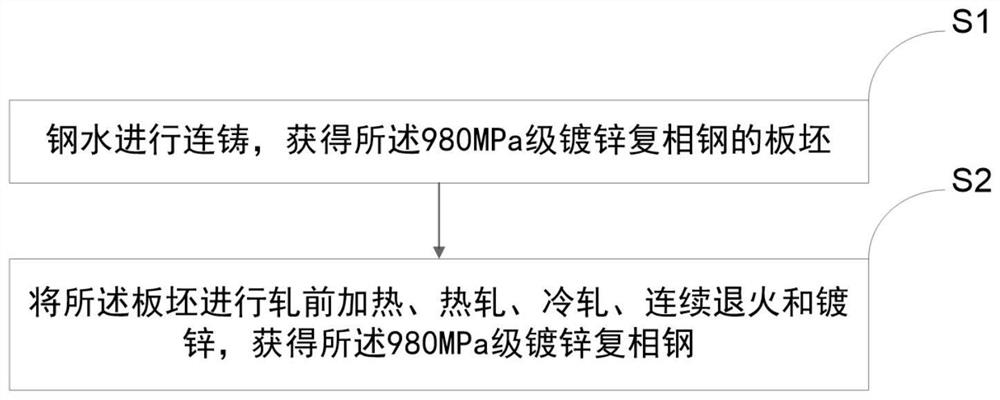

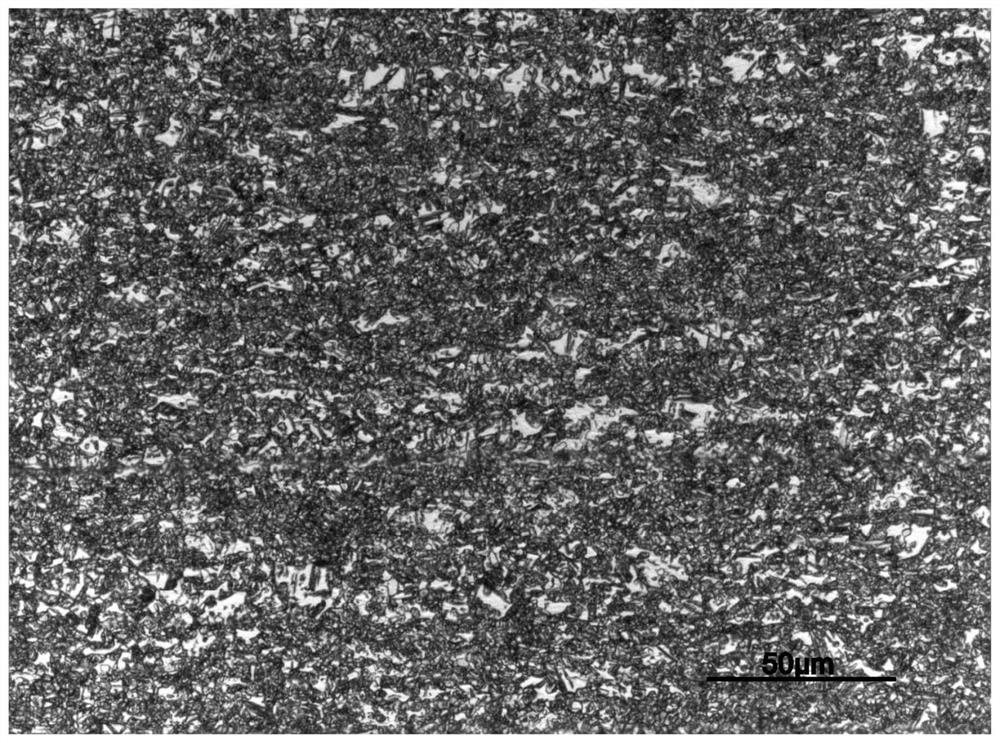

980 MPa-grade galvanized complex-phase steel and preparation method thereof

ActiveCN113528978AImprove bending performanceOptimize chemical compositionHot-dipping/immersion processesProcess efficiency improvementUltimate tensile strengthGalvanization

The invention provides 980 MPa-grade galvanized complex-phase steel and belongs to the technical field of high-strength cold-rolled hot-galvanized steel. The steel comprises the following chemical components including, by mass: 0.10% to 0.12% of C, 0.5% to 1.0% of Si, 2.0% to 2.5% of Mn, 0.03% to 0.1% of Alt, 0.03% to 0.04% of Ti, less than or equal to 0.01% of P, less than or equal to 0.01% of S, less than or equal to 0.004% of N and the balance Fe and trace elements. The 980 MPa-grade galvanized complex-phase steel has high yield strength, and is matched with good ductility and high bendability. The invention further provides a preparation method of the 980 MPa grade galvanized complex-phase steel.

Owner:SHOUGANG CORPORATION

Zinc alloy material for degradable cardiovascular stent and preparation method of zinc alloy material

PendingCN113444919AReduced Galvanic CorrosionImprove degradation uniformitySurgeryMagnesiumChloroethane

The invention relates to a zinc alloy material for a degradable cardiovascular stent and a preparation method of the zinc alloy material, and belongs to the technical field of materials. The zinc alloy material comprises, by weight, 0.03-0.07% of Mg, 0.03-0.07% of Mn, less than or equal to 10ppm of inevitable impurities and the balance Zn. The preparation method comprises the following steps that (1) pure zinc is heated to 600 + / -5 DEG C, melted, magnesium metal, manganese metal and phosphorus are sequentially added, and uniformly stirred, the temperature is reduced to 550 + / -5 DEG C, hexachloroethane is pressed to preserve heat and stand for 10-20 minutes, and metal melt is cooled to 500 + / -10 DEG C, and cast; (2) secondary magnetic suspension smelting is carried out, so that the component uniformity deviation is smaller than + / -0.02 wt.%; (3) heat is preserved at 350 DEG C for 5 hours, temperature is raised to 370 DEG C, heat is preserved for 5 hours, and cooling is performed to the room temperature in water; (4) heat preservation is conducted for 60-80 min at the temperature of 300-400 DEG C, and then hot forging deformation is conducted at the temperature of 300-400 DEG C; and (5) heat preservation is conducted for 30 min at the temperature of 150 DEG C, and then reverse hot extrusion deformation is conducted at the temperature of 150 DEG C. According to the zinc alloy material for the degradable cardiovascular stent and the preparation method of the zinc alloy material, a Zn-Mg-Mn alloy is excellent in mechanical property and uniform in tissue component, and can be used for preparing the biodegradable cardiovascular stent.

