Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

248 results about "Surface plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

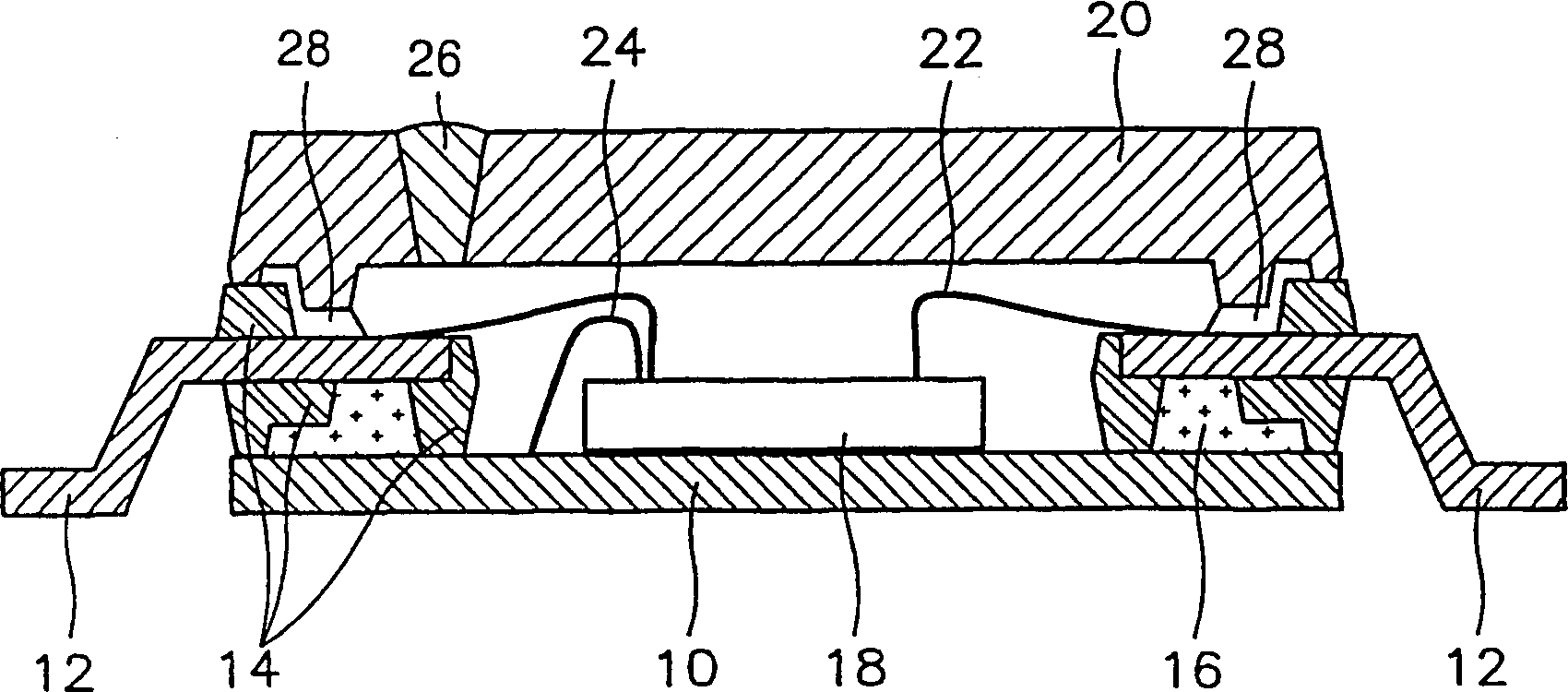

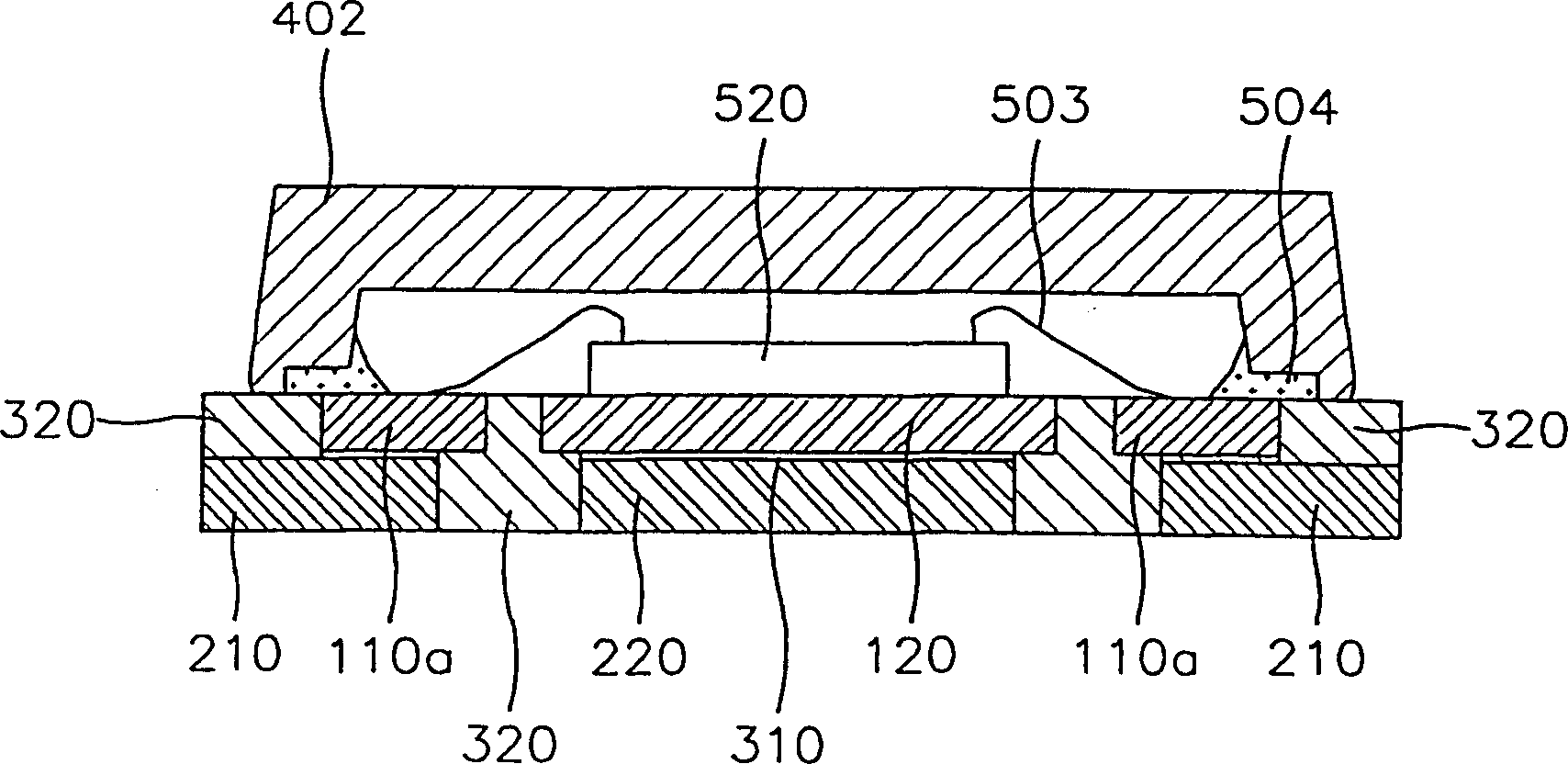

Plastic package base, air cavity type package and their manufacturing methods

InactiveCN1449583AHermetically sealedSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

Owner:SAHAVIRIYA STEEL INDUSTRIES

Method for producing vehicle-used stabilizer bar with high corrosion resistance

InactiveCN101618508AImprove surface strengthOther manufacturing equipments/toolsSurface plasticQuenching

The invention discloses a method for producing a vehicle-used stabilizer bar with high corrosion resistance, which relates to the processing technology field of metal parts, in particular to a production process of an automotive stabilizer bar. The production process comprises the following steps: blanking, bending, forging, drilling and reaming, boring, quenching and tempering, correcting, rotoblasting, phosphating, surface plastic-spraying and finally pressing into a bushing. Through the process, the corrosion resistance of the surface of the stabilizer bar is effectively improved and the service life is also prolonged. After the corrosion resistance test of 150 hours is carried out according to the method in QC / T484-1999, the spread of unilateral corrosion along the cutting does not exceed 2 mm and the check result shows that the unilateral corrosion is 1.3 mm.

Owner:YANGZHOU DONGSHENG AUTOMOBILE PARTS LTD BY SHARE LTD

Wear resistant type plastic floor and its production technology

ActiveCN1903926AGood mechanical propertiesExcellent weather and corrosion resistanceFlat articlesSpecific gravityWear resistant

The present invention relates to an abrasion-resistant plastic floor board and its production process. Said process includes the following steps: using waste and old plastic powder as main raw material, adding active calcium carbonate and plastic filling agent as auxiliary raw material, mixing them and extruding them to obtain plastic foamed granules, die-pressing and forming, cooling, setting, drawing and cutting so as to obtain the invented plastic base plate, then sticking plastic protection film on its surface, so that the invented plastic floor board finished product can be made up.

