Polyurethane adhesive used for structural bonding of power battery PACK

A polyurethane adhesive, power battery technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of PI, PET material bonding is not ideal, poor aging resistance, bonding Poor performance and other problems, to achieve the effect of improving mechanical properties and aging properties, excellent aging resistance, and excellent bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

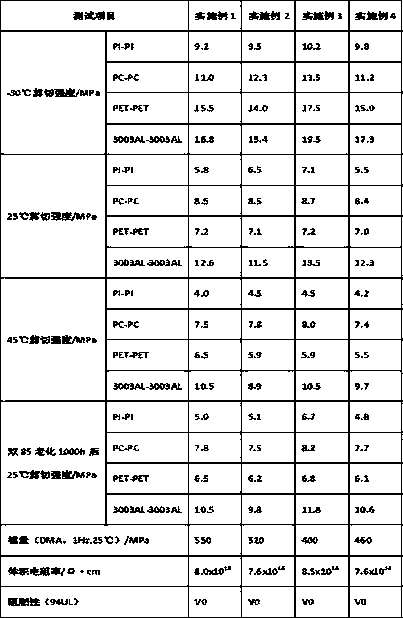

Examples

Embodiment 1

[0027] (1) Preparation of epoxy resin polyol: Mix 30kg of bisphenol F diglycidyl ether epoxy resin and 5.5kg of diphenylmethane diisocyanate, the mixing order is to add isocyanate to epoxy resin, and use a stirring speed of 300r / min for stirring treatment, adjust the temperature to 210°C, after the reaction for 1h, lower the temperature to 45°C, add 50kg of polyoxypropylene triol with a molecular weight of 1000, keep stirring and slowly adjust the temperature to 70°C, and react for 2h After cooling to normal temperature to obtain epoxy resin polyol, stand-by;

[0028] (2) Preparation of isocyanate-terminated polyurethane prepolymer: Take 100kg of polyoxypropylene diol with a molecular weight of 2000 and heat it up to 110°C and vacuumize it to -0.098MPa. During this process, stir at a stirring speed of 450r / min and keep stirring for dehydration After 2 hours, cool down to 45°C, add 120kg of liquefied MDI in proportion, adjust the temperature to 70°C after the reaction temperat...

Embodiment 2

[0032] (1) Preparation of epoxy resin polyol: Mix 30kg of bisphenol A diglycidyl ether epoxy resin and 5kg of diphenylmethane diisocyanate, the mixing order is to add isocyanate to epoxy resin, and use a stirring speed of 300r / Min for stirring treatment, adjust the temperature to 210°C, after 1 hour of reaction, lower the temperature to 45°C, add 50kg of polyoxypropylene triol with a molecular weight of 1000, keep stirring and slowly adjust the temperature to 70°C, after 2 hours of reaction Cool to normal temperature to obtain epoxy resin polyol, stand-by;

[0033](2) Preparation of isocyanate-terminated polyurethane prepolymer: Take 100kg of castor oil-modified diol with a molecular weight of 3000 and heat it up to 110°C and vacuumize it to -0.098MPa. During this process, stir at a stirring speed of 450r / min. After stirring and dehydrating for 2 hours, cool down to 45°C, add 110kg of liquefied MDI in proportion, adjust the temperature to 70°C after the reaction temperature n...

Embodiment 3

[0037] (1) Preparation of epoxy resin polyol: Mix 30kg of bisphenol F diglycidyl ether epoxy resin and 6kg of liquefied MDI. The mixing order is to add isocyanate to the epoxy resin, and use a stirring speed of 300r / min for stirring treatment , adjust the temperature to 210°C, reduce the temperature to 45°C after 1 hour of reaction, add 50 kg of castor oil modified polyol with a molecular weight of 1000, keep stirring and slowly adjust the temperature to 70°C, and cool to room temperature after 2 hours of reaction Get epoxy resin polyol, stand-by;

[0038] (2) Preparation of isocyanate-terminated polyurethane prepolymer: Take 100kg of castor oil-modified diol with a molecular weight of 2000 and heat it up to 110°C and vacuumize it to -0.098MPa. During this process, stir at a stirring speed of 450r / min. After stirring and dehydrating for 2 hours, cool down to 45°C, add 120kg of liquefied MDI in proportion, adjust the temperature to 70°C after the reaction temperature no longer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com