Hot-rolled weathering angle steel with good low-temperature toughness and production method thereof

A low-temperature toughness and weather-resistant technology, applied in the field of iron and steel smelting, can solve the problems of easy generation of subcutaneous air bubbles, low yield of cast slab, failure to reach and other problems, and achieve the effect of facilitating mass production, simple and easy process, and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

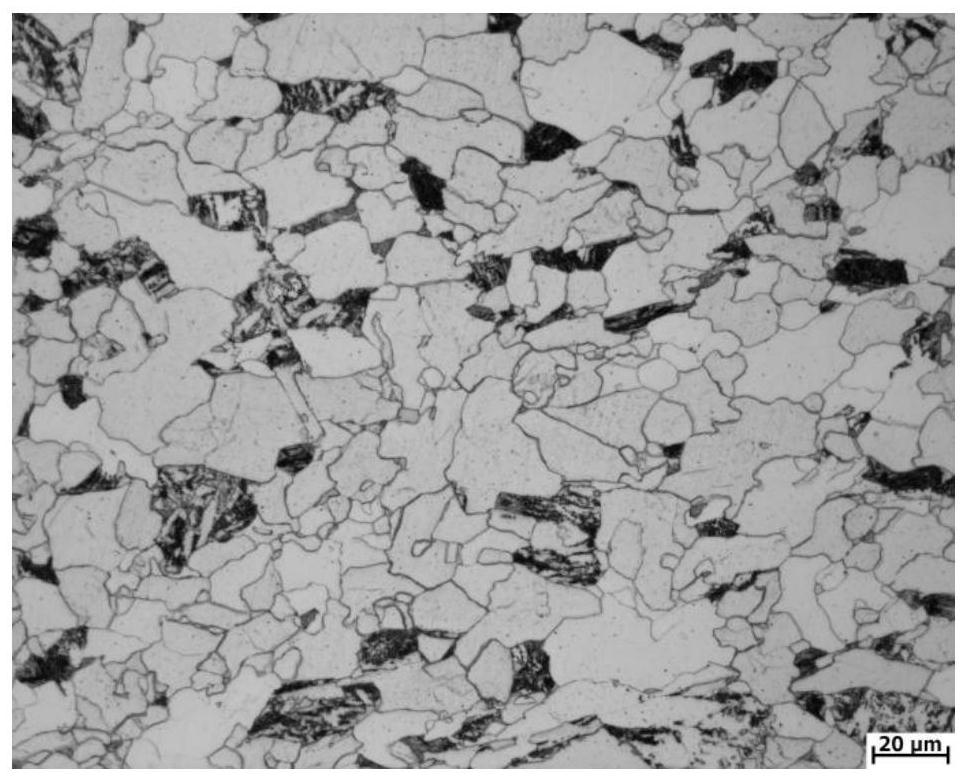

Image

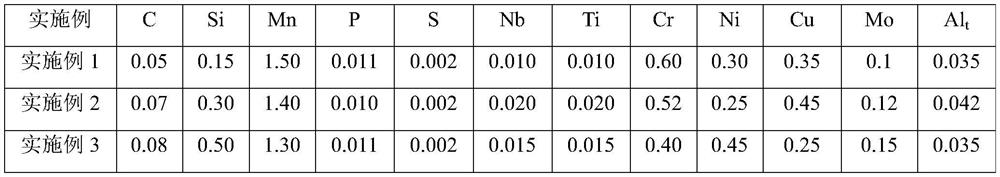

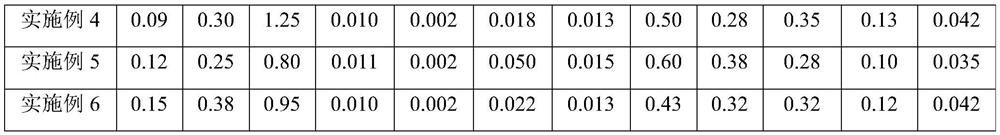

Examples

Embodiment Construction

[0023] A hot-rolled weather-resistant angle steel with good low-temperature toughness and a production method thereof, which adopt a controlled rolling and controlled cooling process, and the specific steps are as follows:

[0024] Billet heating: the billet is heated in the furnace, and the austenitizing temperature is 1240°C

[0025] One-stage rolling: the rough rolling temperature is 1080°C, and 25MPa high-pressure water is used for descaling, with 1-2 descaling steps to ensure that the iron scale is removed;

[0026] Two-stage rolling: the finish rolling temperature is 945°C; followed by laminar cooling, the reddening temperature is 735°C, and the cooling rate is 7.5°C / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com