Owner:无锡市中德装饰新材料有限公司

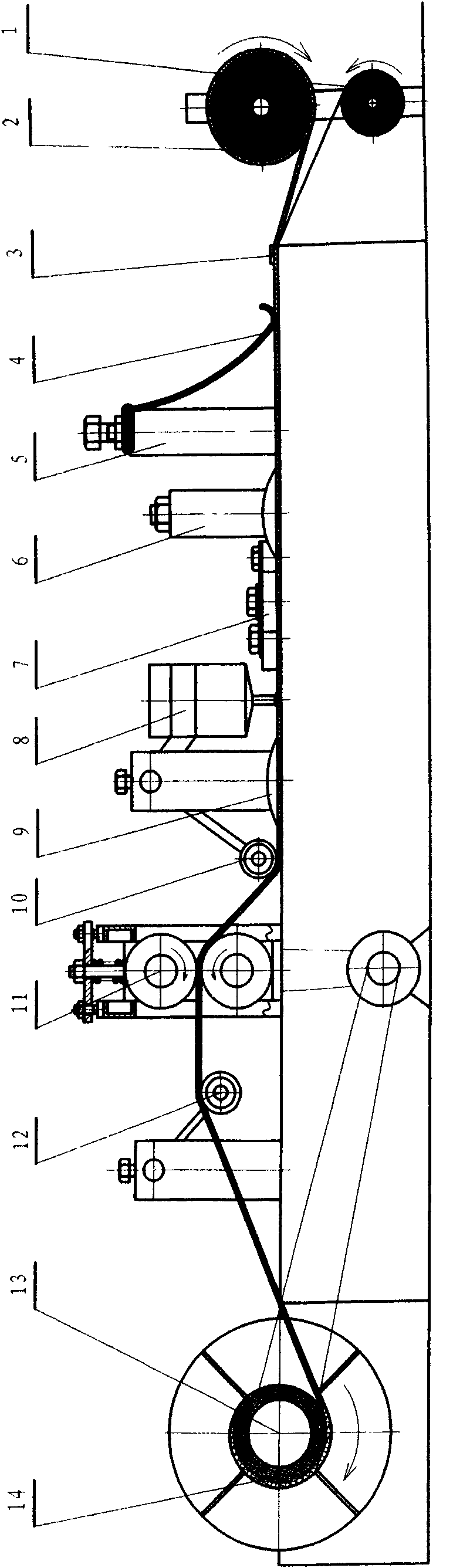

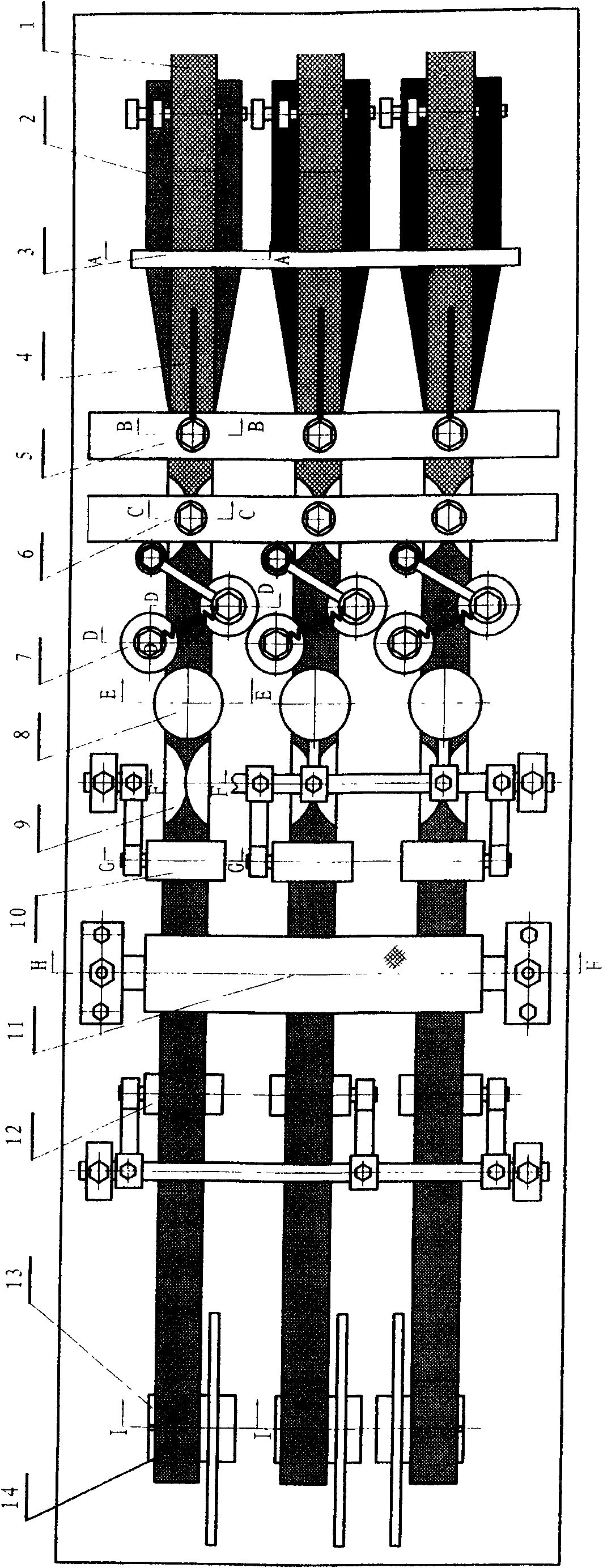

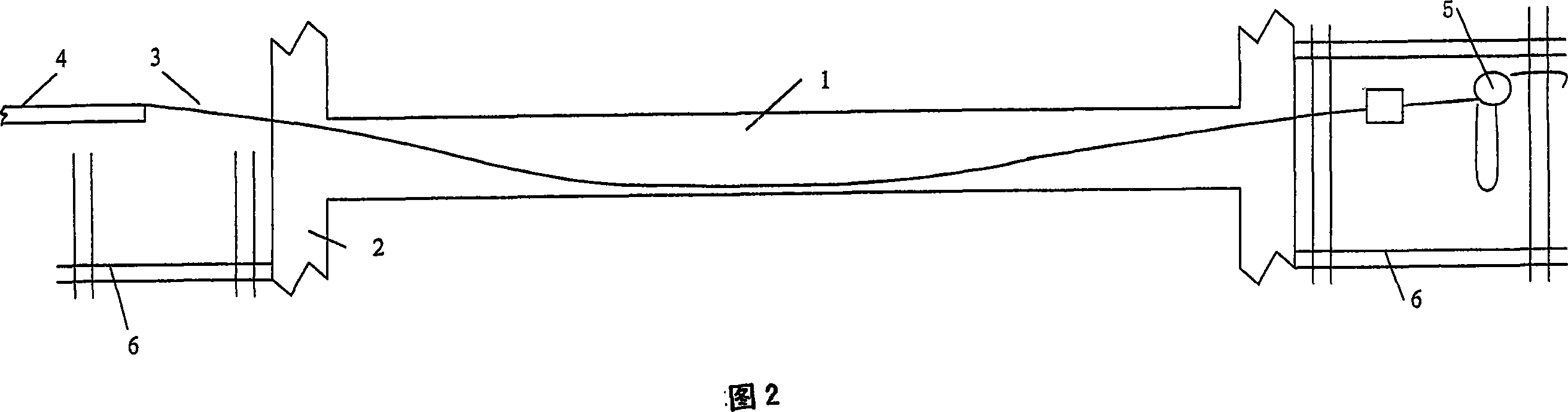

Manufacturing machine of multi-width type full-automatic plastic drainage plate

InactiveCN102649340AImprove work efficiencyReduce labor intensityLaminationLamination apparatusDrive shaftGear wheel

The invention relates to a manufacturing machine of a multi-width full-automatic plastic drain board and particularly relates to the synchronous full-automatic coating and sticking technology for the non-woven fabric of a multi-surface plastic drain board. The manufacturing machine comprises a coating device, a sticking device, a traction device, a winding device and an auxiliary device, and is characterized in that the coating device comprises a primary coating device provided with a shaped outer frame and a shaped inner frame, a secondary coating device provided with a pressure plate adjusting bolt, an inclined plane plate and a pressure plate, and an edge flattening device provided with a suspension rod, a tension spring and a pressure wheel; the sticking device comprises a rubber tube provided with an electric heater and a glue spreading nozzle, a shaping device provided with a planar plate, and a flattening device provided with a pressure roller, a cantilever and a support; the traction device comprises a traction pressure roller, an adjusting bolt, a pressure roller bracket, a spring and a gear; the winding device comprises a reeling core wheel hub, a transmission shaft, a nut, a spring and a bearing support; and the auxiliary device comprises a limiting plate, a hold-down strip, a carrier roller and a gearbox. The manufacturing machine provided by the invention has the advantages of energy conservation, high operating efficiency, low labor intensity and the like.

Owner:JIANGSU DEYING ENG MATERIALS

Conductive polycarbonate-base granules containing multi-dimensional carbon nanomaterial and preparing method and application thereof

ActiveCN106147185AEnrichment inhibitionEliminate surface precipitationElectromagnetic shieldingMulti dimensional

The invention discloses conductive polycarbonate-base granules containing a multi-dimensional carbon nanomaterial and a preparing method and application thereof. The granules comprise the nanometer multi-dimensional carbon material, a flexibilizer, a second dispersant, an auxiliary and polycarbonate, wherein the nanometer multi-dimensional carbon material is mainly formed by physical blending of nanometer conductive carbon black, carbon nano tubes and graphene. The adding amount of conductive agent in the conductive polycarbonate-base granules is small, injection molding is easy, a product formed through injection molding has excellent anti-static property or electromagnetic shielding property, and surface plastic gathering and conductive agent surface blooming are inhibited greatly or even eliminated compared with existing products.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

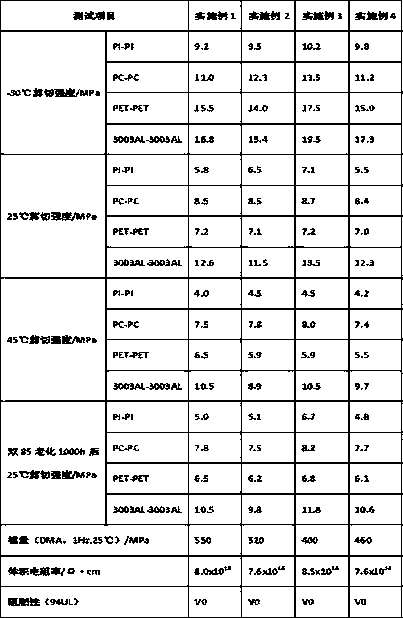

Polyurethane adhesive used for structural bonding of power battery PACK

InactiveCN109609081AImprove heat resistanceLong and smooth molecular chain structureNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyurethane adhesive

The invention relates to a polyurethane adhesive used for structural bonding of power battery PACK. The polyurethane adhesive comprises an A component and a B component, wherein a volume ratio of theA component to the B component is 1:1; the A component comprises the following materials, in parts by weight: 5-20 parts of an epoxy resin modified polyol, 15-30 parts of a benzene ring-containing polyol, 10-25 parts of a bio-based polyol, 0-3 parts of a crosslinking agent, 0-0.05 part of a catalyst, 20-35 parts of a flame retardant, 3-10 parts of a molecular sieve and 0-5 parts of a thixotropic agent; and the B component comprises the following materials, in parts by weight: 50-70 parts of an isocyanate-terminated polyurethane prepolymer, 0-20 parts of isocyanate, 18-30 parts of a flame retardant, 0.1-0.3 part of an adhesion accelerant, 3-10 parts of a molecular sieve and 0-5 parts of a thixotropic agent. The polyurethane adhesive prepared by the invention has excellent bonding propertieson untreated-surface plastic materials such as PI, PET and PC and metal materials such as aluminum, steel and alloys of the aluminum and the steel, excellent aging resistance and a lower modulus.