Owner:NORTHEASTERN UNIV

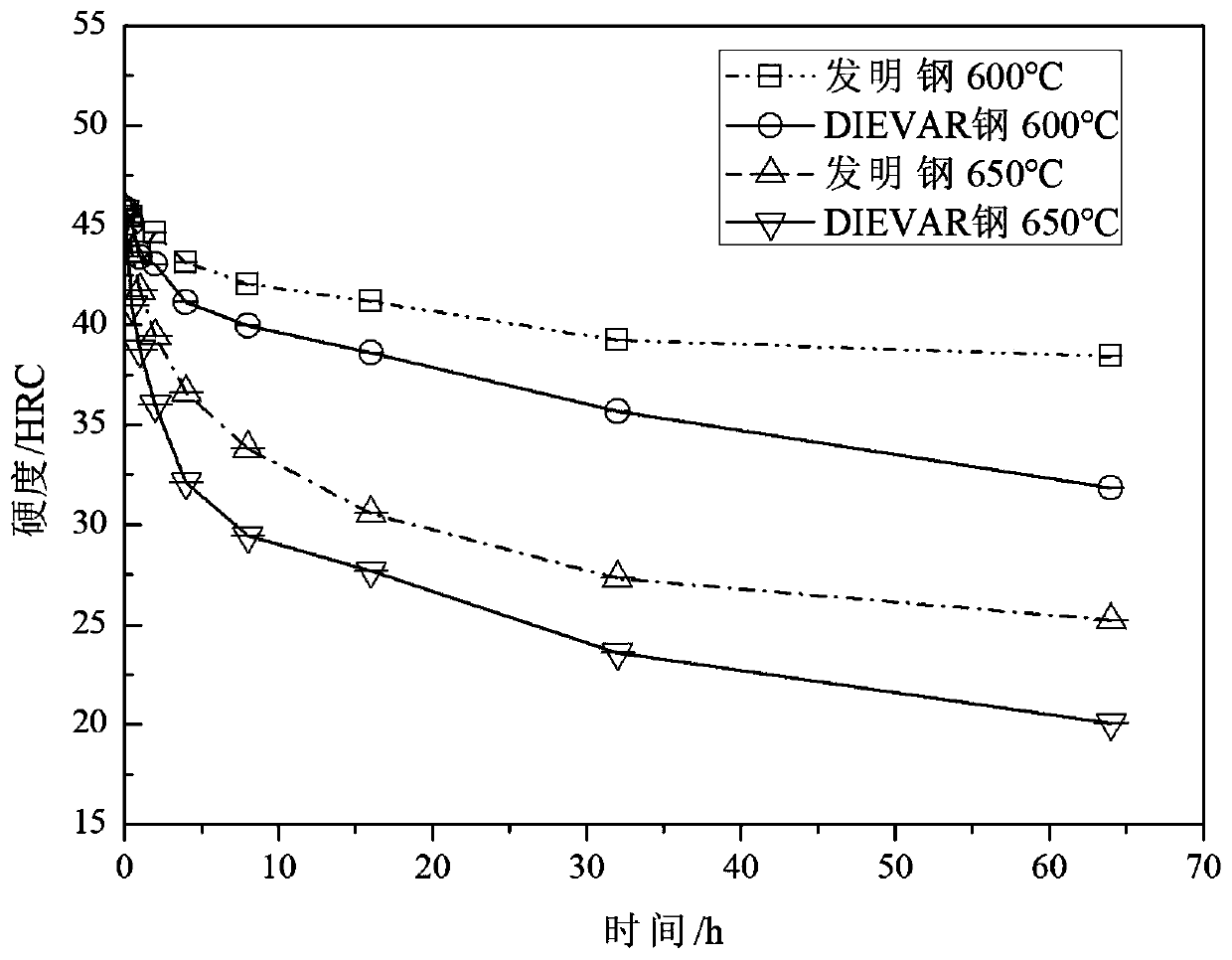

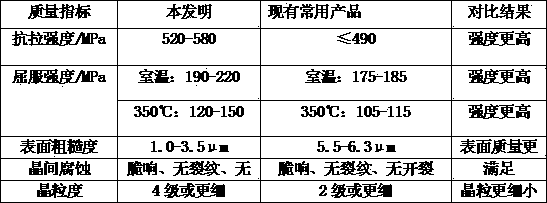

High-thermal-stability die-casting die steel and preparation method thereof

The invention relates to the field of alloy steel manufacture, in particular to a high-thermal-stability die-casting die steel and a preparation and thermal treatment method thereof. The die-casting die steel is prepared from, by mass, 0.3-0.45% of C, 0.2-0.5% of Si, 0.30-0.60% of Mn, 2.00-4.00% of Cr, 1.80-3.00% of Mo, 0.40-0.80% of V, smaller than or equal to 0.005% of S, smaller than or equal to 0.02% of P and the balance Fe. The preparation method of the die-casting die steel comprises the steps of preparation, smelting, casting, electro slag remelting, high-temperature homogenization, forging, solid solution, balling, and quenching and tempering thermal treatment. Compared with common die-casting die steel of H13(4Cr5MoSiV1), DIEVAR(4Dr5Mo2V) and QRO90(4Cr3Mo2V1), the high toughness ratio of the die-casting die steel is guaranteed, and the die-casting die steel has superior thermal stability.

