High strength elastic metallic plastic bush and its prodn. method

A technology of elastic metal and production method, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low strength and low reliability, and achieve the effects of prolonging service life, improving reliability and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a. Use a semi-soft copper-clad steel wire (copper-clad steel composite wire or copper-plated steel wire) with a diameter of 0.35-0.45mm to make a helical spring section. The outer diameter of the helical spring is 2.6-3.3mm, and the pitch is 2-4mm. The length is 25-45mm, spread the spiral spring segments evenly in the forming mold in a disorderly manner, limit and press to make the metal wire elastic pad 2 blank;

[0029] b. Cover the surface plastic layer on the metal wire elastic pad 2 blank, and mold and compound it into a tile surface blank;

[0030] c. Sintering the tile surface blank to make a tile surface with a surface plastic layer 3 embedded on the wire elastic pad 2;

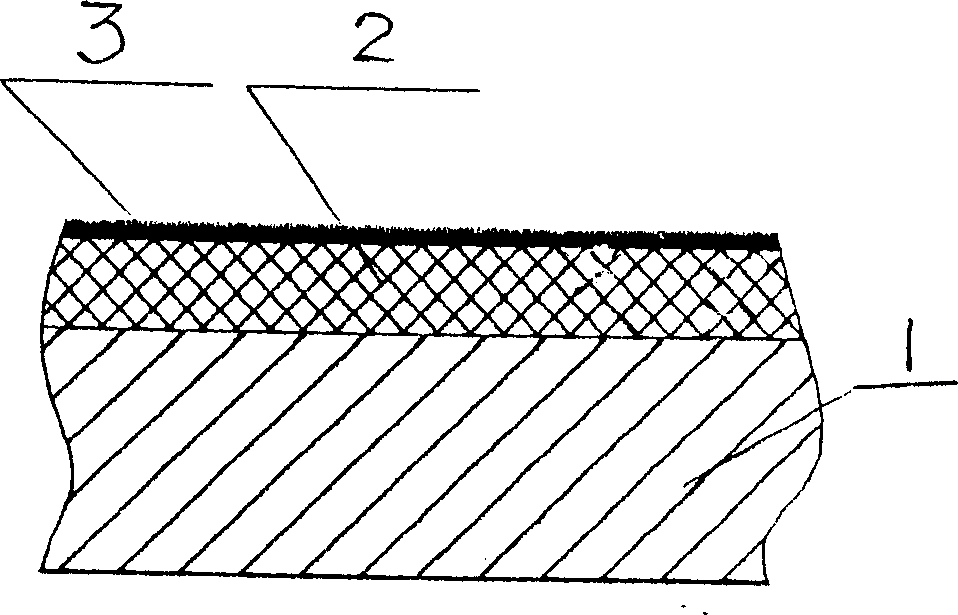

[0031] d. Brazing the tile surface containing solder on the steel tile base 1, that is, it is made as figure 1 The shown product includes a steel tile base 1 on which copper-clad steel wire helical spring elastic pads arranged in disorder are firmly combined, and the copper-clad steel wire hel...

Embodiment 2

[0033] a~c are the same as embodiment 1;

[0034] d. Place the tile surface in an airtight container, and immerse the metal wire elastic pad 2 in liquid solder under the condition of a vacuum of 6-15 Pa, so that the solder is filled into the pores in the metal wire elastic pad 2. cooling, to solidify the solder;

[0035] e. Brazing the tile surface containing solder on the steel tile base 1 .

Embodiment 3

[0037] Others are the same as in embodiment 1 or 2, except that the copper-clad steel wire helical spring segment is spread in the molding die with a magnetic bottom plate, and then other steps are carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com