Owner:YANTAI DARBOND TECH

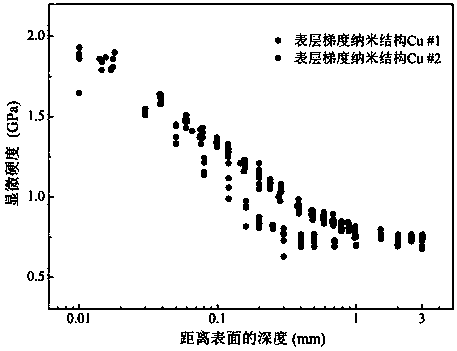

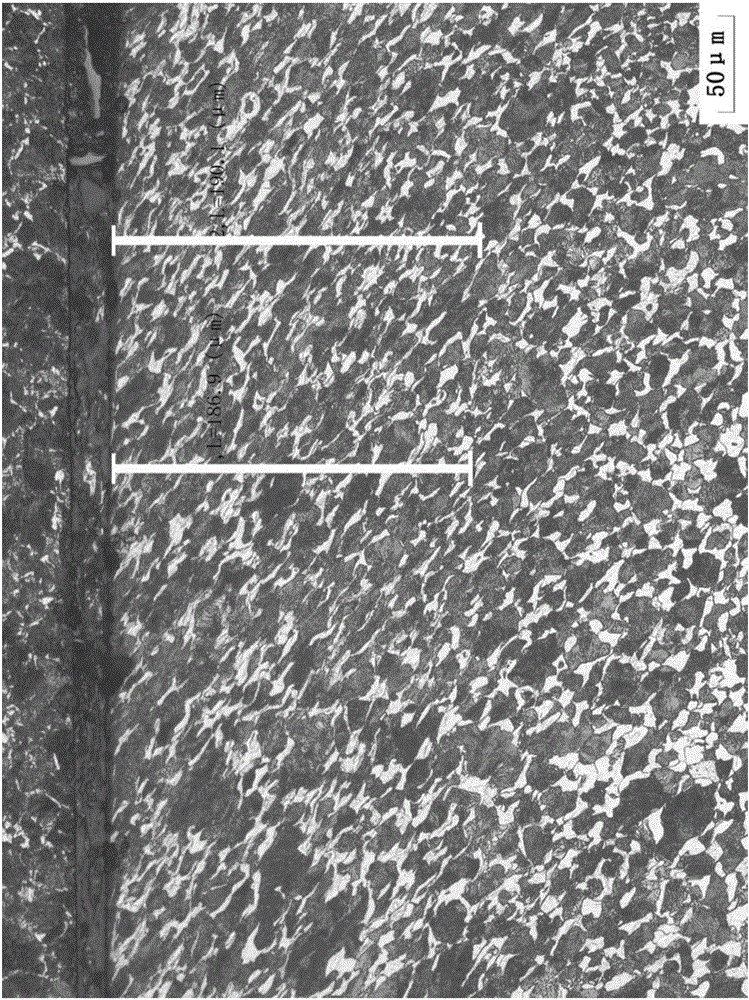

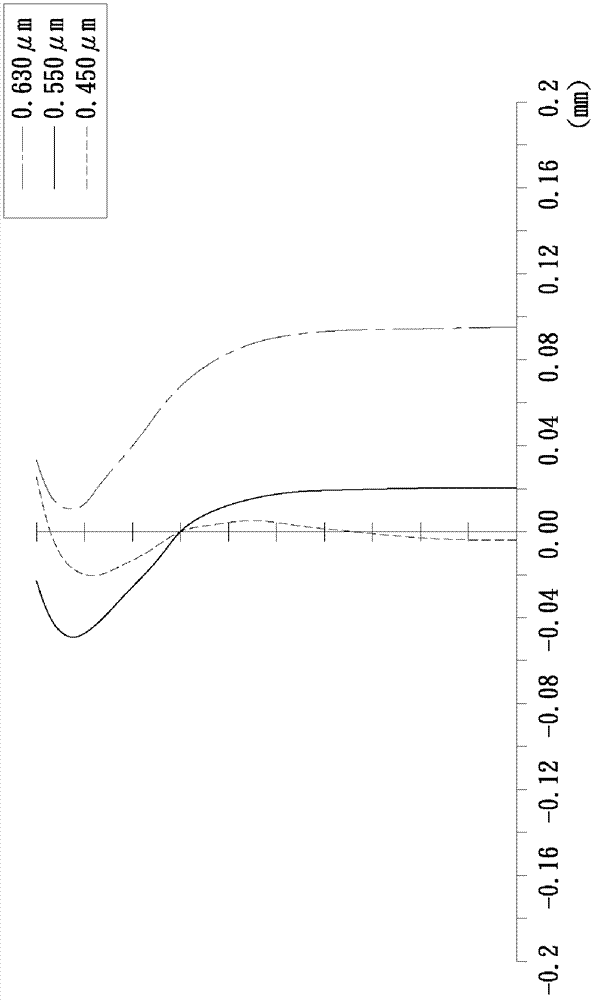

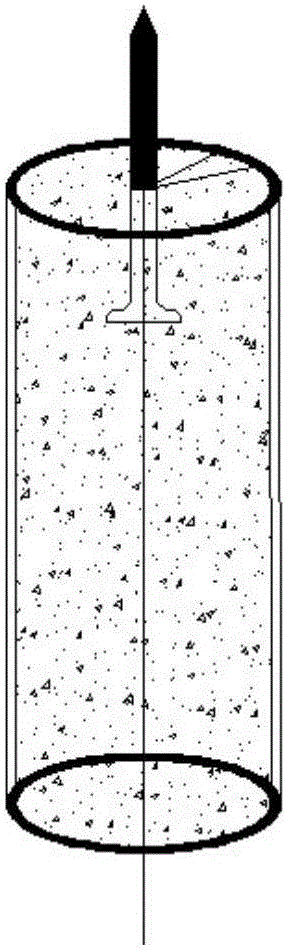

Gradient nanostructure with excellent comprehensive high cycle and low cycle fatigue performance

ActiveCN108913854AAchieve high cycleAchieve low cycle fatigue performancePerformance enhancementMetallic materials

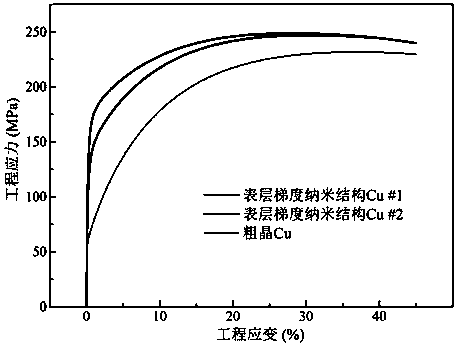

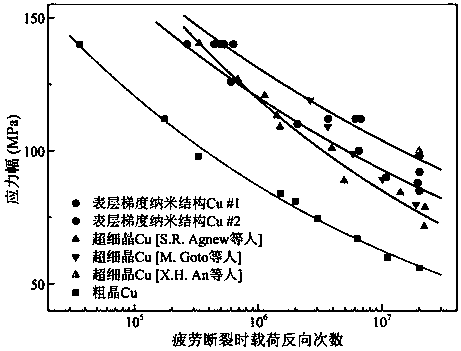

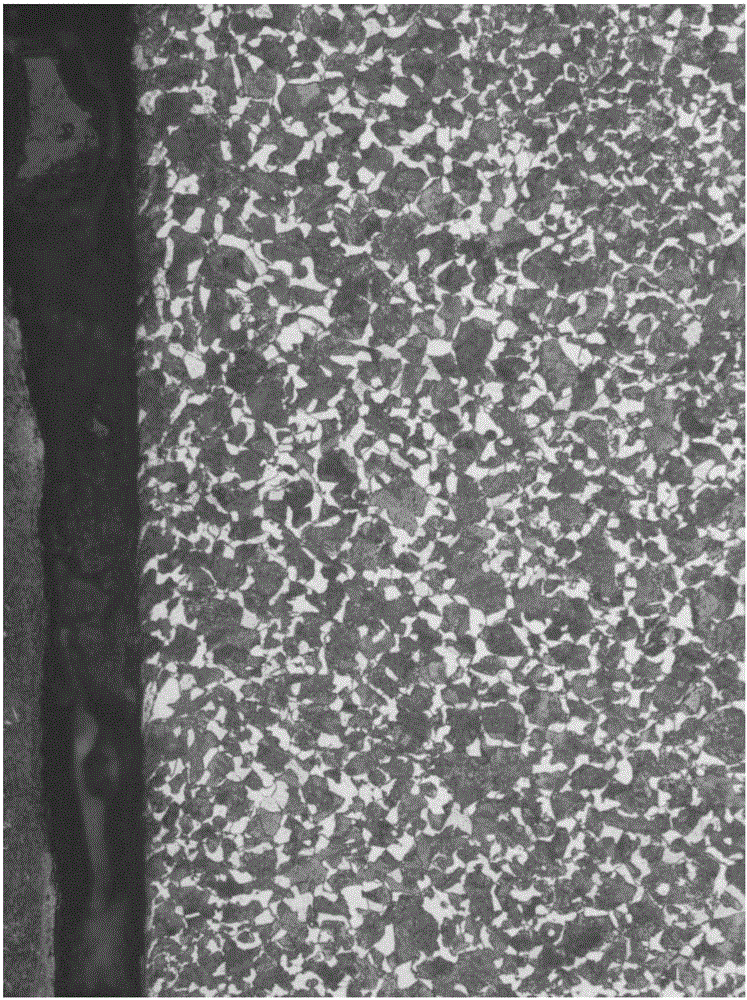

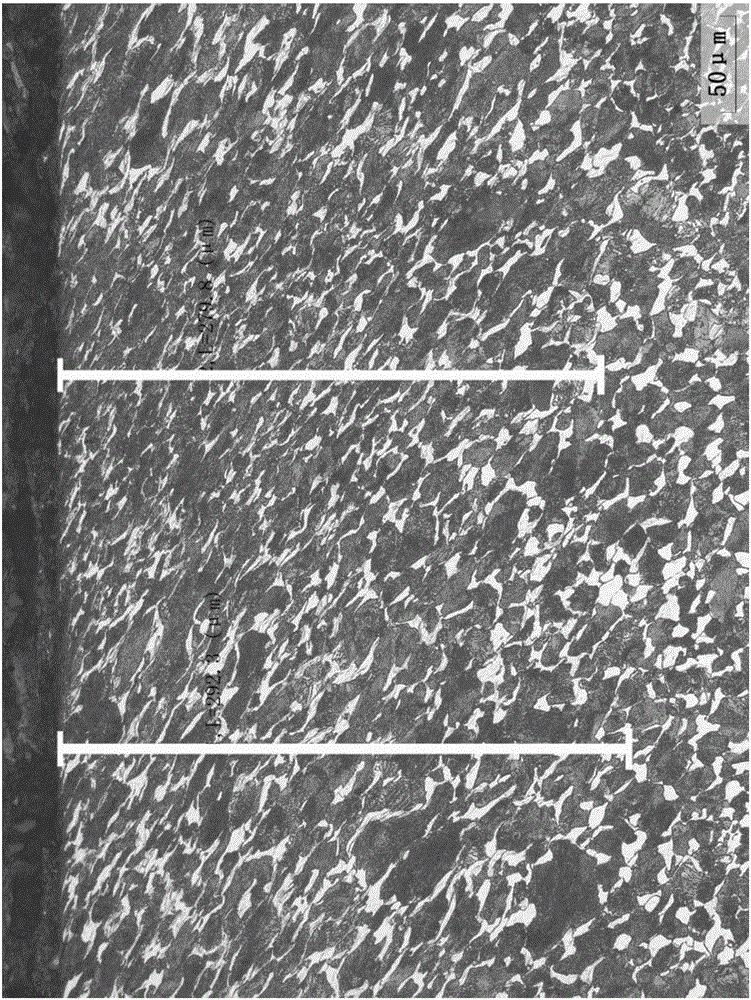

The invention discloses a gradient nanostructure with excellent comprehensive high cycle and low cycle fatigue performance, and belongs to the technical field of metal material fatigue performance enhancement. Specifically, surface plastic processing is conducted, a gradient nanostructure is introduced to the surface of a metal material, and microstructures of the metal material are an surface layer nanocrystalline structure, a subsurface superfine / deformed twin structure and a core original coarse crystal structure, wherein the overall thickness of a gradient nanostructure layer is greater than 50 microns and is within 50-300 microns. Compared with uniform coarse grain structures of the same compositions, the stress control high cycle fatigue limit of a pure-Cu sample with the surface gradient nanostructure is improved by two times, and high cycle fatigue life is prolonged by 15 times; and the strain control low cycle fatigue life is doubled compared with common coarse grain samples.According to the surface layer gradient nanostructured metal material, both the high cycle and low cycle fatigue properties of the metal material are improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Metal surface compound strengthening processing process and application thereof in locomotive wheel processing and turning

The invention provides a metal surface compound strengthening processing process. The metal surface compound strengthening processing process comprises the following operation steps of: I, coating a blocky solid lubricating agent to a surface of a turned metal workpiece; II, in the presence of trace lubricating oil, heating the surface of the metal workpiece coated with the solid lubricating agent, increasing the temperature of the surface of the heated workpiece to 300-480 DEG C, and performing ultrasonic rolling; precisely controlling dose of the lubricating oil to 10-15 ml / min; and repeating the ultrasonic rolling operation until hardness of the surface of the metal workpice reaches requirements. The invention further provides application of the composite strengthening processing process to locomotive wheel processing and turning. Surface hardness and initial wear resistance of the processed locomotive wheel are greatly improved, a surface plastic deformation layer is 250-300 [mu]m, depth of an effective hardening layer is 1.5-3 mm, and an equivalent residual stress value of a surface layer can be 270-350 MPa.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

High strength elastic metallic plastic bush and its prodn. method

The present invention discloses a high-strength elastic metal plastic bearing liner. It includes steel bearing base, on the steel bearing base a metal wire elastic pad is firmly combined, and a surface plastic layer is inlaid on the metal wire elastic pad, the described metal wire elastic pad is a disordered arranged copper-covered steel wire helical spring elastic pad. Besides, said invention also provides its production method and concrete steps.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV +1

Molding type diaphragm filtering plate and molding method

ActiveCN101249703AIncrease elasticityExtended service lifeFiltration separationSurface plasticMechanical engineering

The invention relates to a structure and a molding method for directly molding a diaphragm on the core face of a filter plate. The structure comprises a filter plate core; the filer plate core is disposed in a lower mold frame; a decomposable mold core is arranged on the diaphragm face of the filter plate core; then a plasticized plastic lump is disposed on the diaphragm; an upper mold frame and the lower mold frame are combined and cooled to form an integrated single-surface plastic diaphragm filter plate; then the single-surface filter plate is turned over and disposed in the lower mold frame; the disposable mold core is arranged on the diaphragm face of the filter plate core; the plasticized plastic lump is then placed on the diaphragm face; the upper mold frame and the lower mold frame are then combined and cooled to form an integrated double-surface plastic diaphragm filter plate core.