Owner:SHANGHAI SHIJIN NEW MATERIAL TECH

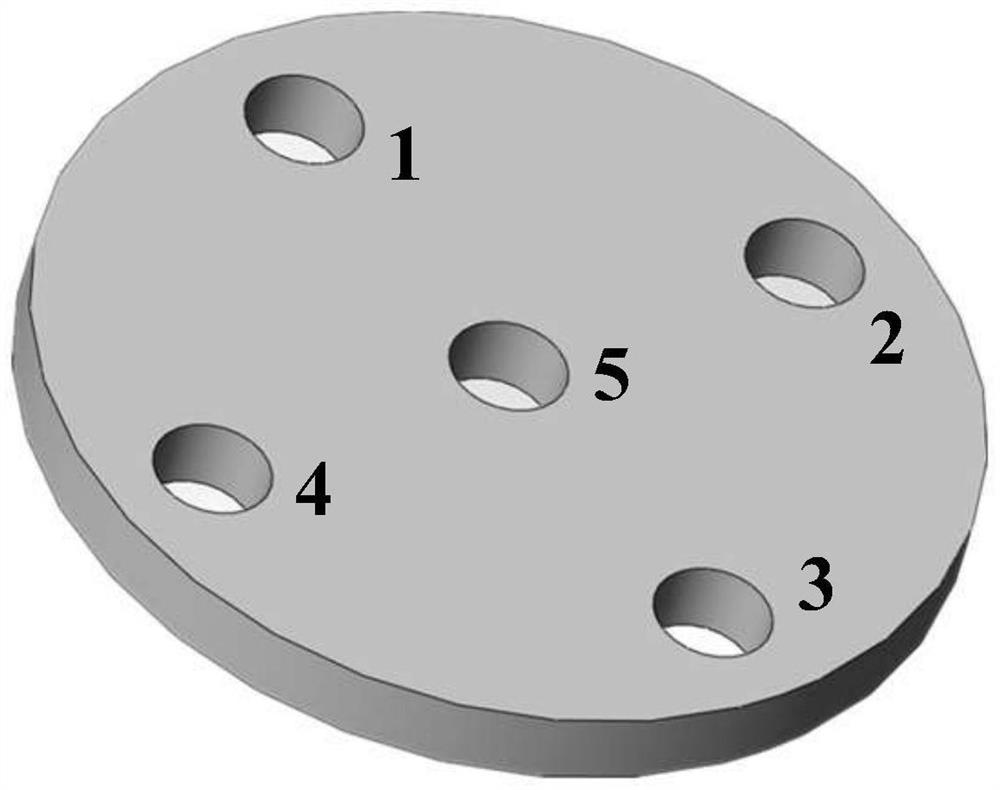

Large-diameter flange and preparation process thereof

ActiveCN103031500BGrain refinementUniform grain refinementFurnace typesHeat treatment furnacesChemical compositionTempering

The invention discloses a large-diameter flange and a preparation process thereof. The large-diameter flange comprises the following chemical components by weight percent: 0.45 to 0.65% of C, 0.25 to 0.30% of Si, 0.85 to 0.95% of Mn, 9 to 11% of Ni, 2 to 3 % of Cr, 0.15 to 0.20% of Nb, 0.85 to 0.95% of Cu, 0.02 to 0.04% of N, 0.13 to 0.15% of Mo, 0.2 to 0.3% of Al, 0.07 to 0.09% of S, 0.03 to 0.04% of Ti, 0.02 to 0.03% of V, 0.002 to 0.004% of B, 6 to 8% of lanthanide rare earth, and the balance of Fe. The processes of twice normalizing and twice tempering and the cooling thermal treatment process are adopted, the flange is guaranteed to have high tensile strength, high yield strength and smaller surface roughness, the structure is more stable and more uniform, and air holes and sand holes are little.

Owner:WUXI HUAERTAI MACHINERY MFG

Magnesium alloy electromagnetic low-temperature semicontinuous casting method

The magnesium alloy electromagnetic low-temp. semicontinuous casting method includes the steps of melting magnesium, adding compound fire-resisting elements, adding alloy elements, heat-insulating, standing still and semicontinuous casting under the electromagnetic field. It utilizes the addition of compound fire-resisting elements to implement smelting of magnesium alloy free from coverage or protection so as to shorten technological process and raise melt quality, and utilizes the application of electromagnetic field and optimization of crystallizer structure to implement the low-temp. and high-speed semicontinuous casting of magnesium alloy.