Owner:HANGZHOU XINGYUAN FILTER TECH

Quench hardening type easy-cutting mirror-surface plastic die steel

The invention relates to a harden quench type easy-cutting anticorrosive mirror face plastic die steel which is characterized by comprising the follow chemical compositions in percentage by weight (wt percent): 0.30 to 0. 70 percent of C, less than or equal to 1.0 percent of Si, less than or equal to 0.9 percent of Mn, 7.0 to 11.5 per cent of Cr, less than or equal to 2.5 percent of Ni, 0.03 to 0.75 percent of B, less than or equal to 1.0 percent of Cu, less than or equal to 0.1 percent of S, less than or equal to 0.04 percent of P, the balance being Fe and inevitable impurities. A metallographic structure consists of a martensite substrate and a few eutectic borides; mass fine granular secondary boron carbides are distributed on the martensite substrate and can be quenched to be hard; the hardness is between 56 HRC and 58 HRC; the harden quench type easy-cutting anticorrosive mirror face plastic die steel has easy cutting, corrosion resistance and mirror face polishing performance.

Owner:NINGBO ZHEDONG PRECISION CASTING

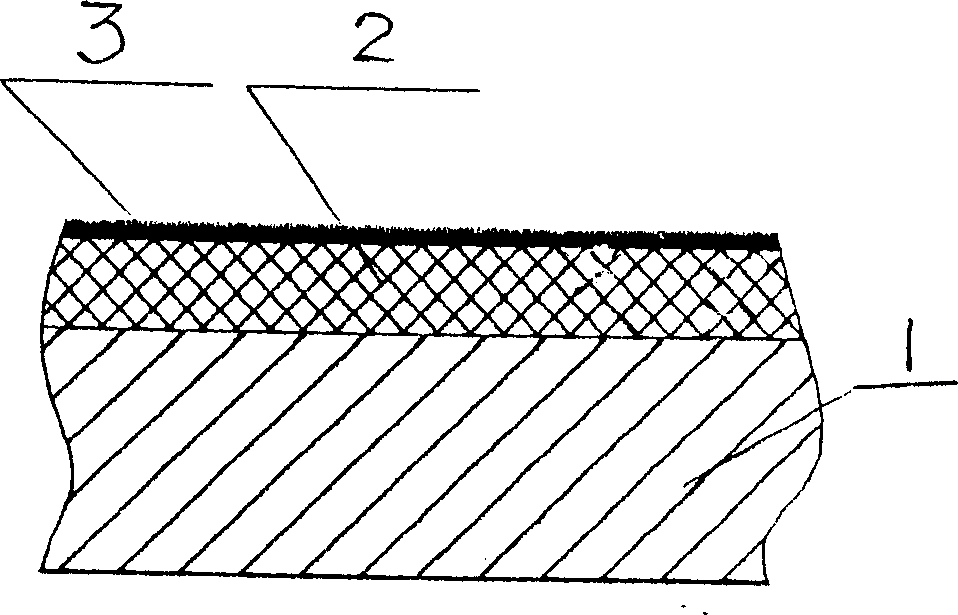

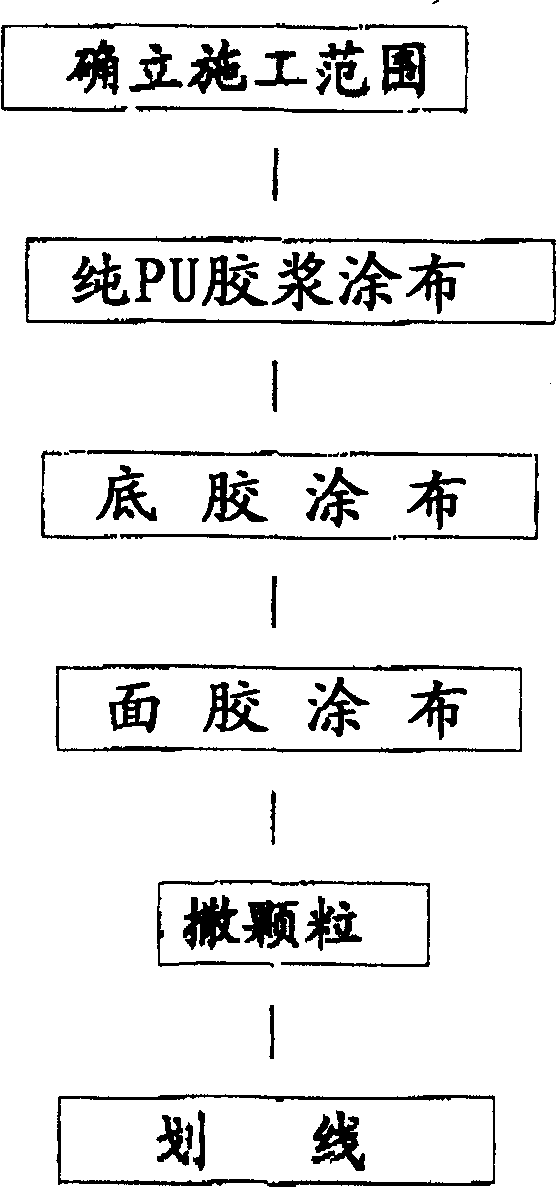

Method for building up plastic race track

InactiveCN1360110APrevent leakageAvoid delaminationGround pavingsPolyurea/polyurethane coatingsHigh surfaceEngineering

A method for paving plastic race track includes such steps as proportioning raw material, cleaning foundation, coating prime paint or pure PU size, spreading base plastics, spreading surface plastic,spraying antiskid plastic particles, recovering excess plastic particles, and drawing lines. Its advantages are uniform thickness, no seam and reflection, high antiwear nature, and high surface quality.

Owner:深圳市奥顺达实业有限公司

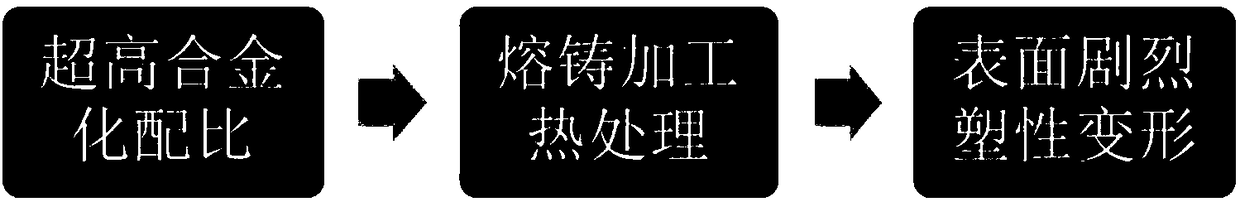

Al-Zn-Mg-Cu aviation aluminum alloy and preparation method thereof

The invention relates to an Al-Zn-Mg-Cu aviation aluminum alloy and a preparation method thereof. The aviation aluminum alloy comprises, by weight, 12-20% of Zn, 1-3% of Mg and 1-2% of Cu. The Al-Zn-Mg-Cu aviation aluminum alloy comprises a core part and a surface plastic deformation layer, wherein the core part is provided with an aging-separated nanocrystalline strengthening phase, and the surface plastic deformation layer is a homogenized solid solution structure which is obtained through severe plastic deformation of the surface. The preparation method comprises the following steps that after the components are distributed according to a design group, casting is carried out, a cast ingot is obtained, and the cast ingot is subjected to homogenization treatment, thermal deformation treatment, solid solution treatment and aging treatment in sequence; materials after aging treatment are obtained, and the materials are taken as materials A; and impurities on the surfaces of the materials A are removed, and the surface severe plastic deformation is carried out; and the Al-Zn-Mg-Cu aviation aluminum alloy is obtained.