Owner:NORTHEASTERN UNIV LIAONING

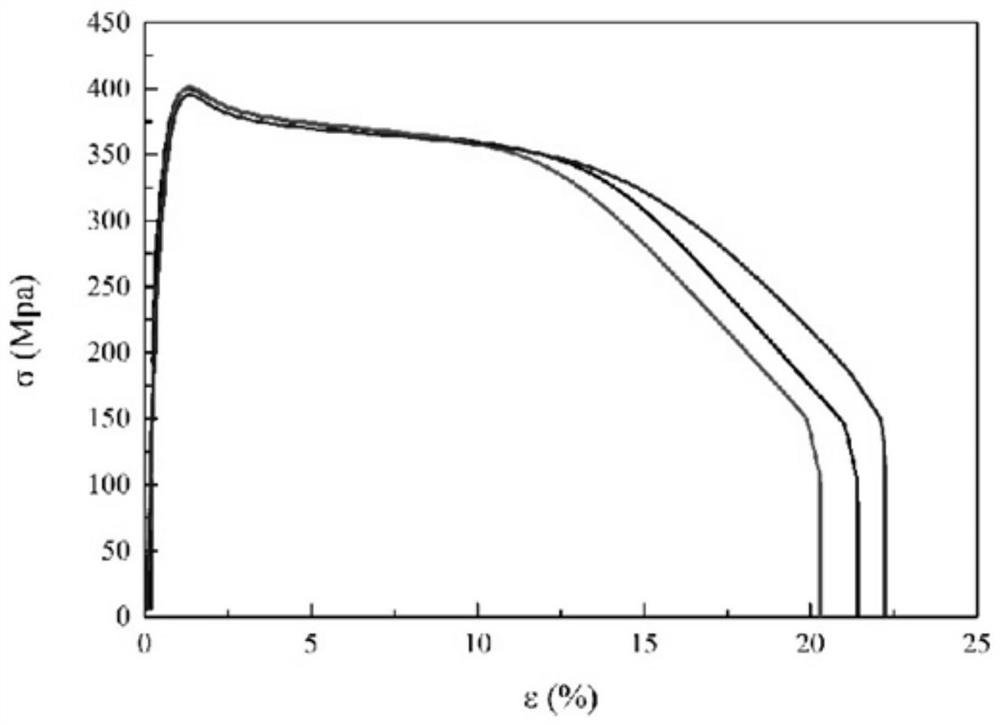

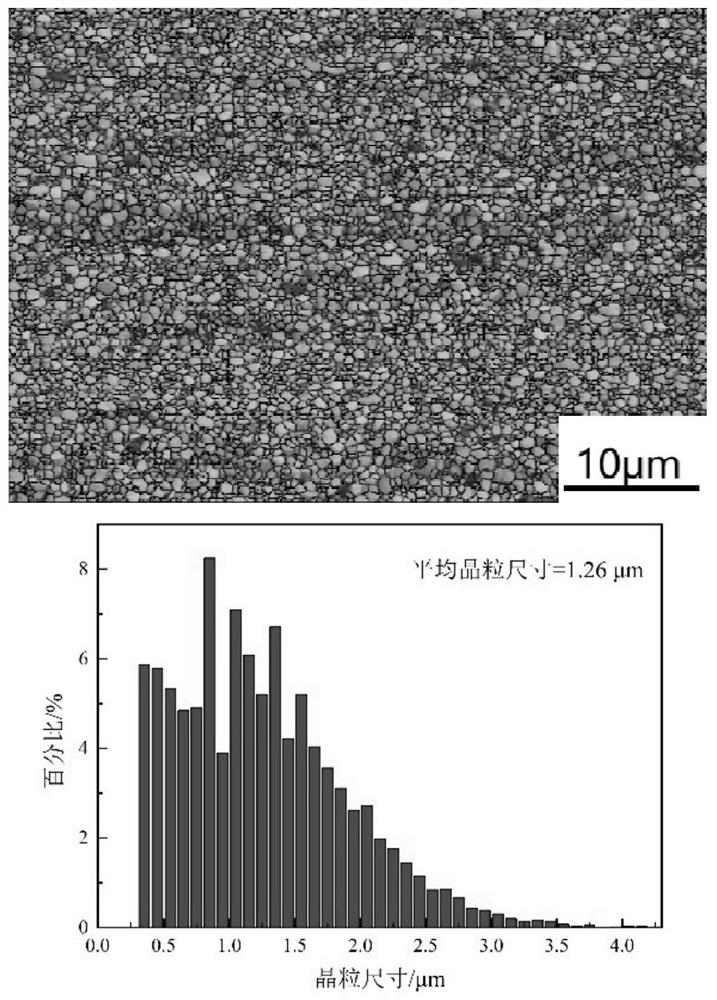

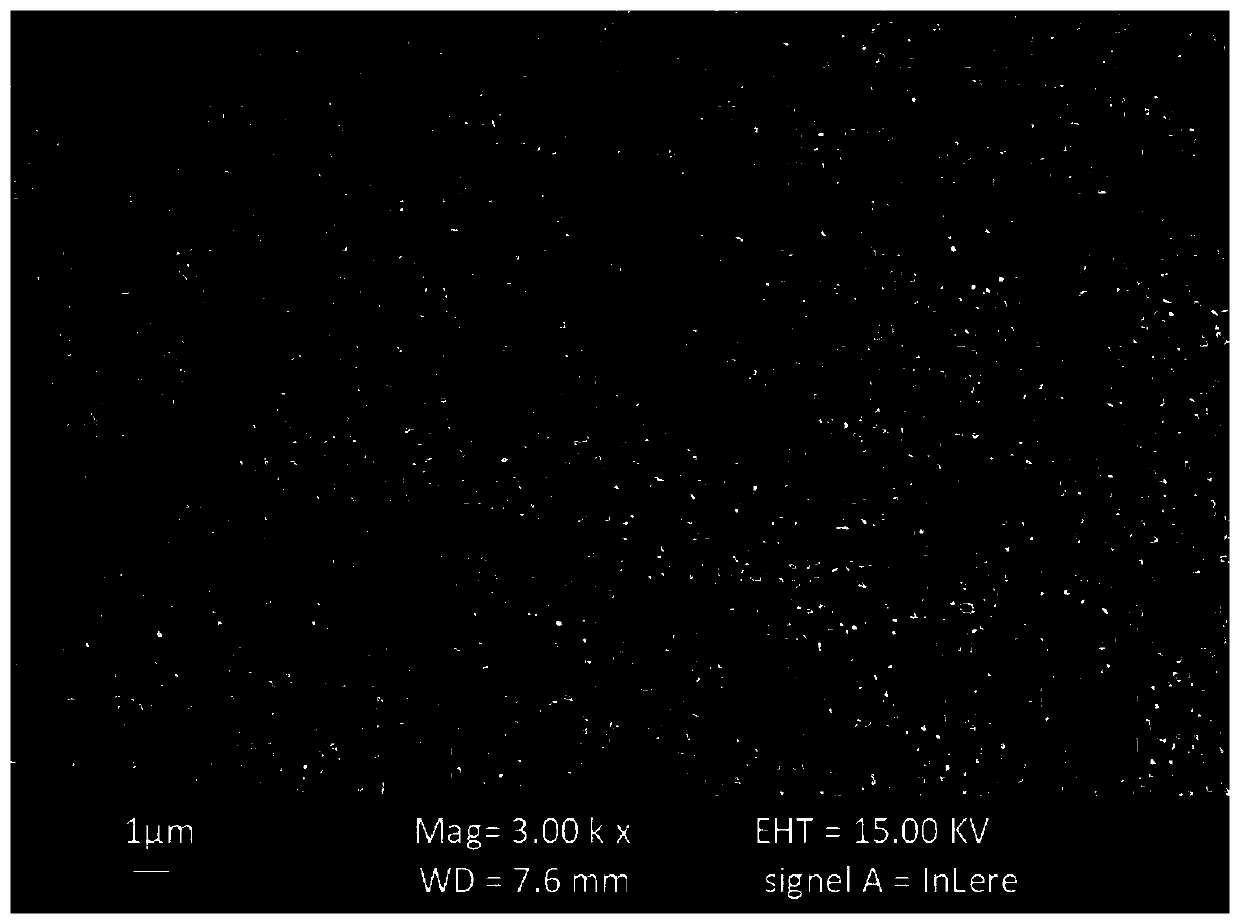

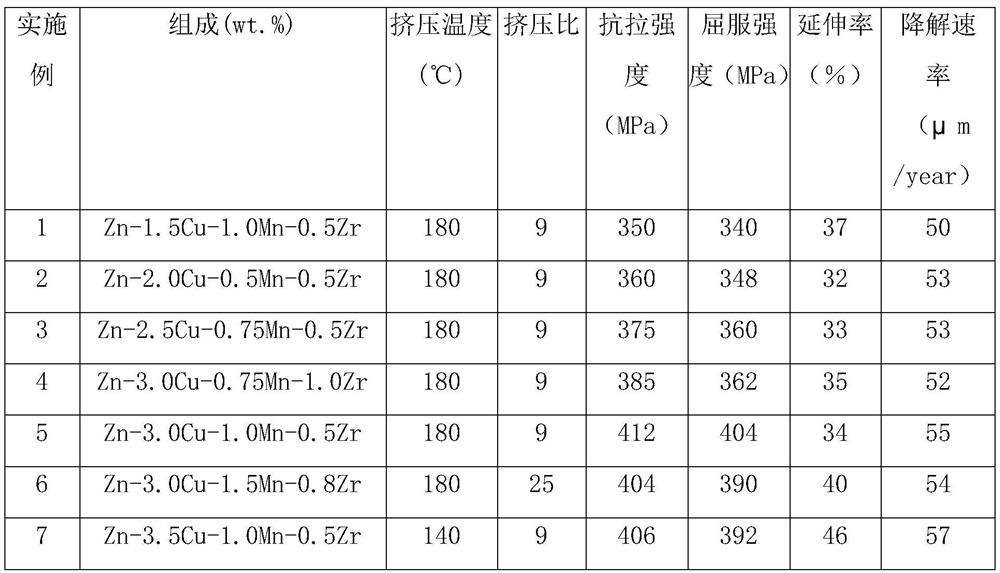

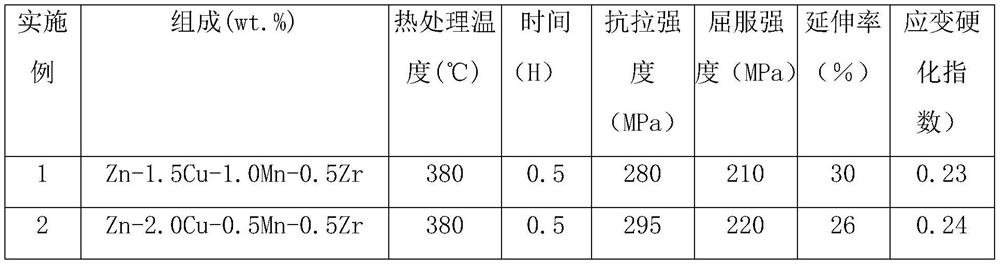

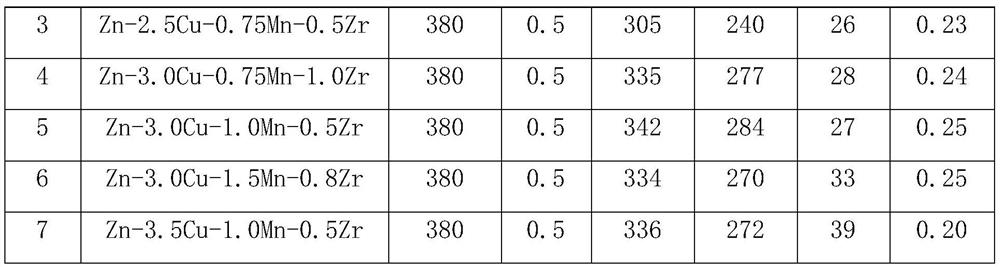

Medical Zn-Cu-Mn-Zr alloy capable of being degraded in living body and high in strength and toughness

ActiveCN112430764AUniform corrosionMeet the requirements of corrosion performanceSurgeryProsthesisCytotoxicityStaphyloccocus aureus

The invention discloses a medical Zn-Cu-Mn-Zr alloy capable of being degraded in a living body and high in strength and toughness. Zn, Cu, Mn and Zr elements are included, the content of Cu is largerthan 0 and smaller than or equal to 4%, the content of Mn is larger than 0 and smaller than or equal to 2%, the content of Zr is larger than 0 and smaller than or equal to 2%, and the balance is Zn. The corrosion rate of the alloy material in simulated body fluid is 35-71 microns / year, and a uniform corrosion degradation mode is shown; and under the conditions of the room temperature and the tensile strain rate of 1 * 10<-3>, the tensile properties are as follows: the yield strength is 200-420 MPa, the tensile strength is 210-440 MPa, and the elongation is 20-65%. The antibacterial rate on staphylococcus aureus and escherichia coli is 90% or higher. After the temperature at 380 DEG C is kept for 0.5 hour, the strain hardening index n is greater than or equal to 0.2 at the stage of true strain of 5%-15%; and moreover, no obvious cytotoxicity exists, and the biocompatibility is relatively good.

Owner:SHANGHAI JIAO TONG UNIV

Indium tungsten oxide target material and preparation method thereof

PendingCN114702304AHigh densityTissue uniform refinementFinal product manufactureVacuum evaporation coatingOxygen vacancyIndium

The invention provides an indium tungsten oxide target material and a preparation method thereof, and belongs to the technical field of photoelectric materials. The preparation method comprises the following steps: mixing indium oxide and tungsten oxide according to a stoichiometric ratio, and calcining to enable the indium oxide and the tungsten oxide to be subjected to complete solid-phase reaction to obtain In6WO12; the generation of oxygen vacancies can be inhibited by calcining in an oxygen atmosphere, so that the density of the product is improved; in6WO12 is mixed with indium oxide, water, a dispersing agent and a binding agent, then pressure grouting is conducted, the dispersion degree of the In6WO12 phase in the target material is improved, and meanwhile the compactness of the target material is further improved; and a dispersing agent and a binding agent are removed through degreasing treatment, and step variable-temperature sintering is combined, so that the obtained target material is uniform in structure refinement and high in density. Experimental results of the embodiment show that the relative density of the indium tungsten oxide target material prepared by the preparation method provided by the invention is 98.1-99.6%.

Owner:ZHENGZHOU UNIV

A kind of graphene-loaded grain refining material of al-mg alloy wire and preparation method thereof

The invention discloses a graphene-supported grain refinement material of Al-Mg alloy wire and a preparation method thereof. The graphene-supported grain refinement material is composed of a weight percentage of Gp0.10%-0.20%. , V0.10%‑0.20%, Zr0.10%‑0.20%, Mn0.20%, Ti0.20%, Fe0.40%, Si0.08%, Cr0.20%, Cu0.40%; the preparation The method is to use the intermediate grain refining alloy to be uniformly mixed and then briquetting, sintering annealing, mechanical alloying and melting. into the aluminum-magnesium solution. The invention improves the strength and conductivity of the aluminum-magnesium alloy wire, reduces the breakage rate and fineness of the material wire, and improves the performance of the aluminum-magnesium alloy wire material.