Owner:CENT SOUTH UNIV

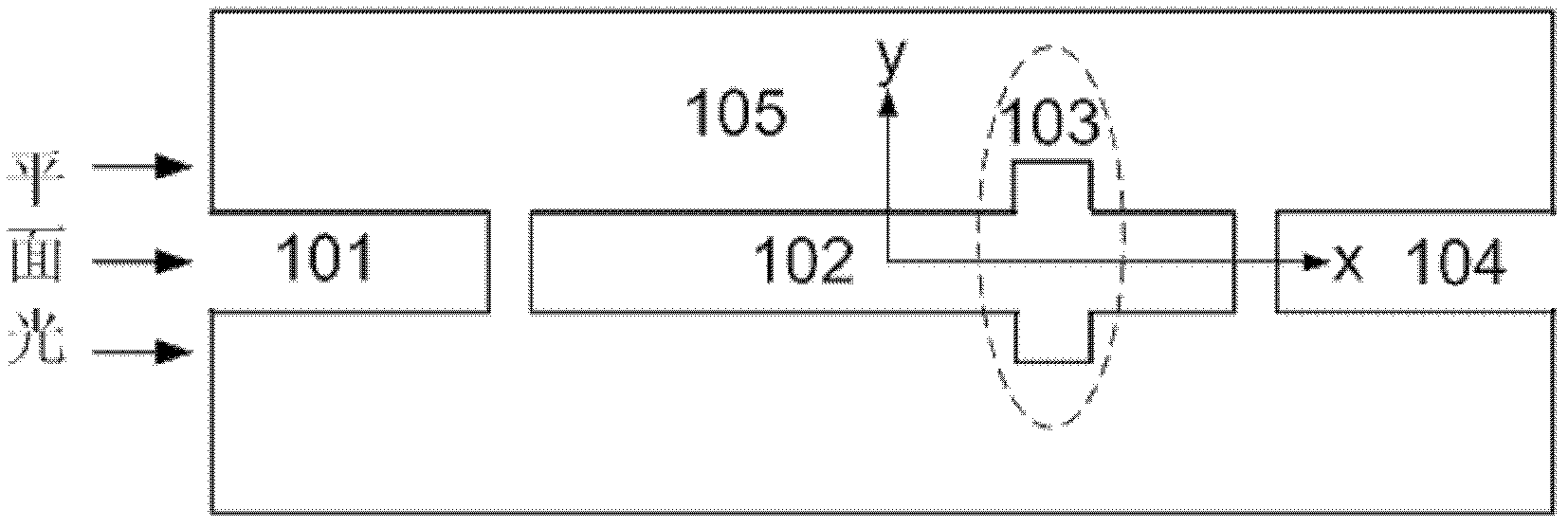

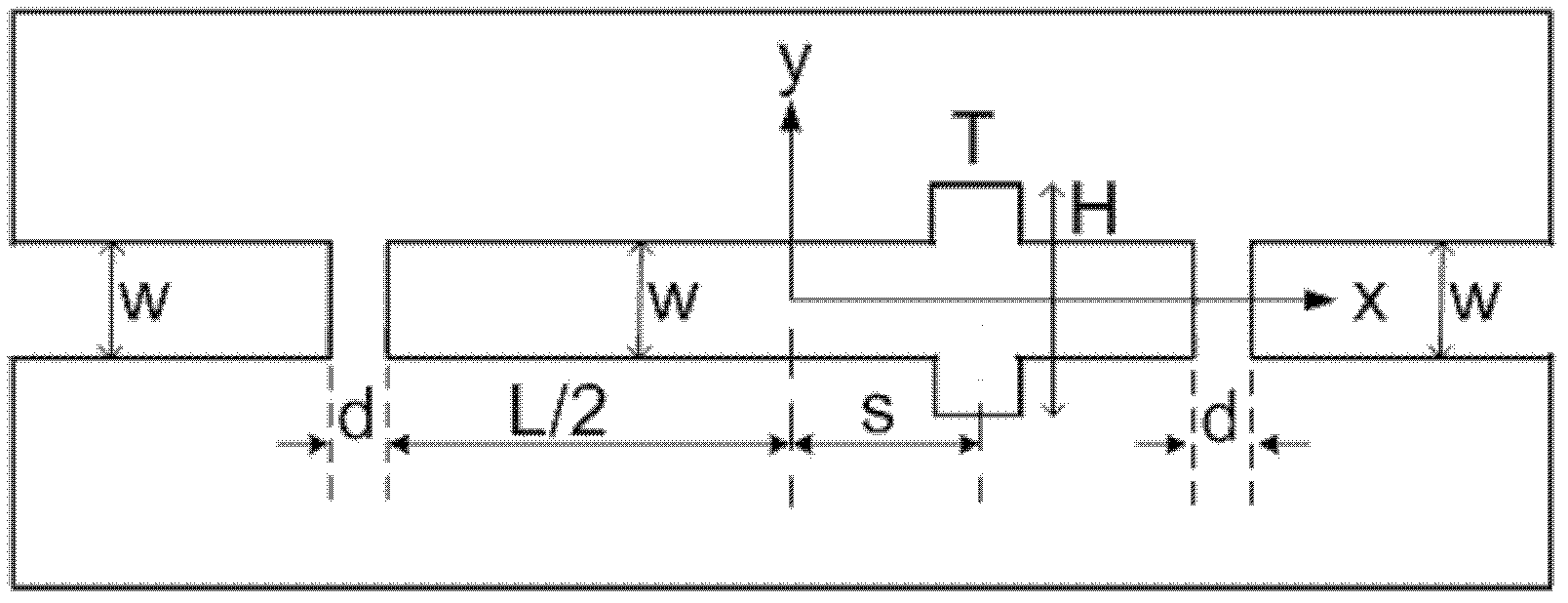

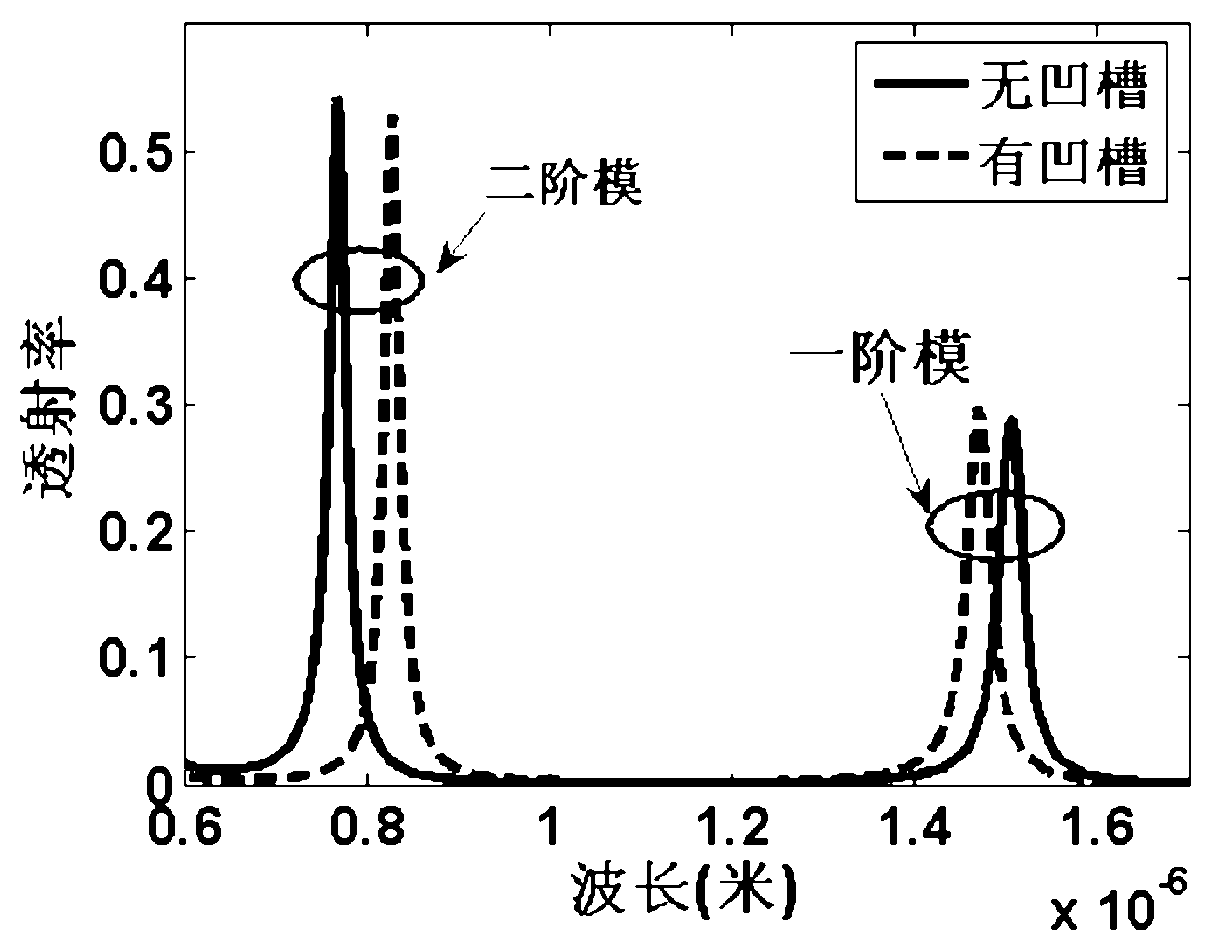

Method for regulating free spectral range by equilong rectangular cavity surface plasma band pass filter

InactiveCN102608707AFlexible and adjustable free spectral rangeEnables a wide range of tuningOptical light guidesBand-pass filterLength wave

The invention discloses a method for regulating a free spectral range by an equilong rectangular cavity surface plasma band pass filter. The method comprises the steps of: changing the position of a groove (103) in a rectangular cavity (102) under the condition of unchangeable length of the rectangular cavity (102) for realizing the flexible and adjustable free spectral range; and changing the position of one peak wavelength by adopting a geometrical parameter selectivity of the groove (103) under the condition that the groove (103) is in some special positions so as to realize the flexible and adjustable free spectral range of a filter. According to the invention, on the basis of ensuring that the surface plastic filter is realized, the flexible and adjustable free spectral range of the filter is realized, and the flexibility of a photon integrated loop is enhanced.

Owner:闫连山 +1

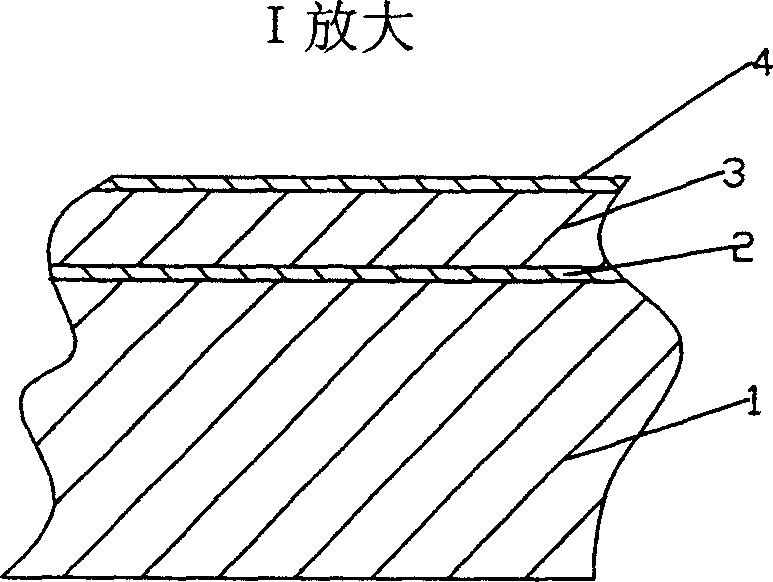

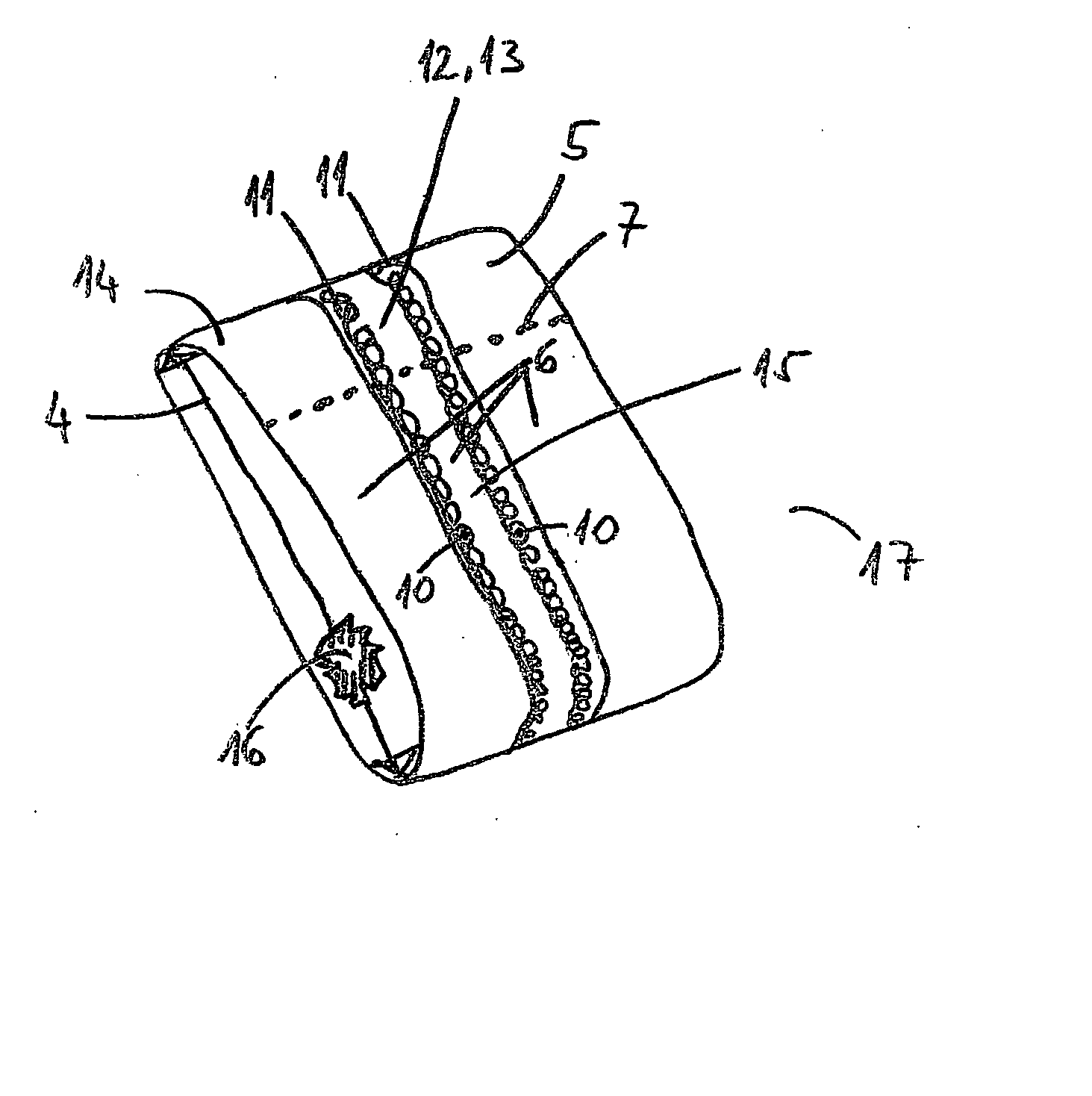

Packaging Methods And Packaging Matreials For Fine Powders

A method for treating a package. In the method a first plastic film sack (14) is provided, that has a flexible wall (18) comprising a plastic film (3), the wall (18) having an outer surface (5). A second plastic film sack is provided. A product of powder form is provided that has an upper size limit which is the particle size smaller than 1 mass-percent of the particles of the product of powder form, which upper size limit is at most 5000 microns and a lower size limit which is the particle size bigger than 1 mass-percent of the particles of the product of powder form. The product of powder form is packed in the first plastic film sack (14), and the first plastic film sack is, at least partly, placed upon the second plastic film sack. According to the invention, such a first plastic film sack is provided in which at least a part of the outer surface (5) of the flexible wall (18), the roughened surface-part (6), comprises antislip protrusions (7) which antislip protrusions (7) are constituted by roughening particles, of polymer material, fixed to the outer surface (5) and the height (8), above the outer surface (5) of the plastic film wall, of at least a part of the antislip protrusions (7) is bigger than the lower size limit of the product of powder form.

Owner:MANDZSU SR JOZSEF +2

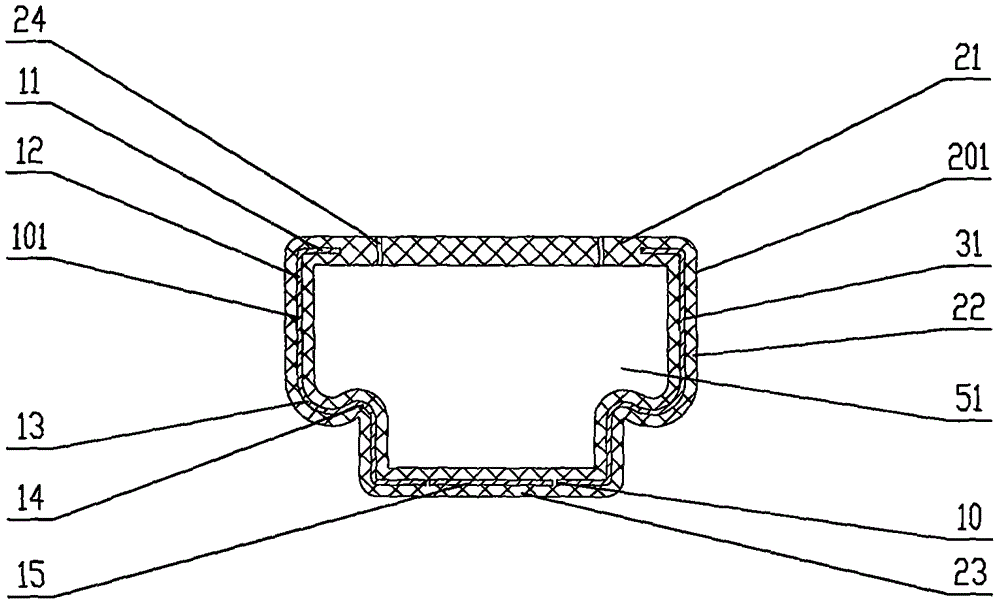

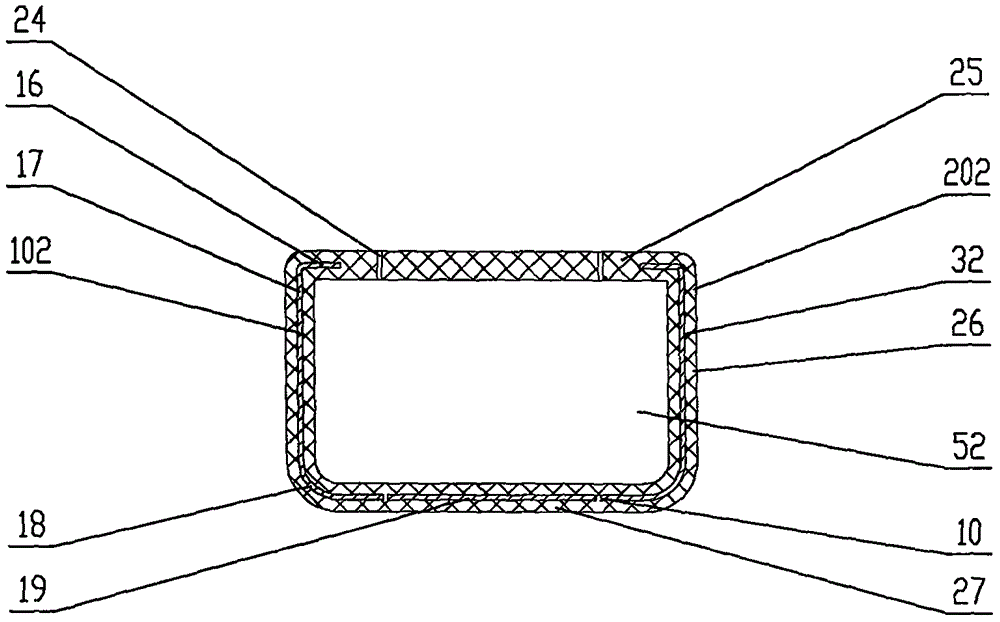

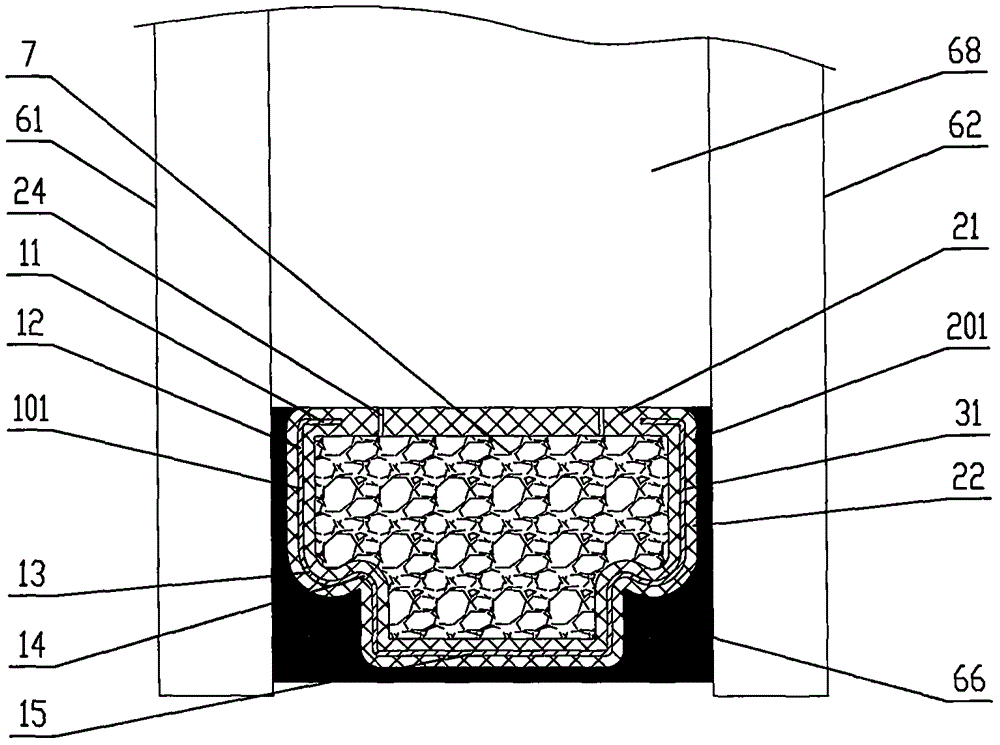

Hollow glass heat insulating strip and hollow glass

The invention discloses a hollow glass heat insulating strip and hollow glass which are mainly used for manufacturing hollow glass doors and windows and curtain walls for building heat preservation. The hollow glass heat insulating strip comprises a plastic layer, transition layers and a metal layer; the metal layer is a long strip-shaped U-shaped strip of which the upper end is provided with upper bending sections; a buffer region is a connection part of a bulging circular arc A and a recessed circular arc B or a bulging circular arc C part; solvent degreasing treatment or plasma surface degreasing treatment is performed on the metal layer before the transition layers are applied to the metal layer; the transition layers are respectively applied to the inner surface and the outer surface of the metal layer; the plastic layer wraps the transition layers; the plastic layer and the metal layer are bonded together by the transition layers. A moisture absorption molecular sieve is put in a space part of the hollow glass heat insulating strip of the hollow glass; the hollow glass heat insulating strip and cohesive glue are arranged along the circumferential edge of the glass; inert gas fills in a hollow part; the hollow glass is obviously increased in heat insulating property, sealing property and weather fastness.

Owner:DALIAN HUAGONG INNOVATION TECH

Process for manufacturing steel-plastic composite steel belt

InactiveCN101428274AImprove adhesionQuality improvementPretreated surfacesCoatingsHigh pressureHigh voltage

The invention relates to a method for manufacturing a composite plastics-steel steel strip used for package. The steel strip is manufactured through the following steps: conducting the bluing treatment on the steel strip, cooling the steel strip after the bluing treatment, delivering into a high voltage electrostatic plastic-spraying device for the surface plastic spraying, and cooling the steel strip for the shaping after the surface plastic spraying. The invention has the beneficial effects that (1) the technological process is simple, the operation is convenient and controllable, the equipment investment is low, and the popularization and the application are facilitated; (2) the residual heat generated by the induction heating blueing is fully utilized to conduct the plastic spraying during the manufacturing procedure, an integrated continuous production is formed and the energy consumption is saved; (3) the plastic spraying is conducted in an enclosed generator, about 80 percent of the plastic powder ejected by a spray gun is attached to the surface of a steel plate, the residual powder is collected for the reutilization, so that the raw material is effectively saved, and the production environment is cleaned; and (4) the plastic spraying adopts high-pressure electrostatic adsorption principle, the quality of a coating layer is high, the coating layer is beautiful, the bonding power is high, and the production efficiency is high.