Owner:BAISE UNIV

Medical high-elasticity tin-plated alloy wire and preparation method thereof

The present invention discloses a medical high-elasticity tin-plated alloy wire and a preparation method thereof, and belongs to the field of tin-plated alloy wires. The preparation method specifically includes the steps: firstly, melting a copper base material and alloy particles, adding strengthened particles, performing electromagnetic stirring at the pressure of 1-3 Mpa, then, performing casting to form a copper alloy rod, and then, performing wire drawing, annealing treatment, acid pickling, drying and tin plating to prepare the tin-plated alloy wire. According to the present invention, electromagnetic stirring is adopted during melting, so that crystals in a copper alloy can be obviously refined; meanwhile, crystal grains are converted into rosa-shaped structures along with pressurization, so that nearly-spherical structures are increased; and finally, all the crystal grains are converted into granular crystals, the structures are more uniform and refined in the subsequent wire drawing process, so that the strength of the copper alloy rod is improved.

Owner:JIANGXI FUHONG METAL CO LTD

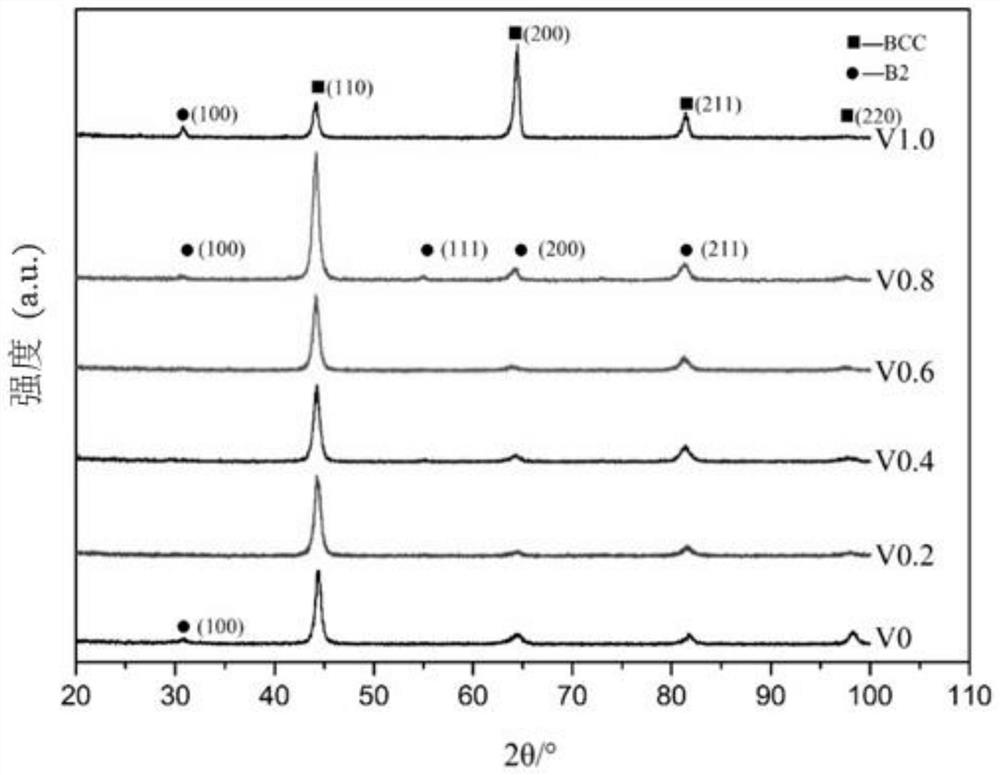

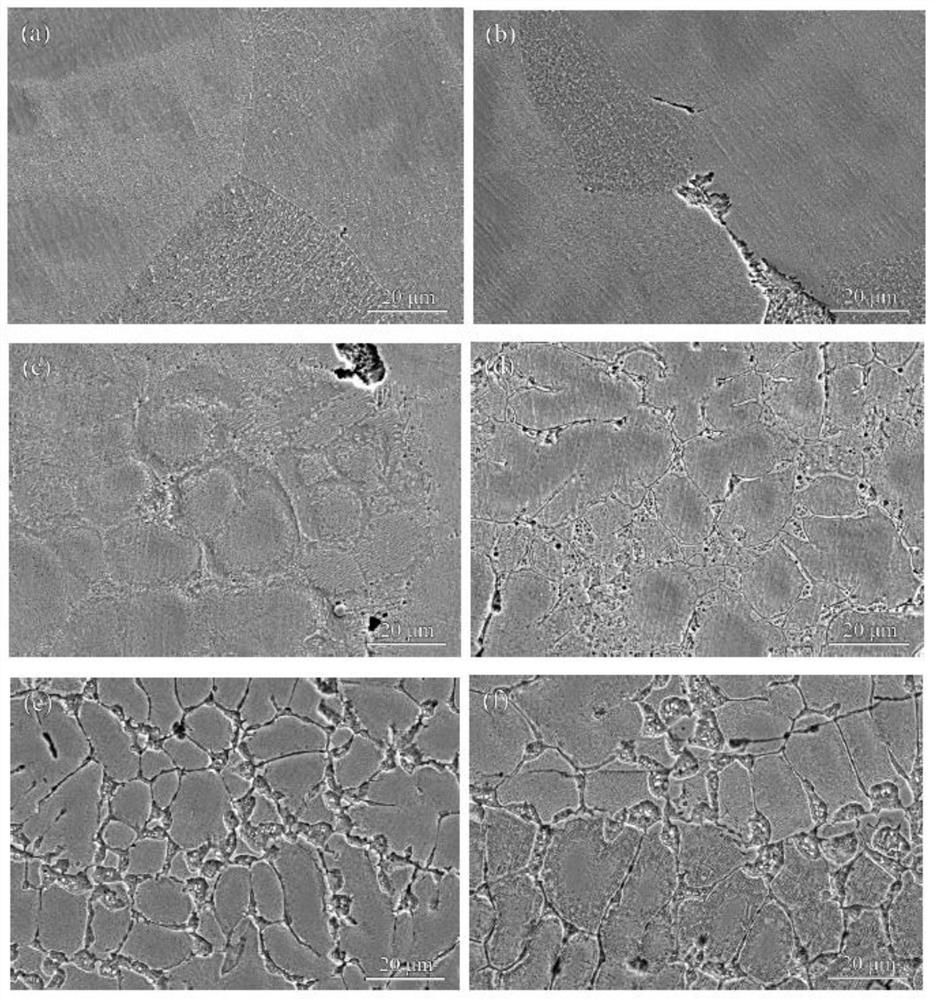

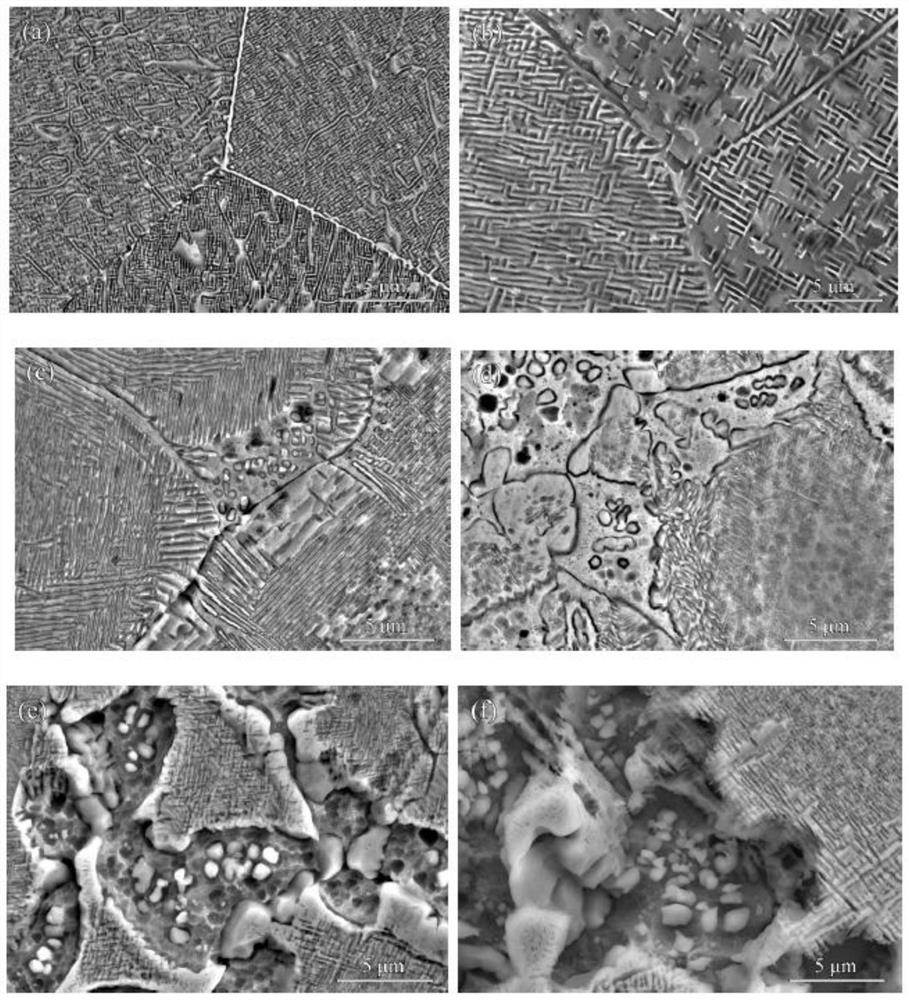

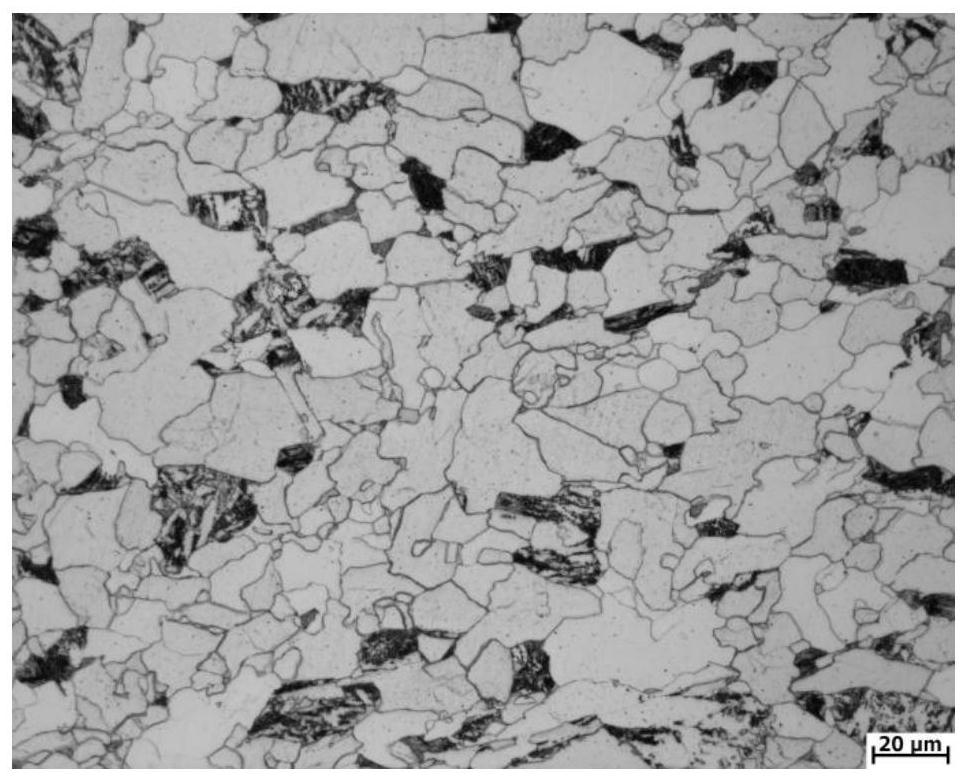

a l1 2 Precipitation-strengthened high-entropy alloy and preparation method thereof

The invention relates to the technical field of alloy preparation, in particular to a L1 2 The invention discloses a precipitation-strengthened high-entropy alloy and a preparation method thereof, which are suitable for high-strength and wear-resistant components used in service at room temperature. The L1 2 Type precipitation-strengthened high-entropy alloys are directly mixed with TiN ceramic phases in AlCoCrFeNi high-entropy alloys with a body-centered cubic structure to obtain nanostructures (Ni 3 [Al, Ti]) of AlCoCrFeNi(TiN) x High entropy alloy, x is 0.2, 0.4, 0.6, 0.8, 1.0. The present invention prepares high-entropy alloys containing ceramic phases through vacuum electric arc furnace melting technology, and obtains L1 with better toughness by adjusting the content of TiN elements in different atomic ratios. 2 type nanostructure (Ni 3 [Al, Ti]), analyze and observe the change of mechanical properties, so as to obtain the high-entropy alloy with the best comprehensive mechanical properties.