Owner:武汉市江夏区江南实业有限公司

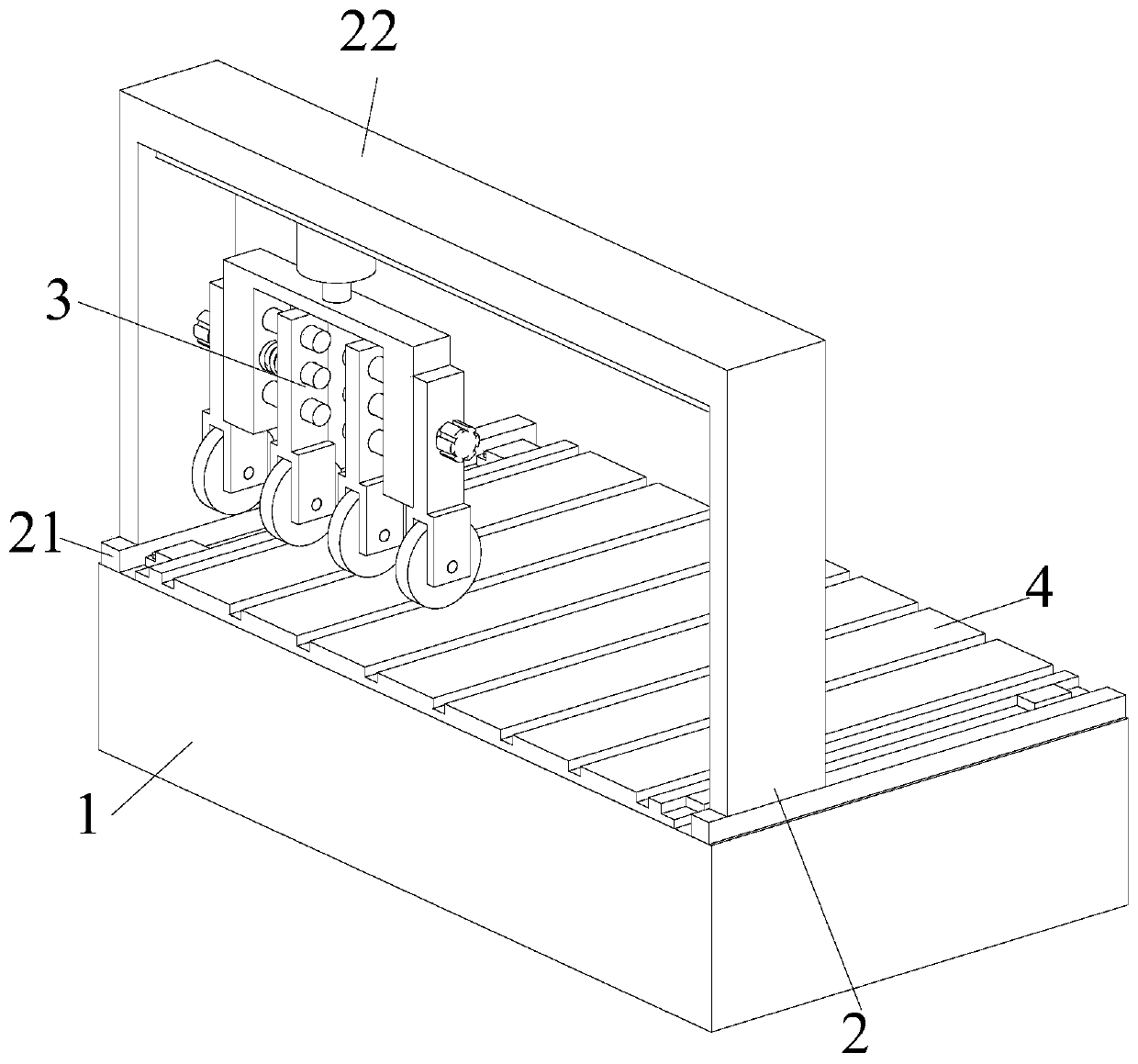

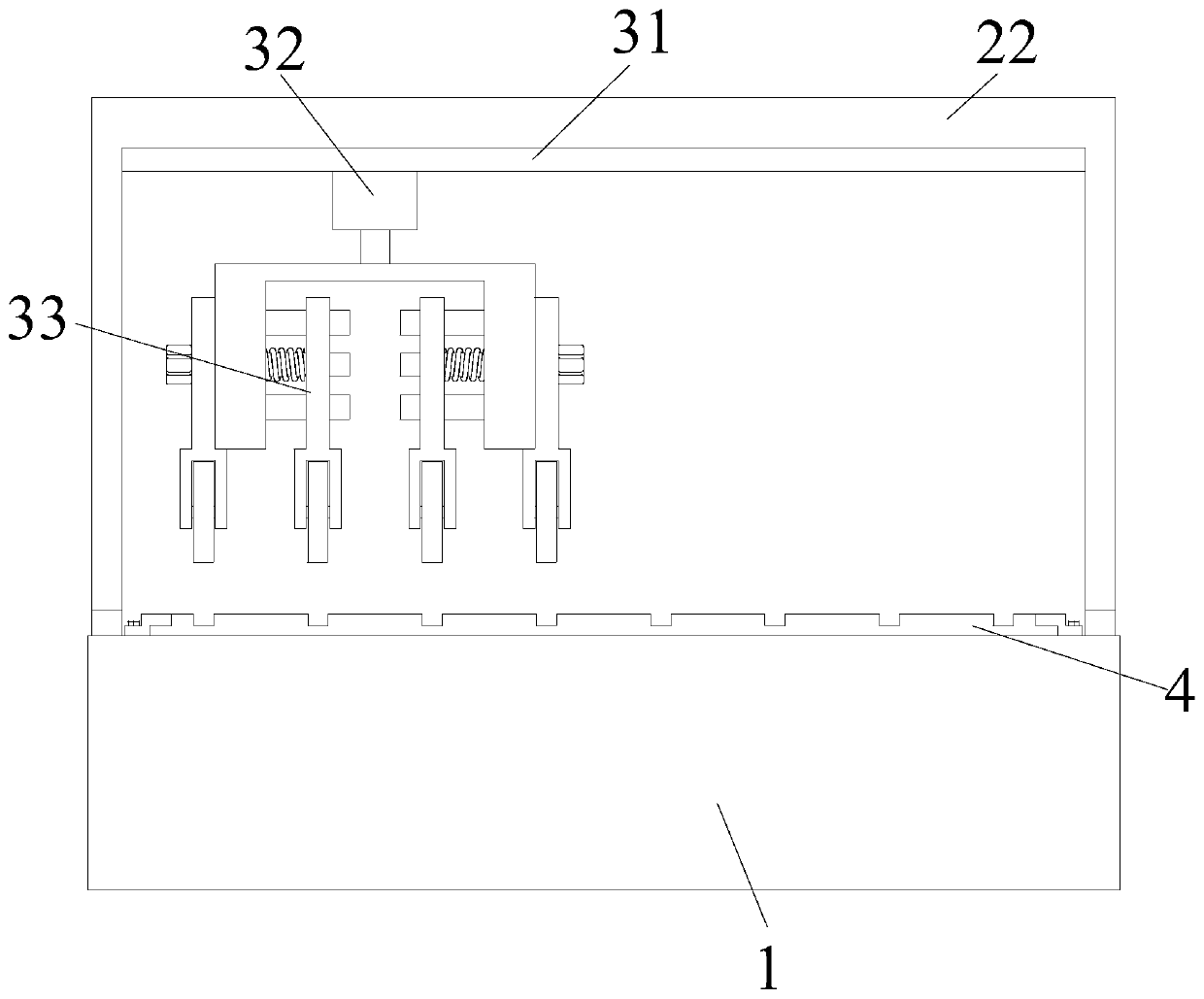

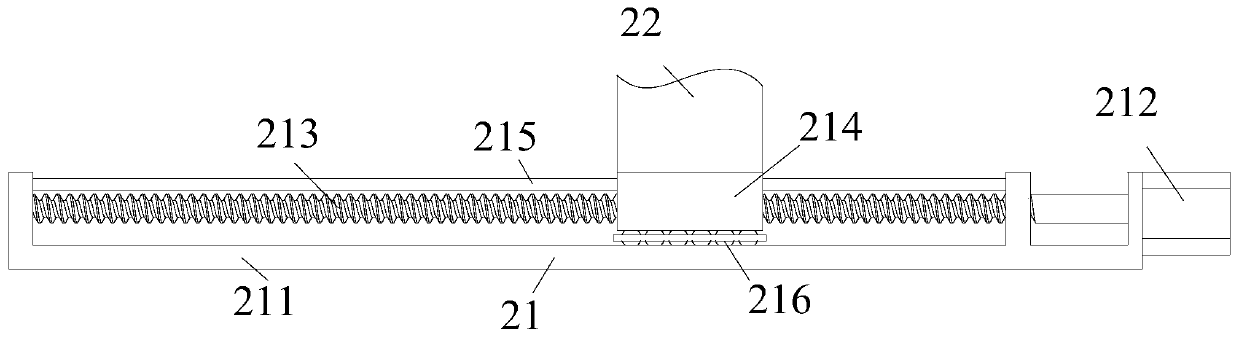

Workpiece surface plastic deformation rolling device and using method thereof

ActiveCN110538910AImprove processing efficiencyAvoid rust-prone situationsShaping toolsSheet steelWave shape

The invention relates to a workpiece surface plastic deformation rolling device and a using method thereof. The device comprises a workbench, a moving device, a rolling device and a lower die plate, the moving device is mounted at the upper end of the workbench, the rolling device is arranged inside the moving device, the lower die plate is mounted at the upper end of the workbench in a threaded connection mode, and the lower die plate is located in the moving device. According to the workpiece surface plastic deformation rolling device and the using method thereof, the problems that when existing color steel tile machining equipment is used for machining a steel plate, the color steel tile only can be formed through rolling of five to six times usually during rolling machining of one color steel tile, the forming process is tedious, the machining efficiency is low, in the case of the existing color steel tile machining equipment, one piece of rolling equipment usually only can be usedfor machining the color steel tile with one wave shape, and the surface of the steel plate is prone to be scratched in the rolling machining process of the color steel tile, so that the surface of the color steel tile is prone to be rusted can be solved.

Owner:TAIZHOU SRUITE IMP &EXP CO LTD

Soft magnet ferrite magnetic ring surface plastic coating method

InactiveCN1410171AEffective burialHigh qualification rate of plastic coatingPretreated surfacesInductances/transformers/magnets manufactureMetallurgySoft magnet

A method for coating plastics on the surface of soft magnetic ferrite ring features the plastic coating technology including powder spraying twice and thermosetting twice is used, and the additional powder is supplemented to the upper and lower end faces of magnetic ring for increasing its thickness. Its advantage is high voltage withstanding of ferrite ring (more than 200V).

Owner:祁关泉

Non-water-seepage type particle-surface plastic track

The invention relates to a plastic track, in particular to a non-water-seepage type particle-surface plastic track, and aims to solve the technical problems in the prior art. According to the technical scheme, the non-water-seepage type particle-surface plastic track comprises a base layer, a PU primer and black particle mixed layer and an EPDM particle and PU glue solution mixed layer. The construction method of the non-water-seepage type particle-surface plastic track includes: sweeping an asphalt concrete foundation and a cement concrete foundation; well mixing mixed polyurethane adhesives, catalysts and black particles, laying the mixed materials on the foundation layer, laying curing agent to cure the laid materials, and defoaming; well mixing track finish paint with EPDM particles 1-3mm in diameter, and spraying the mixed materials on the PU primer and black particle mixed layer. The non-water-seepage type particle-surface plastic track is capable of being used in all weather, capable of reducing impacts, good in wear resistance, good in weather resistance, good in nail resistance, and widely applicable to schools of different levels and kinds and professional stadiums.

Owner:GUANGZHOU SHENGBANG SPORTS GROUND MATERIAL CO LTD

Solid wastes die pressing composite method for manufacturing new pattern building board

InactiveCN1621637AHigh surface finishConstruction materialSolid waste managementSurface finishWear resistant

The present invention is molding and combining method of making building board with solid waste. Wood dust and waste plastic are kneaded to form wood-plastic composite, waste plastic and flyash are kneaded to form plastic-flyash composite, and the composite board with one middle wood-plastic composite layer and two surface plastic-flyash composite layers is then produced through molding. The composite board product has compression strength of 22-36 MPa, bending strength of 15-28 MPa, bending modulus of 450-980 MPa, breaking elongation of 80-300 %, oxygen index not lower than 25 and use temperature range of -20 deg.c to +55 deg.c, and is mildew-proof, antiageing, wear resistant, corrosion resistant, hydrophobic and smooth. When used as building formwork, the composite board may be used for over 50 times.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Photostudio with turntable driving mechanism

The invention discloses a photostudio with a turntable driving mechanism. According to the photostudio with the turntable driving mechanism, a power source (such as a motor) drives a timing kit belt wheel, and more than two timing kit belt wheels are driven to contact with the side surface of a turntable with more than two points through one timing kit belt so as to increase the friction force and reduce slipping once multi-point synchronous starting and braking to stop occurring. The photostudio is formed by arranging a laminated material placing platform on a transparent glass plate or a transparent plastic plate, and covering another half transparent curved-surface plastic plate; and a light set can be arranged at the bottom of the laminated material placing platform so as to achieve the effect of shooting without shadow.

Owner:ORTERY TECH

Sealing method of steel-frame reinforced plastic composite pipe

The invention discloses a sealing method of a steel-frame reinforced plastic composite pipe, comprising the following steps: grinding the end surfaces to be smooth, removing a pipe material (1), a plastic pre-heating ring (2) and a plastic sealing ring (4) of an oxidation layer, installing on a welding machine and clamping and keeping the end surfaces to be aligned; using a milling cutter to millthe end surfaces of the sealing ring to be melted; installing a heating plate (3) between the plastic pre-heating ring (2) and the plastic sealing ring (4), and applying pressure of 0.15MP; heating the heating plate (3), releasing pressure when the temperature of the steel-frame composite pipe end surface plastic is 210+ / -10 DEG C, and drawing the heating plate (3) fast; stably closing the pre-heating ring and the sealing ring; and disassembling the clamp after the cooling nominal wall thickness / 2 of the melted areas adds ten minutes, and taking out the pipe material. The stability of sealingquality of the pipe material and the leakproofness of the pipe system are respectively and obviously improved, the used staffs and the equipment in the procedure of sealing are obviously reduced, thusleading the sealing cost of the pipe material to be obviously reduced.

Owner:DAQING PETROLEUM ADMINISTRATION

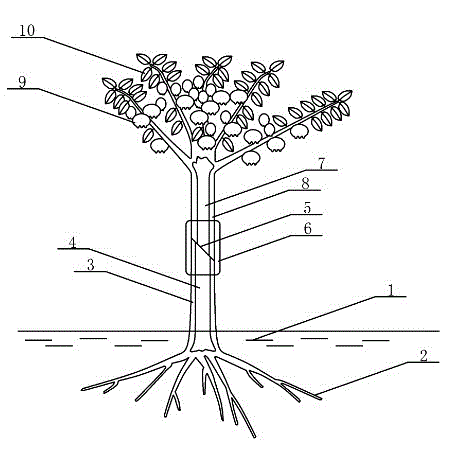

Growth-promoting adhesive sleeve stem stuck around the joint between oriental blueberry truck and grafted blueberry shoot or branch

The invention relates to a growth-promoting adhesive sleeve stuck around the joint between an oriental blueberry stem stock and a grafted blueberry shoot or branch, which belongs to the technical field of emerging applications of fruit trees. An oriental blueberry is planted in suitable soil, the root system of the oriental blueberry grows in the soil and absorbs moisture and nutrient, the upper end of the stem of the oriental blueberry is cut into a slope, the lower end of a chosen blueberry stem as thick as the stem is cut into a slope, the xylems and phloems of the slopes of the two stems need to be tightly butted as the slope of the oriental blueberry stem is butted with the slope of the blueberry stem, the growth-promoting adhesive sleeve is stuck around the butt joint between the slopes, i.e., a surface plastic protective film of the growth-promoting adhesive sleeve is first torn off, a middle adhesive layer attached on a bottom air-permeable fabric layer is stuck around the joint along with the bottom air-permeable fabric layer, auxin and nutrient elements contained in the adhesive can permeate onto the slopes to promote the healing of the cambium of the stock and the graft, and thereby the survival rate of the blueberry shoot or branch grafted on the oriental blueberry stock can be increased.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Method for producing elastic metal-plastic axle bush

ActiveCN1850413APrevent oxidationImprove compound precisionSoldering apparatusSolderingSurface plastic

The present invention discloses a production method of elastic metal plastic bush. It is characterized by that said production method includes the following steps: on the metal wire elastic pad making bush surface in which a surface plastic layer is inlaid; placing the bush surface in a closed container, under the condition of that vacuum degree is 6-15 Pa soaking the metal wire elastic pad in liquid soldering material to make the soldering material be filled into pores in the metal wire elastic pad, then soldering the bush surface containing soldering material on the steel bush base.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV +1

Environment protection elastic metallic plastic bush

The present invention discloses an environment-protecting type elastic metal plastic bearing liner. It includes steel brearing base, on the steel bearing base a metal wire elastic pad is firmly combined, on the metal wire elastic pad a surface plastic layer is inlaid, the described surface plastic layer is made of modified polytetrafluoroethylene powder material, said powder material is prepared by using (by wt%) 2-8% of aramid fibre, 20-30% of polyphenyl ester or polyimide and the rest is polytetrafluoroethylene.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV +1

Zoom projection lens

The invention relates to a zoom projection lens. The zoom projection lens comprises a first lens group and a second lens group which are sequentially arranged from an object end to an image end of the lens, the first lens group has a negative refractive index and is composed of a first lens, the second lens group has a positive refractive index and is composed of a second lens, a third lens, a fourth lens and an aperture stop which is located between the second lens and the third lens, the first lens is an aspheric surface plastic lens, and the third lens or the fourth lens is an aspheric surface glass lens. The zoom projection lens satisfies the relationship that 1.463<| tt / lt | <1.505, wherein tt represents the total length of the zoom projection lens, and lt represents the length of the zoom projection lens; and the zoom projection lens is only composed of four lenses, and the quantity of the lenses is reduced, so that costs are saved, the requirements of lightness and shortness can be met, and aberration of projection images can be effectively corrected by means of the aspheric lenses.

Owner:ASIA OPTICAL CO INC

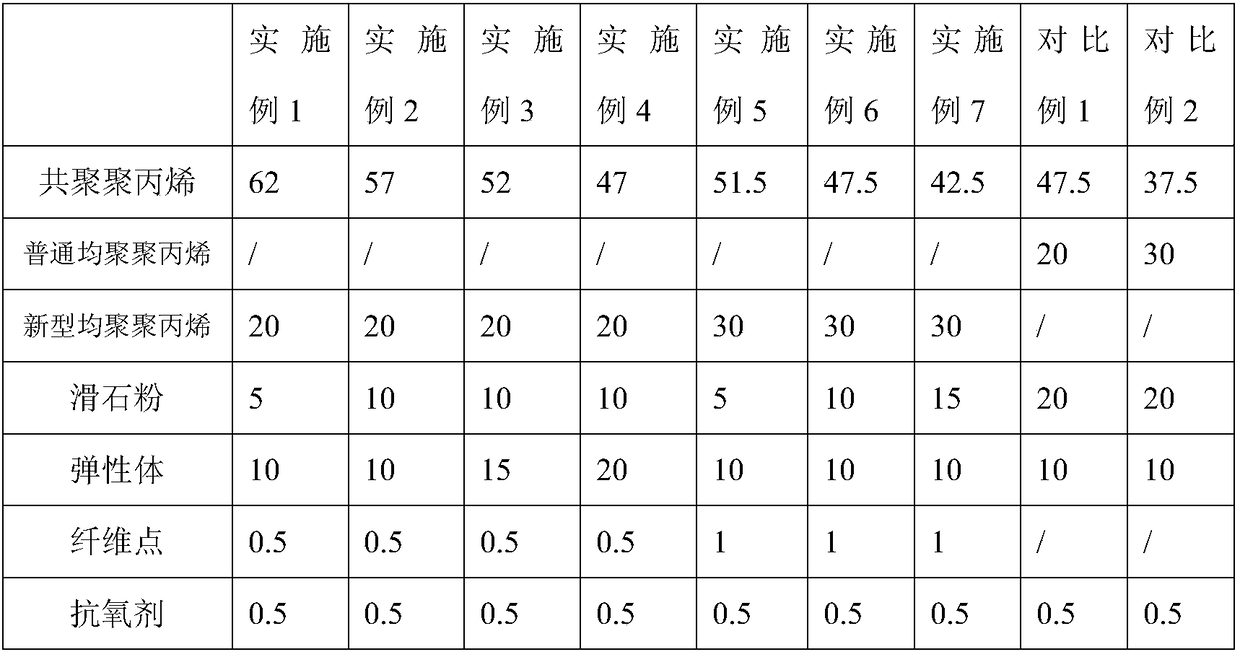

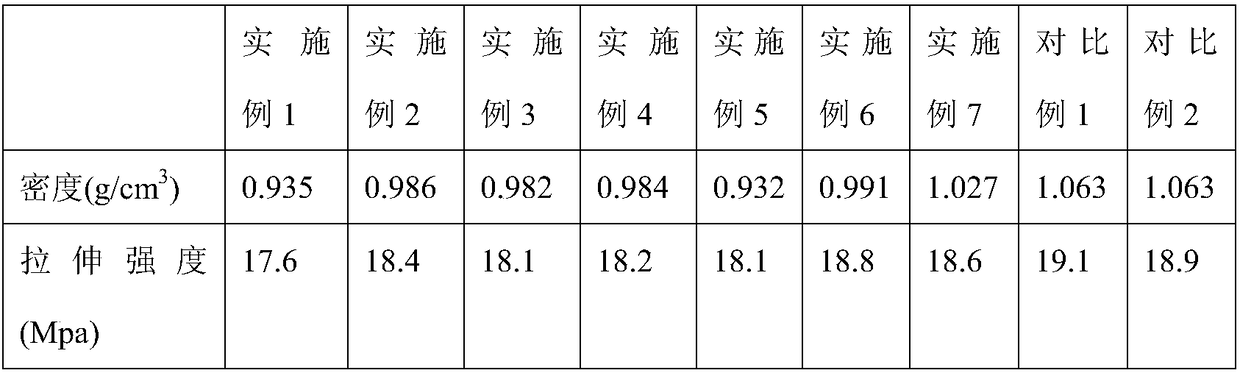

Polypropylene composite material with low density, high performance and flocking-like effect, and preparation method thereof

The invention discloses a polypropylene composite material with low density, high performance and a flocking-like effect, and a preparation method thereof. The polypropylene composite material consists of the following raw materials in parts by weight: 67-82 parts of polypropylene, 5-20 parts of talcum powder, 10-20 parts of elastomer, 0.1-2 parts of fiber spot, 0.1-2 parts of antioxygen and 0-2 parts of other auxiliary agent. On the basis of the basic formula of the polypropylene composite material, polypropylene base material formula design is optimized, the contents of talcum powder fillingcomponents are reduced, the polypropylene base material and the talcum powder perform a synergistic effect to prepare the polypropylene composite material with low density and high performance. In addition, a fiber spot substance is introduced into the polypropylene composite material system, and has the characteristics of small dosage, easiness in adding and the like, the mechanical performanceof the material is not affected, and the addition of the fiber spot can be used for lowering the surface plastic feeling and glossiness of the polypropylene composite material so as to present a certain matte and flocking-like effect.

Owner:CHONGQNG PRET NEW MATERIAL +4

Construction technique for rebuilding prestressing force system after built prestressing force system destroyed in reinforced concrete structure

InactiveCN101063374AChange sizeReduce loadBuilding repairsBuilding material handlingReinforced concretePre stress

The invention discloses a construction art for rebuilding a broken inherent stress system after breaking a built inherent stress system in a reinforcement concrete structure, comprising the steps as removing a former broken inherent stress cable via an anchorage, stripping a surface plastic hood of a new inherent stress cable with same size and intensity of the former broken inherent stress cable, preparing a reinforcement with smaller diameter to the diameter of the former broken inherent stress cable, wherein the length of the reinforcement should be more then the cable of 50cm, and pulling out the former broken inherent stress cable, inserting the reinforcement into a former structure pore path, welding one end of the new inherent stress cable with one end of the reinforcement, connecting another end of the reinforcement with a chain block and pulling the reinforcement, inserting the new inherent stress cable into a hole via the reinforcement in the hole, extending the new inherent stress cable to meet a former design stress of a single cable and then anchoring.

Owner:浙江省二建建设集团有限公司

Device and method for controlling thickness and flatness of concrete floor

InactiveCN106760552AThickness dimension is easy to controlSimple designBuilding material handlingRebarSurface plastic

Owner:LONGYUAN CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com