Owner:SHENYANG POLYTECHNIC UNIV

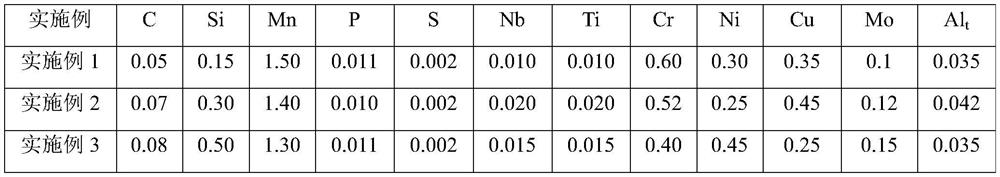

Hot-rolled weathering angle steel with good low-temperature toughness and production method thereof

The invention discloses a hot-rolled weather-resistant angle steel with good low-temperature toughness and a production method thereof, and relates to the technical field of iron and steel smelting. Its chemical composition and mass percentage are as follows: C: 0.05%-0.15%, Si: 0.15%-0.50%, Mn: 0.80%~1.50%, P: 0.008%~0.015%, S≤0.005%, Nb: 0.010%~0.050%, Ti: 0.010%~0.020%, Ni: 0.25%~0.45%, Cr: 0.40%~ 0.60%, Cu: 0.25% to 0.45%, Mo: 0.10% to 0.3%, Al: 0.015% to 0.050%. Designed with low-carbon components and delivered by controlled rolling and controlled cooling process, the hot-rolled weather-resistant angle steel products with good low-temperature toughness are obtained, with low carbon equivalent, good welding performance and corrosion resistance.

Owner:NANJING IRON & STEEL CO LTD

Oversized high-strength heatproof magnesium alloy ingot blank semicontinuous casting technique

The invention relates to an oversized high-strength heatproof magnesium alloy ingot blank semicontinuous casting technique. The alloy comprises the following components by weight percent: 6-13% of Gd, 2-6% of Y, 0.3-0.8% of Zr and the balance of Mg and irremovable impurity elements. The technique comprises the steps of melting magnesium ingots, adding solvents, adding alloy elements, refining, degassing, removing impurities, preserving heat and standing, and semicontinuously casting under the low casting speed by using a counter-pressure gas fluid-guiding method at low temperature and under low cooling speed. In the invention, technique parameters such as the casting temperature, the cooling speed, the ingot pulling speed, the inner liquid level height of a crystallizer, and the like are controlled to obtain the oversized high-strength magnesium alloy ingot blank with flat and smooth surface, refining and uniform tissue and no solute segregation, and the diameter of the ingot blank isfrom 220 mm to 505 mm. The length of the ingot is 1000-5000 mm. The invention meets the requirements for the oversized ingot blank required by high-strength heatproof magnesium alloy materials in thefields of aerospace, information electronics, communications and transportation, and the like.

Owner:CENT SOUTH UNIV

one to add ceo 2 iron-based cr 3 c 2 Laser cladding coating and preparation method thereof

ActiveCN105112909BHigh hardnessImprove wear resistanceMetallic material coating processesAlloyHardness

The invention discloses an iron-based Cr3C2 laser-cladding coating added with CeO2 and a preparation method of the coating, and belongs to the technical field of surface modification. The coating is prepared by uniformly mixing the following components in percentage by mass for laser-cladding: 65-73% of iron-based self-fluxing alloy powder, 26.5-34% of Cr3C2 alloy powder and 0.5-1% of CeO2 powder. The preparation method comprises the following steps: powder preparation; uniform mixing and drying; preparation and post-treatment of the coating. Through adoption the technical scheme, the rigidity, abrasion resistance and high-temperature oxidation resistance of the coating can be improved; besides, the forming quality and cladding property of the coating can be remarkably improved to inhibit and eliminate bubbles and cracks.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

A processing technology of chrome-zirconium-copper contact wire for high-speed electrified railway

ActiveCN111799035BIncrease profitReduce energy consumptionApparatus for heat treatmentConductive materialCopper wireElectro conductivity

The invention discloses a process for processing chromium-zirconium copper contact wires for high-speed electrified railways, which is specifically carried out according to the following steps: continuous casting of chromium-zirconium copper rod blanks by upward drawing-continuous extrusion-solution heat treatment-continuous rolling-aging heat treatment-peeling Drawing to finished products, this process not only realizes the large-length and large-unit-weight industrial production of high-speed railway chromium-zirconium-copper contact wires, but also makes the product performance more excellent. Through continuous extrusion and rolling, the material structure is further refined and uniform, and the average grain The particle size is 10-50μm, the mechanical properties of the material are further improved, the tensile strength Rm is over 600Mpa, and the electrical conductivity is over 80% IACS. It has the advantages of stable quality and high material utilization rate, breaking a new path for the localization of chrome-zirconium-copper contact wire A new way, suitable for widespread promotion.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

A kind of ultrafine grain ta material and preparation method thereof

The invention relates to an ultrafine grained Ta material and a preparation method thereof. Grain size of the ultrafine grained Ta material is smaller than or equal to 3 mu m; ultimate strength of thematerial is higher than or equal to 410 MPa, and yield strength is higher than or equal to 300 MPa. The preparation method of the material comprises the following steps: electron beam melting is performed on a Ta source, after ingot casting, an ingot is sheathed in a protective atmosphere; 3D hot-forging cogging is performed, total deformation of cogging is 65%-75%, and cogging temperature is 1150-1250 DEG C; after cogging, a sheath is removed, and low-temperature and high-temperature cross alternate rolling is performed; the ultrafine grained Ta material is obtained. The process is simple, and the prepared Ta ribbon has uniform and quite fine grains and is endowed with favorable strength, plasticity and toughness. The designed and prepared ultrafine grained Ta ribbon is applied to the high-technology fields of electronics, metallurgy, steel, chemical industry, hard alloys, atomic energy, superconducting technology, automotive electronics, aerospace, medical health and scientific research.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com